Final project

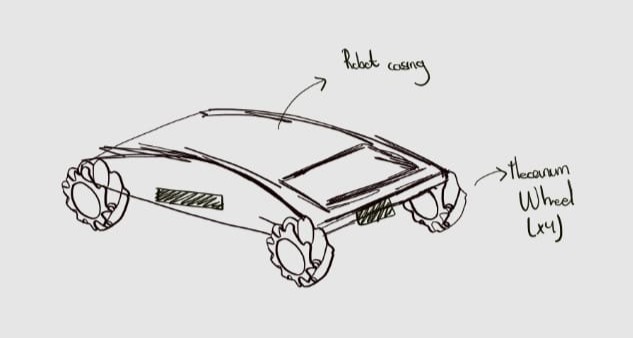

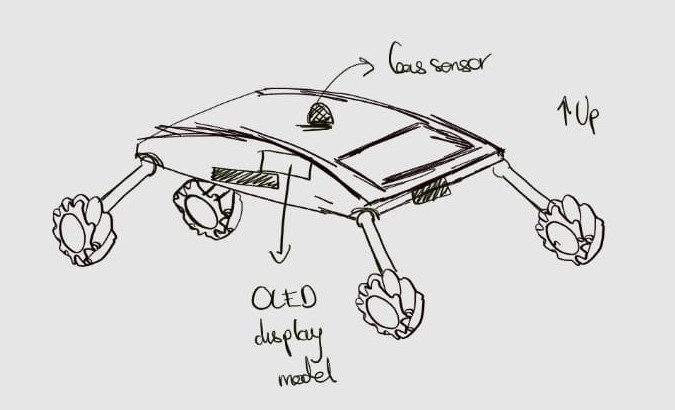

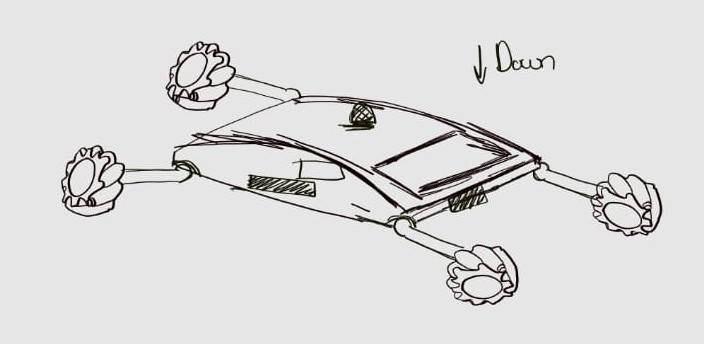

An omnidirectional autonomous mobile robot will be developed, capable of detecting and avoiding obstacles. The system is designed to operate on solid, flat, and stable surfaces. Figure 1 presents the initial conceptual design of the autonomous mobile robot.

Background Idea

The motivation for this project arises from a strong personal interest in robotics, particularly in the field of space robotics. This work is conceived as an opportunity to consolidate fundamental knowledge in mechanics, electronics, and programming, as well as to apply these skills in the design and construction of a functional autonomous vehicle.

Sketch of the Final Project

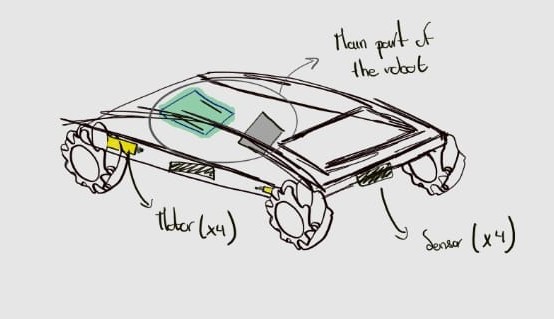

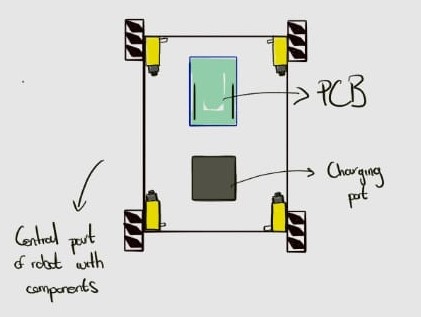

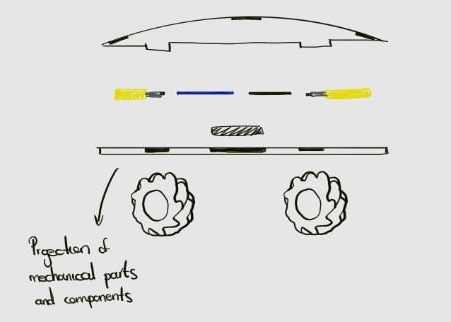

The robot will be equipped with four mecanum wheels, which enable movement in any direction depending on the motion applied to each individual wheel. These wheels will be coupled to TT DC motors and complemented with sensor systems located on the lateral, frontal, and rear sections of the autonomous vehicle. Figure 2 shows the overall robot design with the main components integrated. Figure 3 presents a top view of the robot chassis, while Figure 4 illustrates an exploded view highlighting the central components of the system.

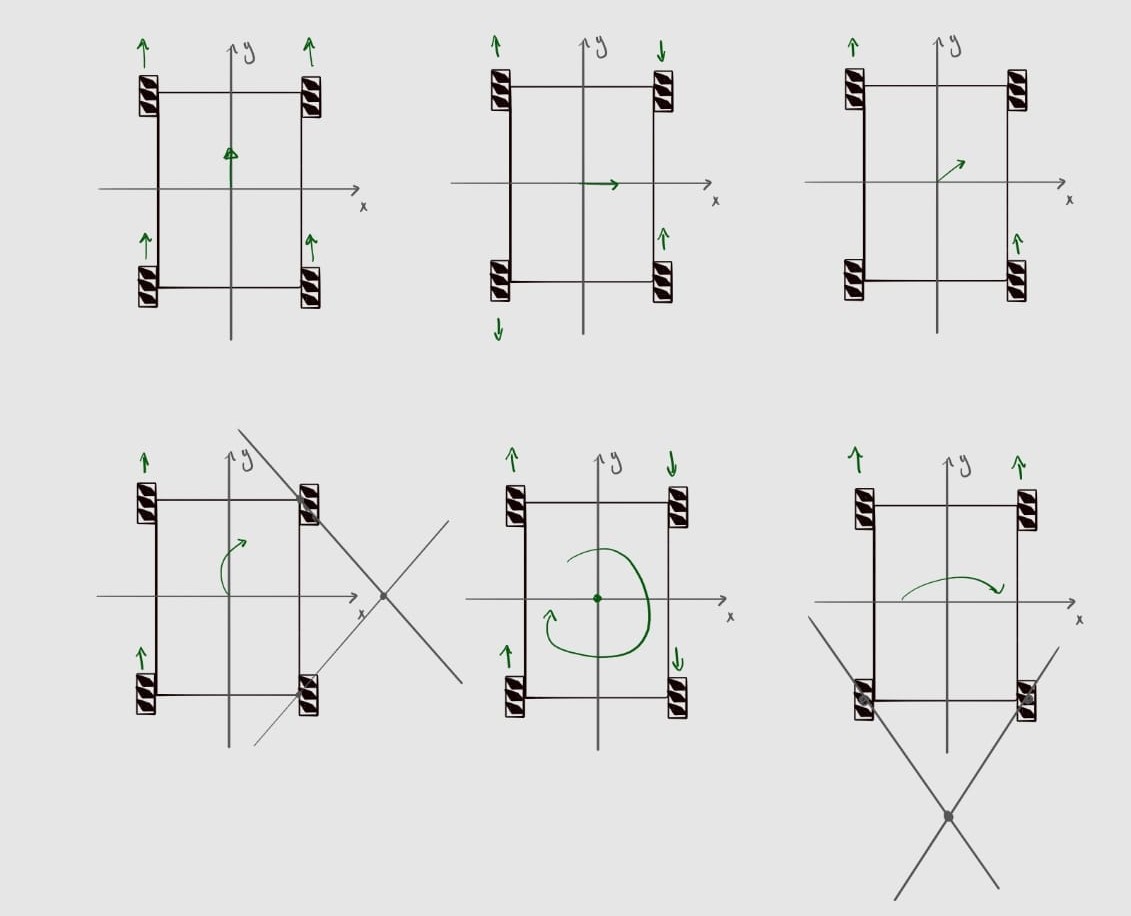

Finally, Figure 5 shows the operation of the robot's movement according to the type of motion imparted to its wheels. This information was obtained from Motion Dynamics.

Expected Challenges

One of the main challenges anticipated during the development of this project is the programming and electronic design of the robot. This is primarily due to the fact that my academic background is not directly focused on these areas, resulting in limited prior experience with the programming languages, development environments, and electronic architectures required for the system. Nevertheless, this project represents an ideal opportunity to acquire and strengthen skills that are not typically addressed within my field of study, contributing significantly to my professional development.

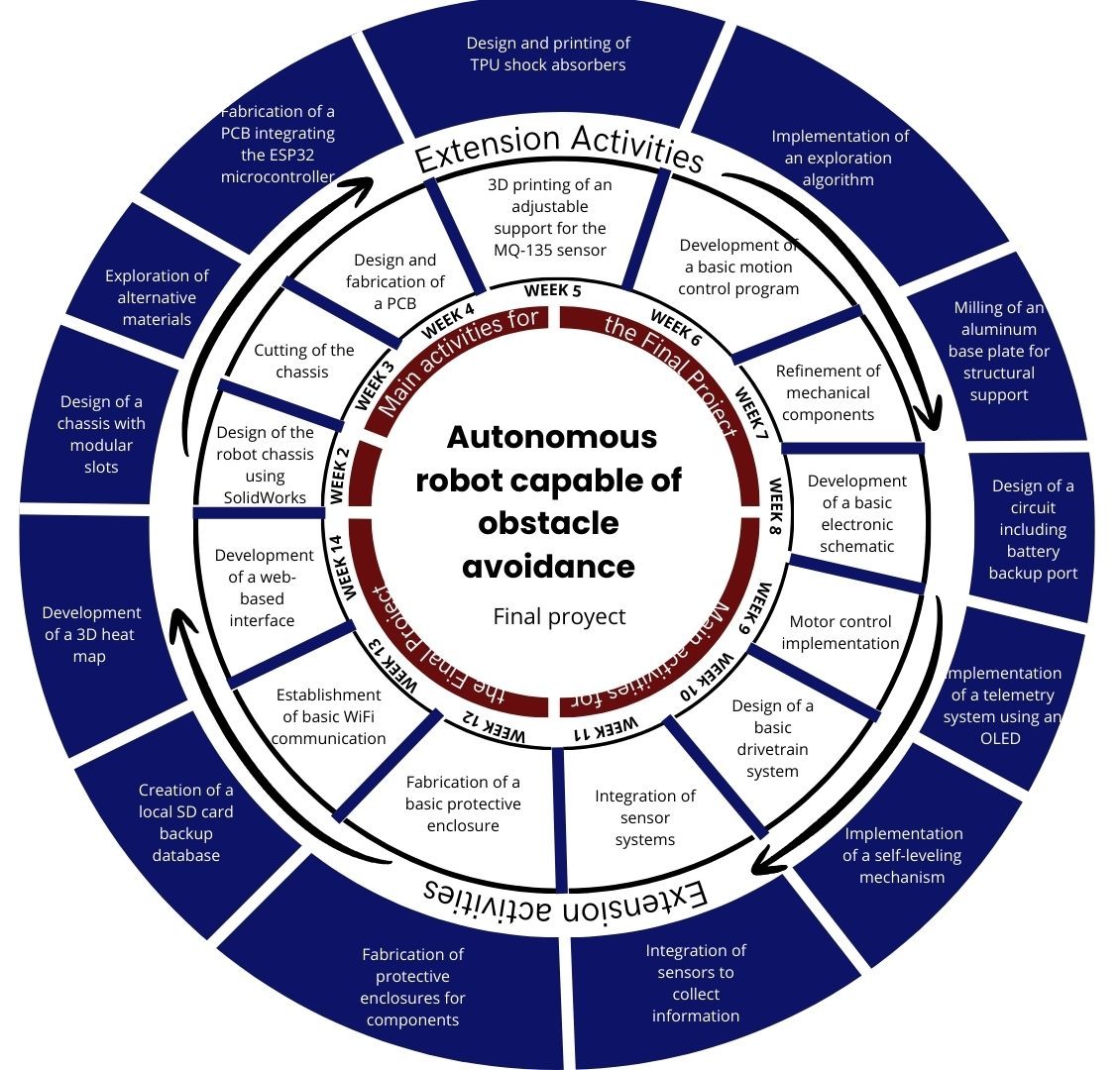

General Schedule of Activities for the Final Project

I wrote a general schedule of activities to organize myself better

| Fablab Week | Main Tasks | Estimated Time |

|---|---|---|

| Week 1. Project management |

|

2-3 days |

| Week 2. Computer Aided Design |

|

2-3 days |

| Week 3. Computer Controlled Cutting |

|

2-3 days |

| Week 4. Electronic Production |

|

3-5 days |

| Week 5. 3D Scanning and printing |

|

2-3 days |

| Week 6. Embedded Programming |

|

3-5 days |

| Week 7. Computer Controlled Machining |

|

3-4 days |

| Week 8. Electronics Design |

|

3-4 days |

| Week 9. Output Devices |

|

2-3 days |

| Week 10. Mechanical Design |

|

2-3 days |

| Week 11. Input Devices |

|

3-4 days |

| Week 12. Molding and Casting |

|

3-4 days |

| Week 13. Embedded Nettworking and Communications |

|

4-5 days |

| Week 14. Interface and Application Programming |

|

4-5 days |

Preliminary Bill of Materials

| Componente | Quantity | Cost (MXN) | Application |

|---|---|---|---|

| TT DC Motor | 4 | $59 | Robot locomotion |

| L298N H-Bridge Motor Driver | 1 | $90 | Control of motor speed and rotation direction |

| Rotary Encoders | 4 | $43 | Controlled measurement of vehicle motion |

| ESP32 DevKit V1 | 1 | $124 | Main microcontroller |

| HC-SR04 Ultrasonic Sensor | 3 | $53 | Obstacle detection |

| LM7805 Voltage Regulator | 1 | $48 | Voltage regulation for motors and sensors |

| AMS1117-3.3 Voltage Regulator | 1 | $12 | Voltage regulation for sensors |

| Male/Female Headers | 1 set | $350 | Electrical connections |

| Dupont Cables (MM, MF, FF) | Various | $59 | Electrical connections |

| Rechargeable Battery (2500 mAh) | 2 | $189 | Power supply |

| Power Switch | 1 | $29 | System power on/off |

| Double-sided Copper Board | 10x10cm | $392 | PCB fabrication |

| SMD Resistors 0805 | Various | $0.24 | PCB components |

| SMD Capacitors 0805 | Various | $129 | PCB components |

Future Work

Based on the initial design, a potential project extension is proposed, focused on the development of a gas-mapping robot operating within a controlled environment. This extension is conceived as an enhancement and expansion of the base system, with potential applications in environmental monitoring and the analysis of current real-world problems.

Design for the Gas-Mapping Robot

The gas-mapping robot will be based on the initial autonomous vehicle design, with modifications to integrate additional sensors and functionalities. The main components of the system will include:

- Chassis: Adapted to accommodate additional sensors and ensure stability during operation.

- Microcontroller: ESP32 or similar, capable of handling multiple sensor inputs and data processing.

- Sensors: Integration of gas sensors such as MQ-135 (smoke), SGP30 (CO₂/VOCs), and DHT22 (temperature and humidity) for comprehensive environmental monitoring.

- Data Storage: Implementation of local data storage using an SD card module, with potential WiFi connectivity for real-time data transmission.

- Power Supply: Enhanced battery system to support additional components and ensure extended operation time.

Schedule for Future Work: Robot Upgrade to Gas-Mapping System

| Fablab Week | Main Tasks | Estimated Time |

|---|---|---|

| Week 1. Project management |

|

1 day |

| Week 2. Computer Aided Design |

|

2-3 days |

| Week 3. Computer Controlled Cutting |

|

1-2 days |

| Week 4. Electronic Production |

|

4-5 days |

| Week 5. 3D Scanning and printing |

|

2-3 days |

| Week 6. Embedded Programming |

|

5-6 days |

| Week 7. Computer Controlled Machining |

|

2-3 days |

| Week 8. Electronics Design |

|

4-6 days |

| Week 9. Output Devices |

|

3-5 days |

| Week 10. Mechanical Design |

|

3-5 days |

| Week 11. Input Devices |

|

3-5 days |

| Week 12. Molding and Casting |

|

2-5 days |

| Week 13. Embedded Nettworking and Communications |

|

3-7 days |

| Week 14. Interface and Application Programming |

|

4-5 days |

Bill of Materials for Future Work

| Componente | Quantity | Cost (MXN) | Application |

|---|---|---|---|

| MQ-135 Gas Sensor | 1 | $53 | Gas and smoke detection |

| SGP30 Sensor | 1 | $199 | CO2 and VOC detection |

| DHT22 Sensor | 1 | $135 | Temperature and humidity measurement |

| SD Card Module | 1 | $49 | Local data storage |

| OLED Display 0.96” | 3* | $103 | Visualization of robot data |

| Motor Rotary Encoders | 2* | $165 | Estimation of traveled distance |

| SD Card Reader Module | 1 | $245 | Local data storage |

| MicroSD Card 16 GB | 1 set | $57 | Data storage |

| Acrylic Sheets | Various | $91 | Enclosure for controlled environment |

Spiral development

As previously discussed, this autonomous mobile robot presents multiple opportunities for future improvement and expansion. Based on this perspective, a Spiral Development is proposed as a visual tool to outline potential milestones and long term development goals, assuming the successful completion of the core project objectives.