Group Assigment Work: Laser Cutting Machine Safety Conditions

This week we have to work in groups on the characterization of the laser cutter, analyzing parameters such as power, focus, cutting speed, joint clearance, and the types of laser cutters available in our FabLab.

Laser Cutting Machines

Among the machines available in our FabLab, the laser cutters are the most frequently used due to their speed and precision in cutting.

Currently, we have three laser cutters: two CO₂ tube laser cutters and one fiber laser. However, for this assignment, we will work specifically with the Nextion laser cutter.

This laser cutter is equipped with a 120W tube and a working bed of 90 x 120 cm.

Fiber laser cutter JPT

Maintenance and Characterization Process

This machine receives scheduled maintenance after a certain number of operating hours, depending on the type of material used and the type of cuts performed.

During this week, we were asked to characterize the machines.

As a first test, the cleaning of the laser head and mirrors was performed. The bed level was also checked, since if it is not properly leveled, the cuts will not be accurate.

To verify the focus, we ensured that the laser was positioned over the area to be cut. A pulse command was used to check the calibration of the machine and to confirm the alignment of the mirrors with the lens.

The laser head was then moved to other reference points to ensure consistent calibration across the working area.

Afterwards, the nozzle height was manually calibrated according to the material thickness, which in this case was 8 mm, following the manufacturer’s recommendations.

Jobs were sent to the laser cutter using the RDWorks software.

Several test cuts were performed.

Safety Conditions for CNC Laser Cutter Use

Proper safety conditions must be followed when operating CNC laser cutting machines to prevent accidents, damage to the equipment, and health risks to users.

Safety Protocol

- Always wear appropriate personal protective equipment (PPE), including safety glasses.

- Never leave the laser cutter unattended while it is operating.

- Ensure proper ventilation and extraction systems are active before starting the machine.

- Verify that the material being cut is suitable for laser cutting and does not emit toxic fumes.

- Check mirror alignment, lens cleanliness, and bed leveling before operation.

- Keep a fire extinguisher nearby and know how to use it.

- Stop the machine immediately if abnormal sounds, flames, or smoke are detected.

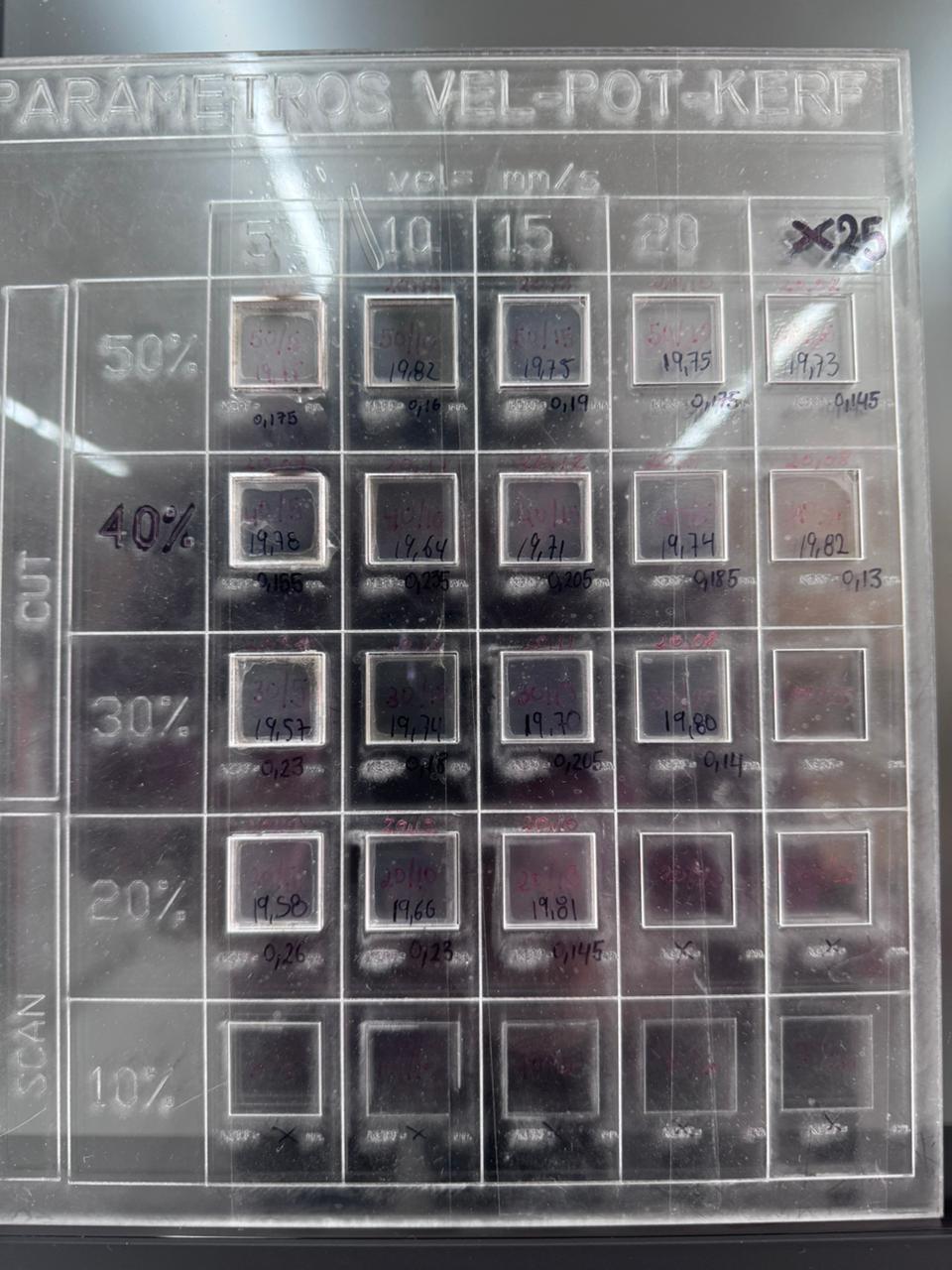

Kerf Calculation

The kerf is the material removed by the laser beam during cutting. Calculating the kerf is essential to ensure proper joint fit and dimensional accuracy.

Kerf Measurement Procedure

- Cut a rectangular test piece with known nominal dimensions.

- Measure the actual dimensions of the cut piece using a caliper.

- Compare the nominal and measured dimensions.

Kerf Formula

Kerf = (Nominal dimension − Measured dimension) / 2

Example:

Nominal width = 50.00 mm

Measured width = 49.60 mm

Kerf = (50.00 − 49.60) / 2 = 0.20 mm

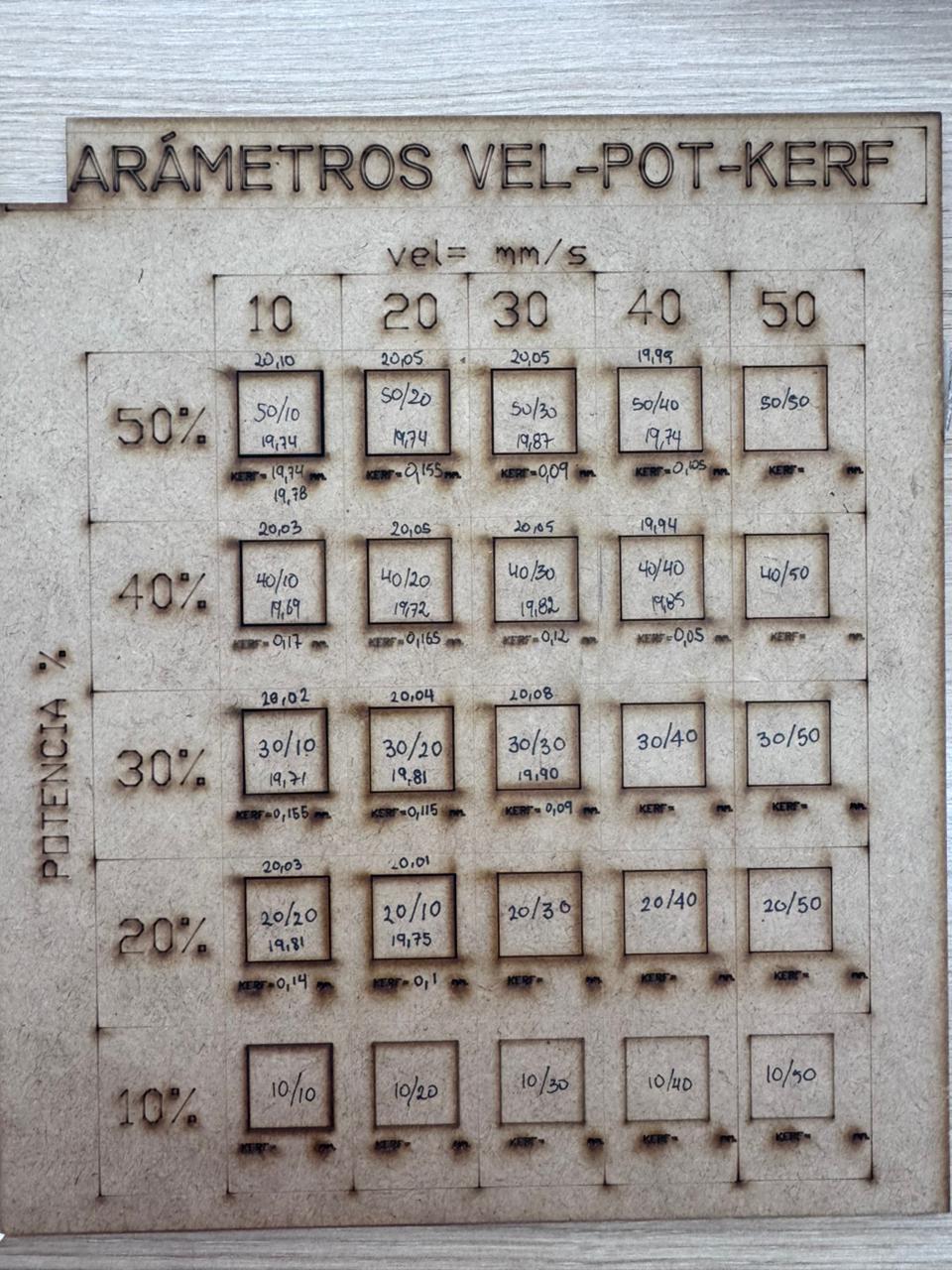

This kerf value can then be used to adjust joint clearances in CAD designs.

Group Assignment

- Group 1: Power and speed characterization

- Group 2: Focus calibration and material thickness analysis

- Group 3: Safety conditions and maintenance procedures

- Group 4: Kerf calculation and joint tolerance testing

Week 02 — Digital Design Tools

Fab Academy 2026 · Jenny Rojas · Industrial FabLab UCuenca

Designing a Parametric Construction Kit

1. Project Overview

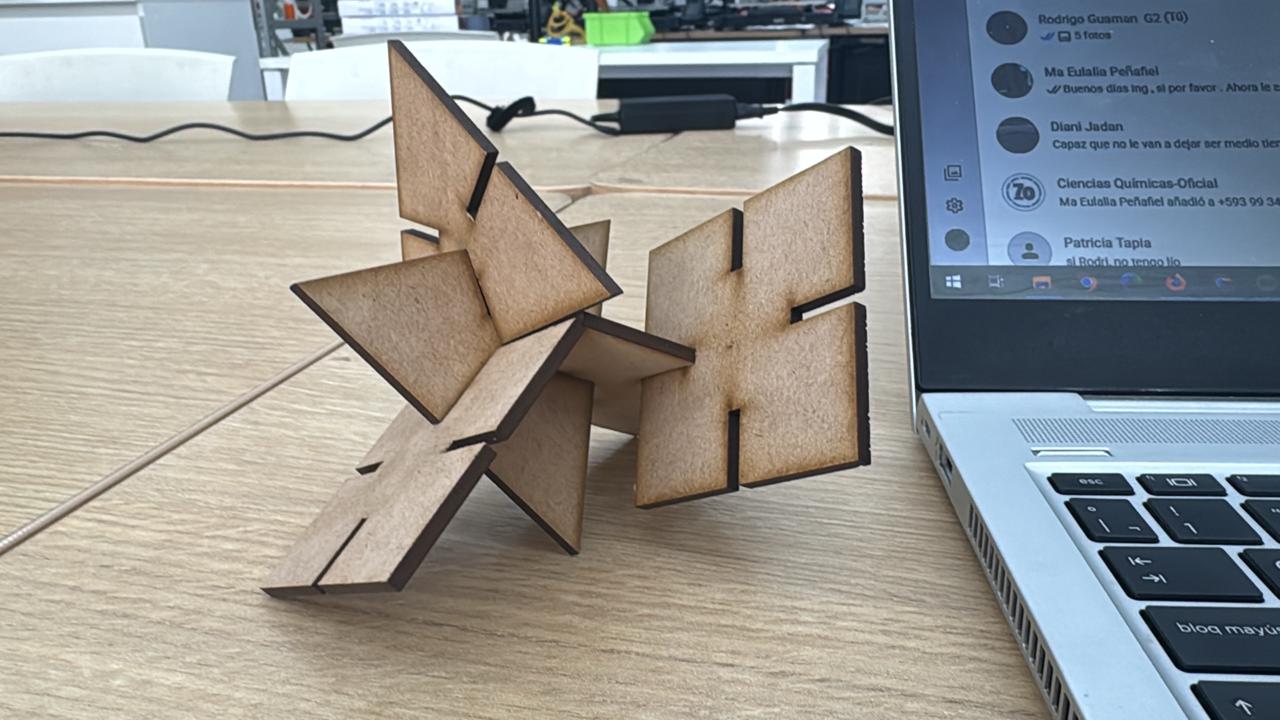

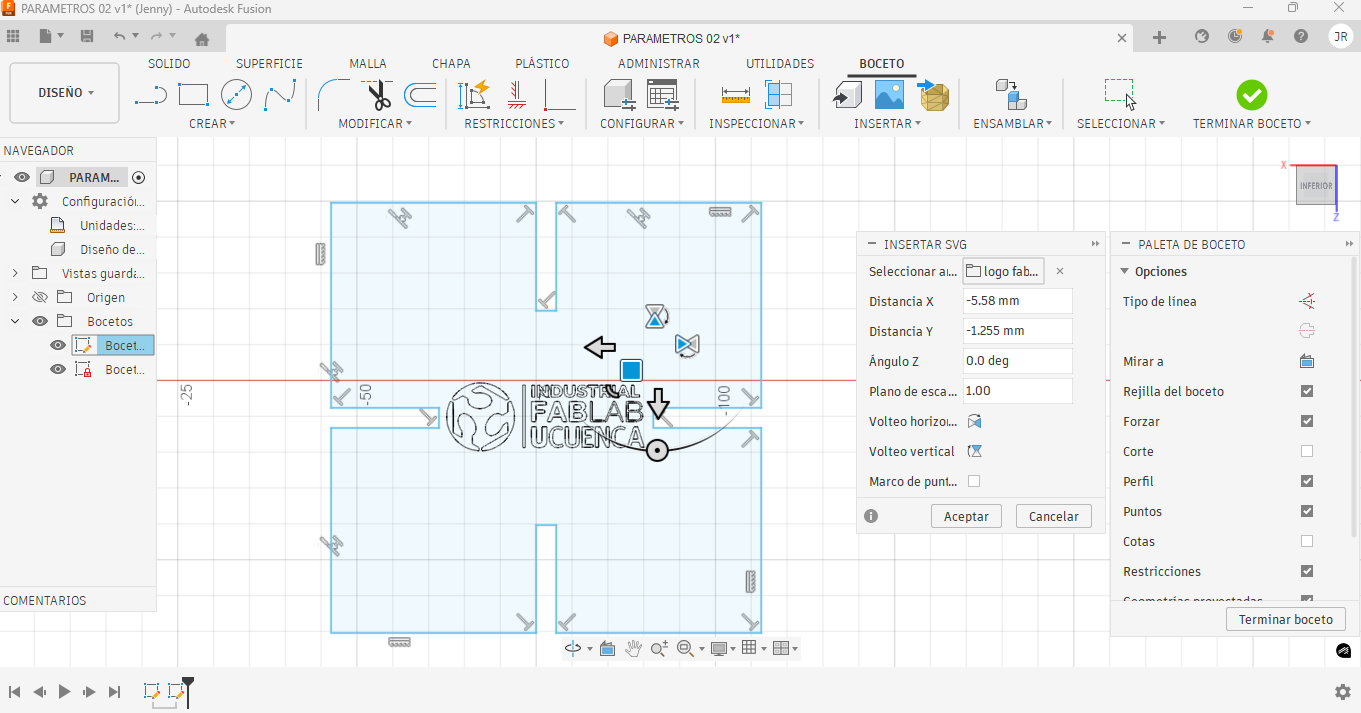

For the construction of a parametric-based kit, Fusion 360 was used as the main design software. The construction model is based on a modular, interlockable link system designed with press-fit joints that follow precise KERF parameters.

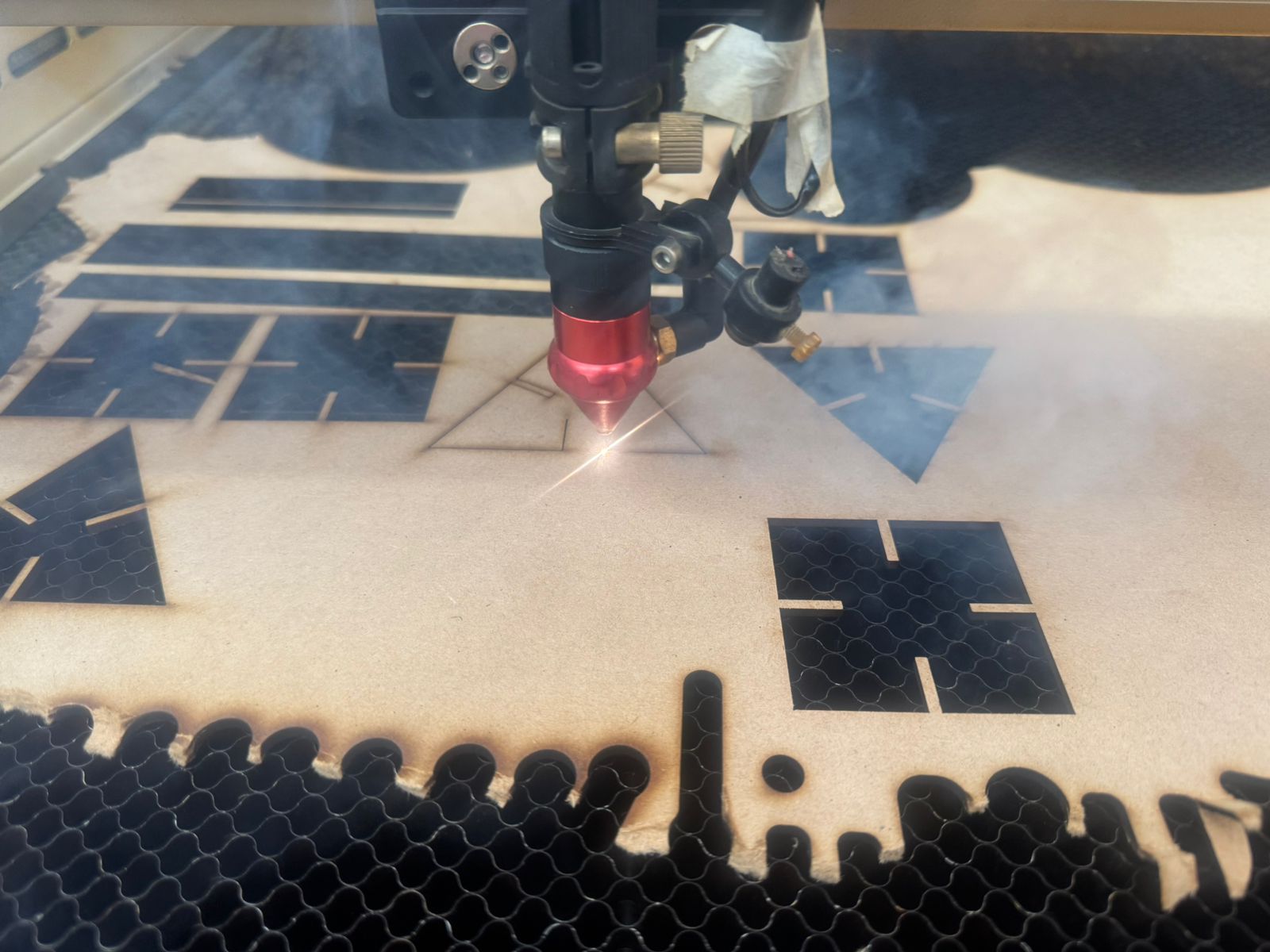

Fabrication was carried out using a 90W CO₂ laser cutting machine available at the Industrial FABLAB, working with MDF material.

2. Initial Sketch and Construction Plan

The design process starts from a construction plan using a curvilinear drawing approach. An initial hand sketch was created on paper to define the basic geometry and dimensions of the assembly links before digital modeling.

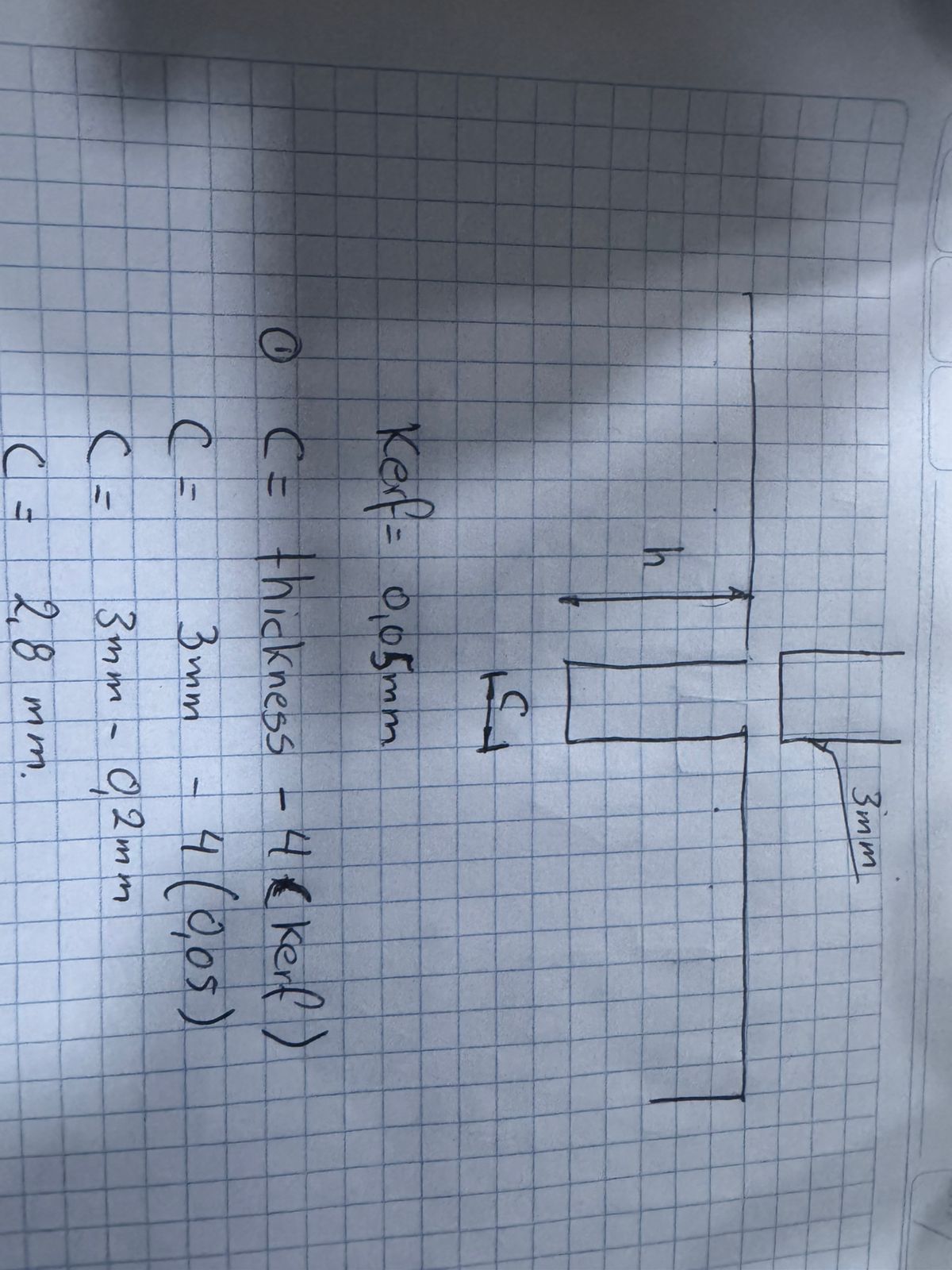

3. Kerf Calculation

To ensure a proper press-fit assembly, the kerf of the laser machine was calculated using a power and speed combination table. The best result was obtained with the following parameters, using the NEXTION equipment:

- Power: 40 watts

- Speed: 40 mm/s

- KERF: 0.05 mm

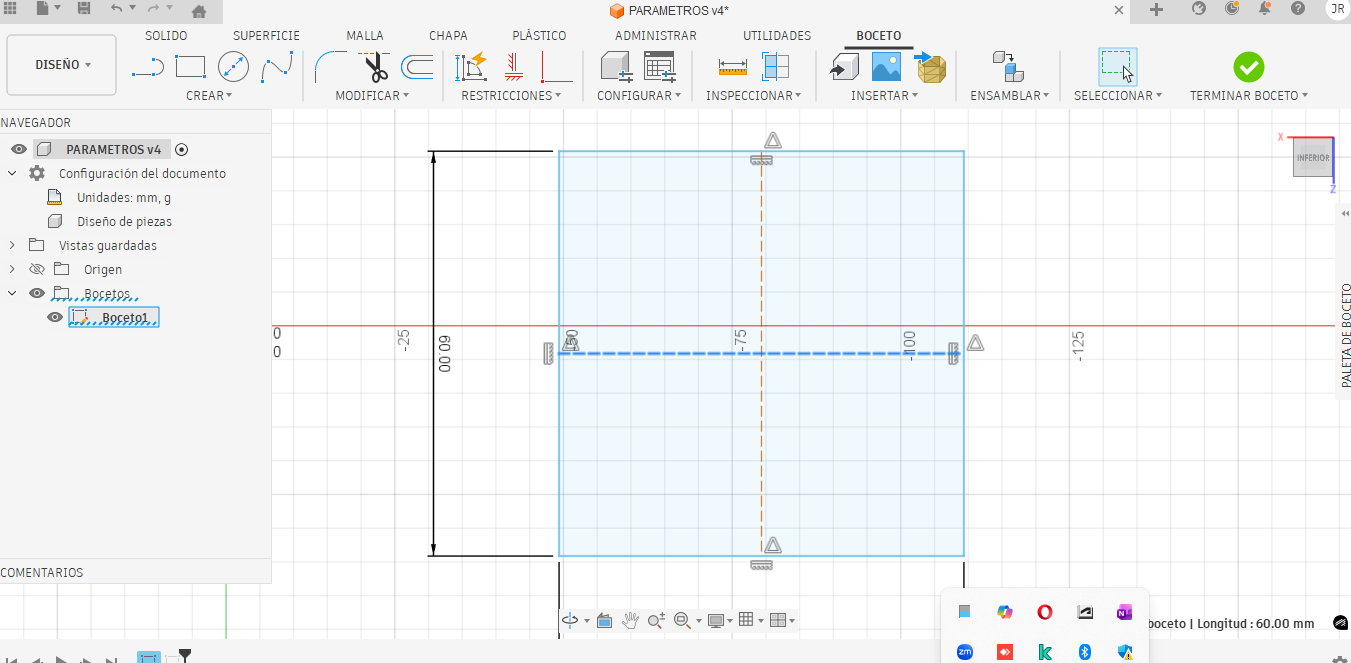

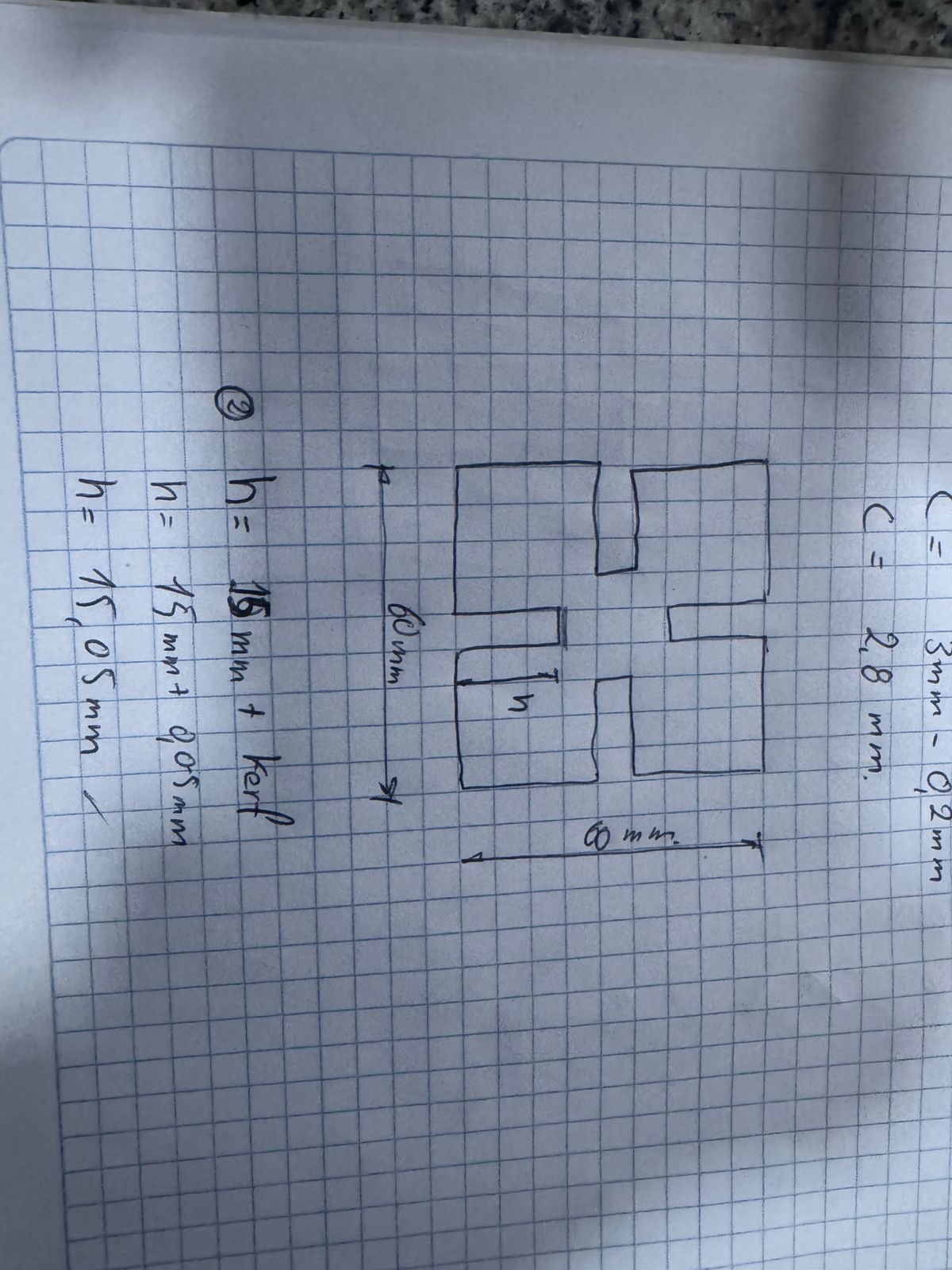

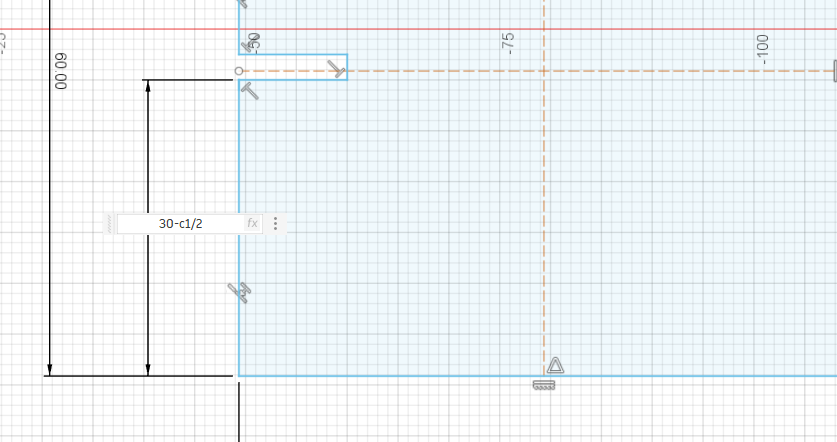

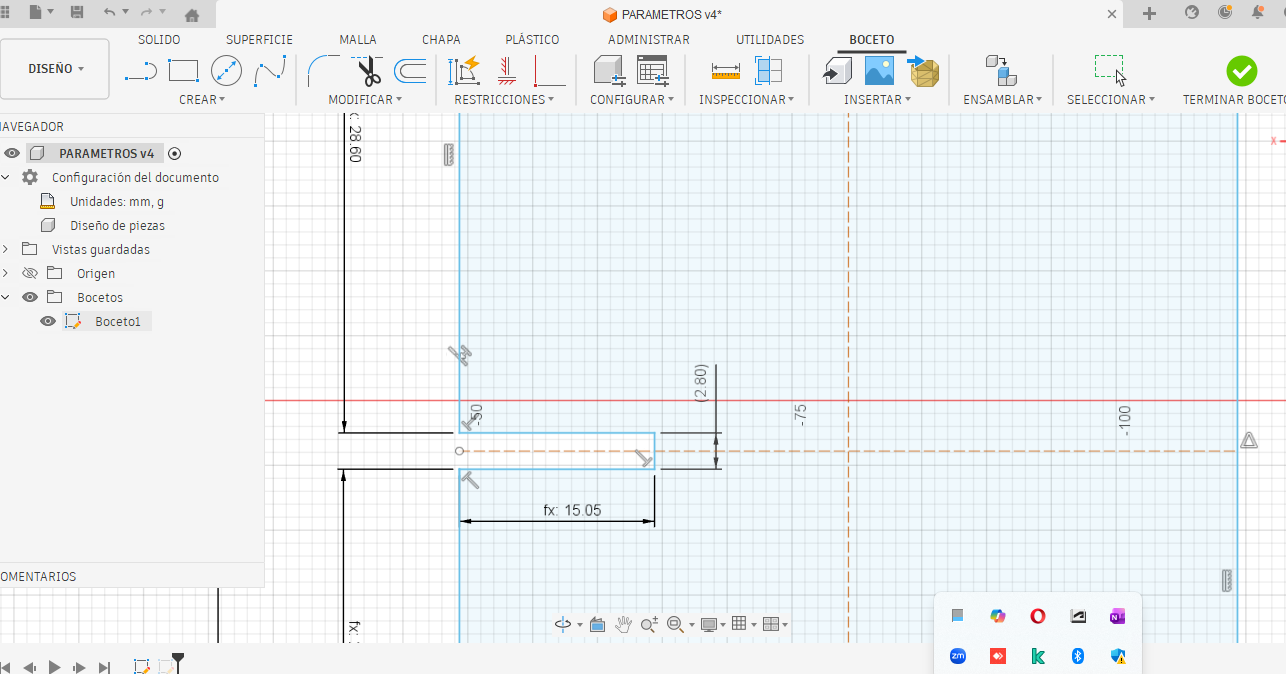

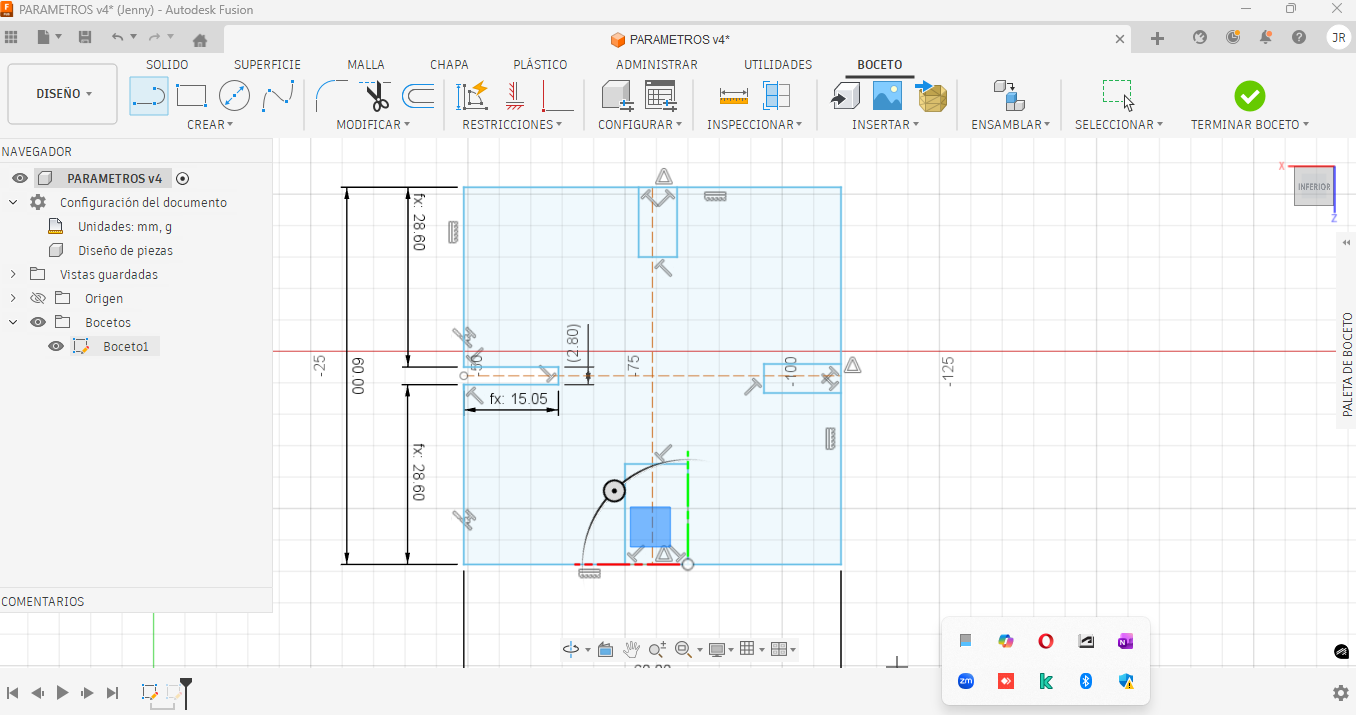

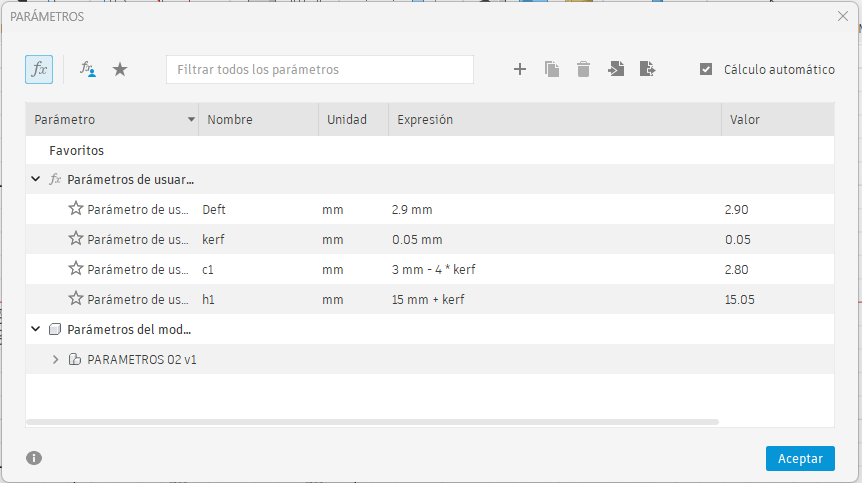

4. Parametric Variable Definition

Once the kerf value was defined, all key variables were parametrized in Fusion 360 to allow flexibility when changing material type, thickness, or machine calibration.

- KERF = 0.05 mm

- h = MDF material thickness – 4 × kerf

- Assembly height = 15 mm

- y = assembly height + kerf

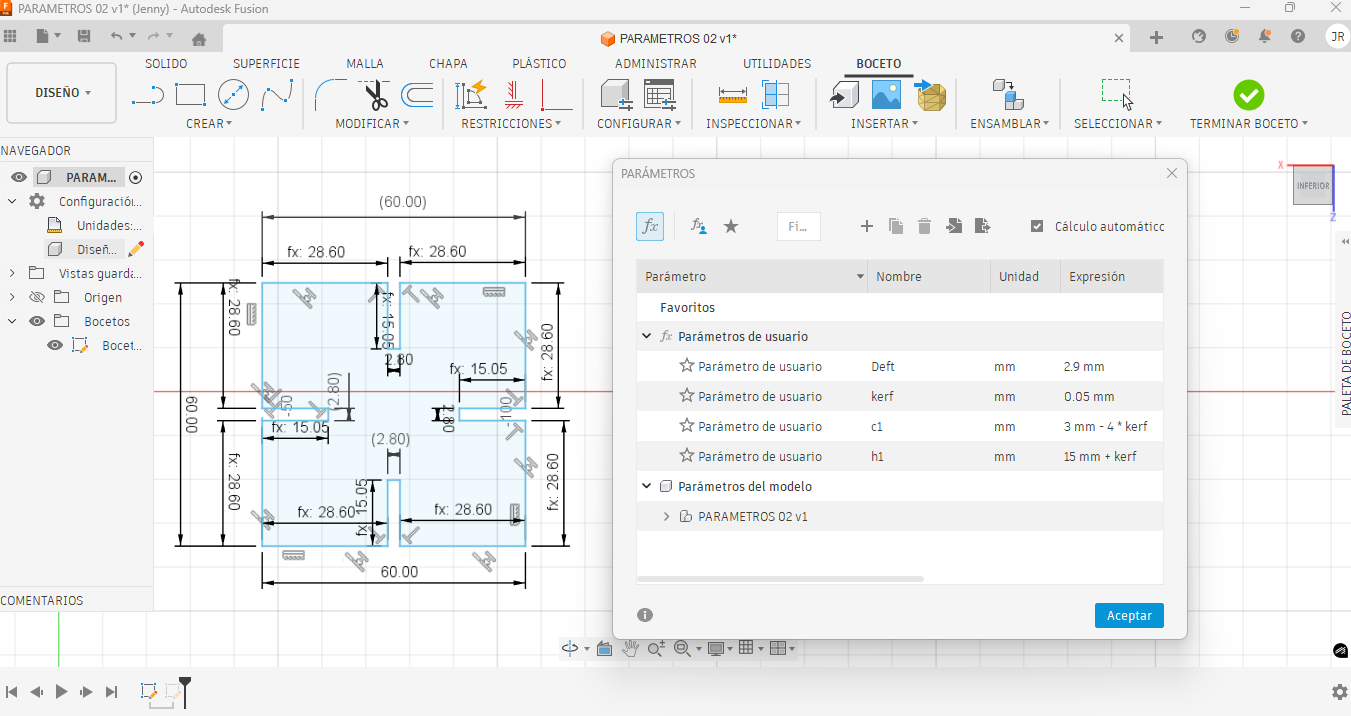

The link geometry was designed within a 60 × 60 mm working area.

5. Parametric Joint and Notch Design

With the base geometry defined, the notches for the joints were drawn using a fully parametric approach. This allows the joint dimensions to be adjusted automatically if the kerf, material, or thickness changes.

6. Tolerance Referencing

All notches were referenced sequentially using the defined parameters and tolerances, ensuring repeatability and a consistent press-fit behavior throughout the assembly.

7. Crossbar Design

The crossbars that support and connect the structure were designed next, using the same parametric variables defined for the main link, maintaining coherence across the system.

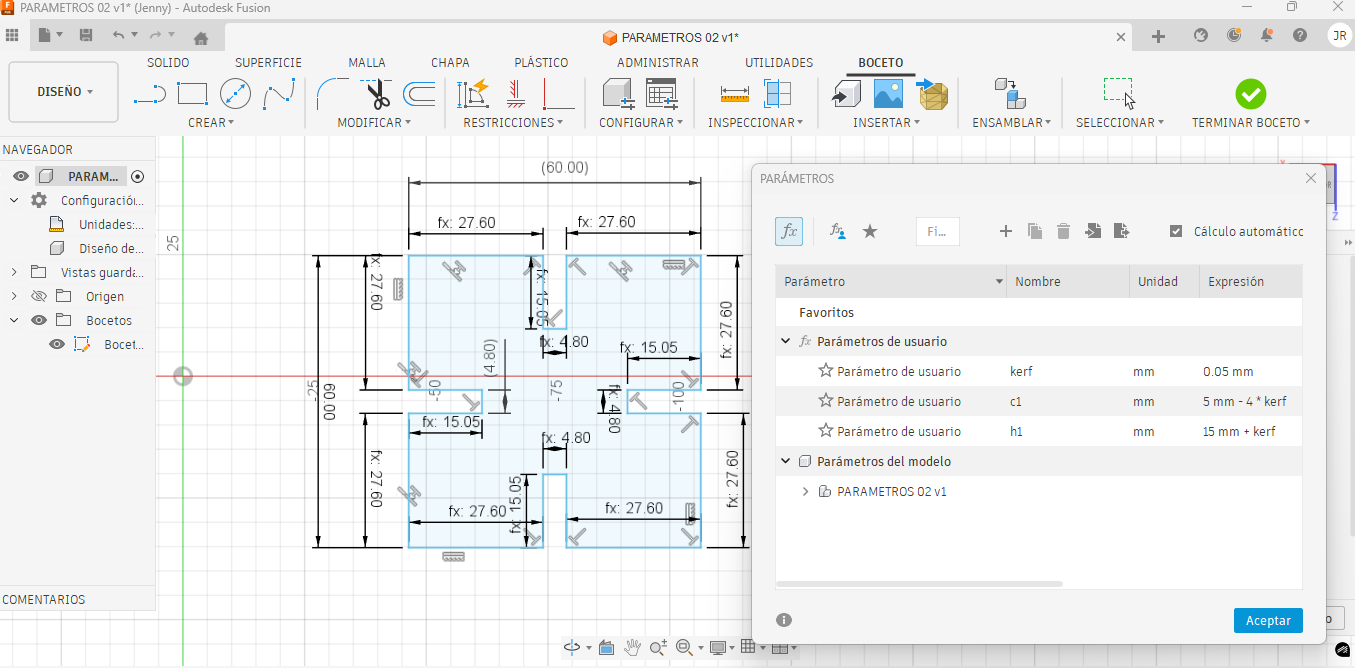

8. Material Thickness Simulation

A simulation was performed using a 5 mm thick material to validate the parametric behavior of the design before fabrication.

- KERF = 0.05 mm

- Material thickness = 5 mm

9. Final Fabrication Setup

After validating the design, final fabrication was prepared by calibrating the laser cutter, paying special attention to the focus height.

10. Final Assembly and Results

Once all parts were cut, the final assembly was carried out. The resulting product shows a strong press-fit behavior, correct kerf compensation, and does not require glue, which was a key requirement for this practice.

11. Downloadable Files

Before adjustment

After adjustment

12. Conclusion

The use of parametric design for press-fit assemblies enabled the development of a flexible construction kit adaptable to different materials, thicknesses, and kerf values. Proper laser calibration and variable definition resulted in a stable, glue-free assembly, fully meeting the objectives of this Fab Academy assignment.