2D, 3D, AI and Multimedia Tools

The objective of this week in Fab Academy is to explore and document a wide range of digital tools rather than mastering a single one. These tools were used to model experimental objects, document the design process, compress image and video files, and preserve original design files as part of a transparent and reproducible workflow.

| Category | Type | Software |

|---|---|---|

| 2D | Raster | GIMP |

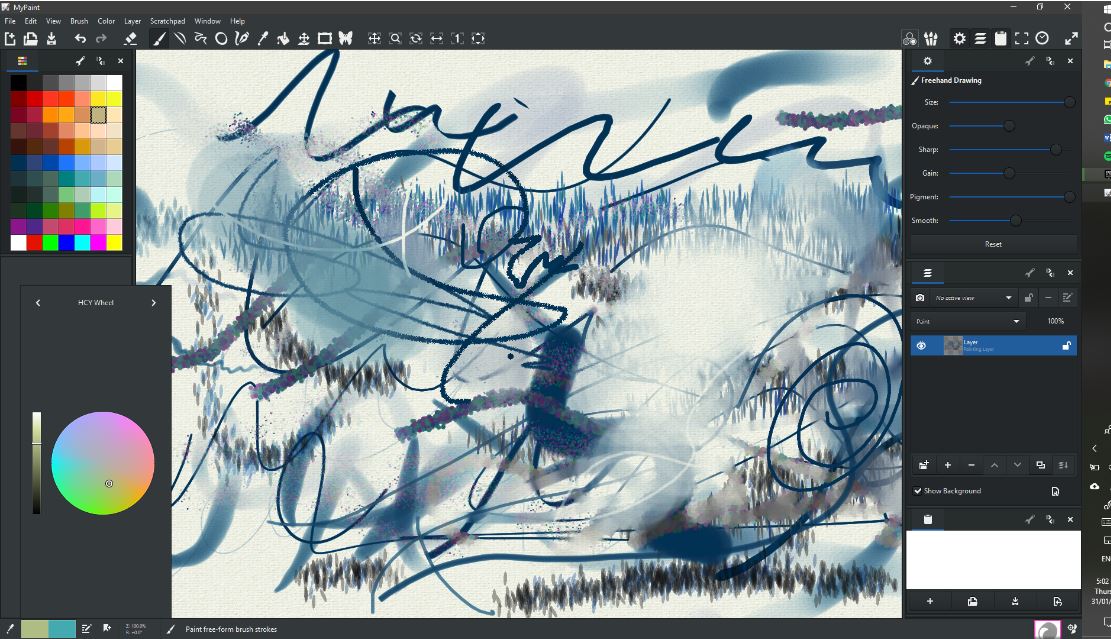

| 2D | Raster | MyPaint |

| 2D | Vector | Inkscape |

| 2D | Vector | CorelDRAW |

| 3D | Program | Tinkercad |

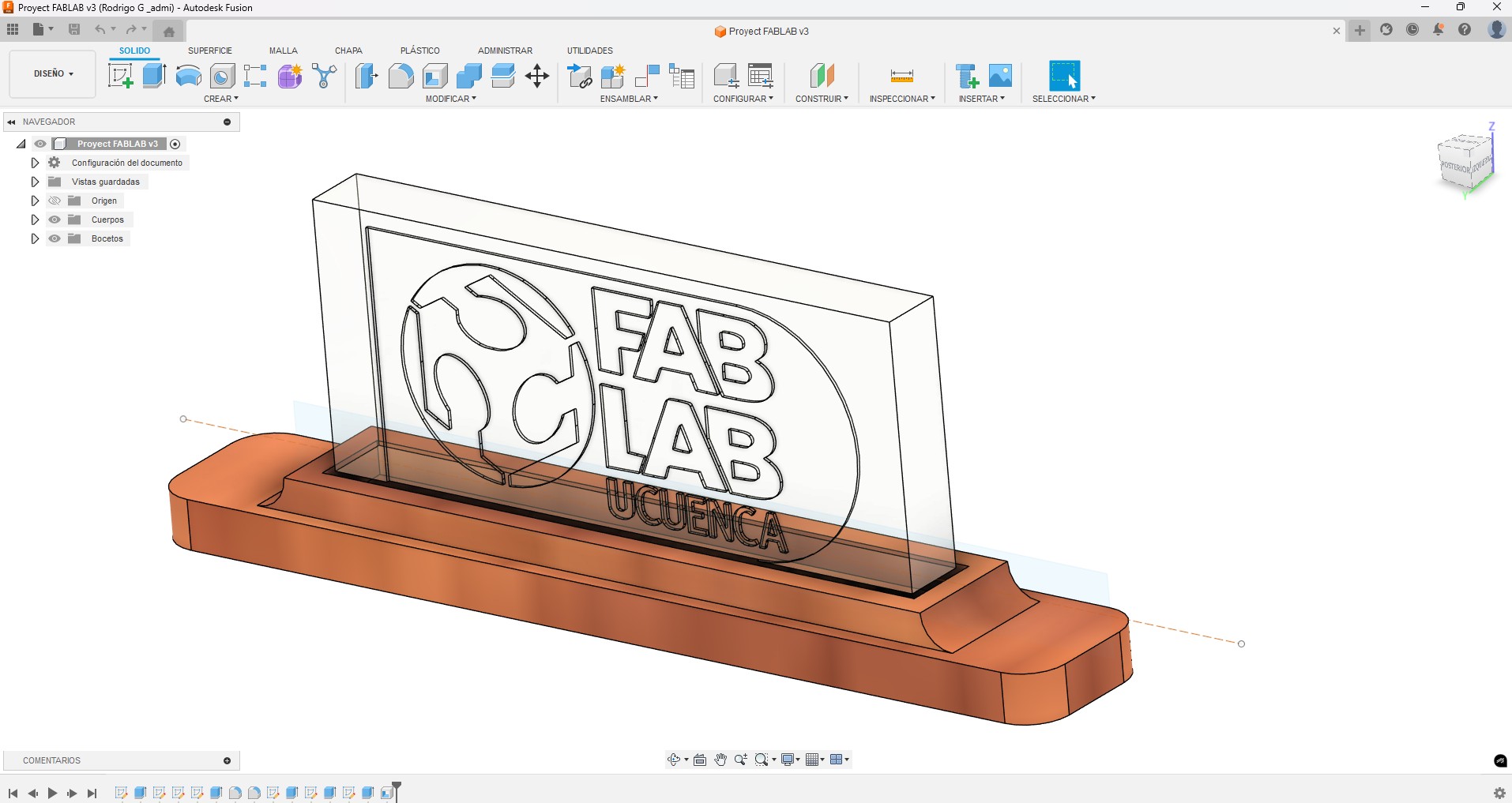

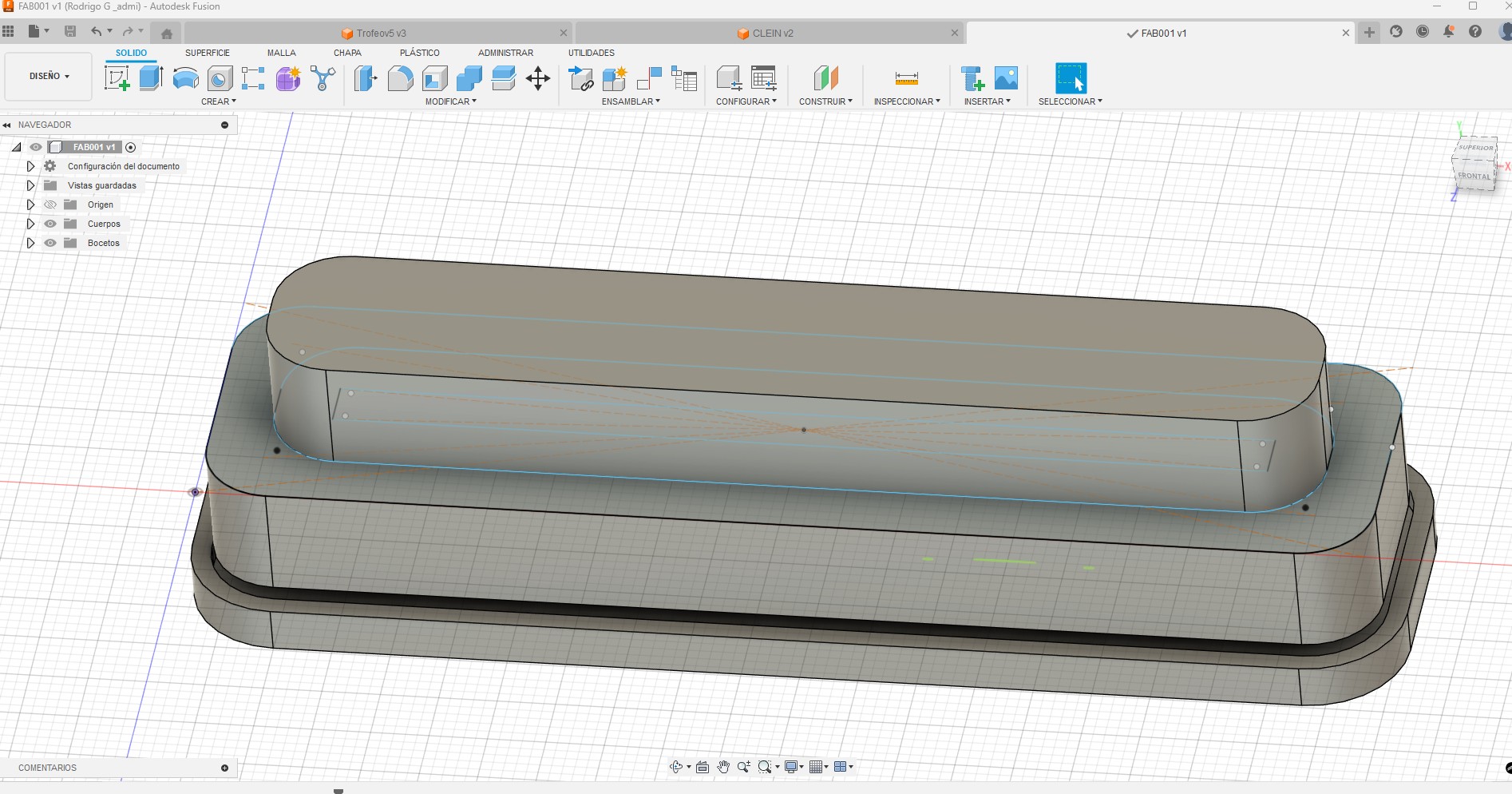

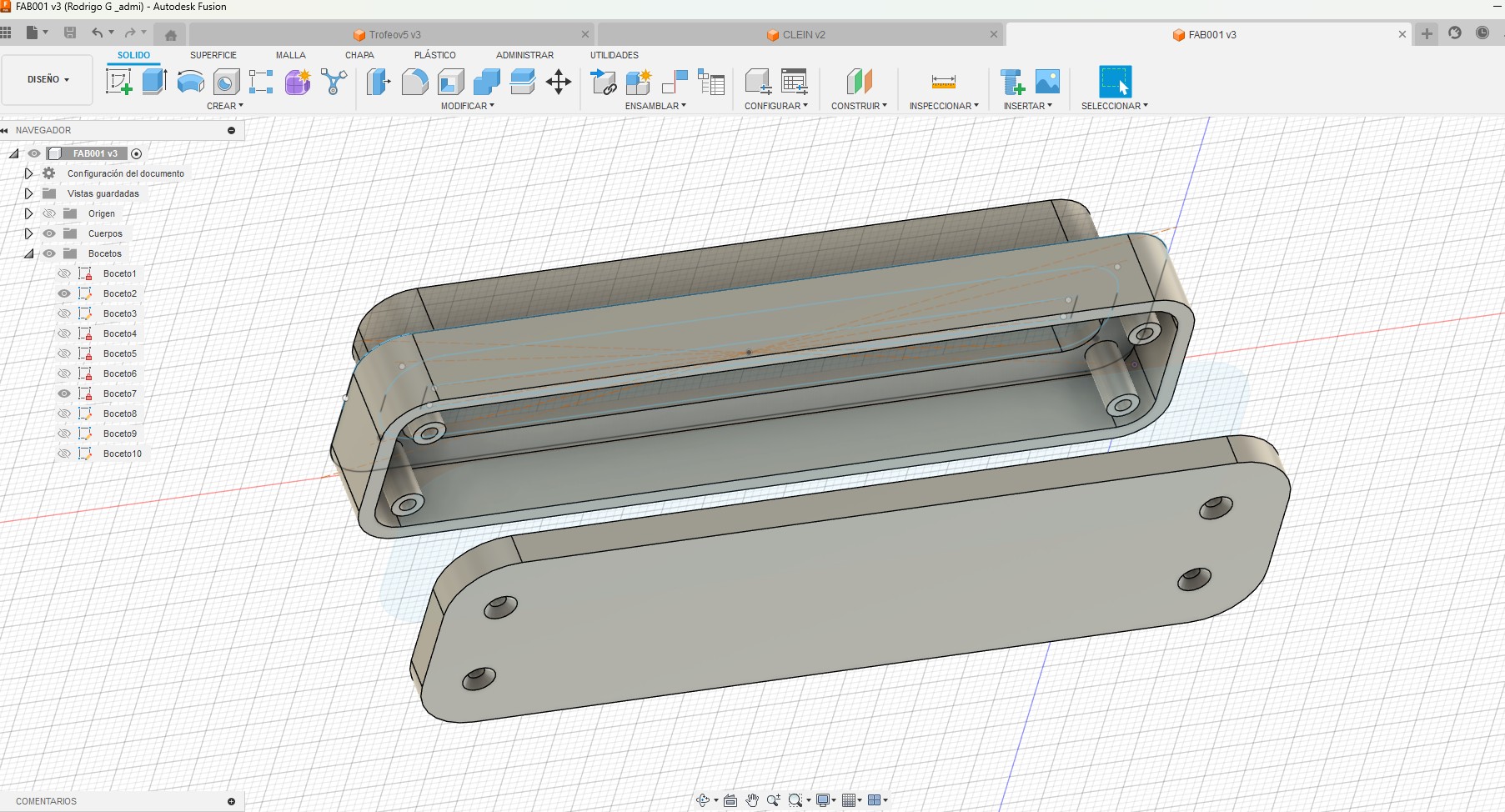

| 3D | Program | Fusion 360 |

| 3D | Program | Blender |

| 3D | Program | Onshape |

| 3D | AI Software | Text to CAD |

| 3D | AI Software | DALL·E |

| Audio/Video | Video | After Effects |

GIMP was used to edit screenshots, photographs, and documentation images. Image compression was performed to reduce file size while maintaining visual clarity for web publication.

MyPaint supported early-stage ideation through freehand digital sketches, enabling rapid visualization of project concepts.

Inkscape was used to create vector files for laser cutting and technical diagrams, ensuring scalable and machine-readable designs.

CorelDRAW was explored as an alternative vector platform, particularly useful for complex laser cutting layouts.

Tinkercad enabled rapid modeling of simple experimental objects and early components of a possible final project.

Fusion 360 was used for parametric and fabrication-oriented modeling, supporting precise dimensions and iterative design.

Blender was explored for mesh-based and organic modeling, expanding creative possibilities beyond parametric CAD tools.

Onshape was tested as a cloud-based CAD platform with built-in collaboration and version control.

Text-to-CAD tools were used to explore AI-assisted 3D generation from textual descriptions, mainly for conceptual reference.

DALL·E supported ideation by generating visual references that helped explore form and aesthetics.

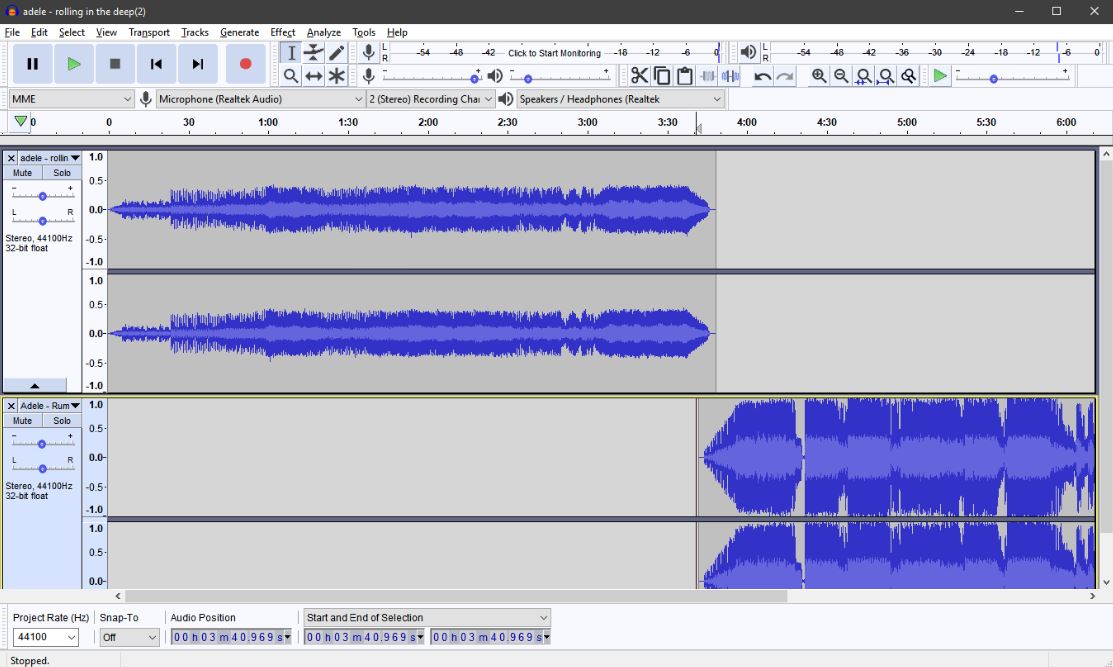

Audacity is an open-source audio editing software widely used for recording, editing, and compressing sound files. In the context of Fab Academy, Audacity is especially useful for documenting projects through voice explanations, narration of design processes, and audio integration in video documentation.

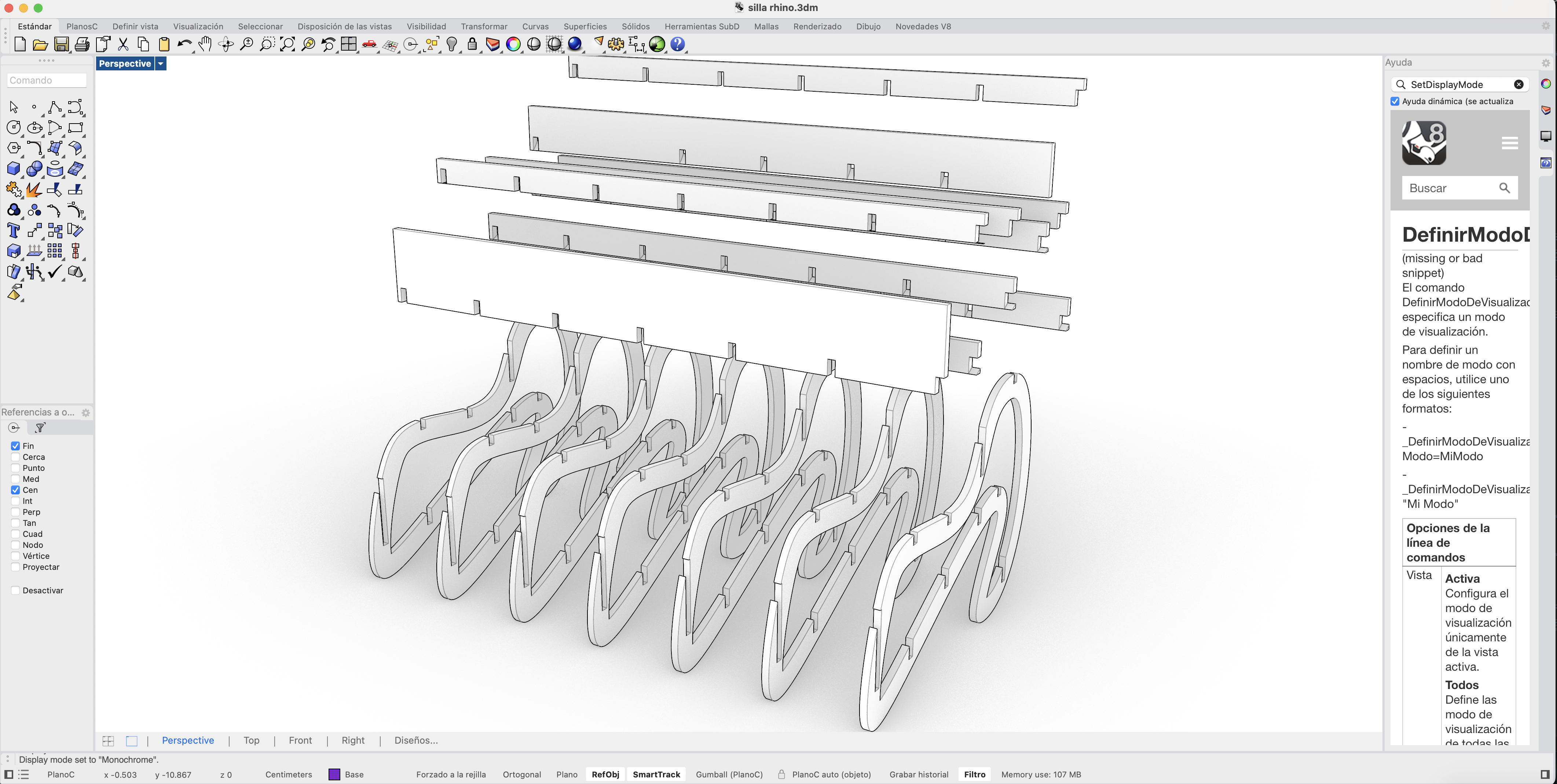

Rhinoceros (Rhino) is a NURBS-based 3D modeling software widely used in architecture, industrial design, and digital fabrication due to its precision, flexibility, and compatibility with fabrication workflows. Unlike purely parametric CAD tools, Rhino allows the designer to freely combine intuitive geometric modeling with exact dimensional control, making it especially suitable for experimental and fabrication-oriented projects.

In this exploration, Rhino was used as the primary modeling environment for the development of a parametric chair. The base geometry of the chair—such as the seat surface, structural ribs, and overall proportions—was first defined using curves, surfaces, and reference planes. This approach allowed quick iteration over form and ergonomics while maintaining precise control over dimensions relevant to digital fabrication processes such as CNC milling or laser cutting.

Grasshopper was used as a complementary visual programming tool to introduce parametric logic into the chair design. Through Grasshopper, key parameters such as seat height, curvature radius, material thickness, spacing between structural elements, and overall width were defined as variables. By modifying these inputs, multiple design variations of the chair could be generated automatically without rebuilding the model from scratch.

This parametric workflow is particularly valuable in Fab Academy because it encourages design exploration, optimization, and adaptability. The same chair model can be adjusted to different users, materials, or fabrication constraints by simply changing numerical values in Grasshopper. The final geometry generated in Rhino can then be exported as DXF, STL, or other fabrication-ready formats, ensuring a seamless transition from design to manufacturing.

Start by opening Rhino and setting the correct units (millimeters recommended for fabrication). Begin with simple reference geometry such as rectangles and lines to define the seat, backrest, and leg proportions. Use the Top and Front views to establish the main dimensions and ergonomic scale.

Use commands such as ExtrudeCrv, Loft, or Sweep to generate surfaces from the base curves. Define the seat and backrest curvature carefully, ensuring smooth transitions and proper alignment between structural elements.

Refine the model by modifying control points and scaling elements proportionally. Verify ergonomic relationships such as seat height, backrest angle, and structural stability. Use Gumball and Control Points tools for precise adjustments.

Organize layers and name critical curves and surfaces clearly. Ensure that the geometry is clean and free of duplicate lines. This preparation allows a smooth transition into Grasshopper for parametric control.

Open Grasshopper and reference the base curves from Rhino. Create numeric sliders to control parameters such as seat height, width, backrest angle, and leg spacing. Connect sliders to transformation components like Move, Scale, and Rotate.

Build relationships between components using mathematical expressions and geometric constraints. Ensure that when one parameter changes, the entire chair adapts proportionally while maintaining structural integrity.

Use control points and graph mappers to adjust the curvature of the seat. This enables ergonomic optimization and aesthetic refinement. Test different curvature intensities dynamically through sliders.

Introduce a thickness parameter to simulate real fabrication constraints. Use Offset Surface or Extrude components to adapt the design according to plywood, MDF, or metal sheet thickness.

Adjust sliders to generate multiple chair configurations. Evaluate proportions, stability, and visual balance. Capture variations to compare ergonomic and structural performance.

Continue experimenting with parameter combinations to explore alternative aesthetics and functional improvements. This stage highlights the flexibility of parametric modeling.

Once the optimal configuration is selected, bake the geometry into Rhino. Check for closed polysurfaces and export the file in formats suitable for CNC cutting, laser cutting, or other digital fabrication methods.

Flatten parts if needed, add tolerances for press-fit joints, and organize components efficiently within material sheets. Verify alignment and toolpath considerations before fabrication.

Export the final parametric chair model and generate documentation including dimensions, material specifications, and assembly diagrams. The design is now ready for production and iterative improvement.

| Software | Ease of Use | Accessibility | Cost | Compatibility | Collaborative Work |

|---|---|---|---|---|---|

| GIMP | Medium | High | High | High | Low |

| MyPaint | High | High | High | Medium | Low |

| Inkscape | Medium | High | High | High | Low |

| CorelDRAW | Medium | Medium | Low | High | Low |

| Tinkercad | High | High | High | Medium | Medium |

| Fusion 360 | Medium | Medium | Medium | High | Medium |

| Blender | Low | High | High | Medium | Low |

| Onshape | Medium | High | Medium | High | High |

| Text to CAD | High | Medium | Medium | Low | Low |

| DALL·E | High | High | Medium | Low | Low |

| After Effects | Low | Medium | Low | High | Low |

Efficient image compression is essential in Fab Academy documentation to ensure fast-loading web pages while preserving technical clarity. The selected workflow prioritizes accessibility, reproducibility, and minimal quality loss.

GIMP was identified as the most viable software for image compression due to its open-source nature, precise export controls, and wide compatibility across operating systems.

This procedure ensures that documentation images remain lightweight, readable, and fully compliant with Fab Academy standards.

✔ Modelled experimental objects and parts of a possible final project in 2D and 3D software

✔ Documented the process using text, images, and screenshots

✔ Compressed image and video files for web documentation

✔ Included original design line and source files