Problem

Many 3D printing materials are sensitive to drafts, ambient temperature changes, and humidity. These conditions can cause warping, layer separation, or inconsistent extrusion. Additionally, print failures (spaghetti, detachment, jams) often happen mid-print and waste time and material if not detected quickly.

Solution

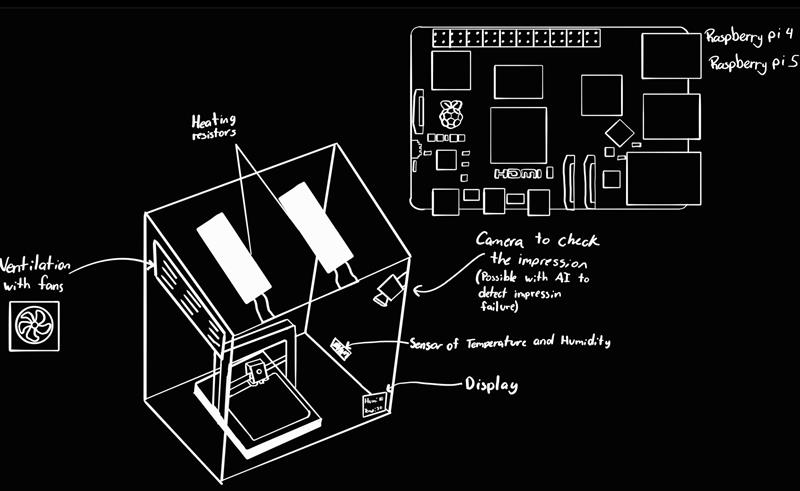

This project proposes a smart enclosure that actively controls the printing environment and supervises the print in real time: a heating module to raise/stabilize temperature, fans for controlled ventilation, a temperature/humidity sensor for feedback, a display for status, and a camera connected to a Raspberry Pi 4/5 to run AI-based failure detection.

Core features

- Heating resistors: increase and maintain internal temperature for better adhesion and reduced warping.

- Active ventilation with fans: controlled airflow to manage temperature and reduce fumes when needed.

- Temperature & humidity sensing: closed-loop monitoring for consistent conditions.

- Status display: live readings (T/H), fan/heater state, alerts.

- Camera + AI print monitoring: detect common failures and trigger warnings or automatic actions.

- Raspberry Pi 4/5: runs the UI, logging, and AI inference pipeline.

System architecture

The Raspberry Pi acts as the central controller. Sensor readings are sampled periodically, and control logic adjusts heating and fans. The camera continuously captures frames; an AI model classifies normal vs. failure states and triggers alerts.

| Module | Input | Output |

|---|---|---|

| Sensor block | Temperature / humidity | Live readings + logging |

| Control block | Setpoints + sensor data | Heater PWM / Fan control |

| Vision + AI | Camera frames | Failure detection + alerts |

| User interface | Status + controls | Display dashboard |

AI print monitoring (concept)

The monitoring pipeline is designed to detect issues such as spaghetti, detachment, or no extrusion. When a failure is detected, the system can:

- Show a warning on the display

- Send a notification

- Pause the printer or switch off heaters/fans (can't be implement in Bambu printers)

Mechanical design

The enclosure is designed around airflow and thermal stability:

- Heaters mounted on the top/side to distribute heat safely (with insulation and guards).

- Fans positioned for controlled intake/exhaust ventilation.

- Camera mount with clear view of the build plate.

- Dedicated compartment for electronics (Pi, power conversion, wiring management).

Next steps

- Define setpoints and control strategy (on/off, PID, or hysteresis control).

- Select sensors, heater power, fan type, and power supply sizing.

- Train/test a lightweight AI model for failure detection (edge inference on Pi).

- Build and validate the enclosure with real printing tests.