Group Assignment

Hero Shot

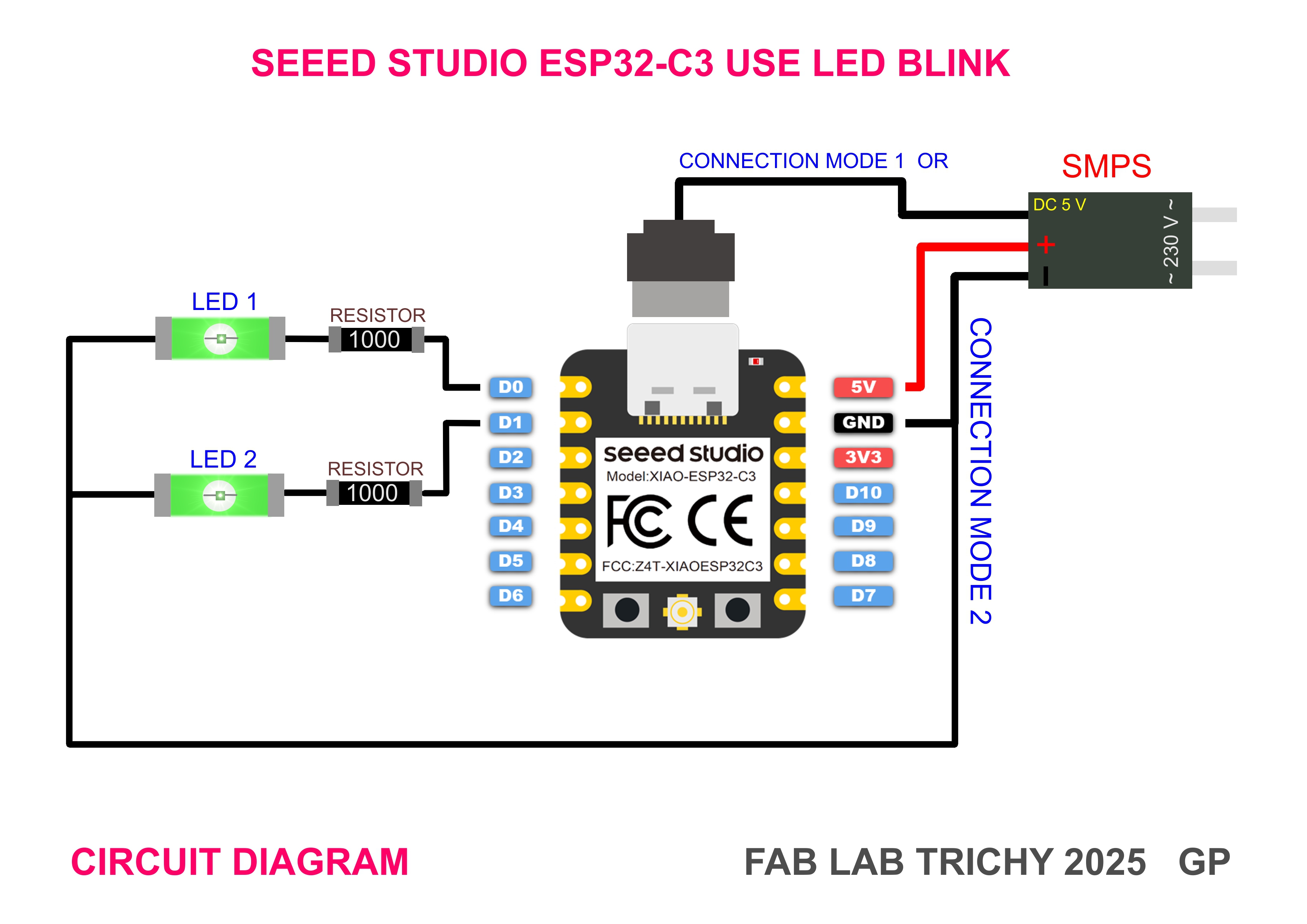

My Objective

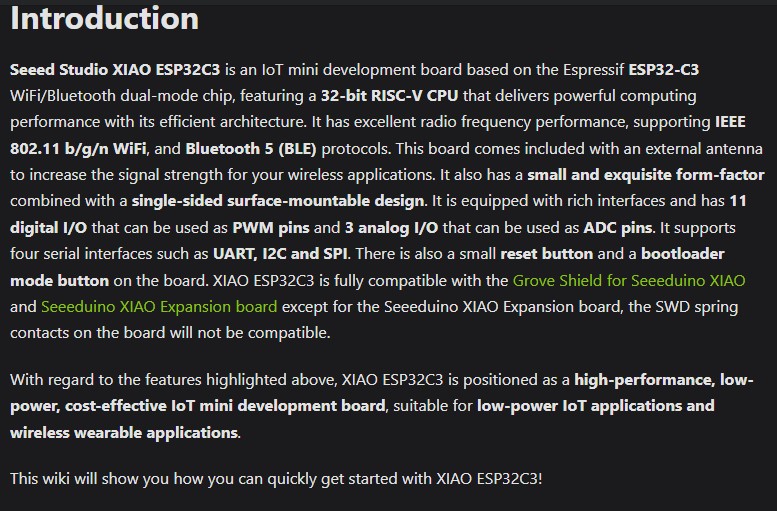

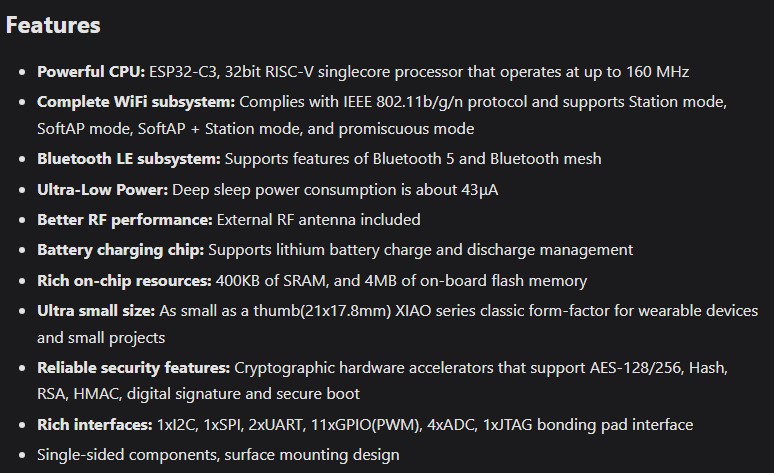

My objective is to design a simple PCB with 2 LEDs, 3 resistors, and a button switch using KiCad. I verified the circuit, generated toolpaths, milled the board, soldered components, and uploaded the code. This process was done under the Seeed Studio workflow for Week 8 Electronics Production.

Tools Required

- KiCad (for schematic and PCB design)

- Mods CE for toolpath generation

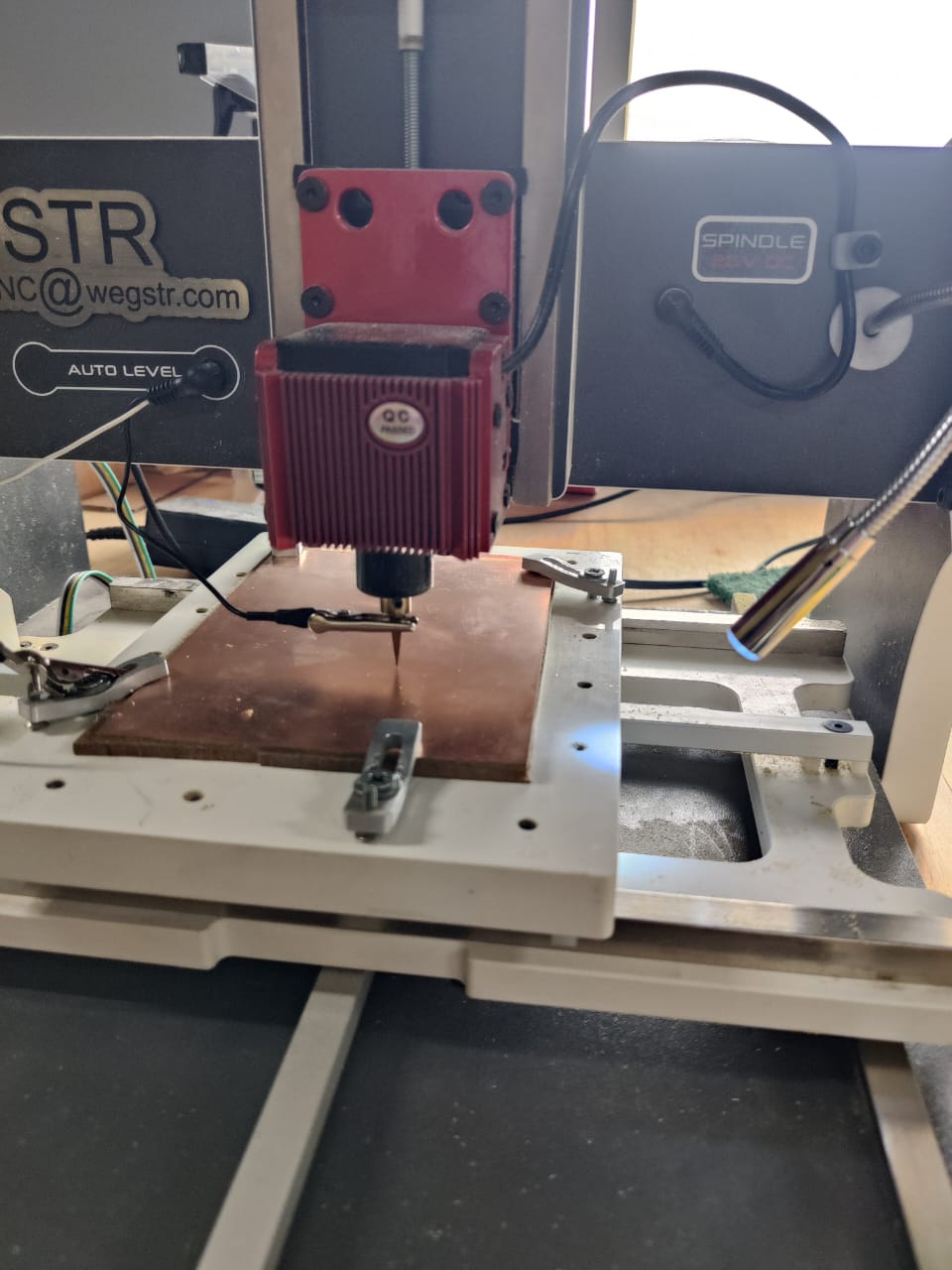

- CNC milling machine Wegstr Machining

- Double-sided PCB blank

- Soldering tools

- Multimeter etc

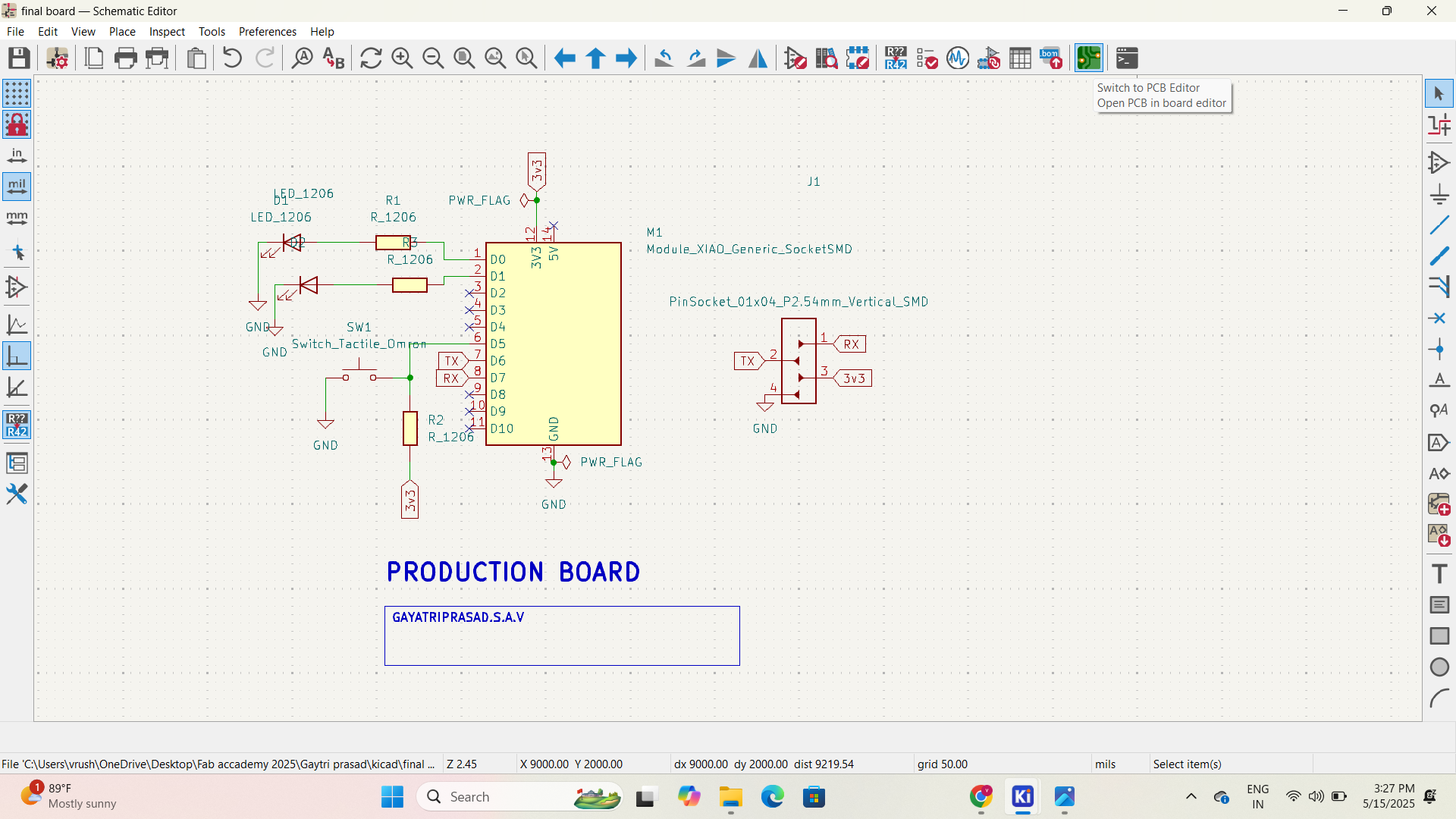

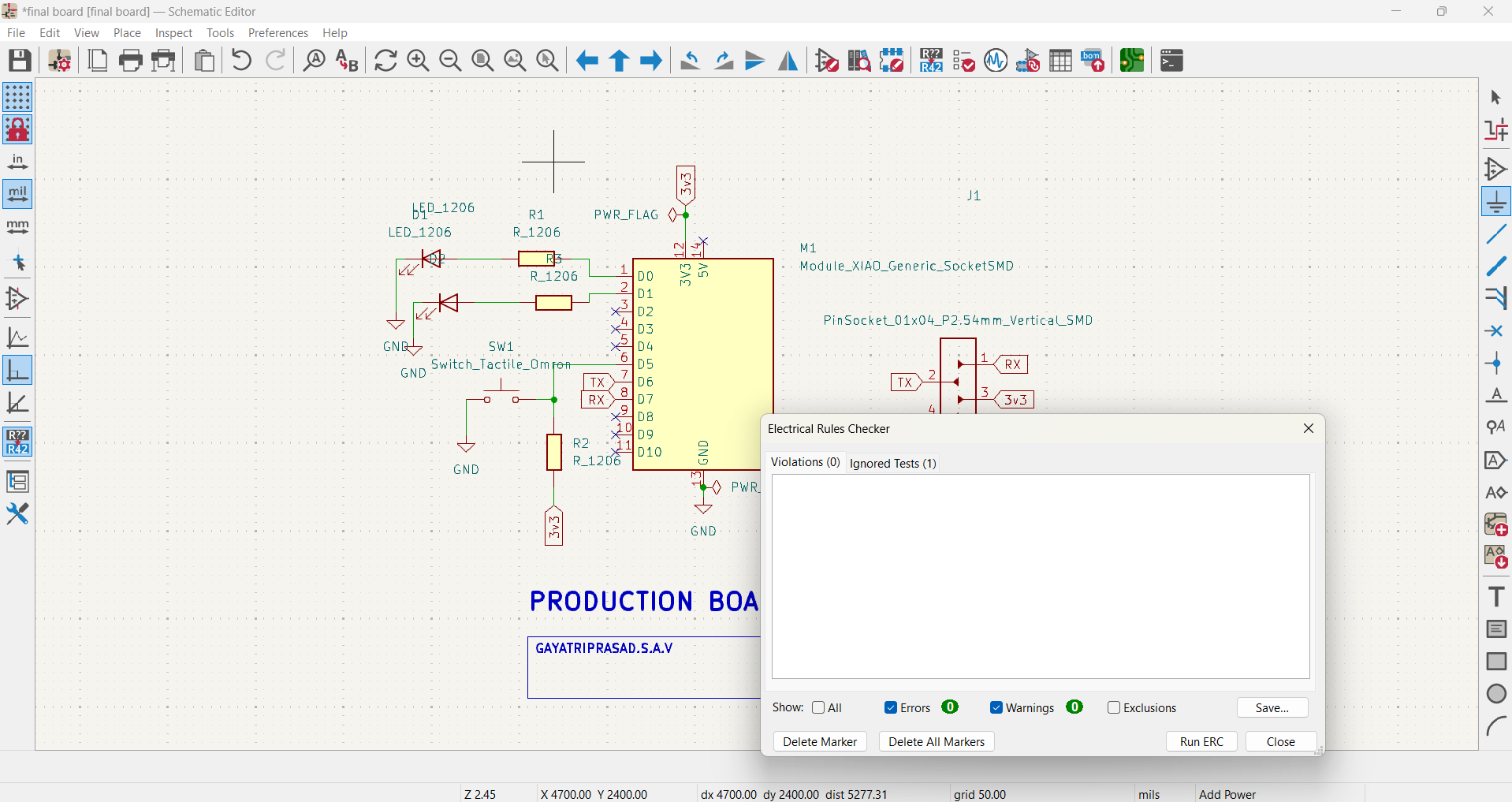

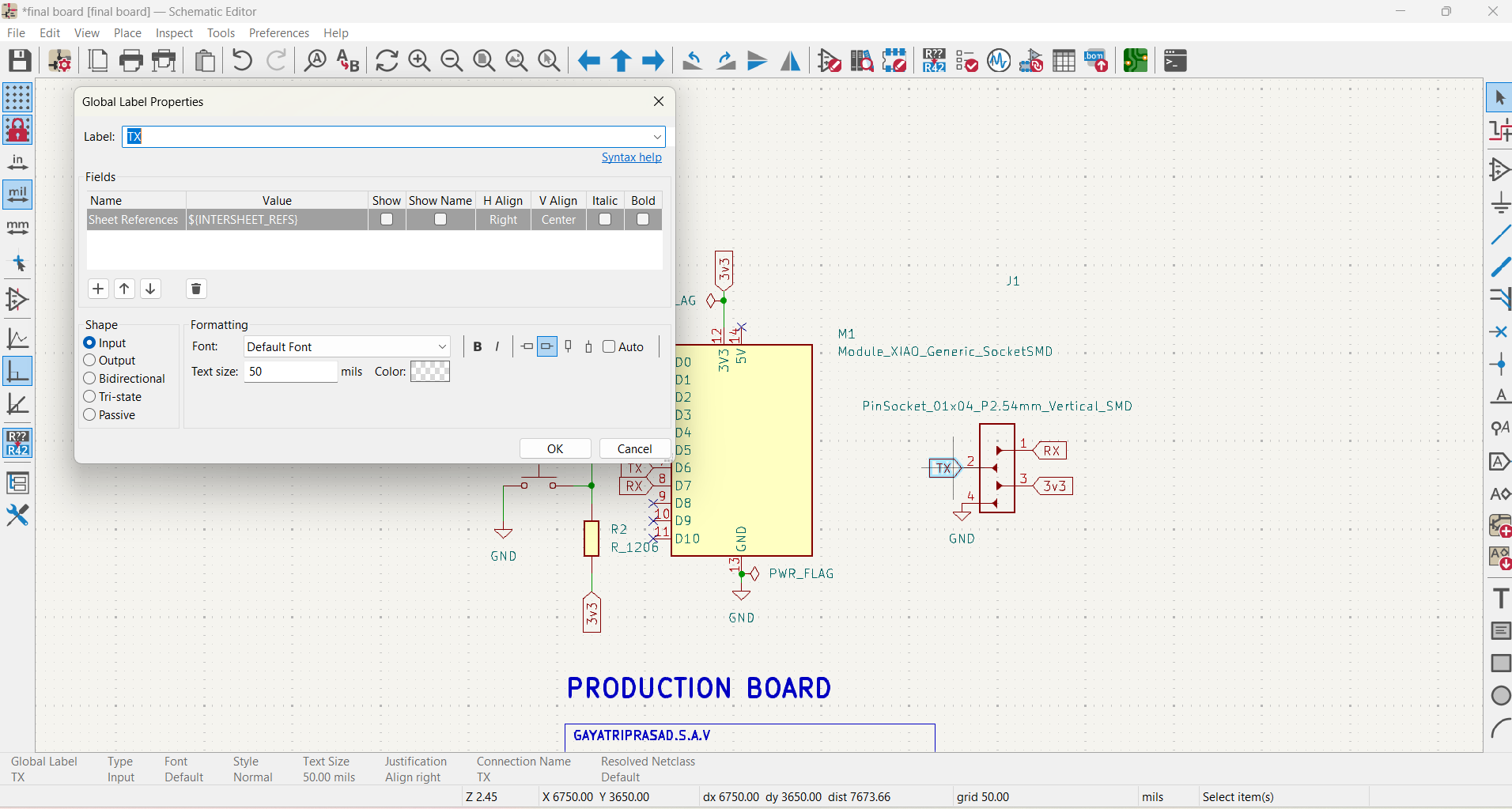

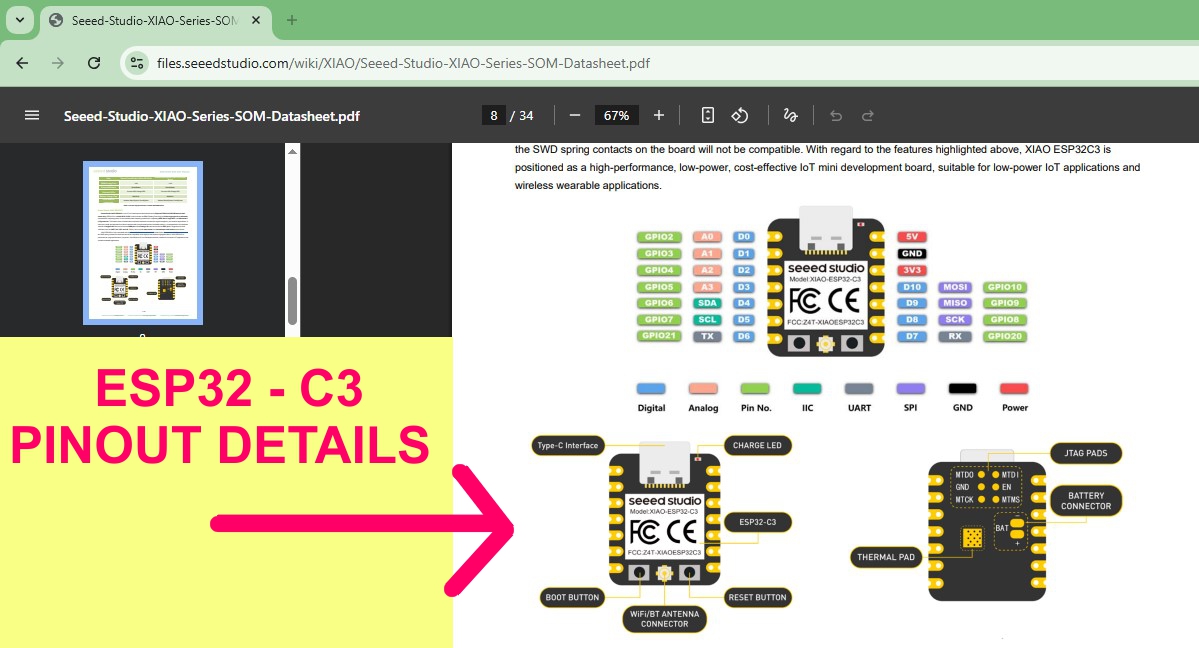

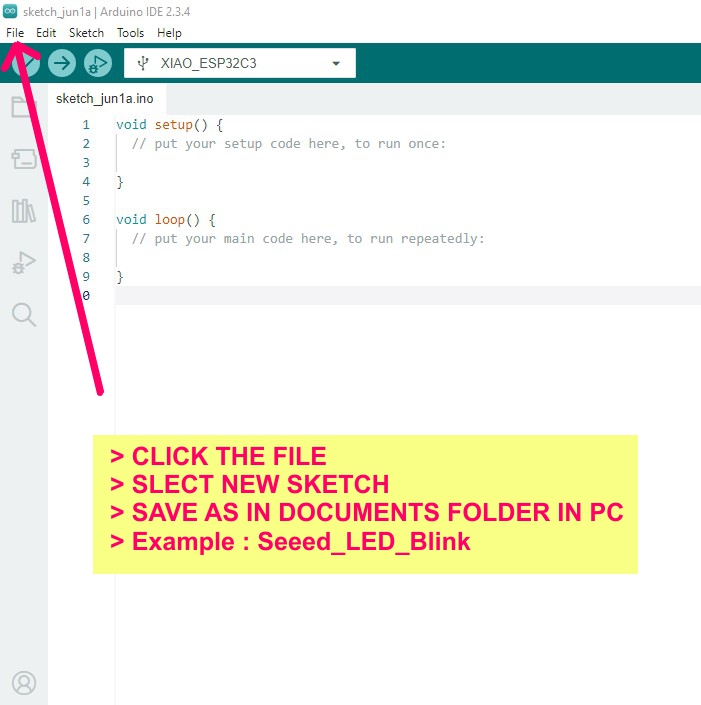

1. Create the KiCad Schematic

- Start a new project in KiCad

- Launch the Schematic Editor

- Add parts ( resistor, LED, button, 6-pin header)

- Annotate schematic

- Assign footprints

- Perform ERC (Electrical Rules Check)

- Complete schematic with labeled components

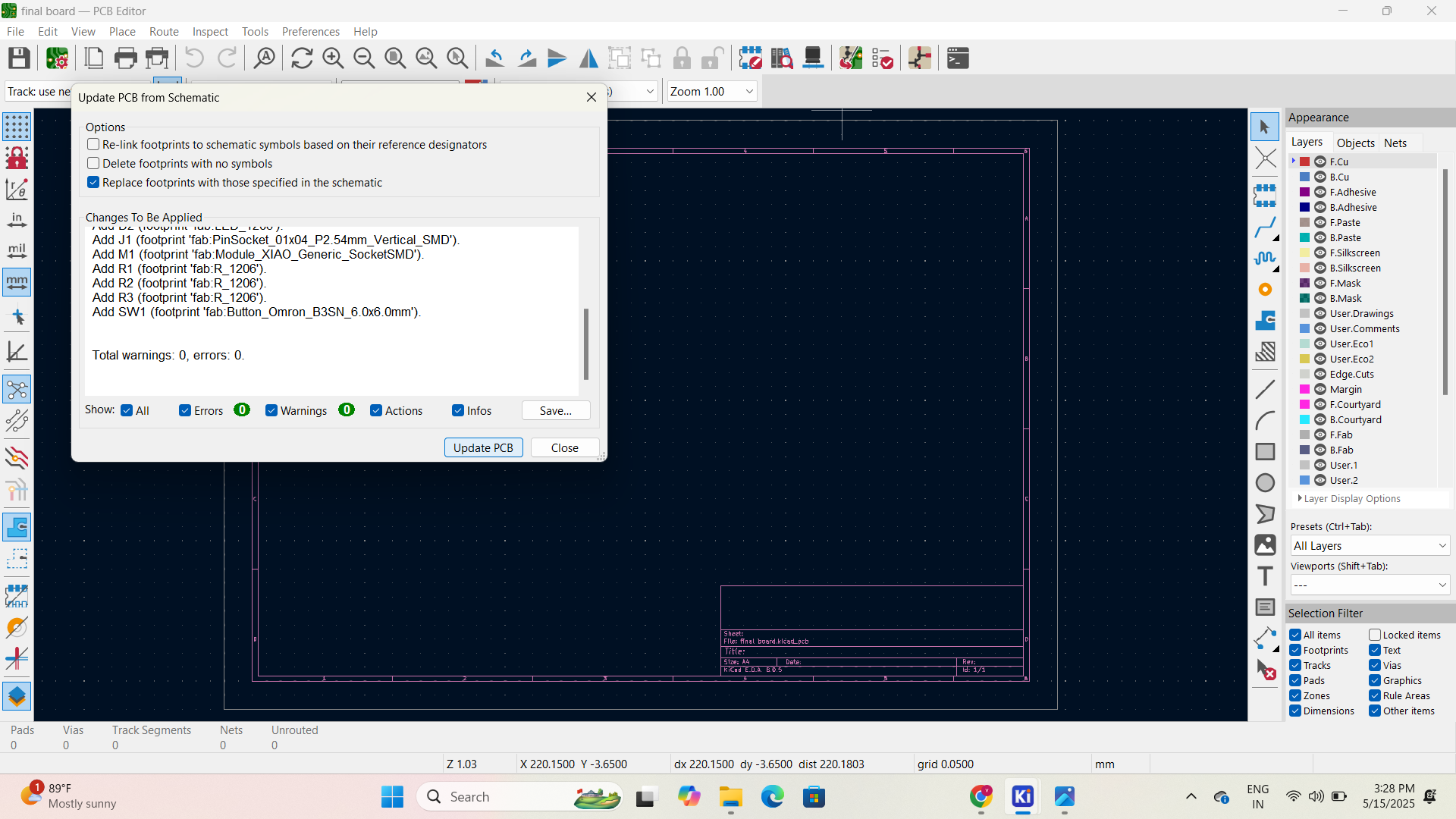

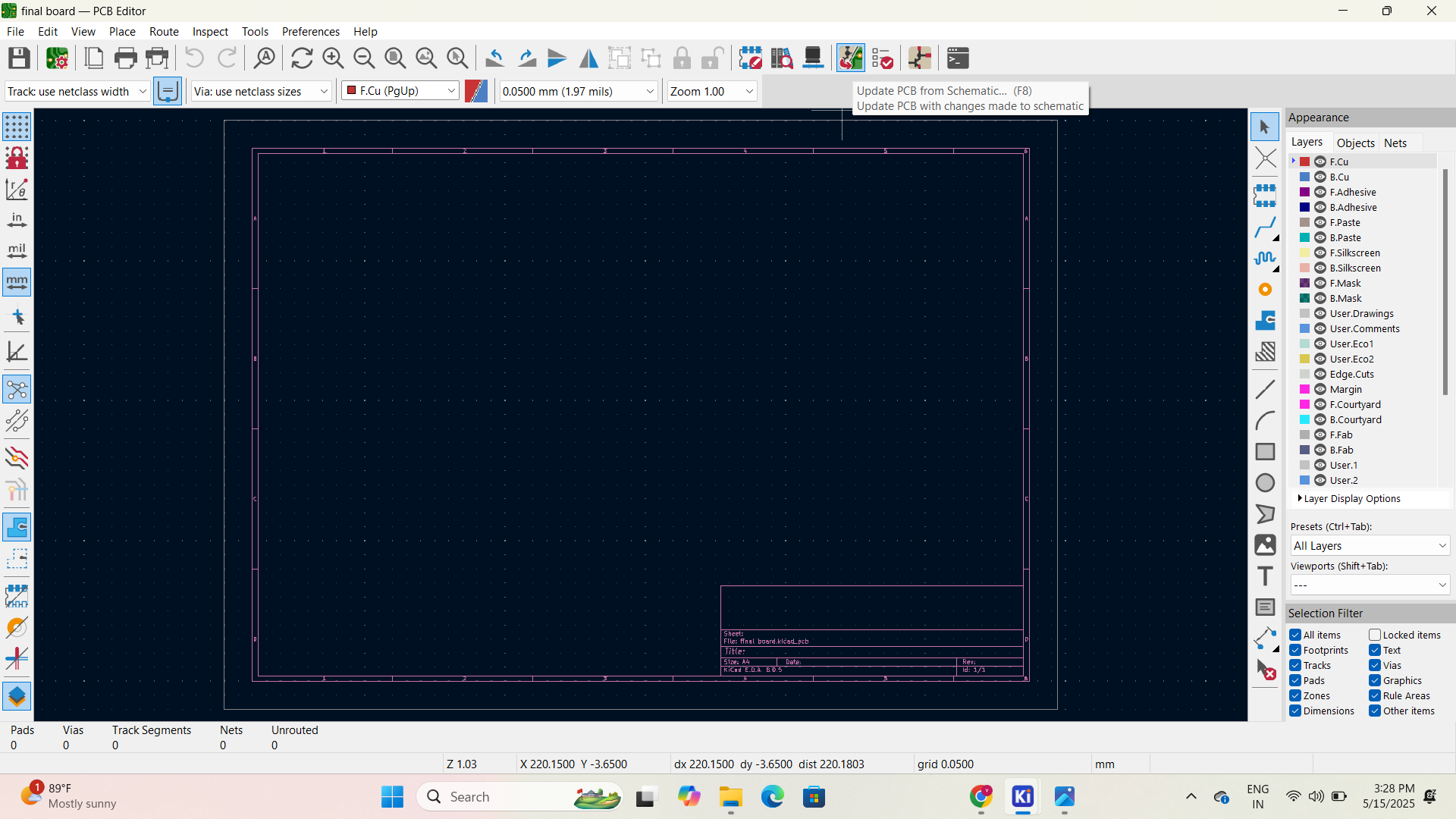

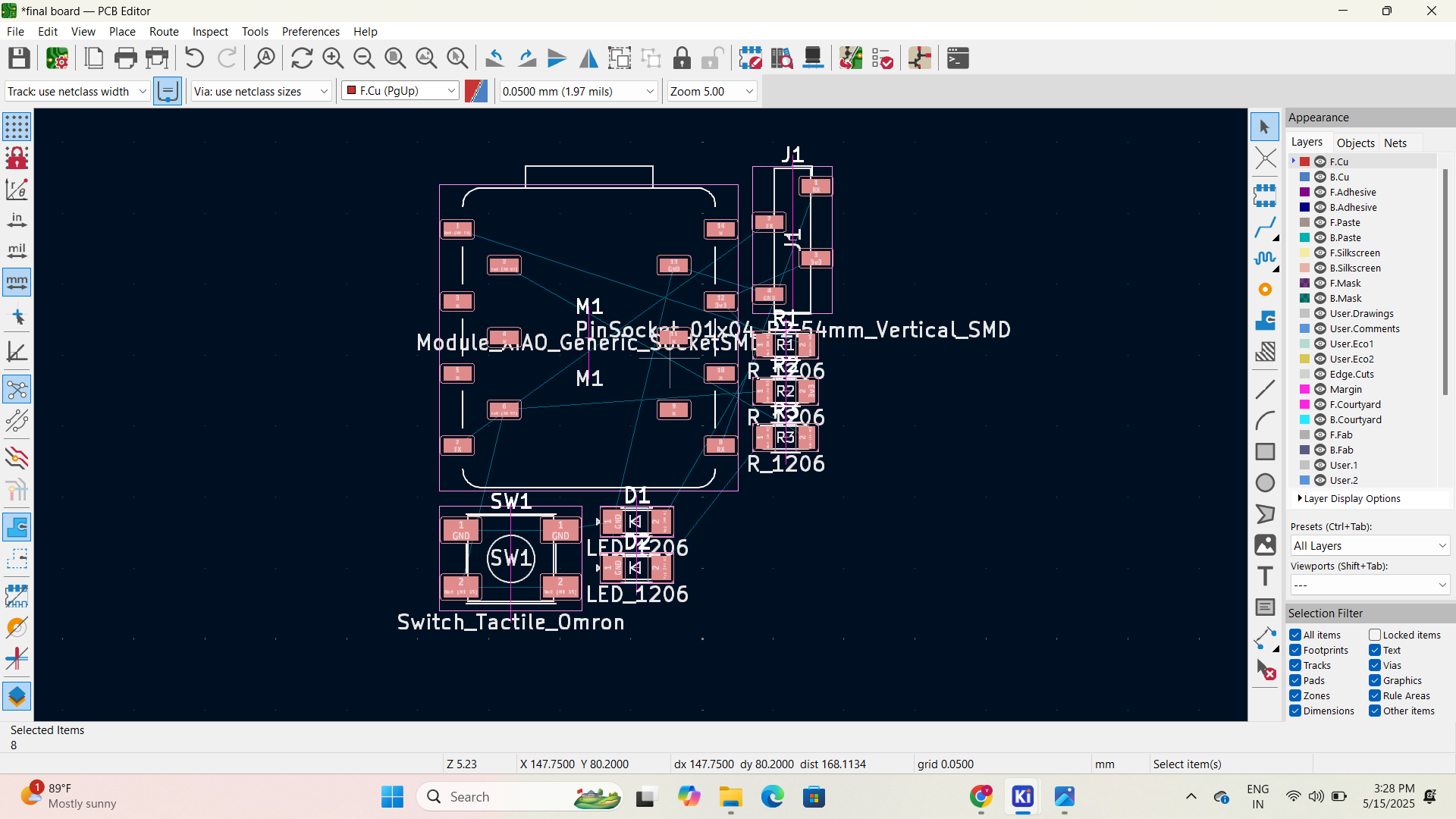

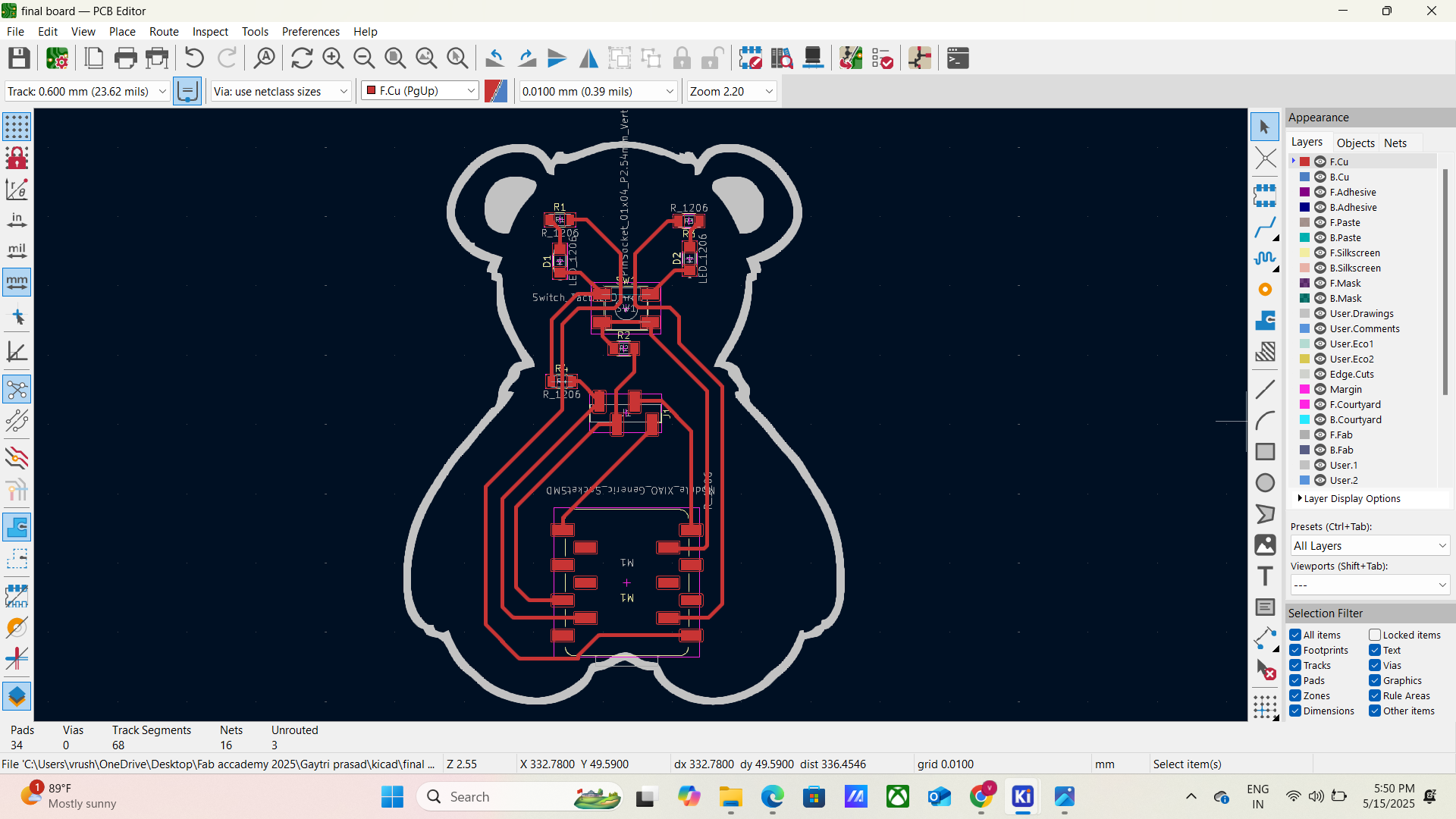

- Open PCB Editor

- Update PCB from schematic or import netlist

- Final layout with board outline

- DRC results

My Objective

2. KiCad PCB Layout Design

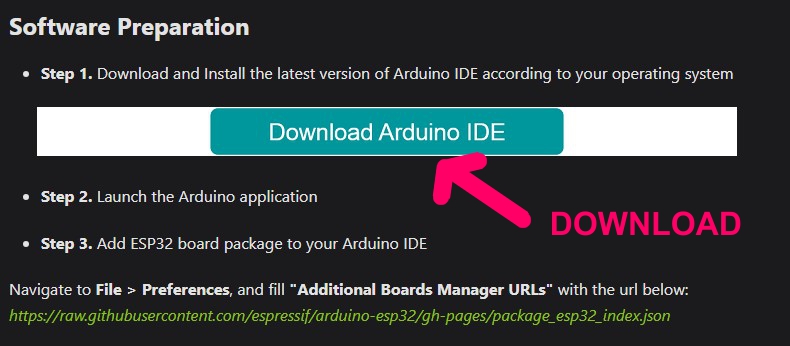

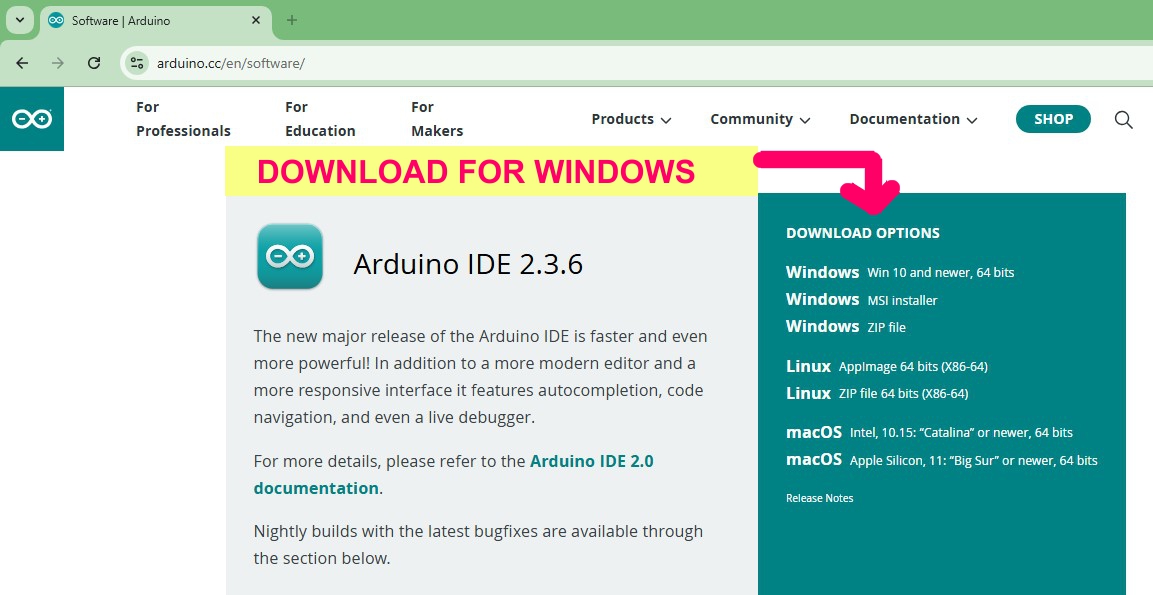

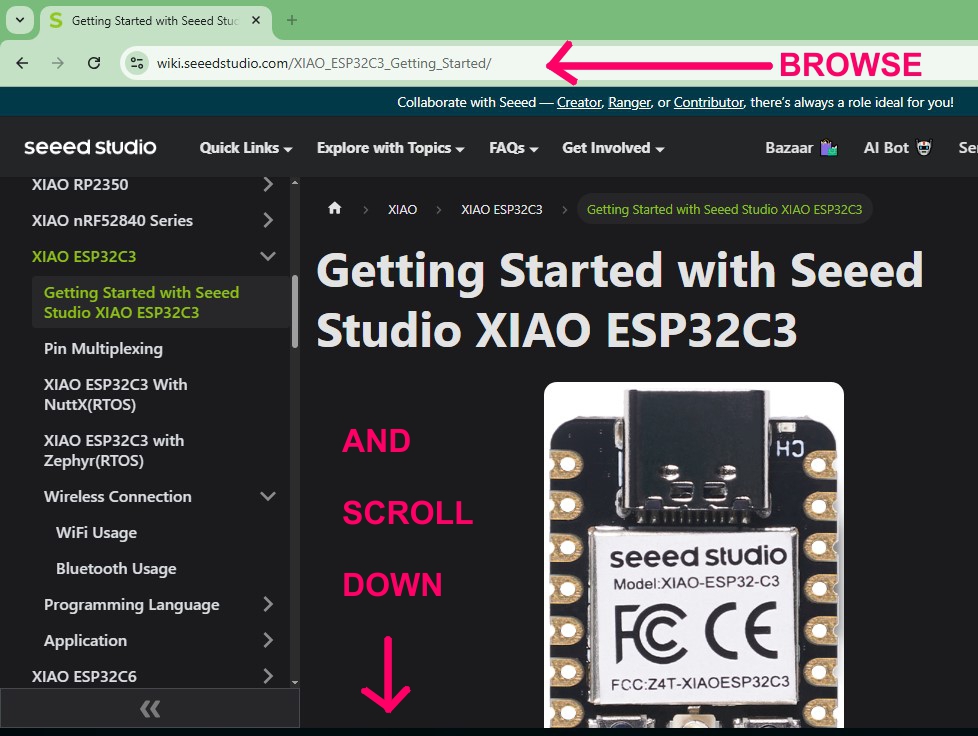

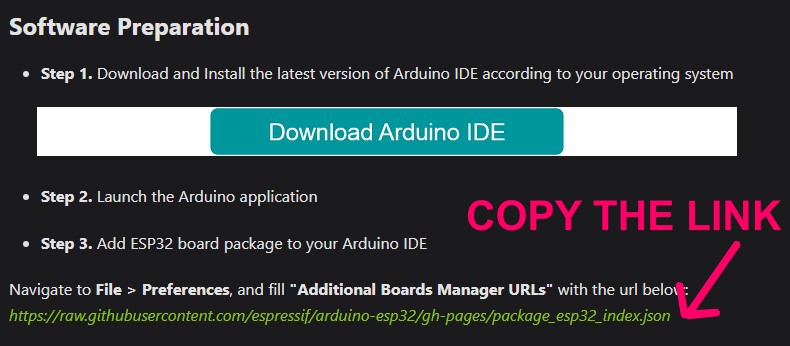

3. Export SVG or Gerber for Milling

- Plot only top copper layer (F.Cu)

- Export to SVG or PNG at 1000 DPI for mods

- Export edge cuts layer for board outline

- Top copper trace export

- Outline layer export

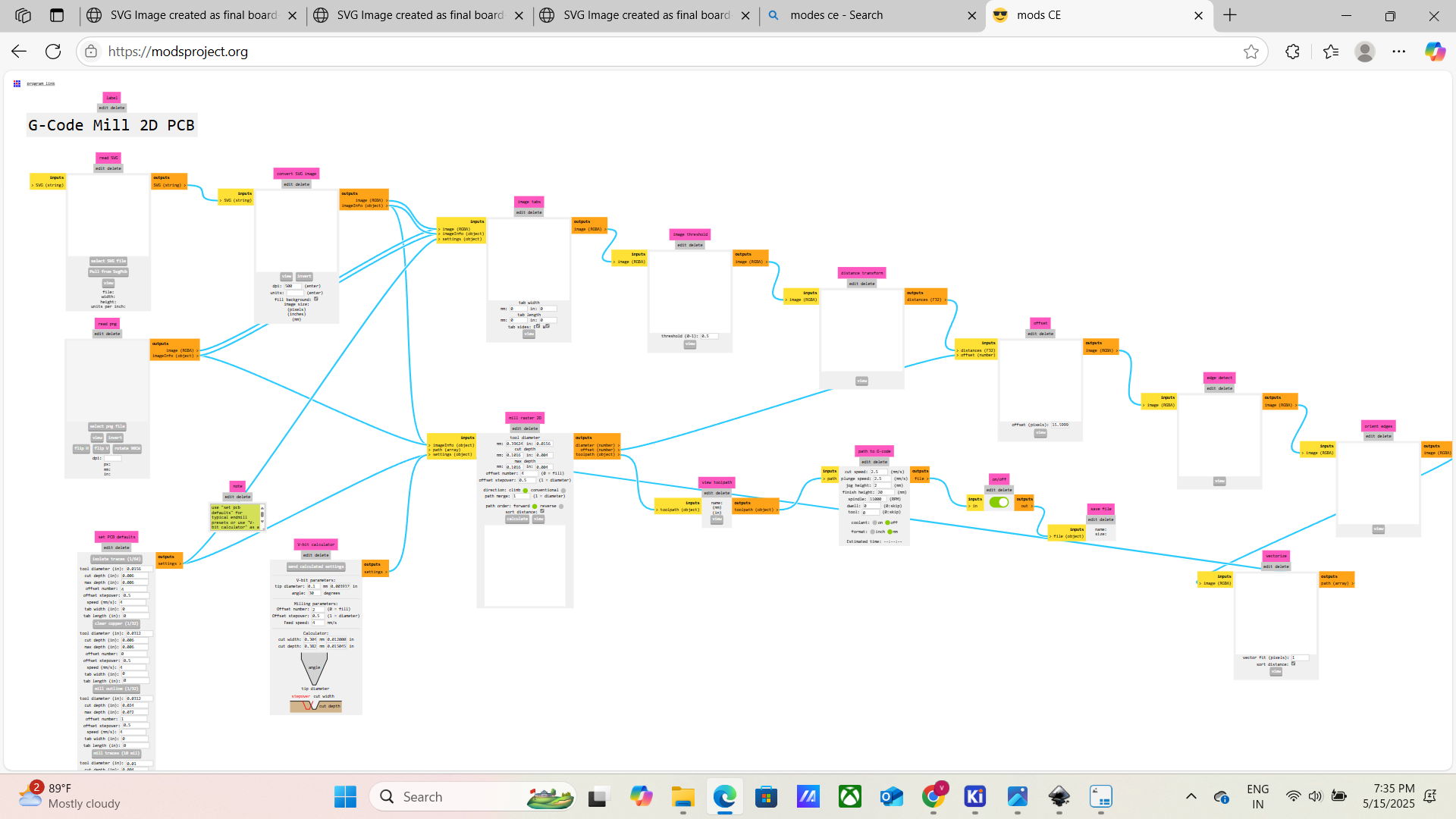

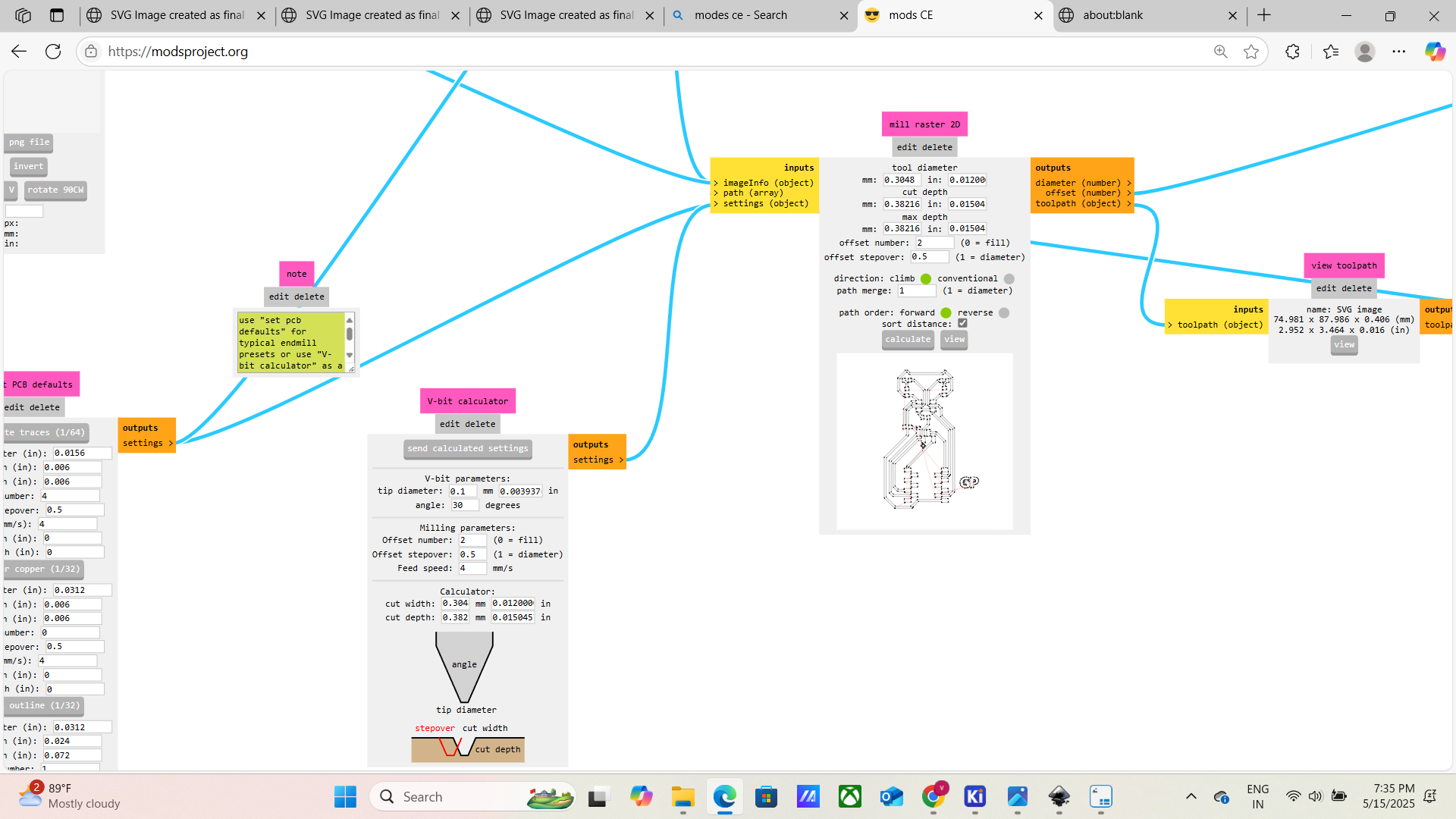

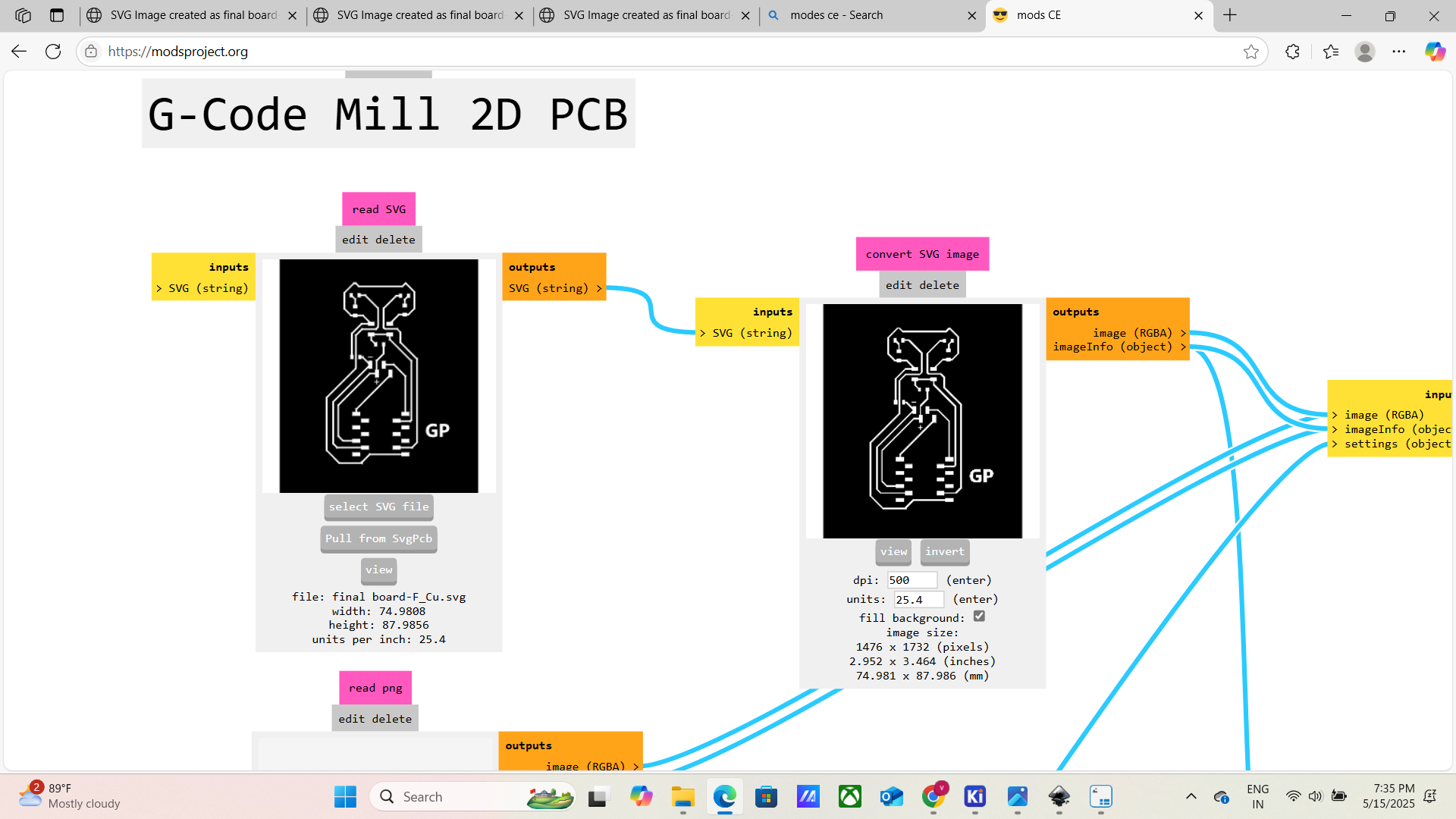

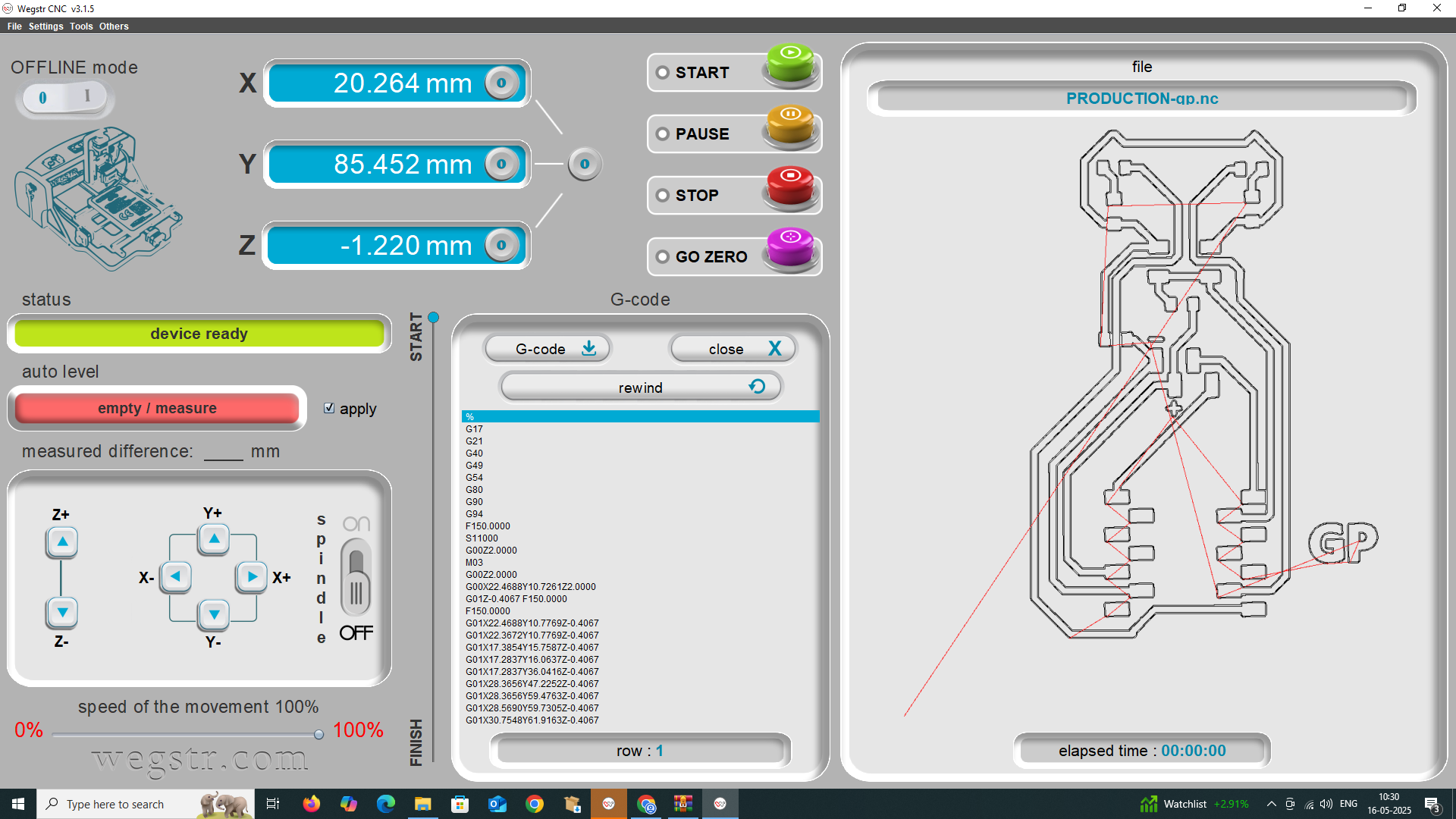

4. Use Mods CE/Fab Modules to Generate Toolpaths

- Load image (traces PNG)

- Select mill traces (1/64")

- Set cut depth: 0.1 mm, max depth: 0.1 mm, tool diameter: 0.4 mm

- Set origin (X=0, Y=0)

- Save the .rml or .nc file

- Repeat for cutout layer with mill outline (1/32")

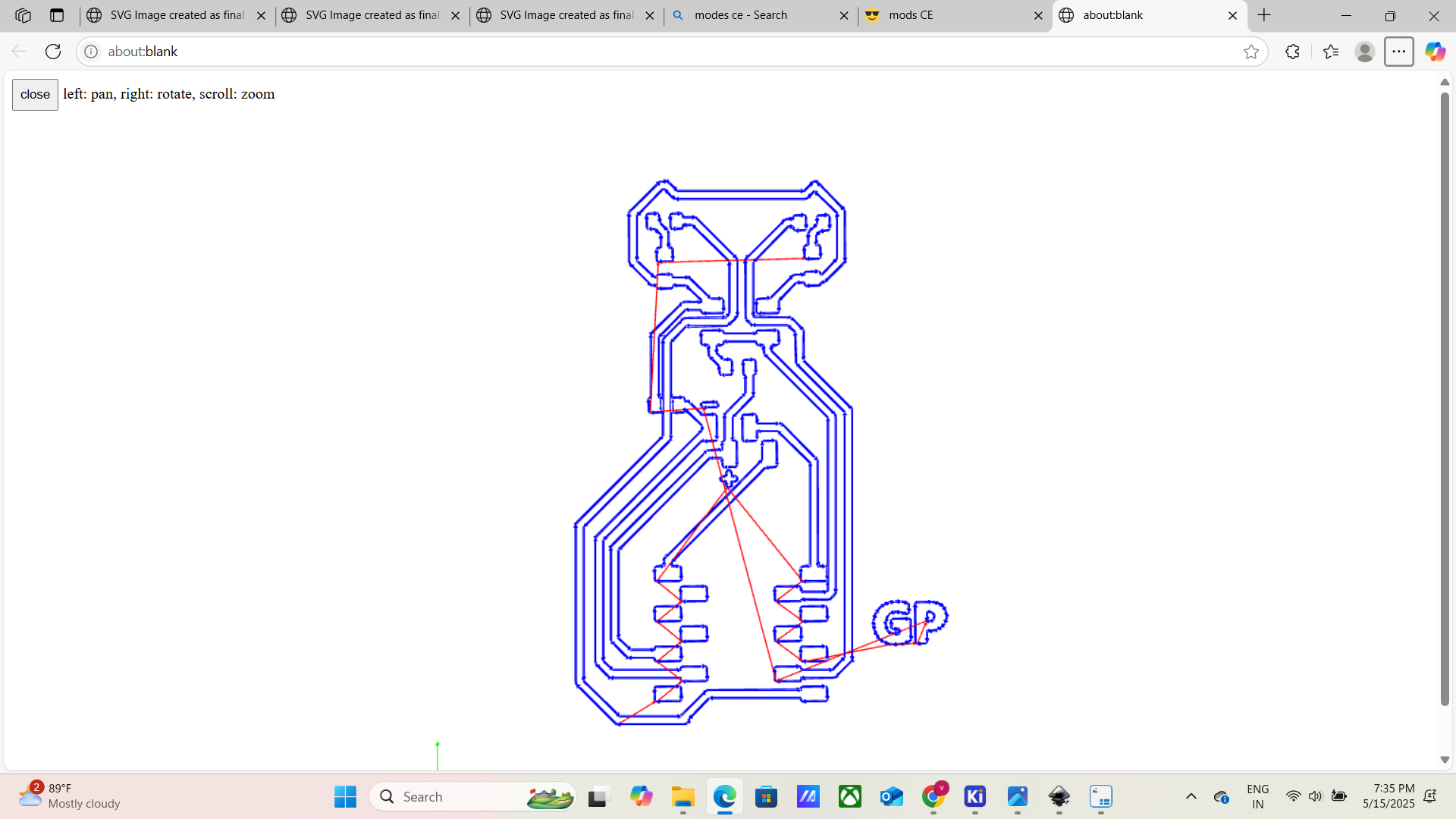

- Mods CE interface with loaded image

- Toolpath preview for traces

- Toolpath preview for cutout

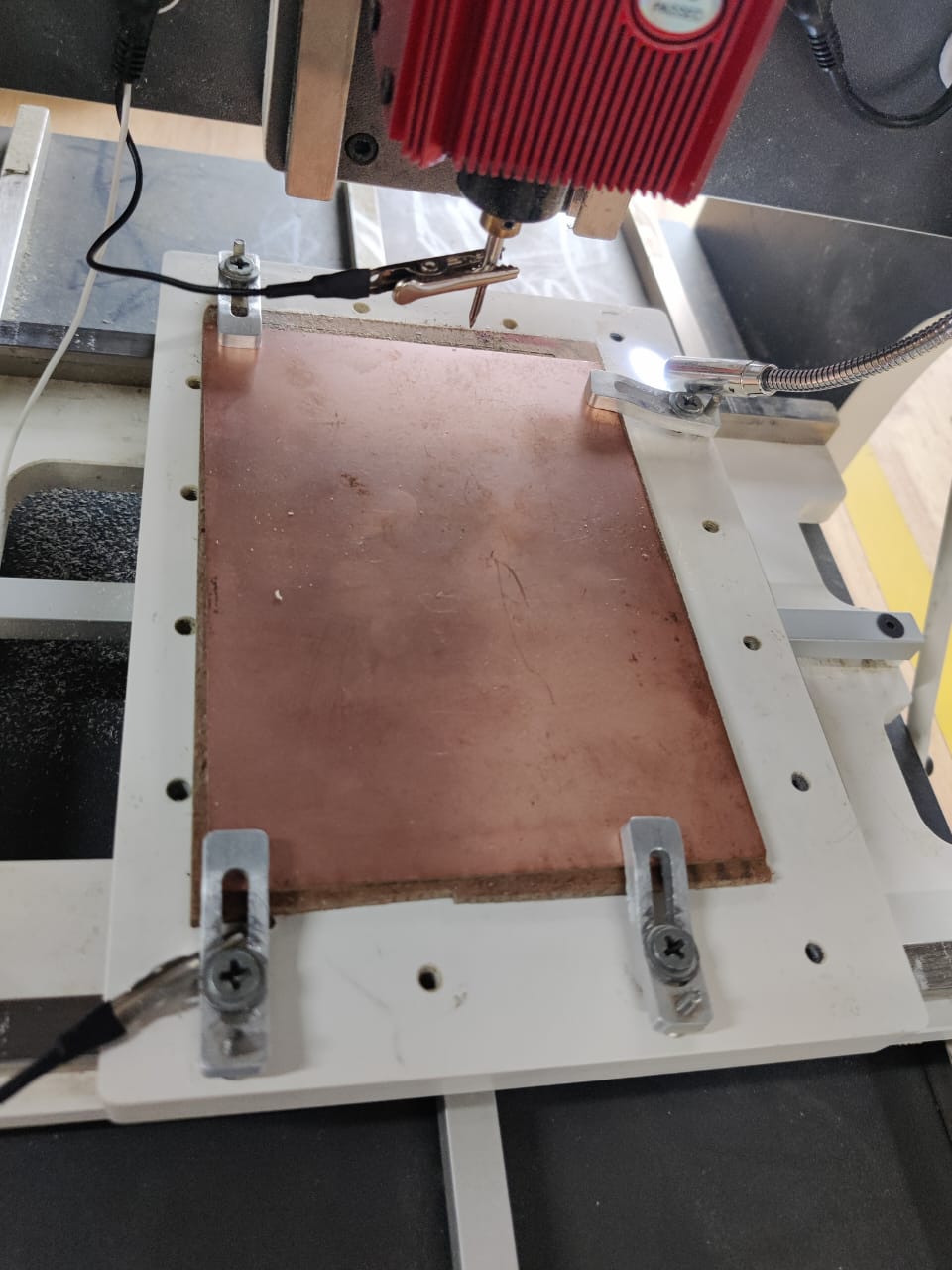

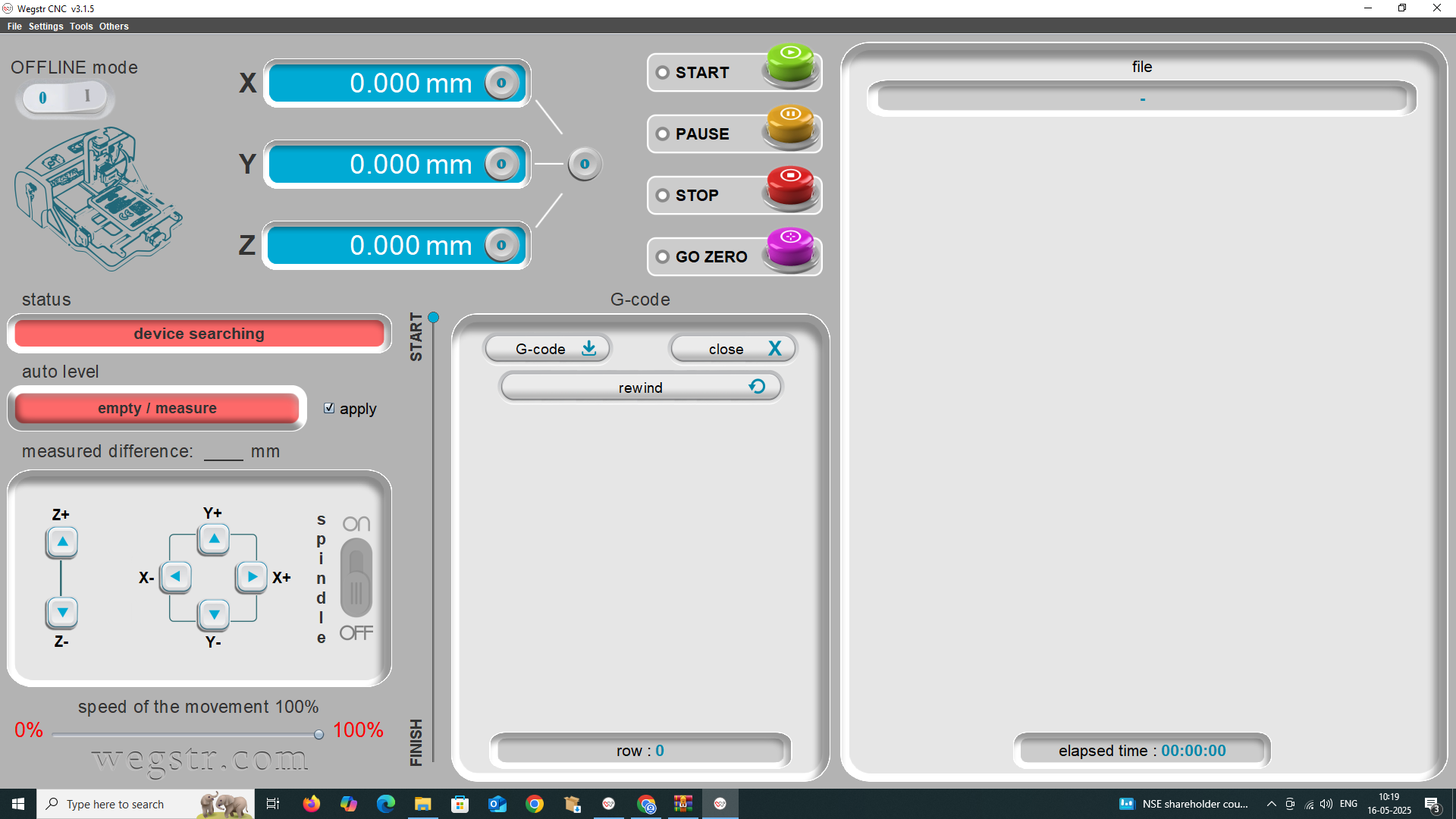

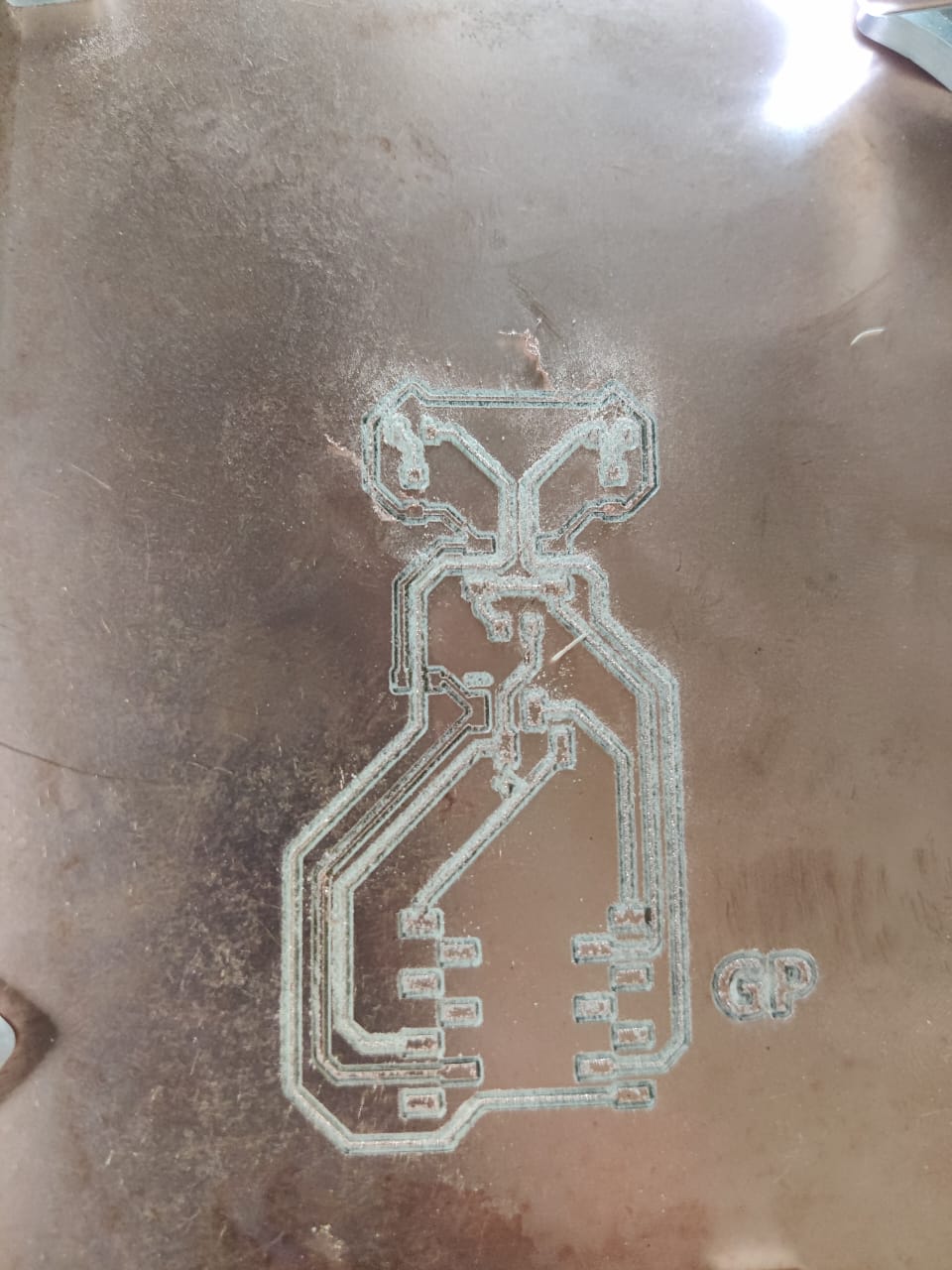

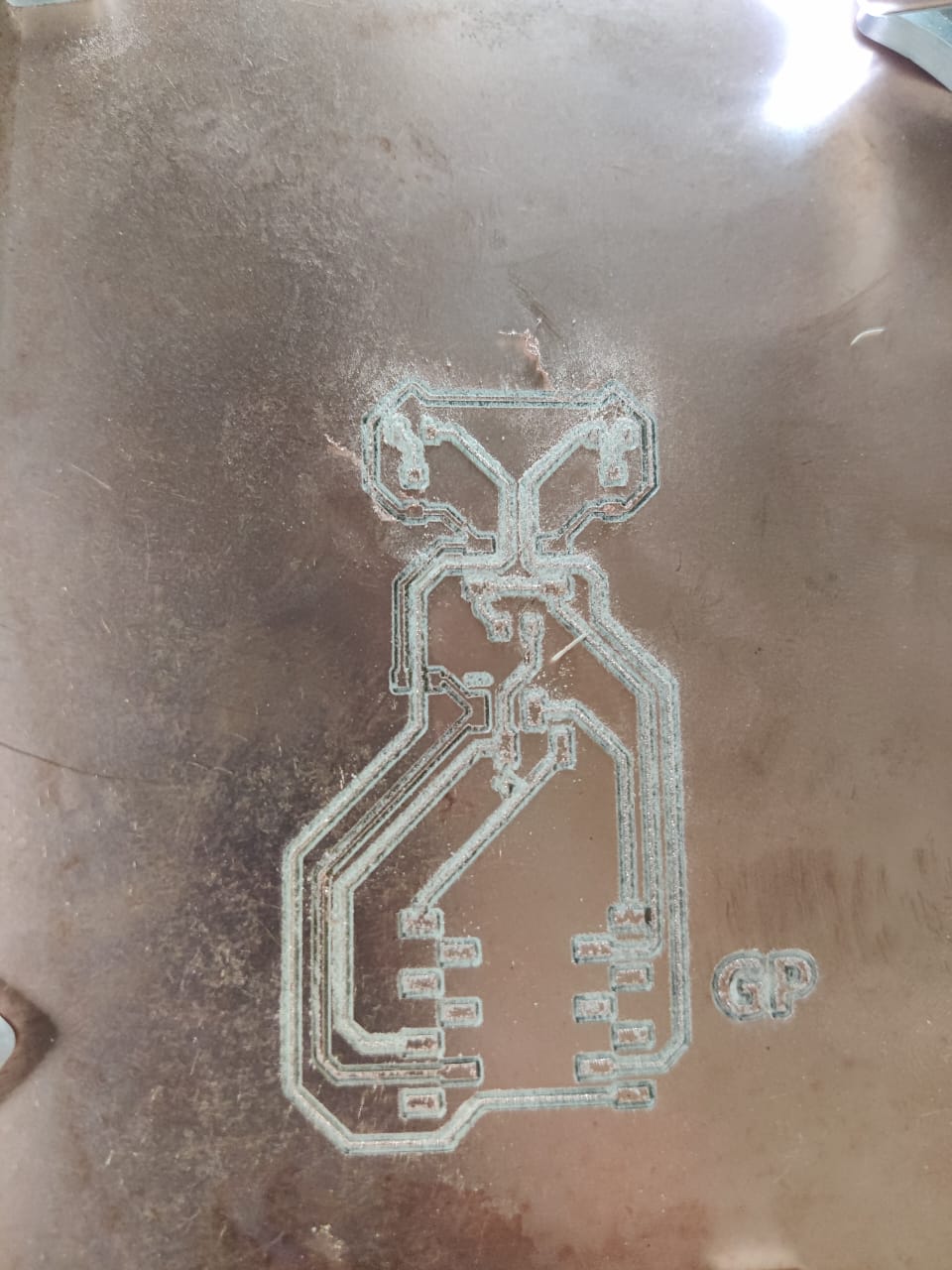

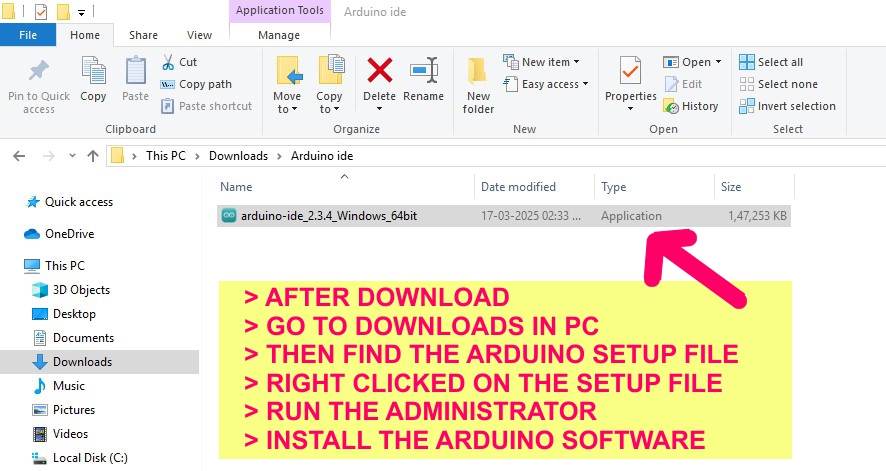

5. Mill the Board

- Secure blank PCB on the CNC bed using tape

- PCB fixed on CNC bed

- Set X, Y, Z origins

- Run the traces toolpath

- Change bit and run cutout toolpath

- level the pcb board

>

>

- Milling in progress

- Final milled PCB board

- Now the circuit is ready

- Now the circuit got edgecut and the board is ready to assemble

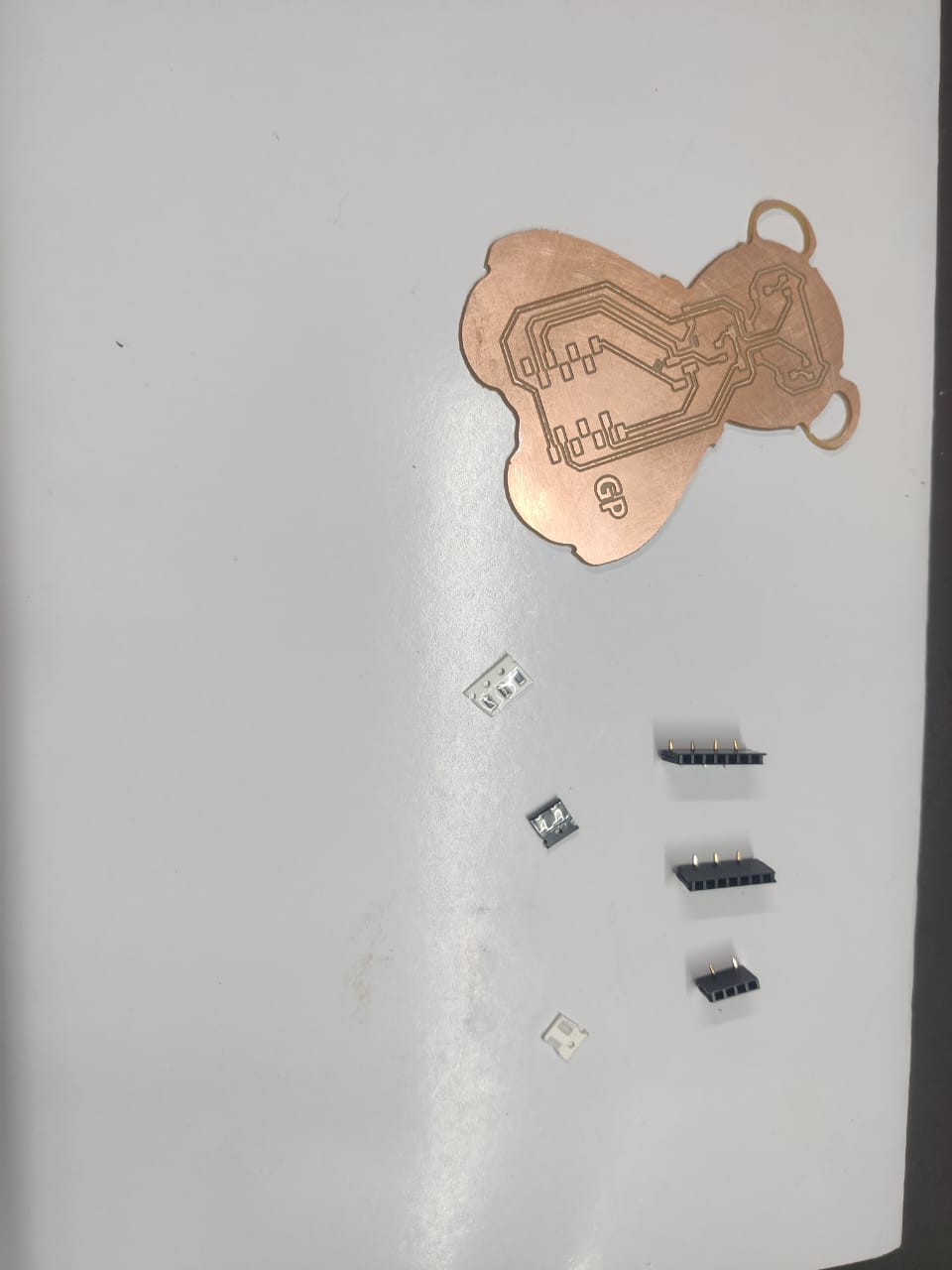

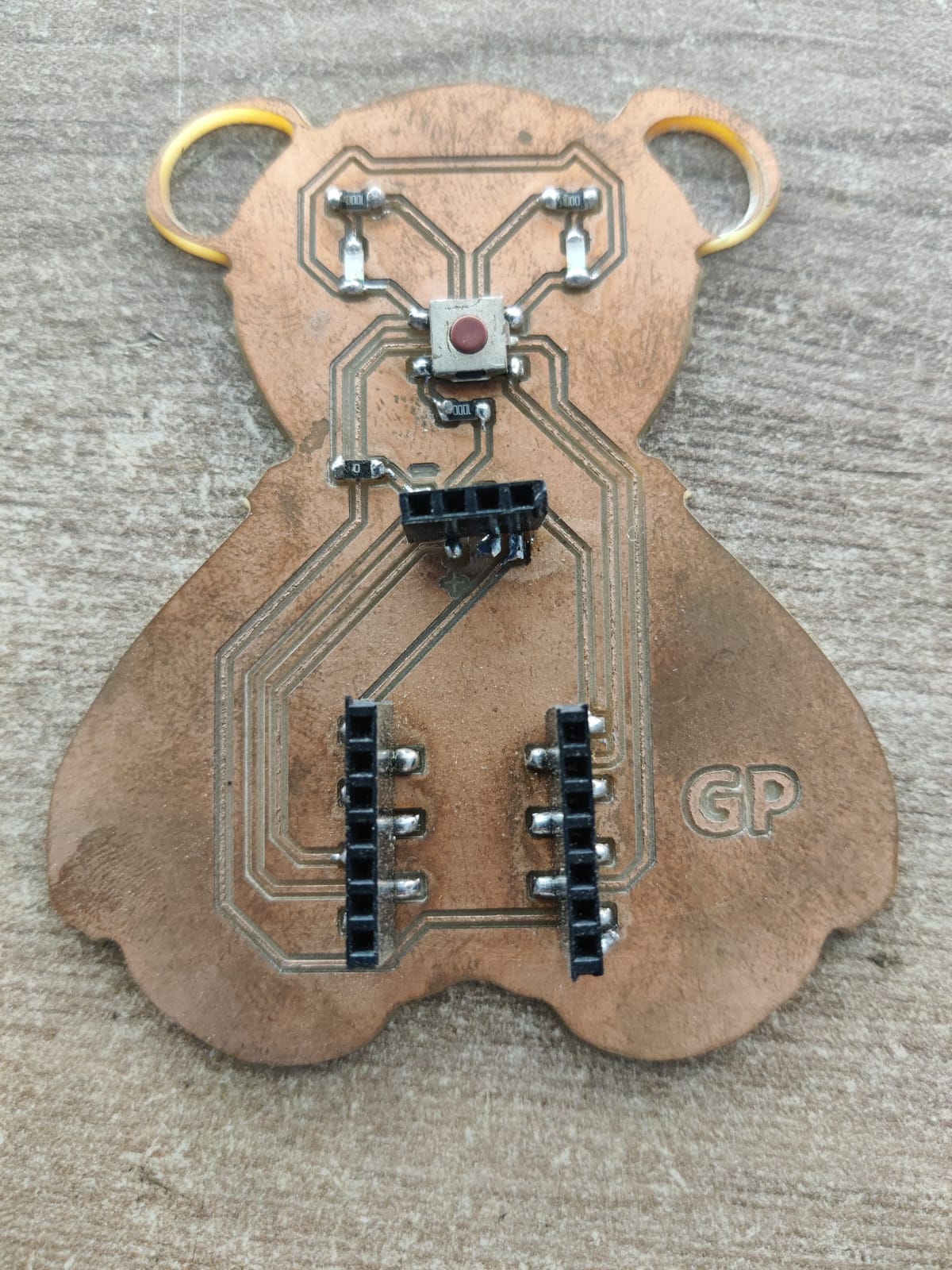

🔌 6. Solder the Components

- Use flux and tweezers for SMD soldering

- Test each connection with multimeter

- Optionally test ISP or UART communication

- Soldering in progress

- Fully assembled board

- Multimeter testing

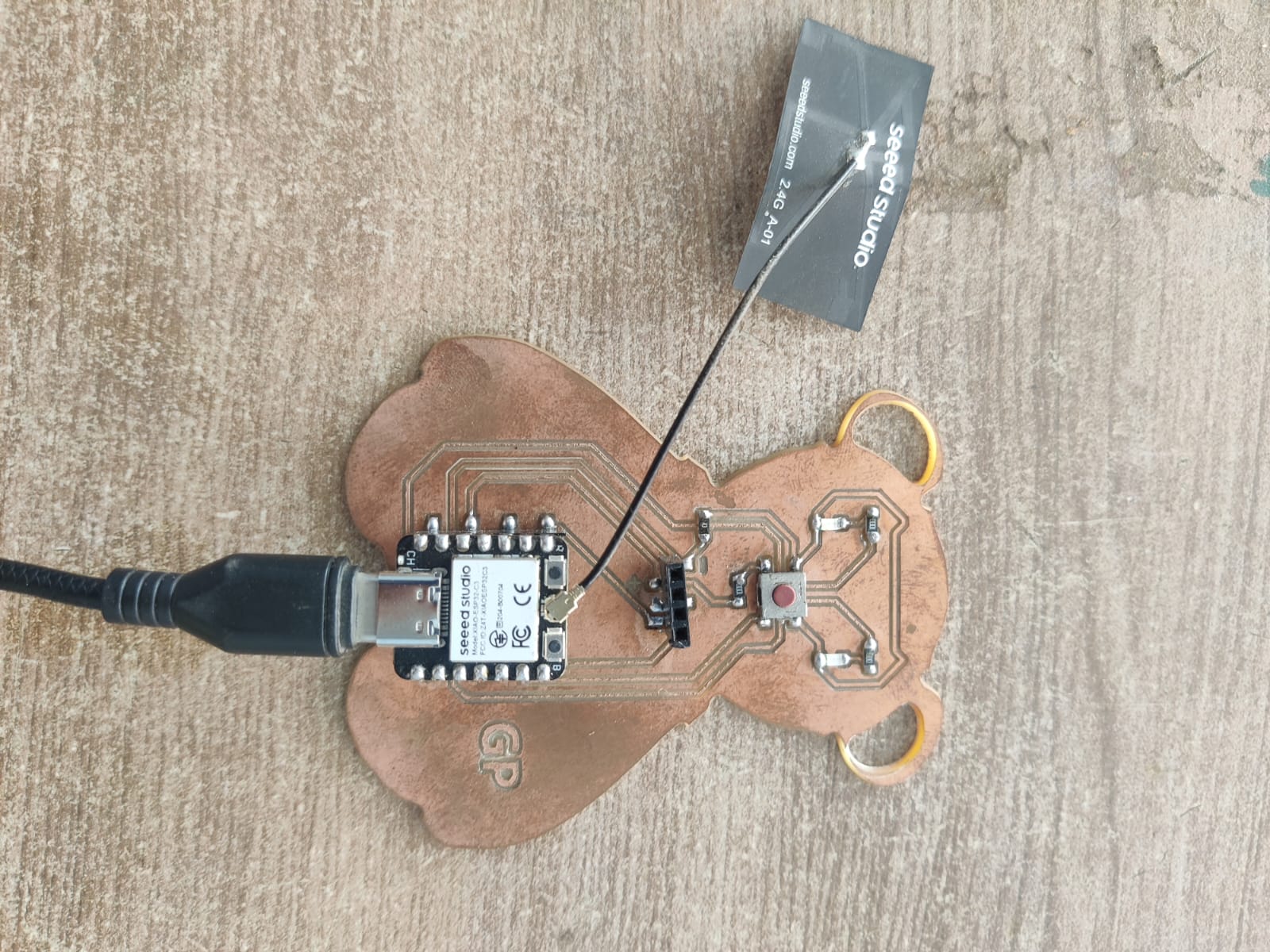

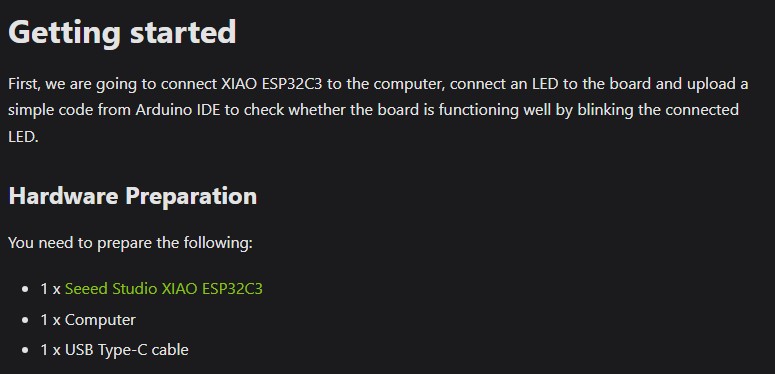

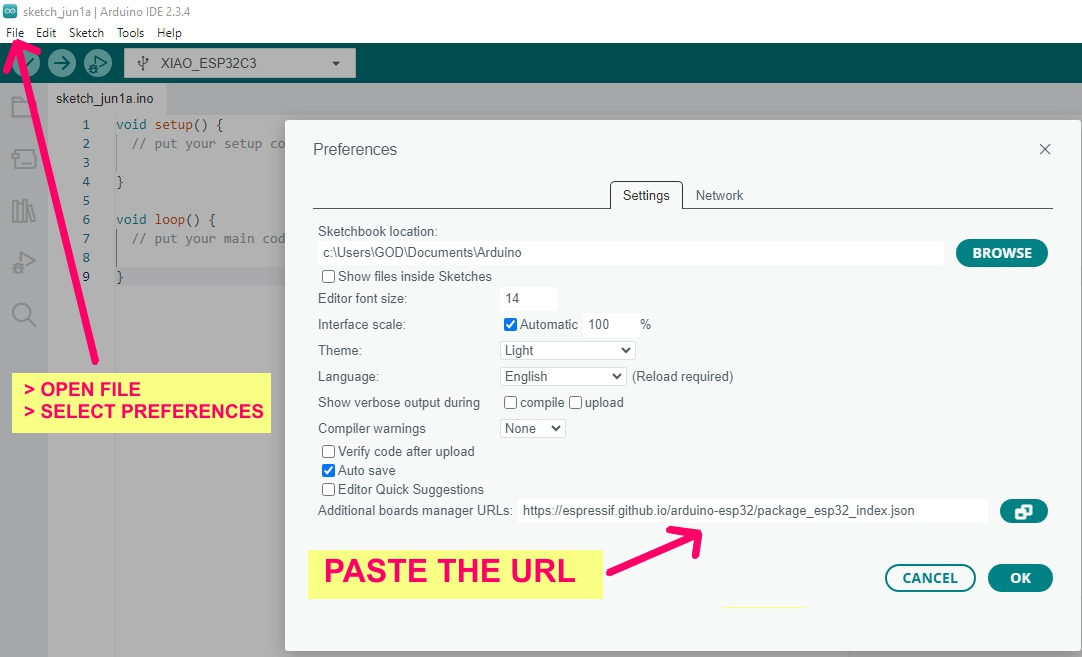

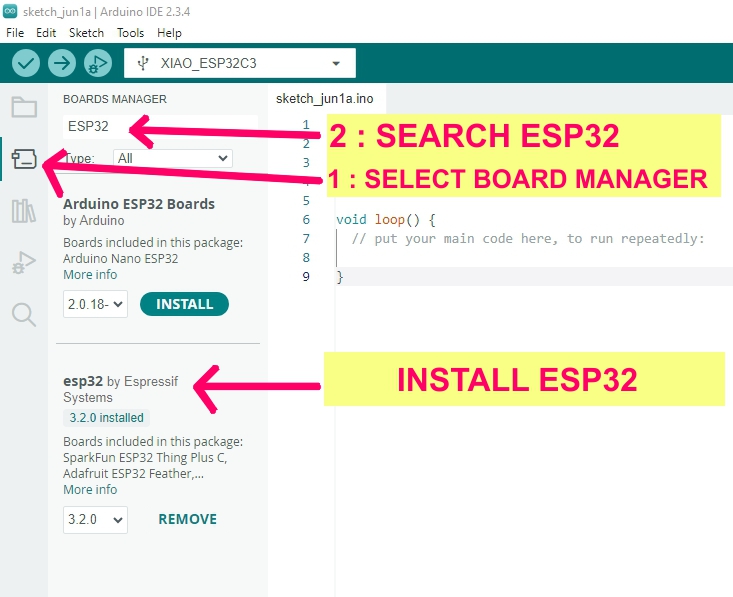

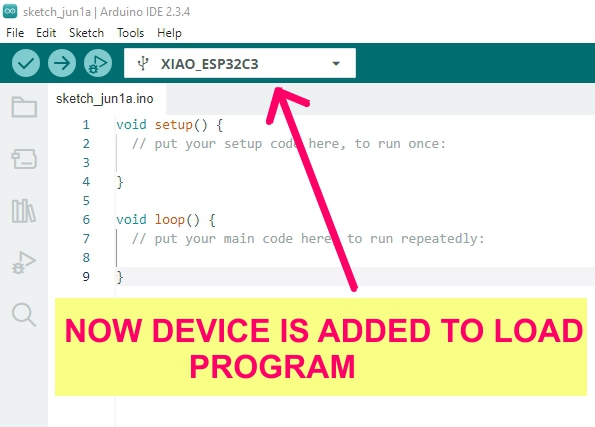

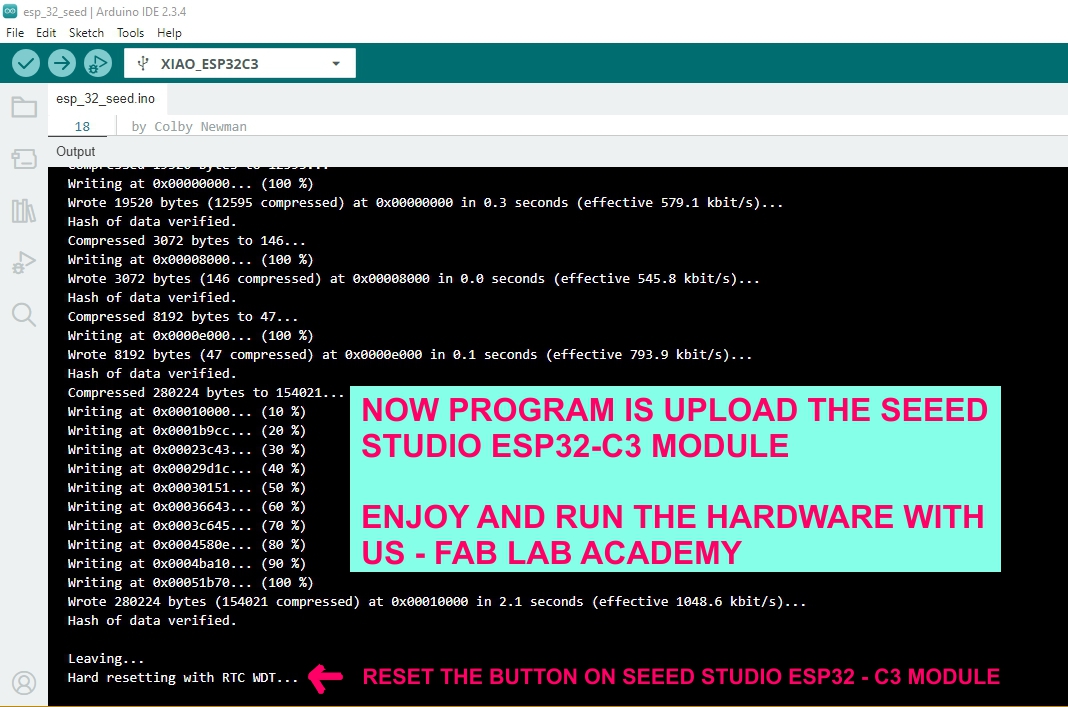

7. Configure and Examine the Board

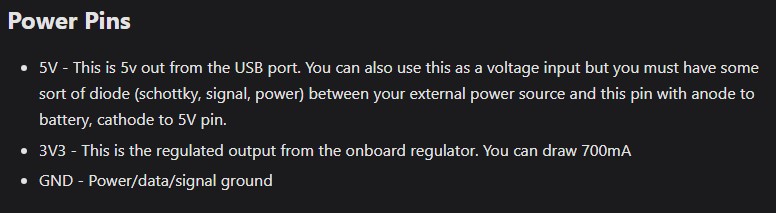

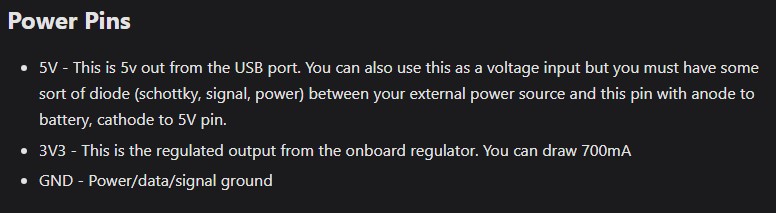

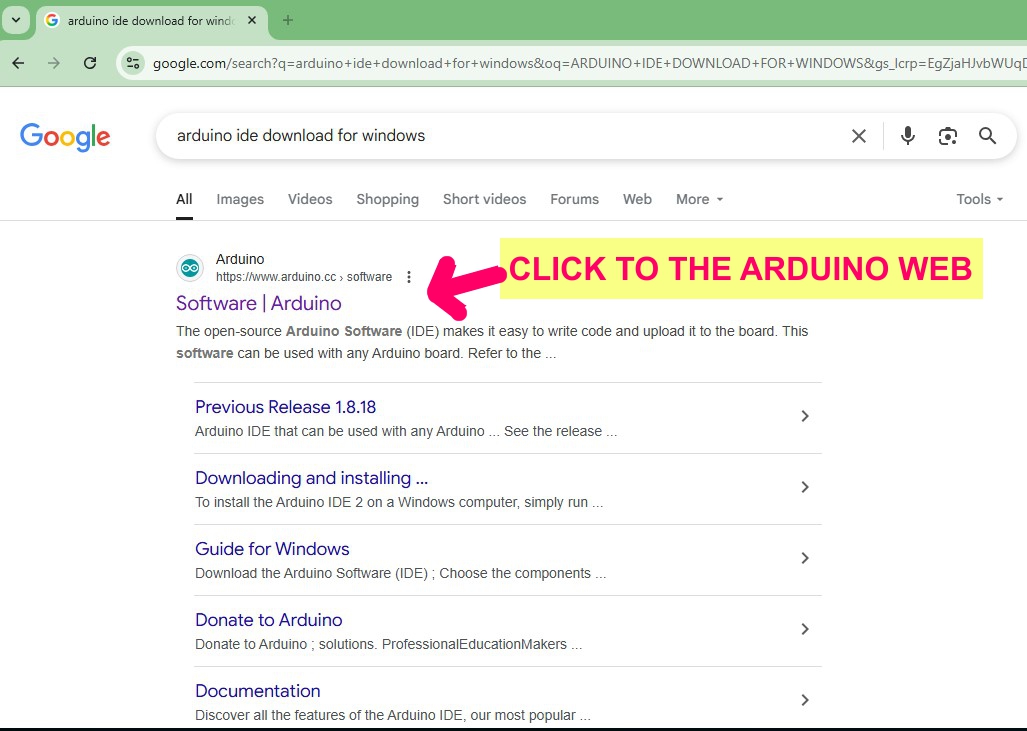

- Connect with USB-to-UART or ISP programmer

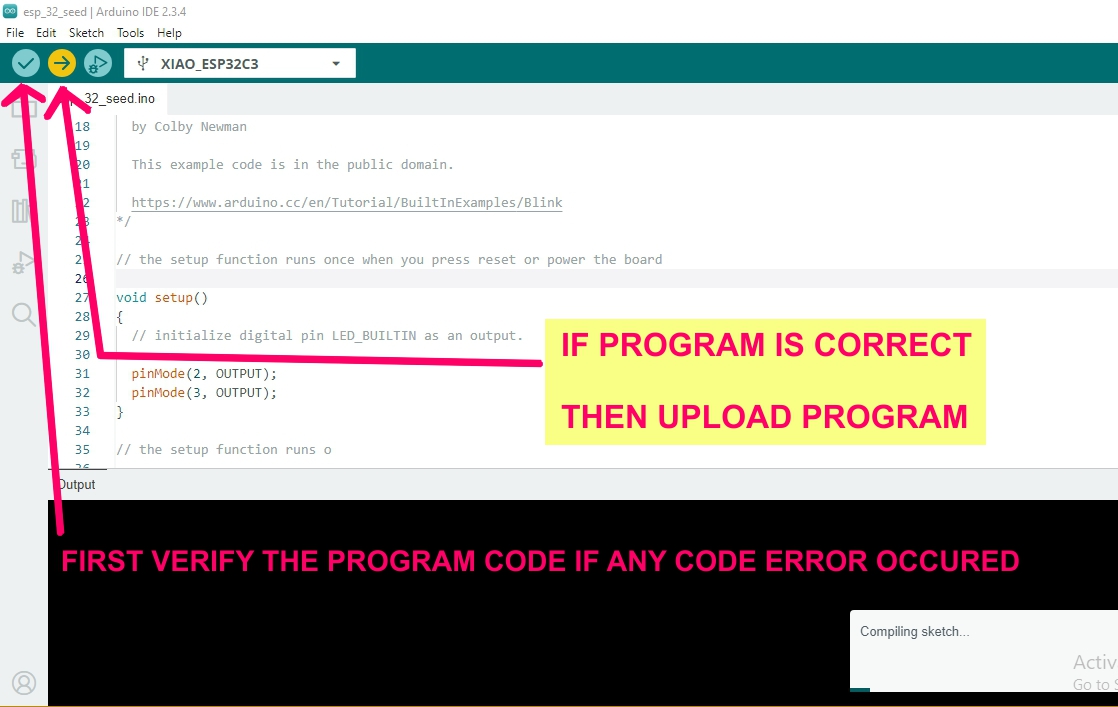

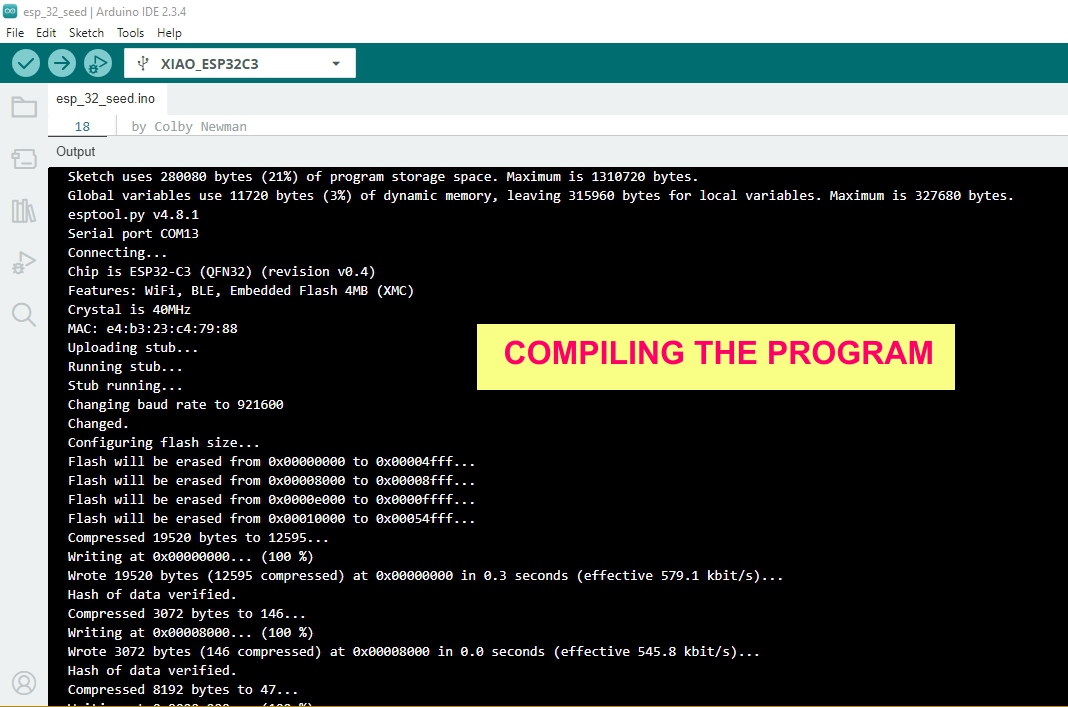

- Burn bootloader or test blinking code

- Use terminal to check serial response (if available)

- Board connected to computer

- Terminal output (if serial used)

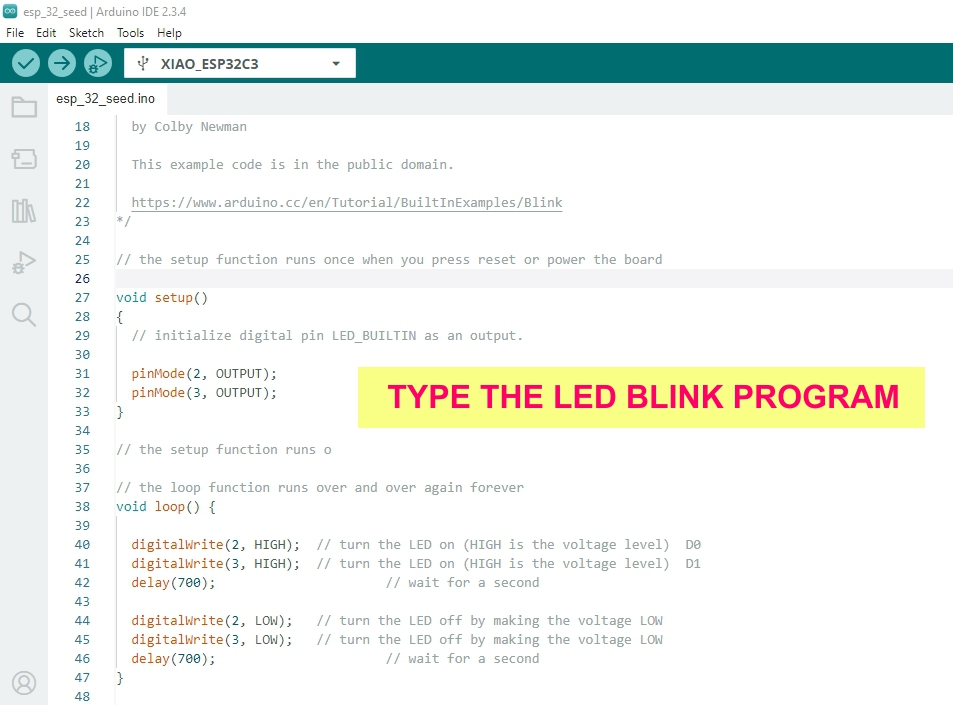

- LED blinking Programming

- // the setup function runs once when you press reset or power the board

- void setup() {

pinMode(2, OUTPUT);

pinMode(3, OUTPUT);

} - // the loop function runs over and over again forever

- void loop() {

digitalWrite(2, HIGH); // turn the LED on

digitalWrite(3, HIGH);

delay(700);

digitalWrite(2, LOW); // turn the LED off

digitalWrite(3, LOW);

delay(700);

}

ul class="code-steps"

Summary Checklist for Documentation

| Stage | Screenshot |

|---|---|

| Schematic | Full circuit & ERC check |

| PCB Layout | Routing + DRC pass |

| Toolpath | Mods/FabModules preview |

| Milling | Process + Finished PCB |

| Assembly | Soldering + Finished board |

| Testing | Programming + Output |