Safety

Summary

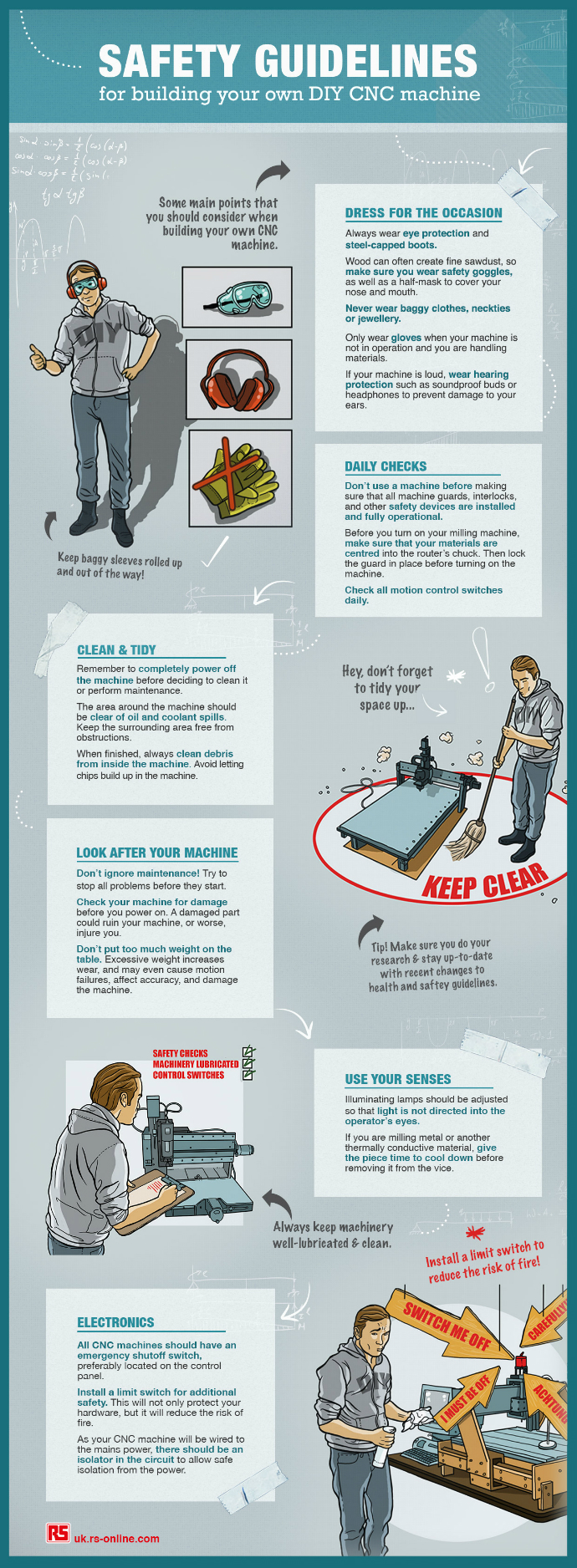

During CNC week, we started by learning about the runout procedure and understanding the potential dangers of operating a CNC machine. This helped us appreciate the importance of staying alert and maintaining safe practices throughout the process. We then moved on to understanding the ShopBot CNC machine itself—its components, how it functions, and how to interact with it safely. After that, we learned about the dust extraction system (duct fan), including how and when to turn it on and off to manage debris during milling. We also covered the locations and use of the two emergency switches, which are critical in case anything goes wrong. Next, we were taught how to properly mount the cutting tool onto the collet, ensuring it’s secure and properly aligned. Finally, we practiced mounting the stock onto the CNC bed and reviewed key safety precautions, including keeping a three-meter safety distance while the machine is in operation.

The group assignment Page :

Work Process Detail

- Runout & Dangers Awareness

We began by understanding what runout is and how even a small misalignment can damage the bit, the stock, or the machine itself. This taught us how dangerous CNC work can be if handled carelessly.

- Machine Overview

We explored the components and functionality of the ShopBot CNC machine. This included understanding the software interface, the motors, spindle, and axis movement.

- Dust Extraction System (Duct Fan)

We learned how to operate the duct fan, which must be turned on before any cutting to prevent dust buildup and ensure clean working conditions.

- Emergency Switches

We located and practiced using both emergency switches on the machine, which must be used immediately in any unsafe situation.

- Mounting the Cutting Tool

Using the right collet size, we mounted the cutting tool carefully, making sure it was tightened properly with the correct wrenches and not overextended.

- Securing the Stock to the Bed

We aligned and clamped the material (usually MDF) tightly on the CNC bed. We also learned how to use screws safely and checked that the bit path wouldn’t collide with any fasteners.

Learning Outcome

From this session, I gained a deeper understanding of CNC machine safety and operation. I learned how to respond in case of an emergency, how to handle the machine and its components responsibly, and how to set up both the tool and the material correctly. These skills are crucial for ensuring both personal and lab safety while working efficiently and effectively.