Final Project Servo Mechanism

Summary

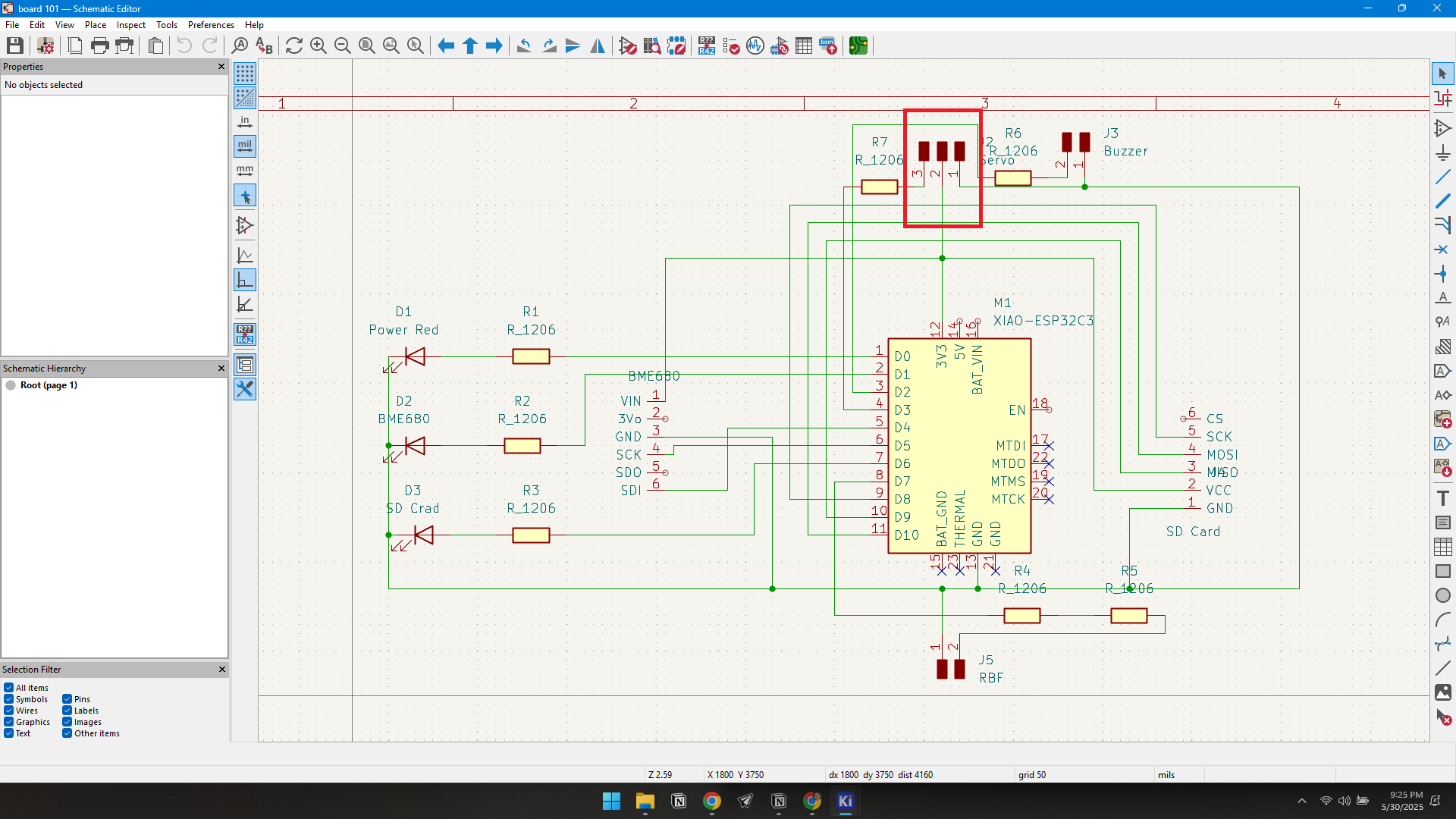

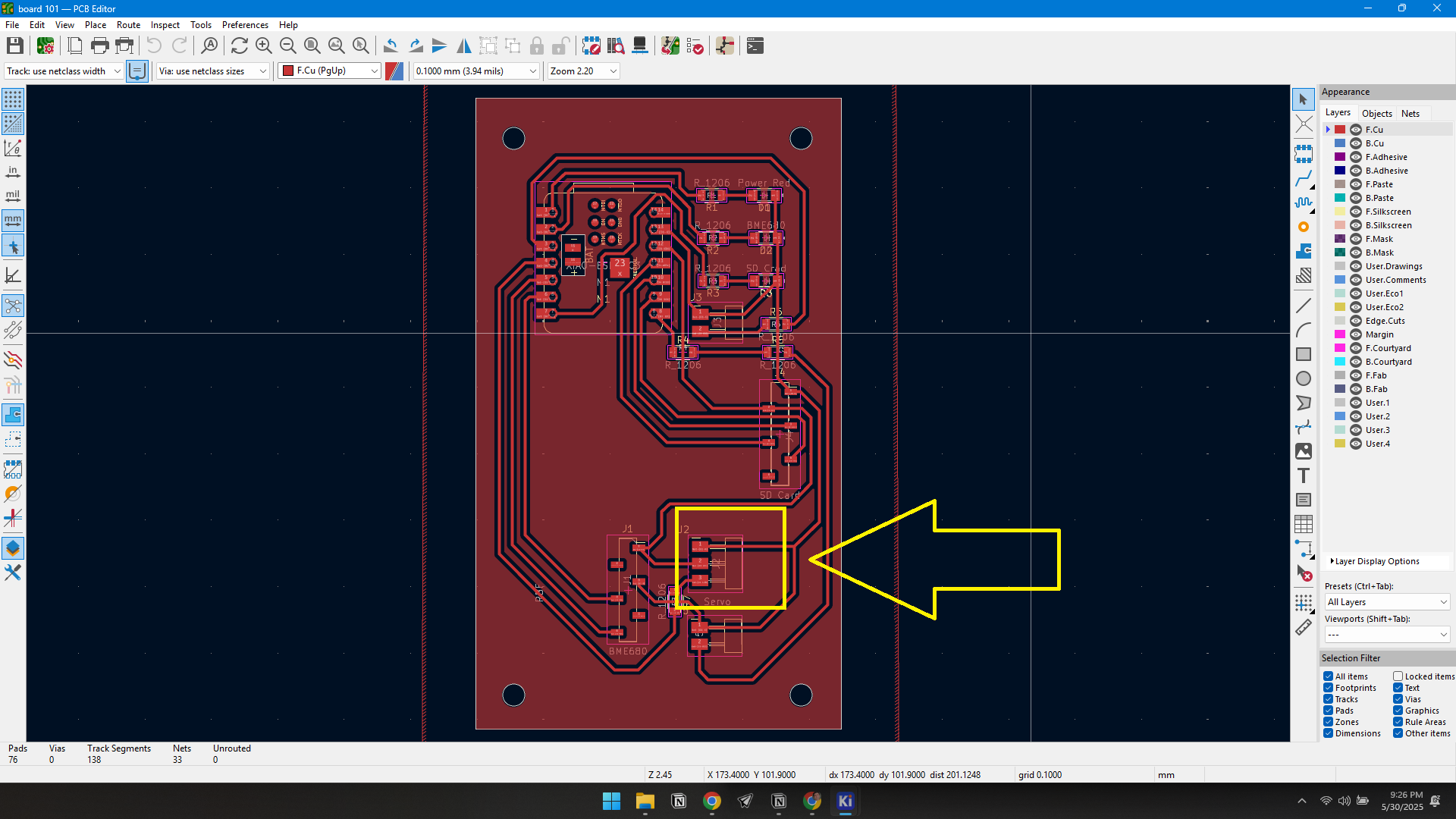

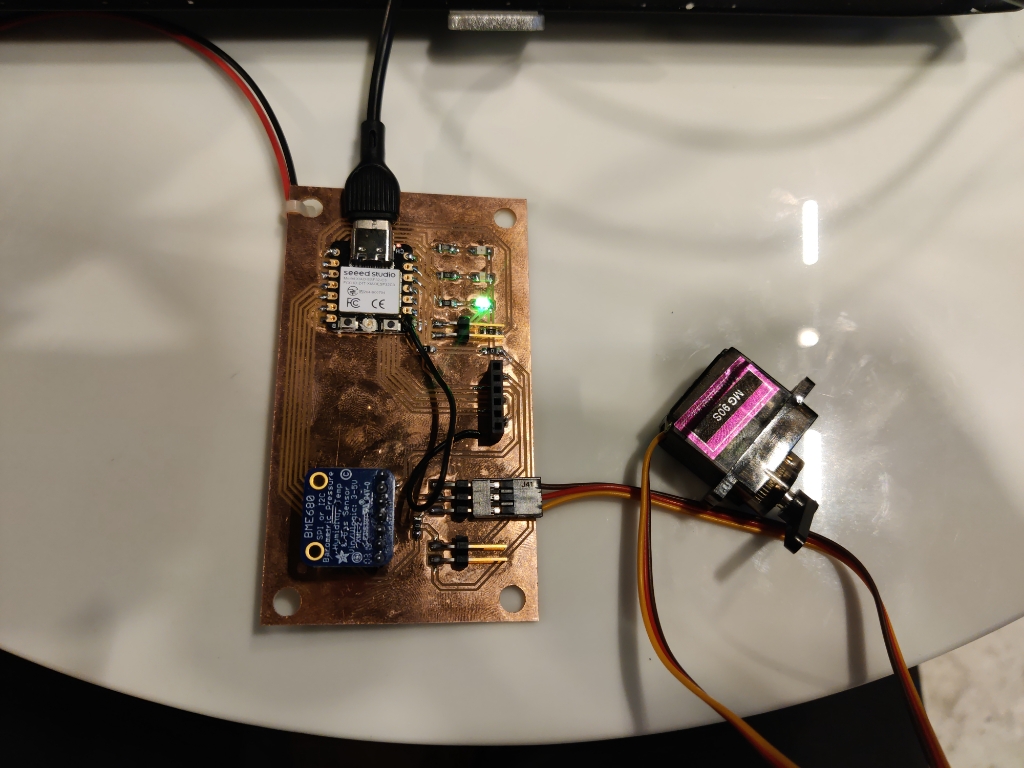

For the output device assignment, I integrated a servo motor with my XIAO ESP32-C3 microcontroller. The goal was to test basic PWM-based control for mechanical movement, which is crucial for my final project—specifically for triggering physical actions like parachute release. This task gave me hands-on experience in working with digital output devices and real-time control logic.

Work Process Detail

1. Servo Motor Selection

- I used a standard SG90 servo motor, which is lightweight and ideal for compact applications like rockets and mechanical triggers.

- Operating voltage: 3V – 6V

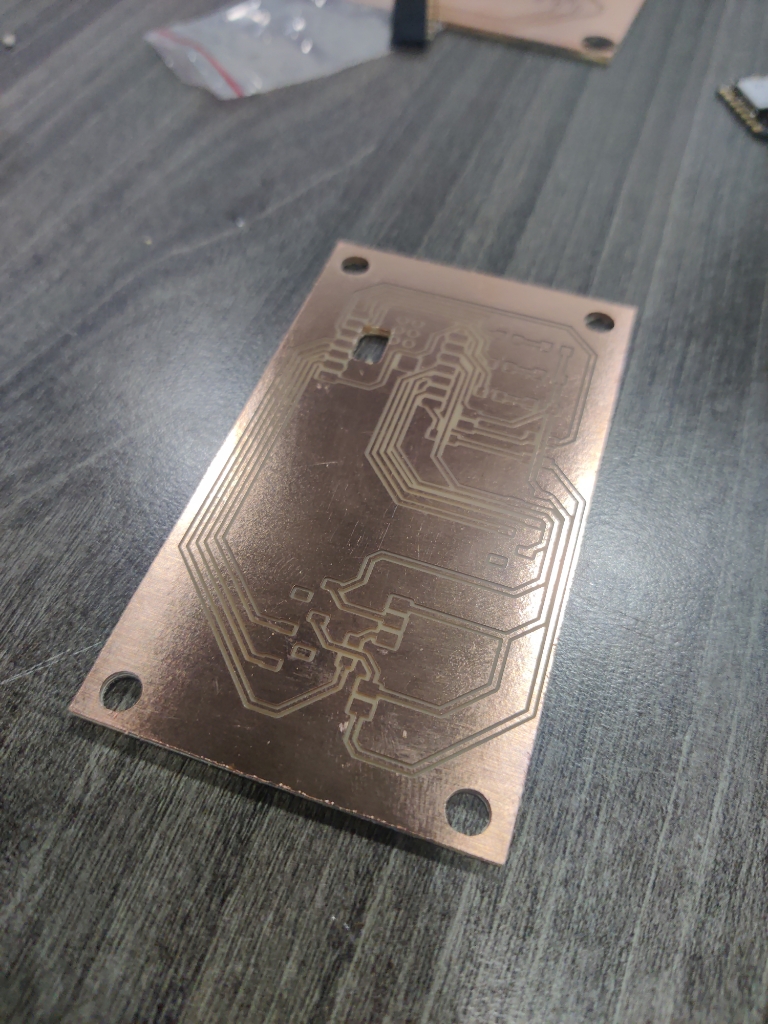

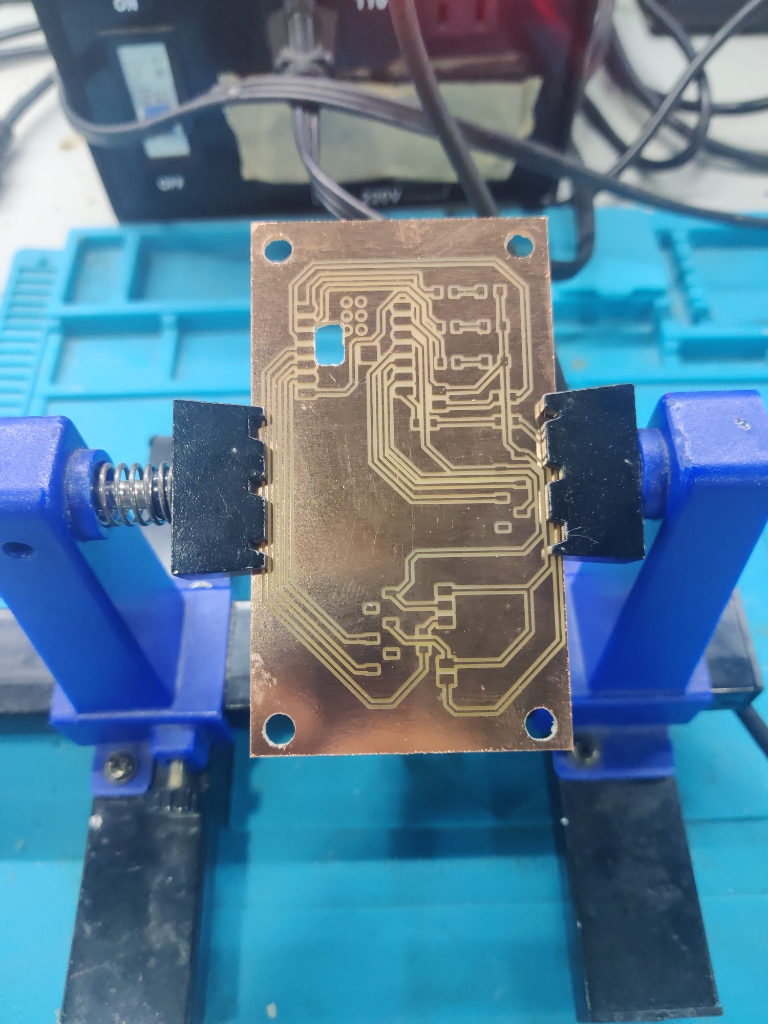

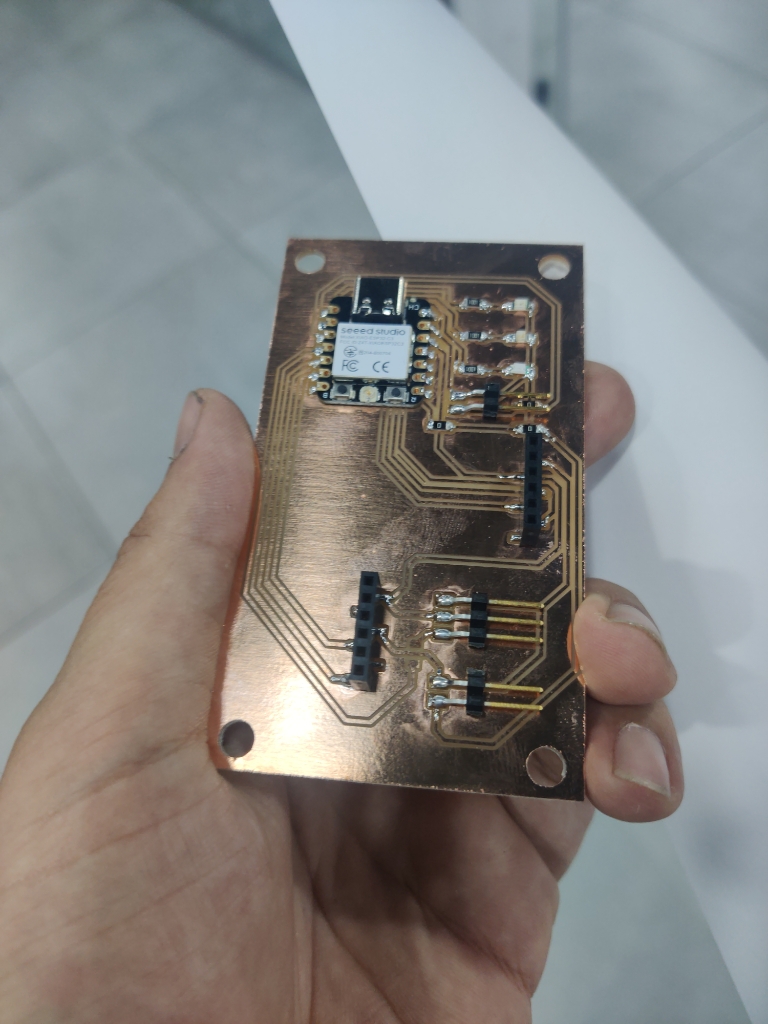

2. Circuit Setup

- Connected the servo signal pin to GPIO 3 on the XIAO ESP32-C3.

- Connected 5V power to the servo using an external power source to avoid overloading the microcontroller.

- GND lines of the ESP32, servo, and power source were all connected to ensure a common reference.

- [ESP32 GPIO 5] -------> [Servo Signal]

[3.3V External Power] --> [Servo VCC]

[Common Ground] ------> [Servo GND] + [ESP32 GND]

- [ESP32 GPIO 5] -------> [Servo Signal]

3. Code Implementation

- Used the ESP32Servo library to generate the required PWM signals.

- The servo was programmed to rotate between defined angles in a loop to simulate mechanical motion like locking/unlocking or latching.

#include <ESP32Servo.h>

Servo myServo; // create servo object

int servoPin = 5; // GPIO 3 on ESP32-C3

int angle = 0; // variable to store the servo position

void setup() {

Serial.begin(115200);

myServo.setPeriodHertz(50); // Standard 50 Hz servo

myServo.attach(servoPin, 500, 2400); // Min and Max pulse width in µs

}

void loop() {

// Sweep from 0 to 180

for (angle = 0; angle <= 180; angle += 1) {

myServo.write(angle);

delay(15);

}

// Sweep back from 180 to 0

for (angle = 180; angle >= 0; angle -= 1) {

myServo.write(angle);

delay(15);

}

}

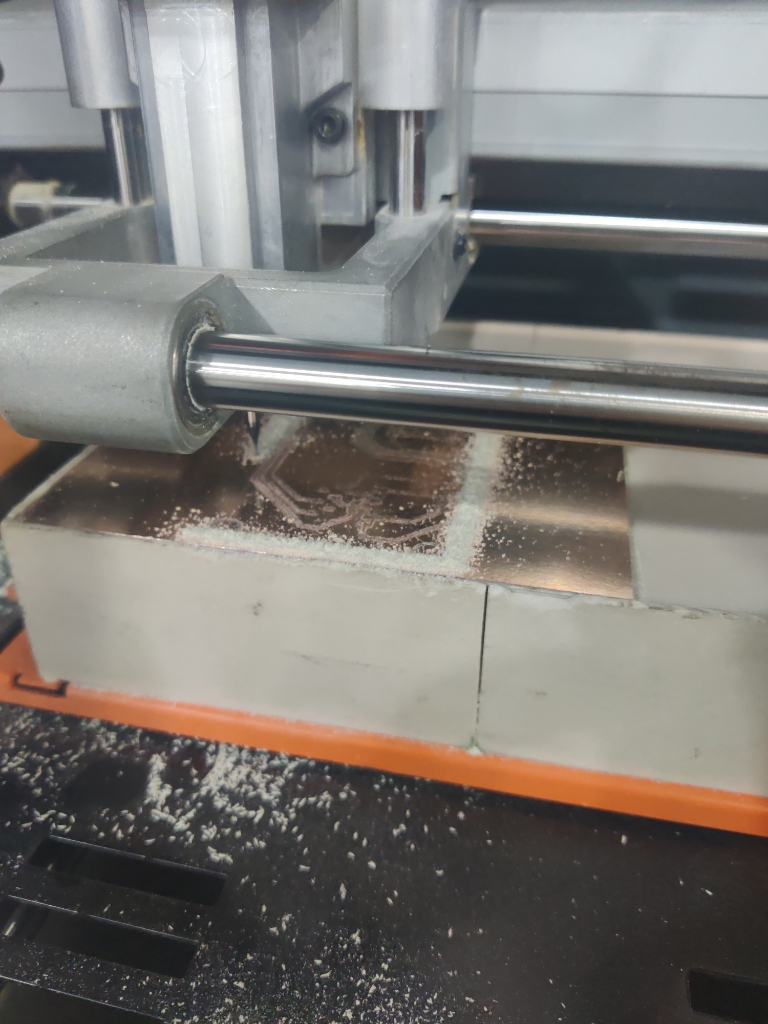

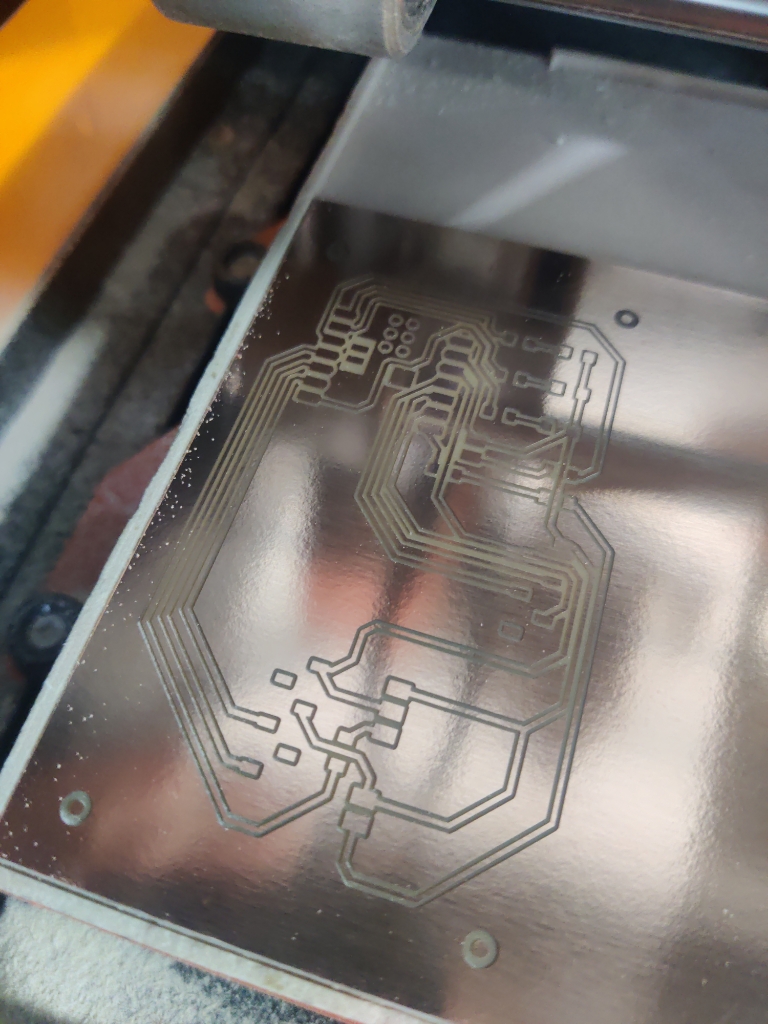

4. Testing & Results

- Tested the servo sweep between 0° and 180°.

- Ensured reliable motion and repeatability.

- Confirmed that the servo can generate enough torque to trigger the mechanical latch for the parachute system.

Learning Outcome

From this task, I gained a clear understanding of:

- Using PWM to control servos with the ESP32-C3.

- Managing power distribution for motor-based output devices.

- Verifying signal stability and physical performance of actuators.

- Building a foundation for combining mechanical movement with sensor-based input logic.