Final Project

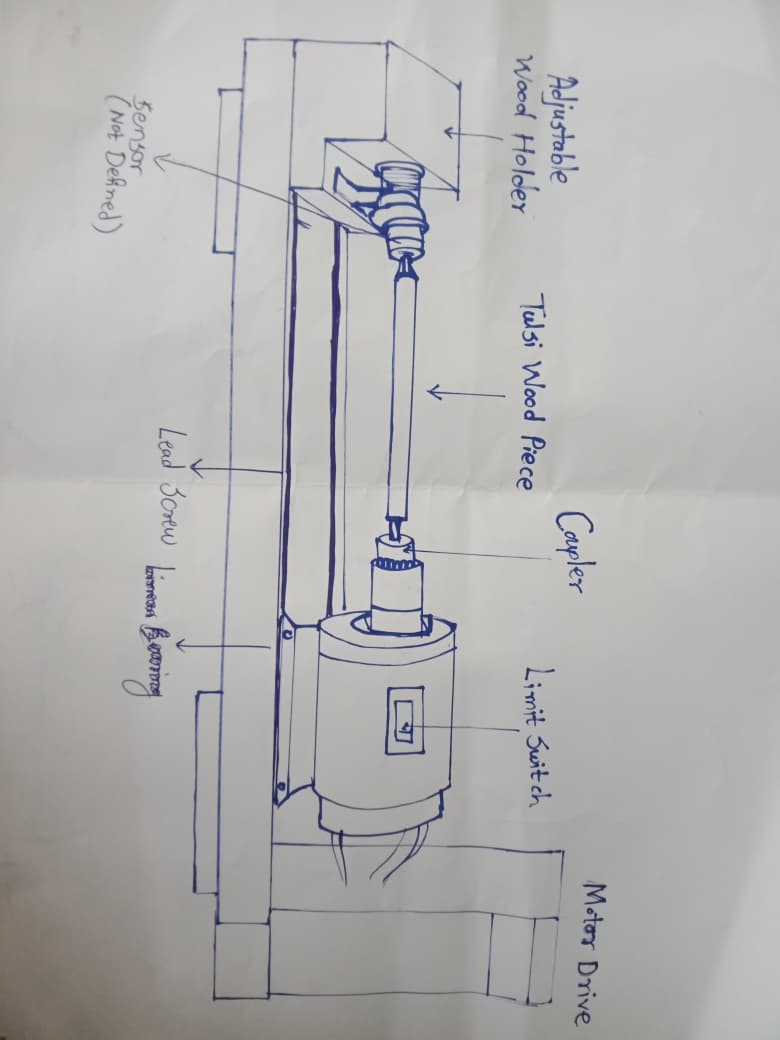

Sketch of the project:

Principles and practices:-

Final project- Tulsimala making system

In many parts of India, Tulsi mala (holy basil bead garland) making is a traditional cottage industry practiced by rural artisans, where beads are made manually from Tulsi wood using hand tools or simple hand-operated devices. This traditional process is time-consuming, physically tiring, and highly dependent on the skill of the artisan, and due to manual operation, the size and shape of beads are often inconsistent, which affects product quality and productivity. Artisans, especially women and elderly workers, face physical strain, low production rates, and safety risks while continuously rotating and shaping the Tulsi wood by hand, which also limits income generation as they are unable to meet increasing market demand within limited working hours. Commercial bead-making machines available in the market are expensive, bulky, and not suitable for small-scale rural setups, as they require higher power, skilled operation, and regular maintenance, which is not feasible for many rural artisans in India. Hence, there is a need for a low-cost, compact, and safe Tulsi mala making machine that can assist artisans by automating the rotation of Tulsi wood, improving accuracy, reducing physical effort, and increasing productivity while remaining affordable and easy to use in rural Indian conditions.

How this project will help

- To study the existing Tulsi mala making process and collect data on how many beads an artisan produces in a day and the number of hours they work per day.

- To analyze the physical effort, time consumption, and limitations of the manual bead-making method.

- To design a semi-automatic Tulsi mala making machine that assists artisans by providing controlled rotation of Tulsi wood.

- To integrate a limit switch for safe and controlled operation of the machine.

- The objective of this project is not to develop a fully automatic system, but to design a semi-automatic Tulsi mala making machine that supports artisans in their work, preserves their skills, reduces physical effort, and improves productivity, while ensuring that human involvement remains an essential part of the process to sustain livelihood and employment.