1. Purpose and Functionality

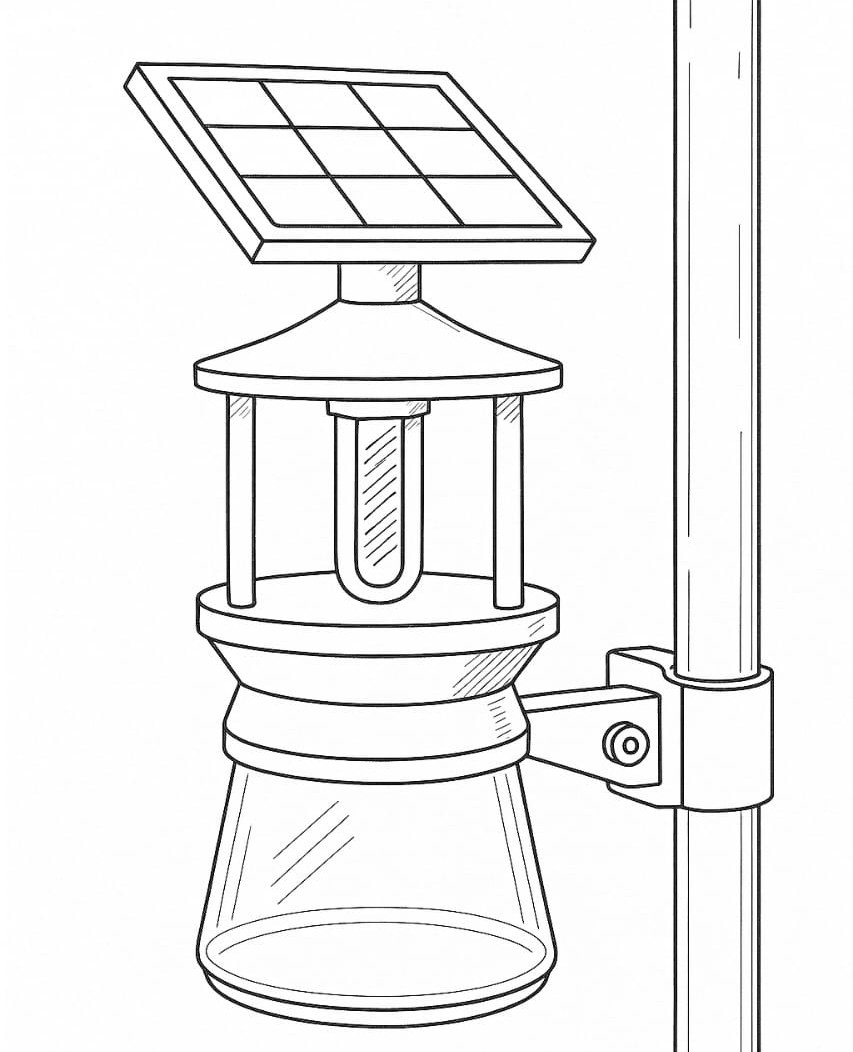

The Mini AgriSun Trap is a cutting-edge, solar-powered device engineered to offer sustainable pest control solutions for agriculture. By harnessing solar energy, this compact trap effectively attracts and captures harmful insects commonly found in crop fields, drastically reducing reliance on chemical pesticides. Its smart design includes an automatic LED lighting system that activates at dusk and powers down after a preset duration, ensuring efficient energy use during the night. This innovation not only safeguards crops but also promotes eco-friendly farming by minimizing environmental harm.

2. Market Landscape and Existing Solutions

In India, the market for solar-powered insect traps is expanding rapidly, fueled by growing awareness of environmentally safe pest management alternatives. Current offerings like the Chipku Mini Solar Insect Trap, Wavar Mini Solar Insect Light Trap, Ugaoo Mini Trap, BuzzZap Mini Solar Trap, and Farmroot Solar Insect Trap demonstrate effective use of UV or LED lights to lure pests. However, many existing models face challenges concerning cost, portability, and multifunctionality. The Mini AgriSun Trap is designed to overcome these issues by providing a cost-effective, lightweight, and adaptable option suitable for various agricultural environments.

3. Sources and Inspiration

The development of the Mini AgriSun Trap is based on expert insights from Vigyan Ashram, comprehensive market surveys of available solar traps, and thorough analysis of scientific and technical literature related to sustainable agriculture and pest control technologies. This extensive research has helped align the project with current agricultural needs and advanced technological standards.

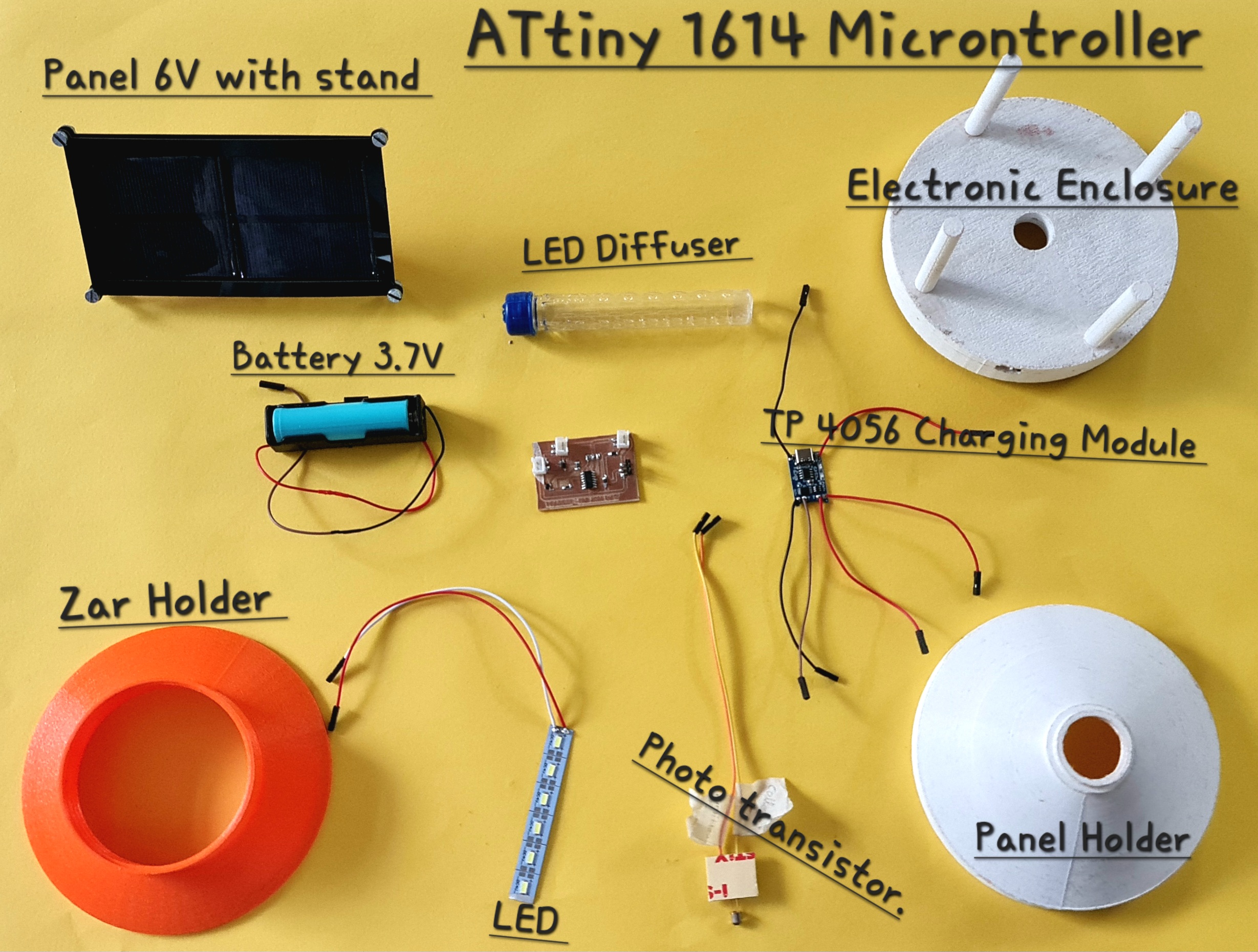

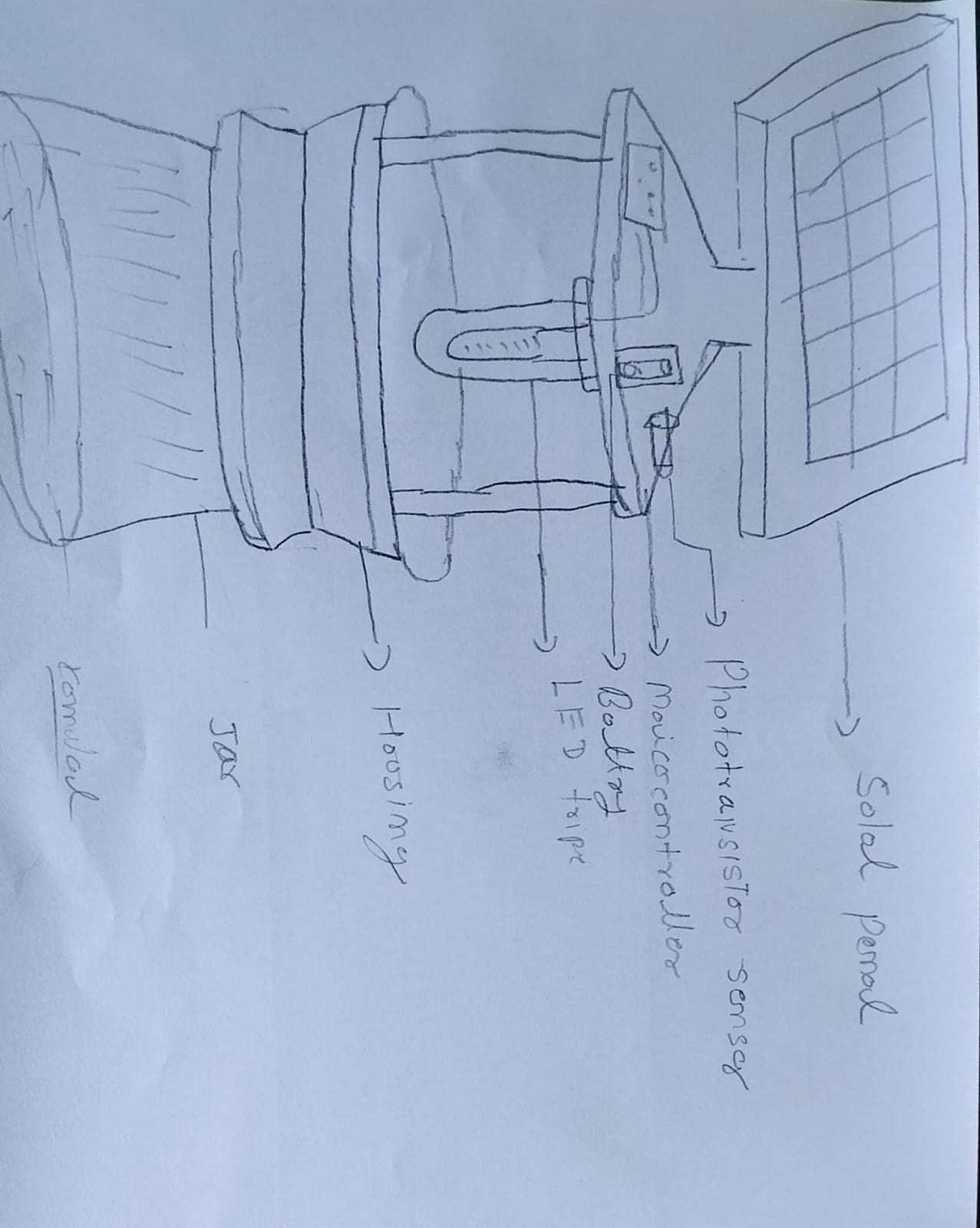

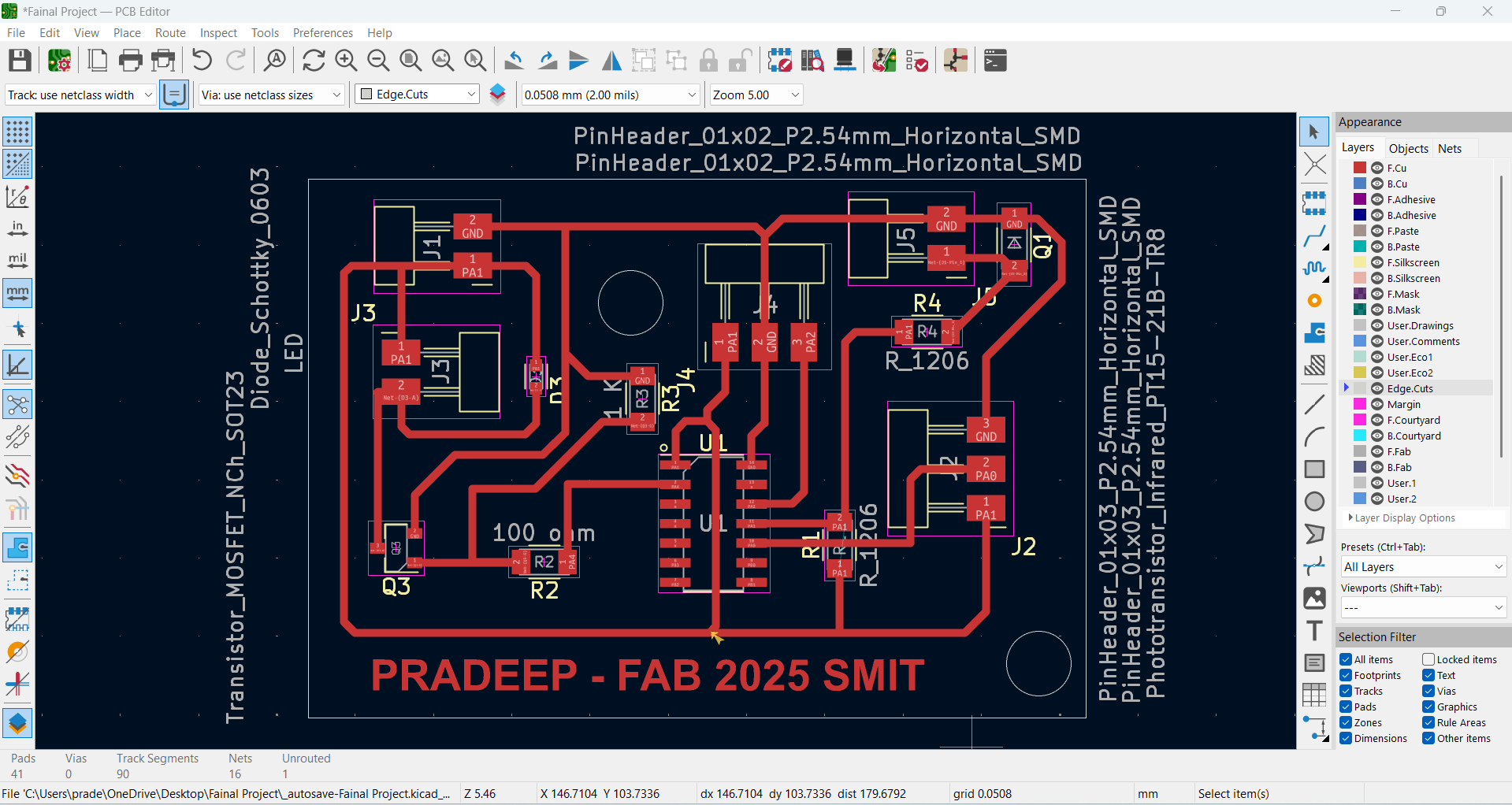

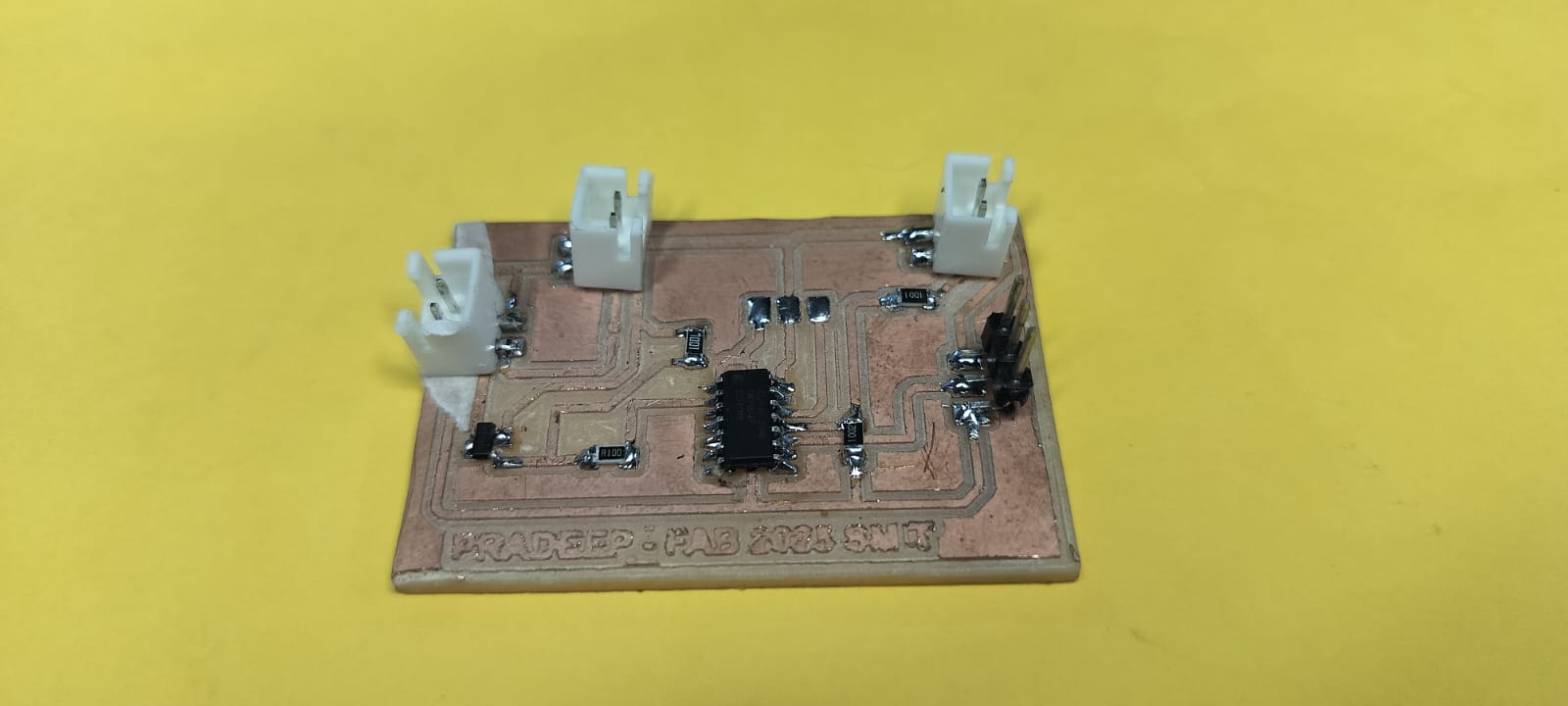

4. Design Elements and Components

This project incorporates a custom-designed Printed Circuit Board (PCB) that seamlessly integrates all electronic components. The housing consists of precisely crafted 3D-printed parts and laser-cut 2D elements, ensuring robust, weatherproof construction. An automated control mechanism governs the LED lighting, turning it on and off based on ambient light levels or scheduled timing to maximize efficiency and energy conservation.

5. Materials and Components List

| S.No. |

Component |

Description |

Cost (INR) |

Cost (USD) |

| 1 |

2D Cutting Parts |

Laser-cut acrylic sheet (6x6 inch, 3mm) |

₹15 |

$0.18 |

| 2 |

3D Printed Parts |

250g PLA filament used for custom enclosures |

₹200 |

$2.41 |

| 3 |

Transparent Jar Box |

Box |

₹15 |

$0.18 |

| 4 |

Solar Panel |

6V, 3W solar panel |

₹110 |

$1.33 |

| 5 |

Rechargeable Battery |

2200 mAh lithium-ion cell |

₹42 |

$0.51 |

| 6 |

TP4056 Charging Module |

Lithium battery charging & protection |

₹12 |

$0.14 |

| 7 |

LEDs |

High brightness white LEDs |

₹35 |

$0.42 |

| 8 |

LED Tube |

Compact light tube for attraction |

₹10 |

$0.12 |

| 9 |

PCB |

Custom printed circuit board |

₹8 |

$0.10 |

| 10 |

ATtiny1614 Microcontroller |

Low-power MCU for automation |

₹76 |

$0.92 |

| 11 |

Phototransistor Sensor |

Detects light levels for control |

₹40 |

$0.48 |

| 12 |

Electronics |

Resistors, diodes, MOSFETs, connectors |

₹30 |

$0.36 |

| Total |

₹593 |

$7.14 |

6. Procurement and Sourcing

The components for the Mini AgriSun Trap will primarily be sourced from local electronic markets, while critical items such as solar panels and rechargeable batteries will be acquired from reputable suppliers located in Pune and other metropolitan hubs. This approach ensures access to high-quality parts at reasonable prices.

7. Estimated Budget

The following table outlines the estimated cost of each component used in the construction of the Mini Agrison Trap. These estimates are based on current market prices and may vary slightly depending on availability and the choice of suppliers. It is important to note that while the current production cost is approximately ₹600 per unit, this amount can be significantly reduced to around ₹400 per unit if manufacturing is done in bulk.

8. Key System Components and Features

- Efficient solar energy capture and power conversion system

- Battery storage ensuring continuous operation through night hours

- LED lighting designed specifically to attract and trap target insect species

- Automated control circuitry for optimized power consumption

- Durable, weather-resistant casing suitable for outdoor use

- Simple maintenance and user-friendly interface for easy operation

9. Manufacturing and Assembly Processes

Manufacturing the Mini AgriSun Trap involves advanced production techniques, including precision milling of PCBs, accurate soldering of components, 3D printing of customized enclosures, and laser cutting for structural parts. Each phase is carefully executed to guarantee the product’s reliability and durability over long-term usage.

10. Key Questions to Address

- What mechanism triggers the LED lights to switch on and off automatically?

- How long can the device function solely on battery power without sunlight?

- Does the solar panel power the trap directly, or only charge the battery?

- Which types of crops or agricultural environments benefit most from this trap?

- Are there backup power options during prolonged cloudy weather?

- Does the device include any fault detection or malfunction alerts?

- What are the recommended procedures for maintenance and troubleshooting?

11. Project Evaluation Criteria

- Reliability and effectiveness of the electronic design

- Efficiency in solar power utilization and battery management

- Responsiveness and accuracy of the automated lighting control system

- Build quality and robustness of physical components

- Ease of installation, daily operation, and upkeep

- Environmental sustainability and minimal ecological impact

- User satisfaction and performance in practical field conditions

Project Status and Reflections

Completed Tasks

- Completed coding for the device’s functionality.

- Pending laser cutting and 3D printing of the physical parts.

Remaining Tasks

- Final product testing and validation.

- Completing assembly and preparing full documentation.

Successes and Challenges

- Successful testing of solar panel, battery, and sensor components.

- 3D printing and laser cutting processes are yet to be completed.

- Final assembly and comprehensive testing are still underway.

Outstanding Questions

- Clarification regarding warranty terms and coverage.

Next Steps and Timeline

- The project aims to be completed by the submission of Assignment 18.

Key Learnings

- Gained deep insights into the complexities of design and programming challenges.

- Realized the significant persistence and effort required to develop a fully functional product.

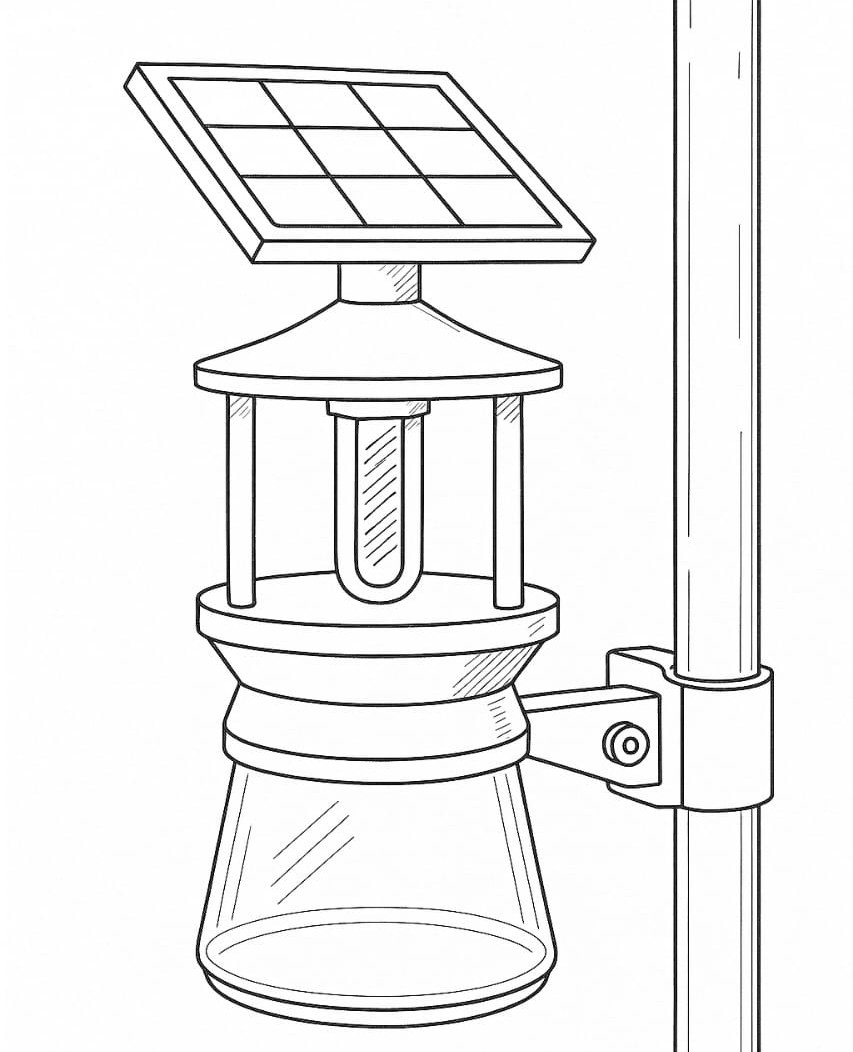

Methods of Packaging

For the Mini AgriSun Trap, packaging was an important part of the design. It helps to protect the system from weather, keeps the electronics safe, and makes the product easy to use in the field. Here is how I did the packaging:

- Enclosure Box: I designed a strong 3D printed box to hold the PCB, battery, and charge controller. The box is waterproof and UV-resistant to survive in farm conditions.

- Transparent Cover: A clear acrylic cover was added so the LED lights and indicators can be seen without opening the case.

- Solar Panel Mount: The solar panel is fixed on top of the box using a metal stand at a 45-degree angle to get maximum sunlight.

- Wire Management: All wires are connected using waterproof connectors and cable sleeves to protect them from dust and moisture.

- Ventilation: Four small side pillars are added to allow airflow. This helps avoid overheating and also keeps insects out.

- Mounting Option: A ring holder is designed at the bottom of the enclosure to make it easy to fix or mount the device wherever needed.

In summary, this packaging keeps the device safe, strong, and easy to install in the farm area.