Parametric Design, Kerf Calibration and Press-Fit Assembly

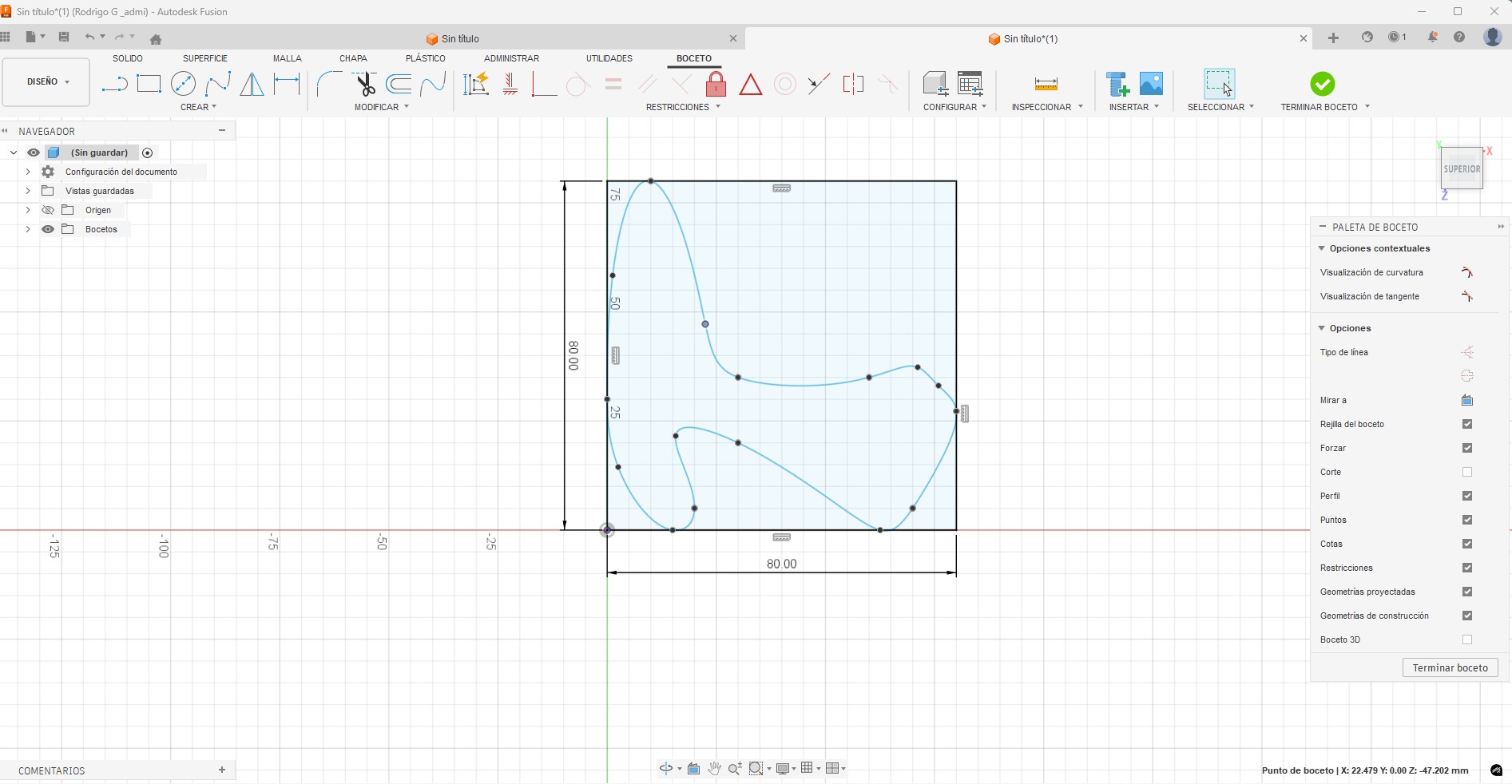

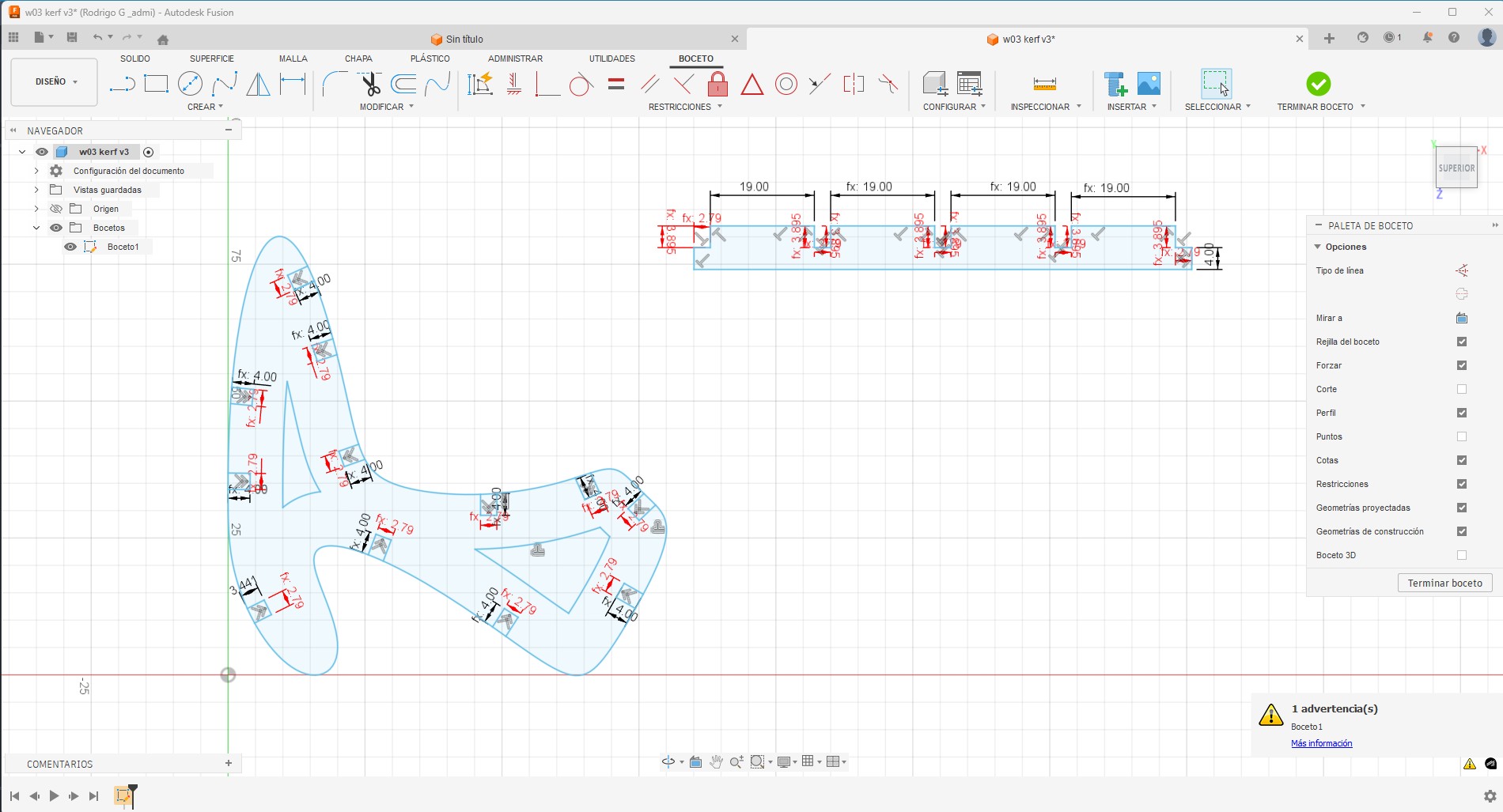

As part of the Fab Academy Week 3 assignment, I designed and fabricated a parametric construction kit focused on press-fit assembly. For the parametric modeling process, I used Fusion 360 as the main CAD software.

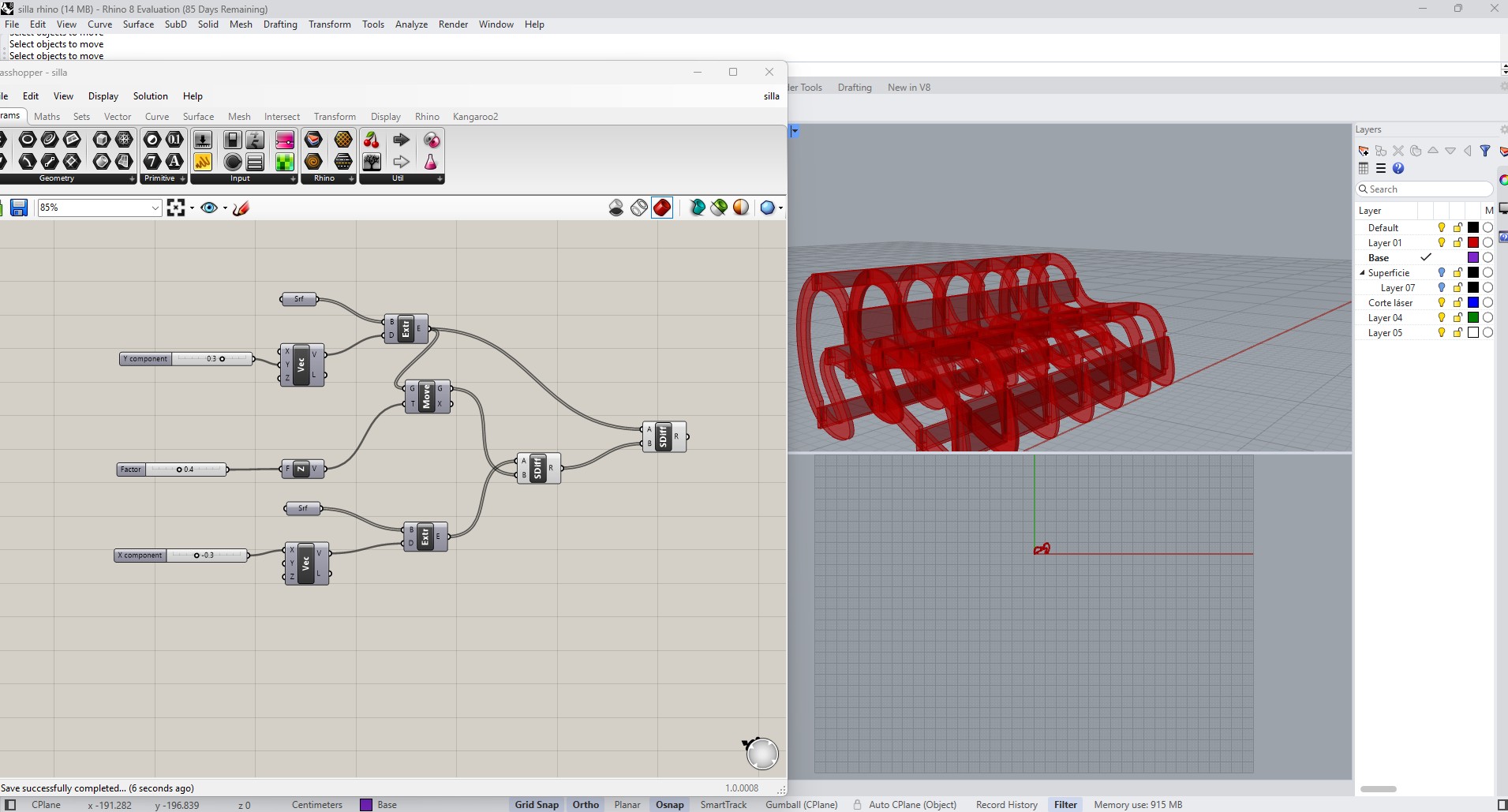

As a construction reference, I based the design on the assembly logic of a pre-designed piece of furniture developed in Rhinoceros with Grasshopper, which can be reviewed in Assignment 02.

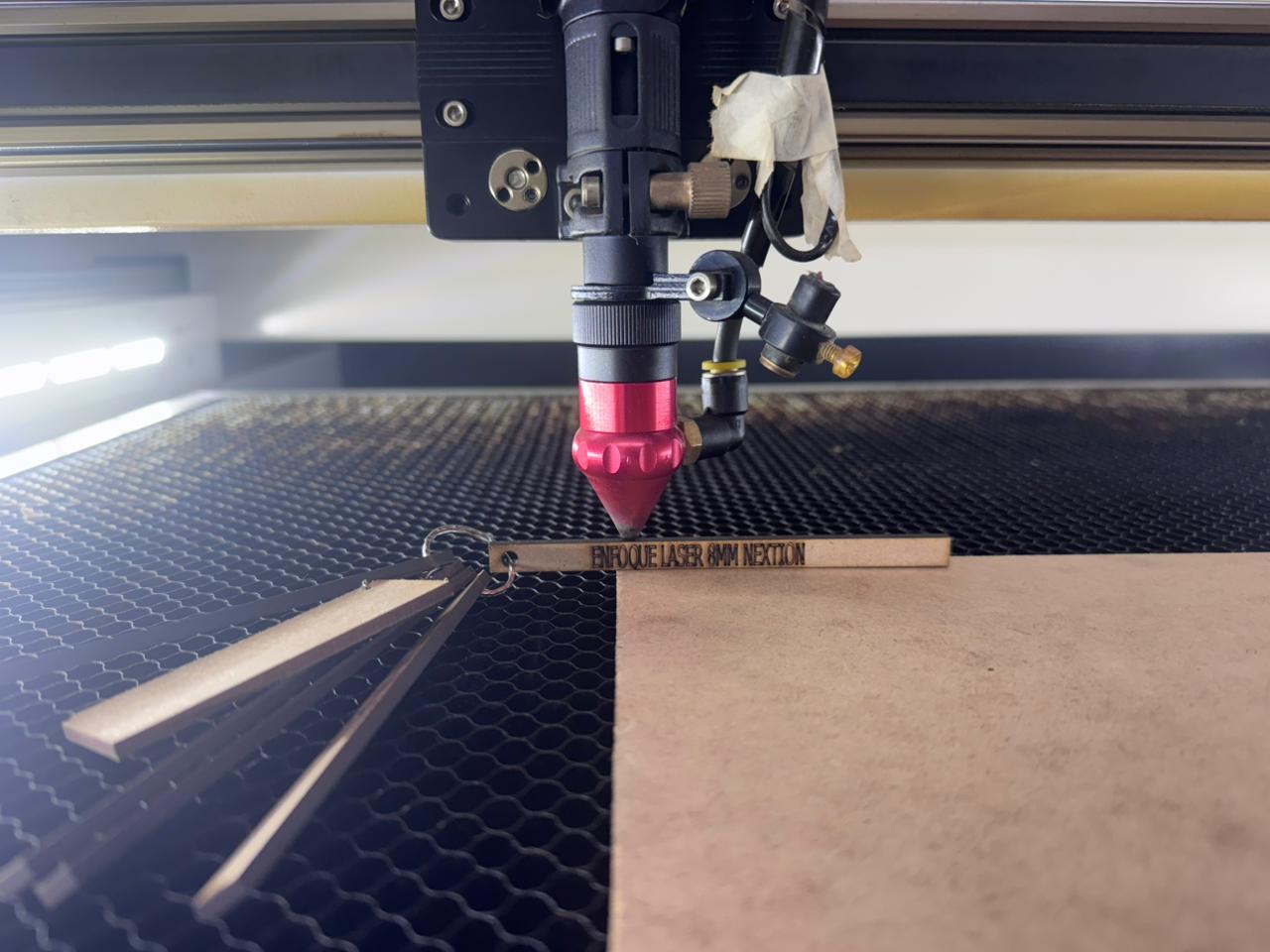

The fabrication process was carried out using a 90 W CO₂ Core Laser cutting machine available at the Industrial FABLAB. The main objective of this exercise was to achieve a fully functional press-fit system without the use of adhesives, relying entirely on parametric control and kerf calibration.

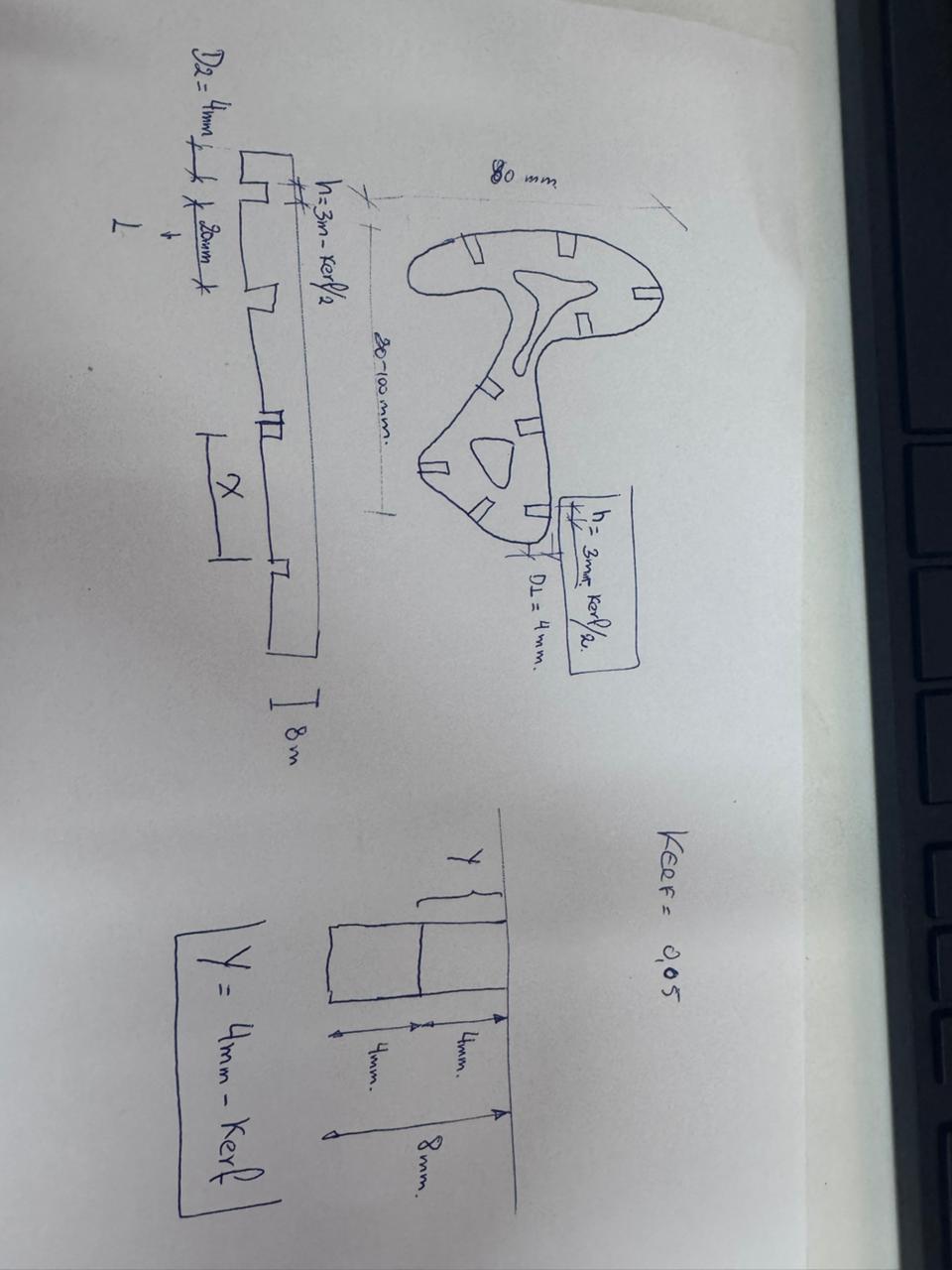

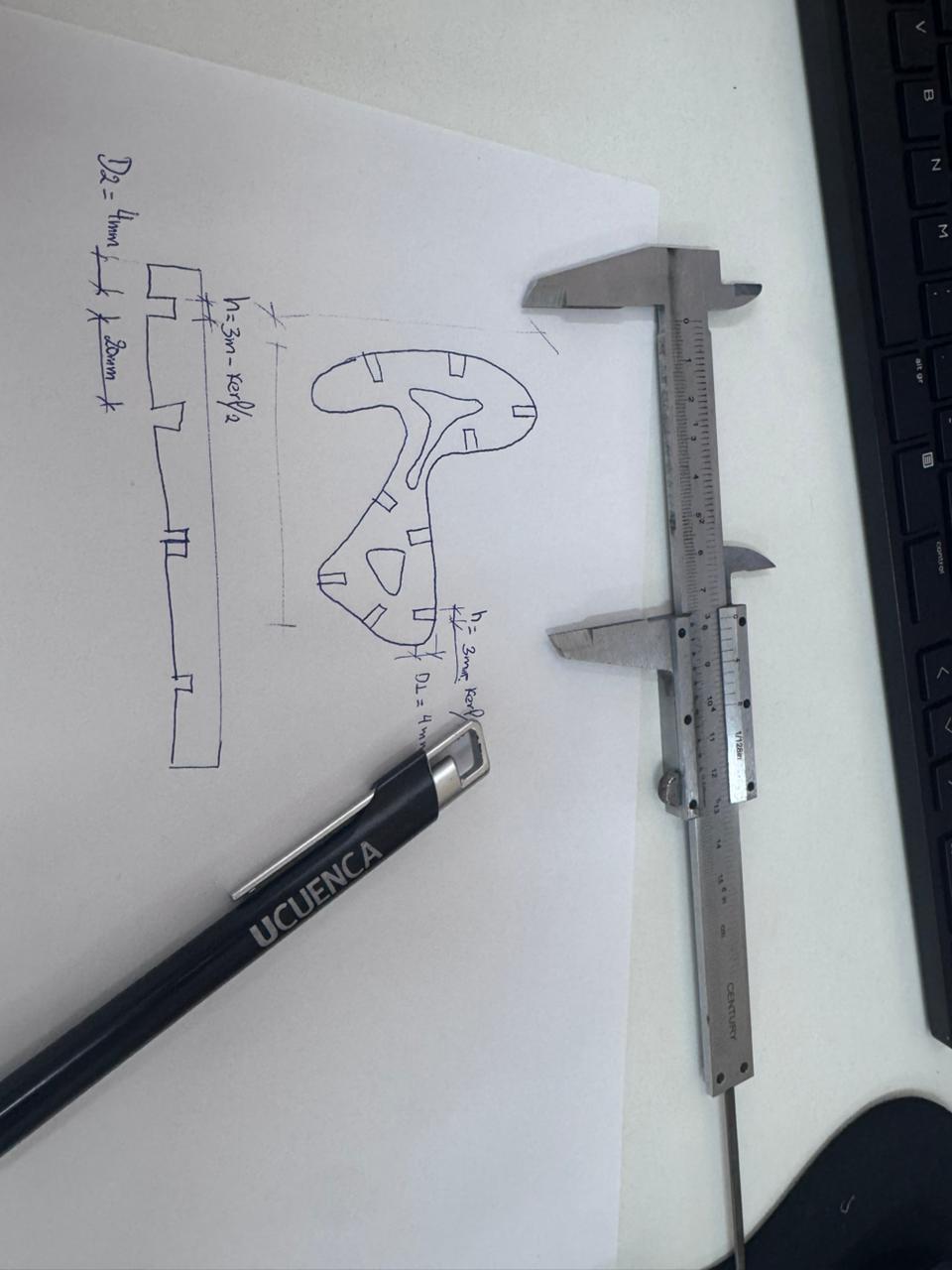

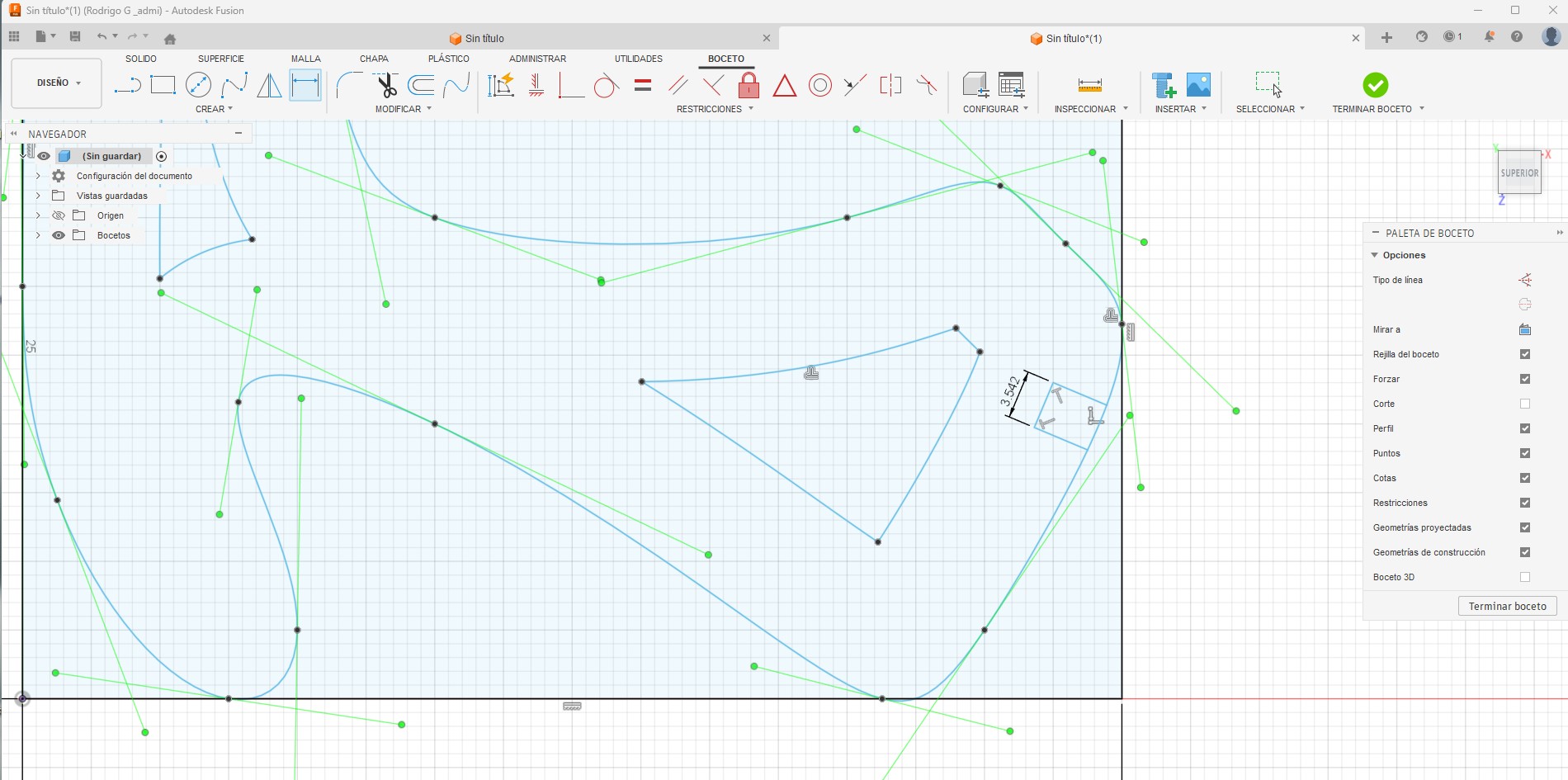

The design process started from a construction plan using curvilinear tracing. Initially, the geometry was explored through hand sketches on paper, defining the shape, proportions, and dimensions of the assembly links before moving into the digital environment.

This step was essential to understand how the individual parts would interact mechanically during assembly and to establish the initial measurements of the press-fit joints.

Image c001

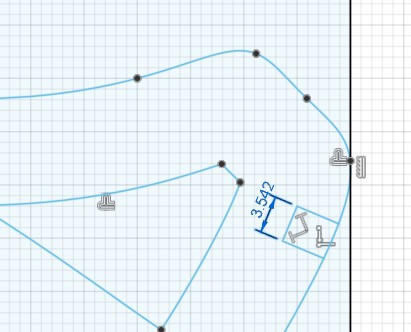

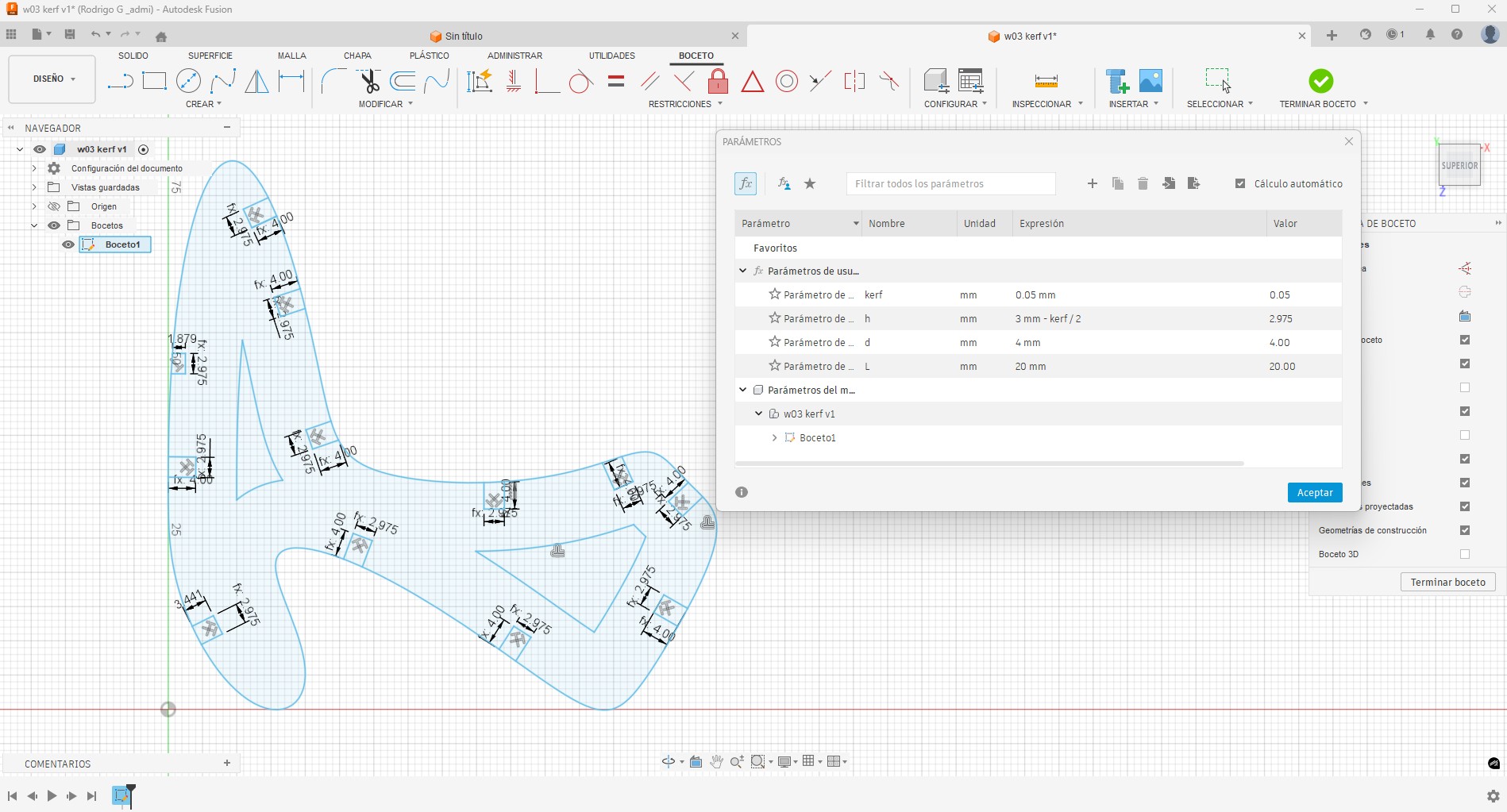

To ensure a precise press-fit assembly, the kerf value of the laser cutting machine was calculated. This was done using a reference table that combines laser power (in watts) and cutting speed (in mm/s).

The best cutting result was obtained using a combination of 40 W power and 40 mm/s speed, which produced a measured kerf of 0.05 mm.

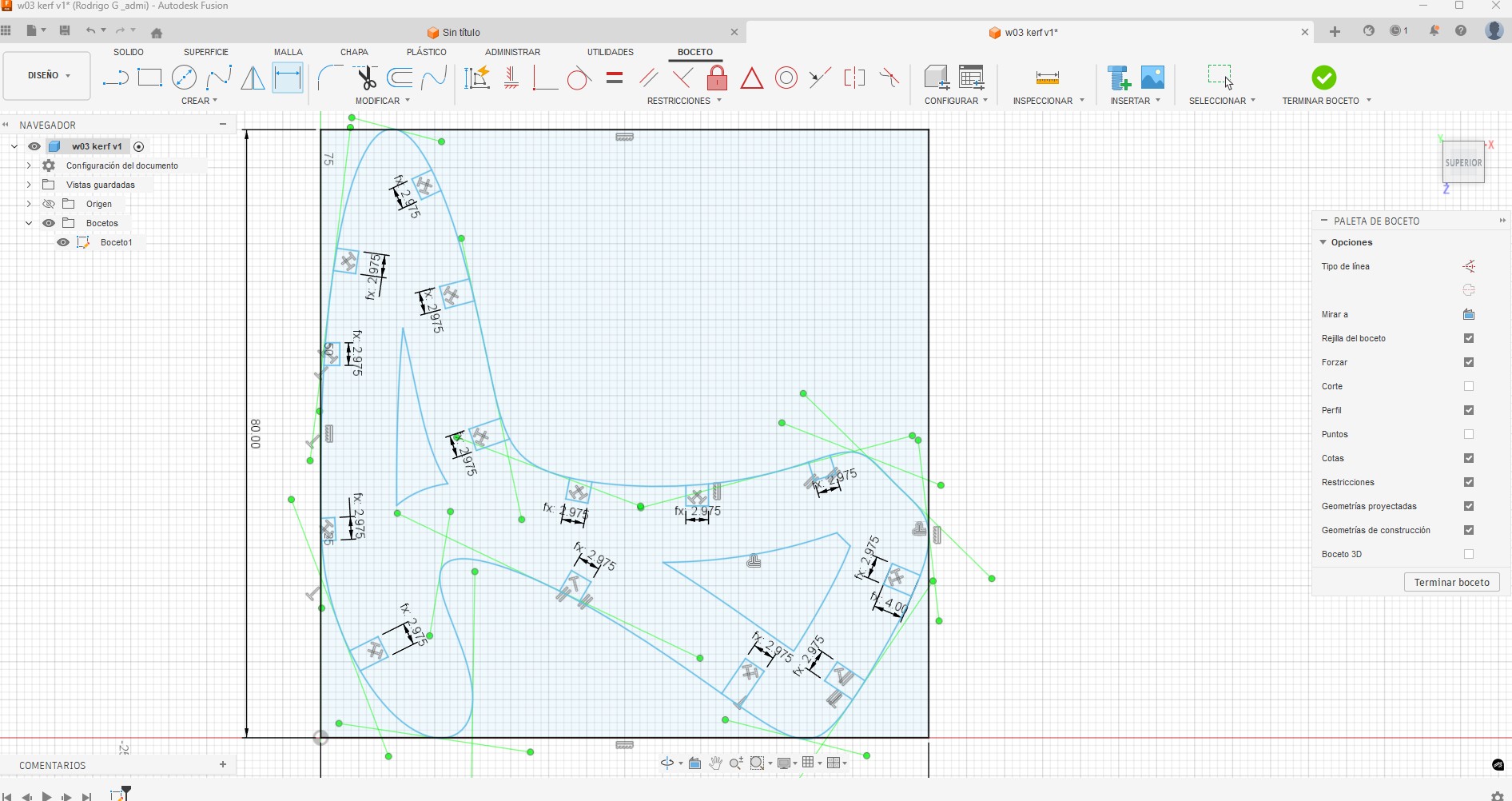

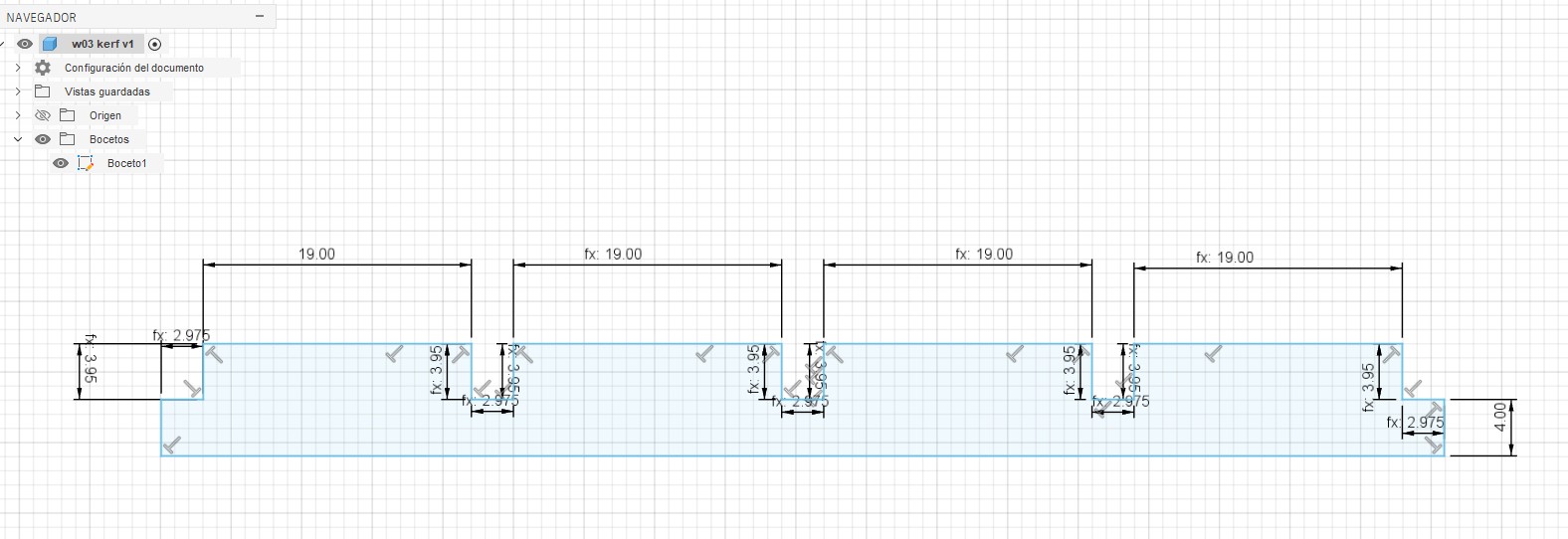

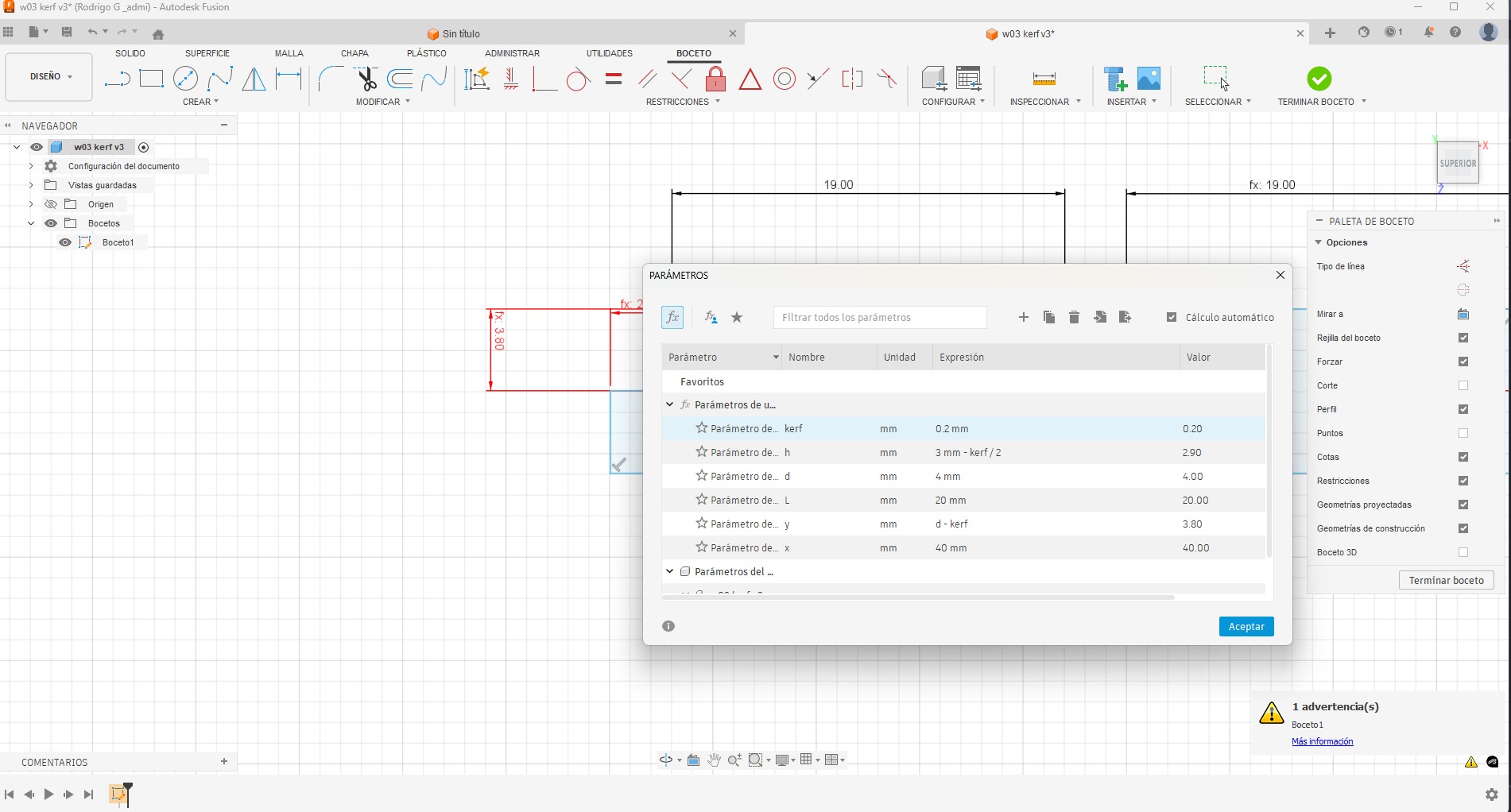

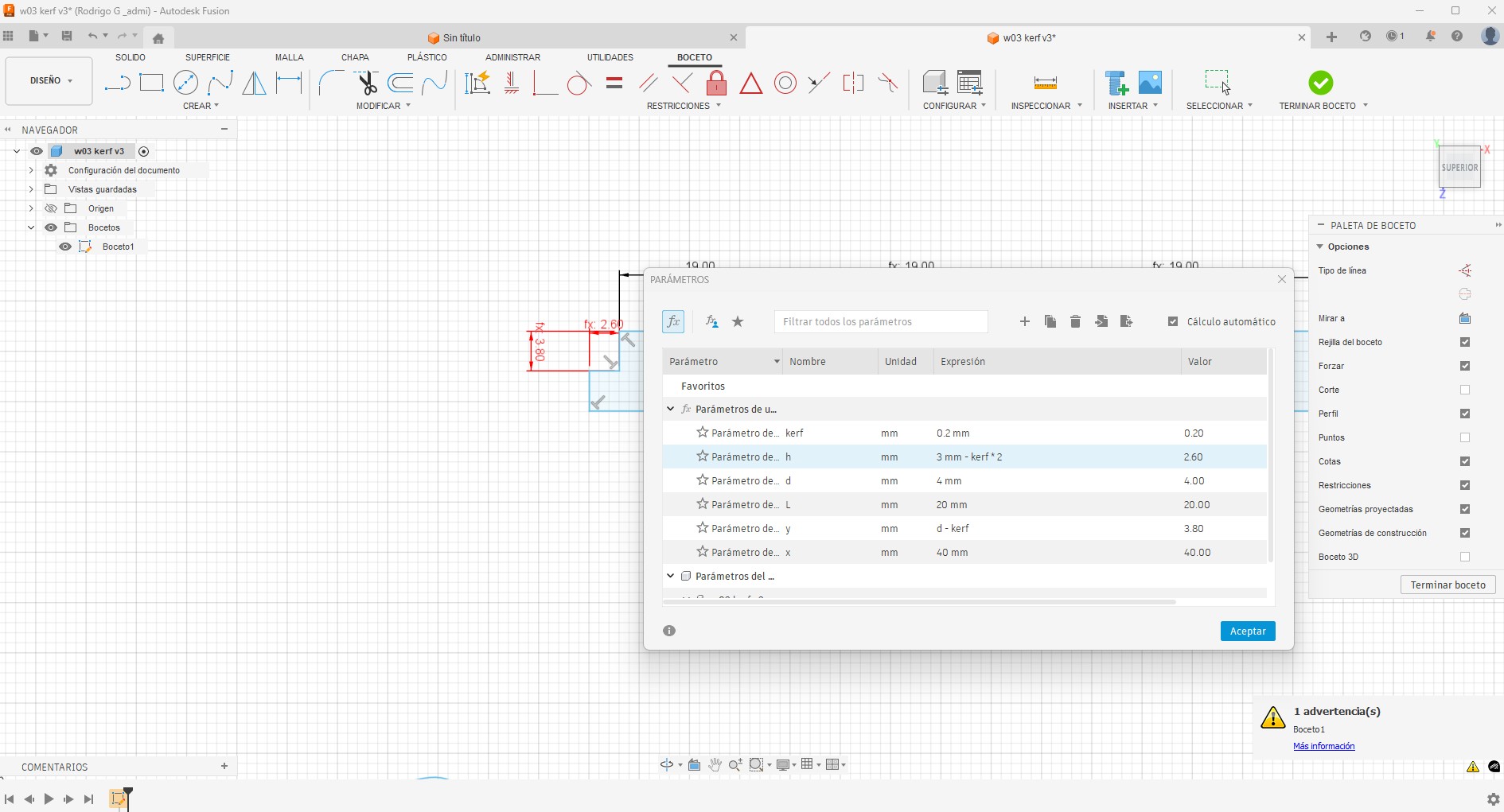

Once the kerf value was established, the design was fully parameterized in Fusion 360 using the following variables:

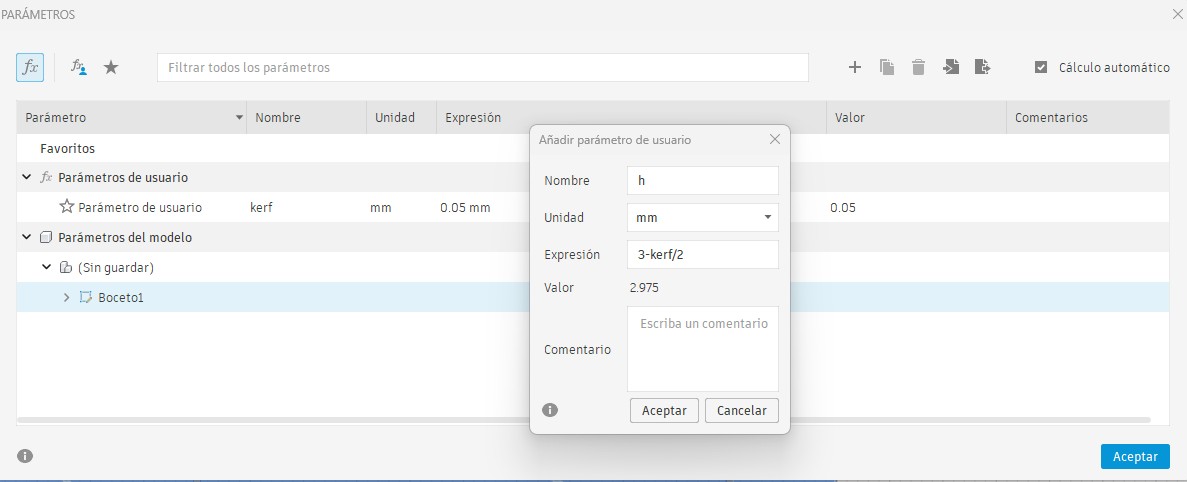

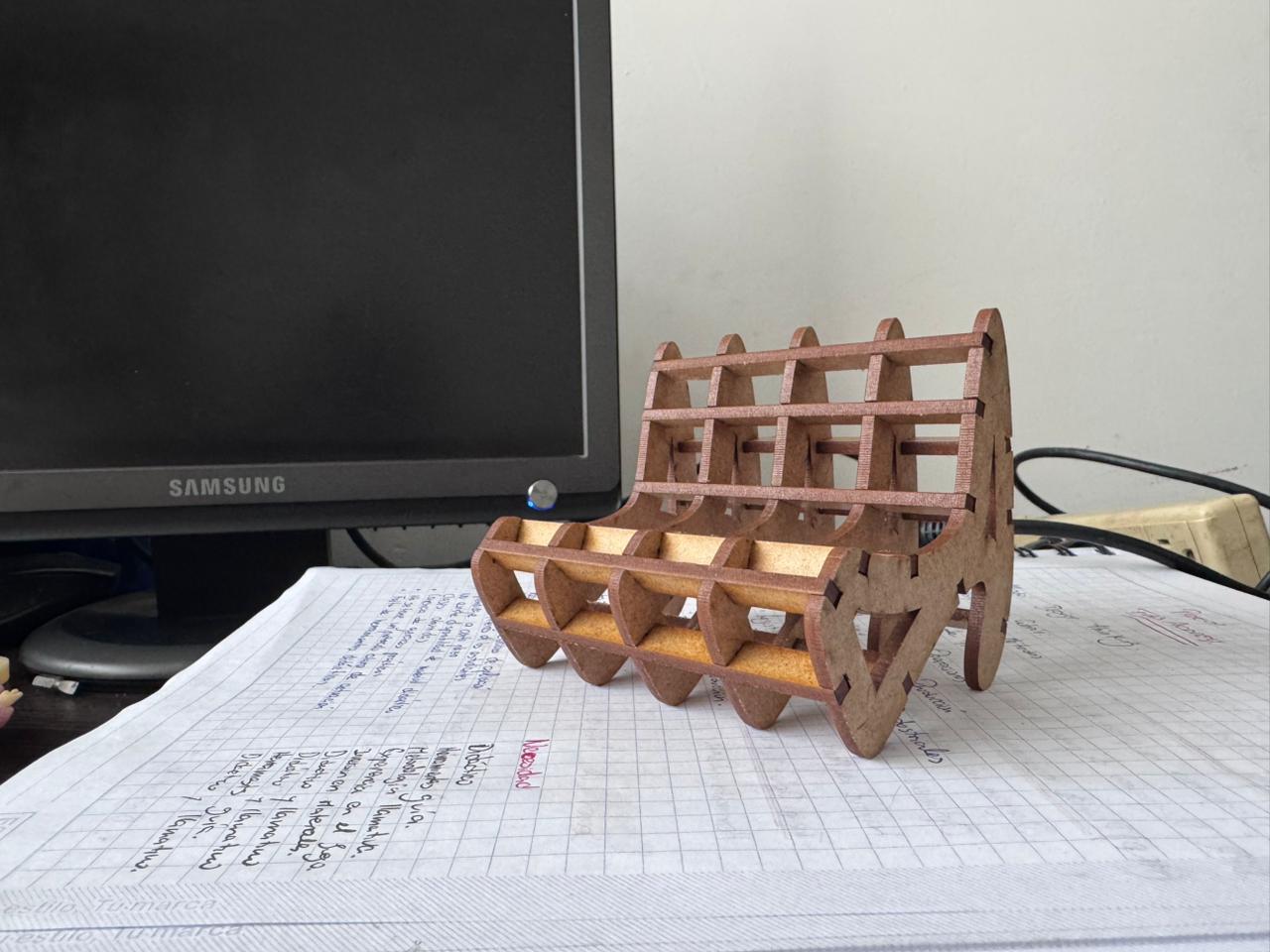

The chair was designed within a working area of 80 × 80 mm, allowing a compact yet functional prototype.

After defining the main geometry, the notches and joints were drawn directly on the construction plane. All joints were designed using parametric values, allowing easy adaptation if a different material, thickness, or kerf value were required.

This approach ensures that the design remains flexible and scalable, which is a key principle in digital fabrication workflows promoted by Fab Academy.

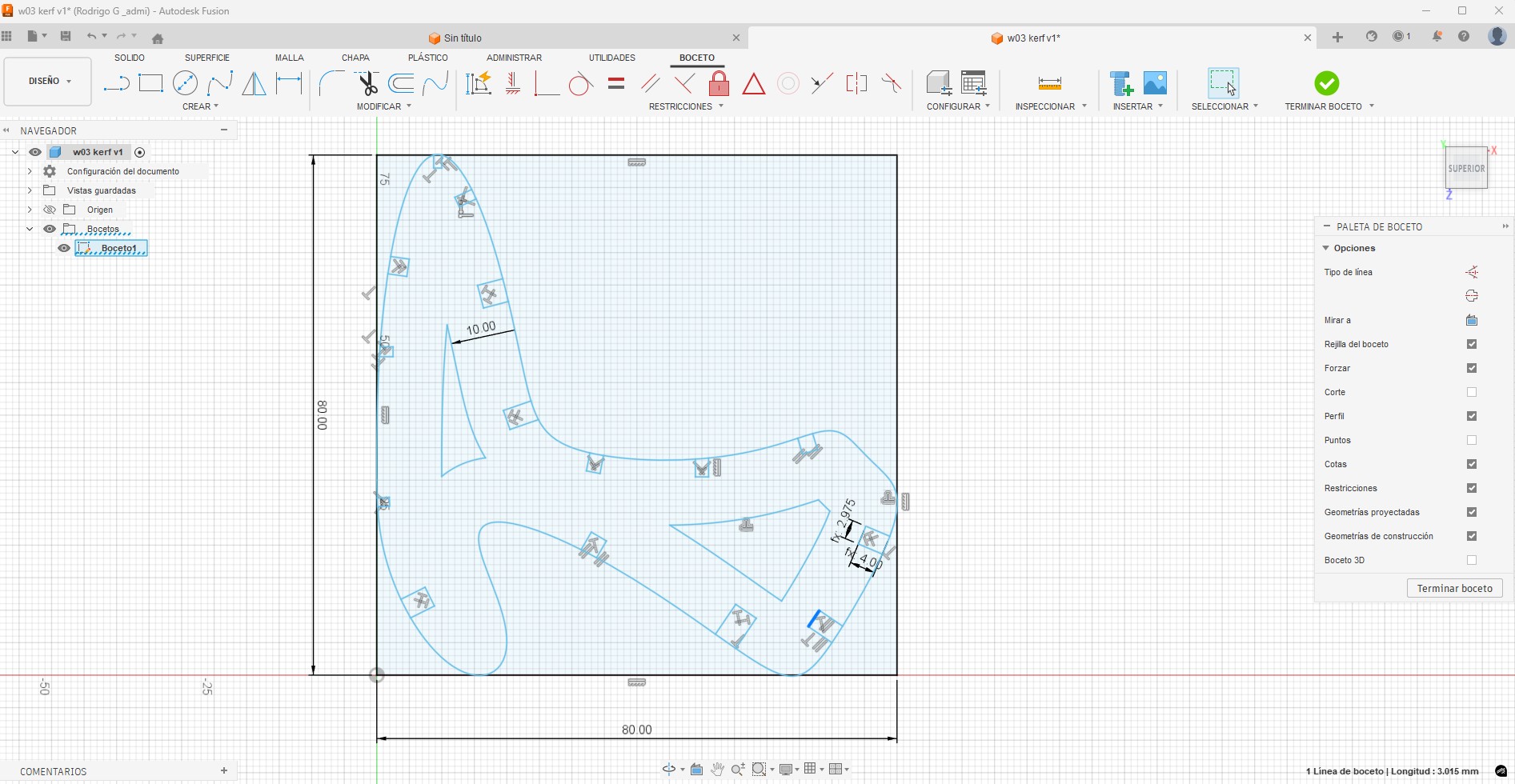

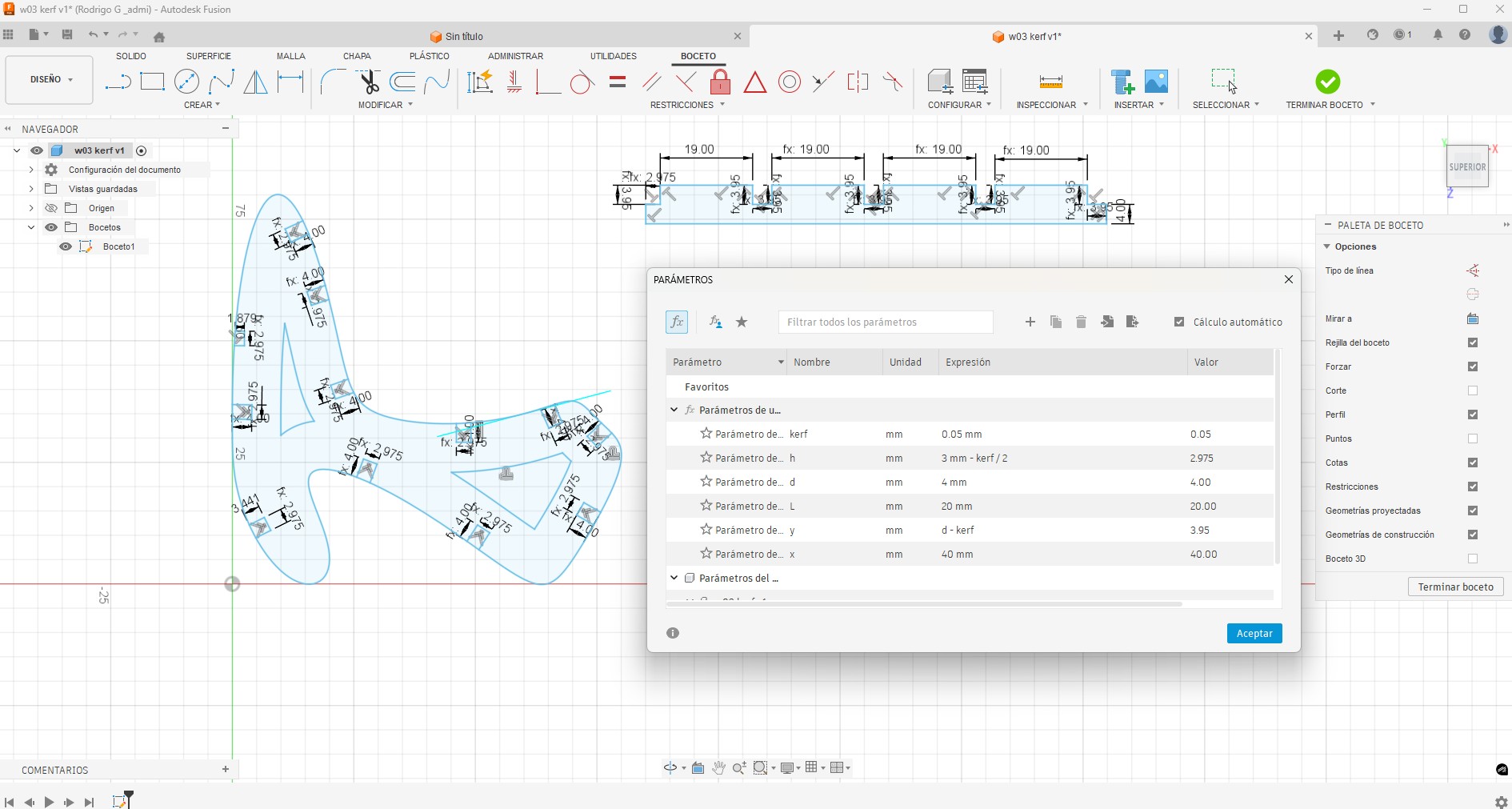

All notches were referenced sequentially using the defined parameters and tolerances. Once the main chair structure was completed, the crossbars (travesaños) were designed using the same parametric logic to ensure consistency throughout the assembly.

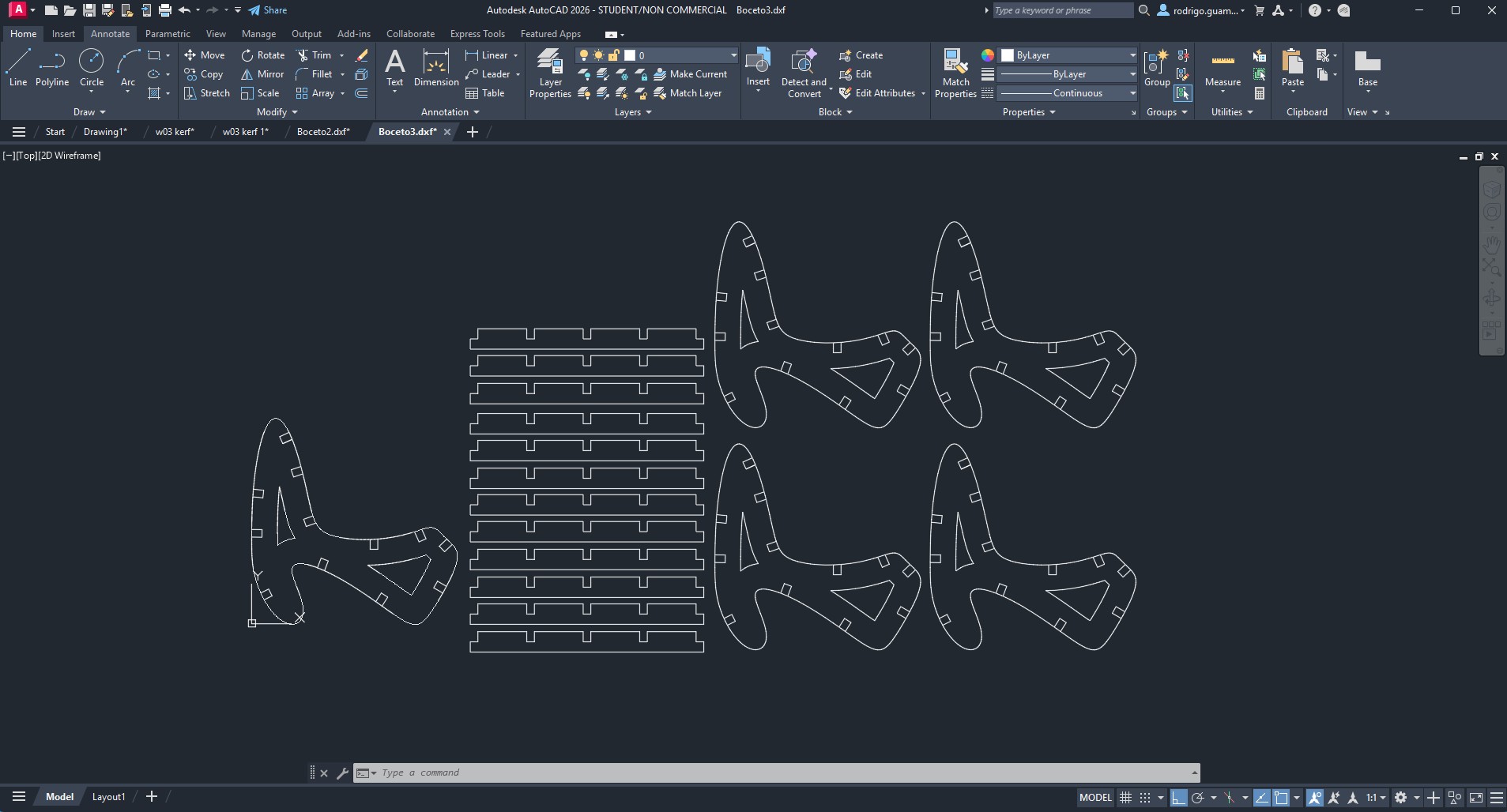

As an additional workflow, AutoCAD was used to duplicate the chair components and crossbars, organizing them efficiently on the cutting layout. The files were exported in DXF format and sent to the laser cutting machine for the first physical test.

During the first iteration, excessive looseness was observed in the joints.

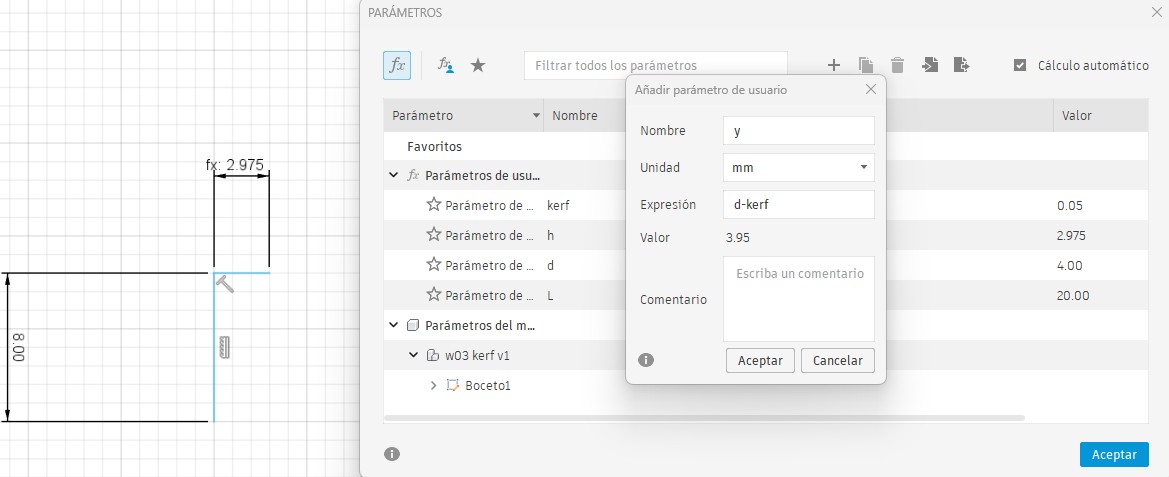

To correct this, the kerf-related parameters were adjusted, increasing the

joint tightness while maintaining the original kerf value.

The updated parameters were:

After recalibrating the parameters and adjusting the laser focus height, the final parts were fabricated. The assembly process was carried out manually, verifying the press-fit behavior of each joint.

Before adjustment:

w03 kerf1.dwg boceto3.dxfAfter adjustment:

w03 con ajustes.f3d Boceto3 con ajuste.dxfThis assignment highlighted the critical role of parametric design in digital fabrication, particularly when working with press-fit systems. Accurate kerf calibration and iterative testing proved essential to achieving a reliable assembly without adhesives.

The integration of Fusion 360, Rhino + Grasshopper references, AutoCAD, and laser cutting workflows reflects the Fab Academy methodology of linking design, experimentation, and manufacturing.

This exercise strengthened my understanding of parametric control, tolerance management, and iterative prototyping, skills that will be directly applied in the development of my final project.