Design/Produce Hall/Barometer Sensor

Summary

For the input device assignment, I designed and fabricated a flexible Hall Effect sensor circuit using KiCad for schematic and PCB design, a UV printer for flexible PCB fabrication, and etching methods for removing excess copper. The result was a lightweight, flexible circuit sticker capable of sensing magnetic fields efficiently, as demonstrated in the final test video.

Work Process Detail

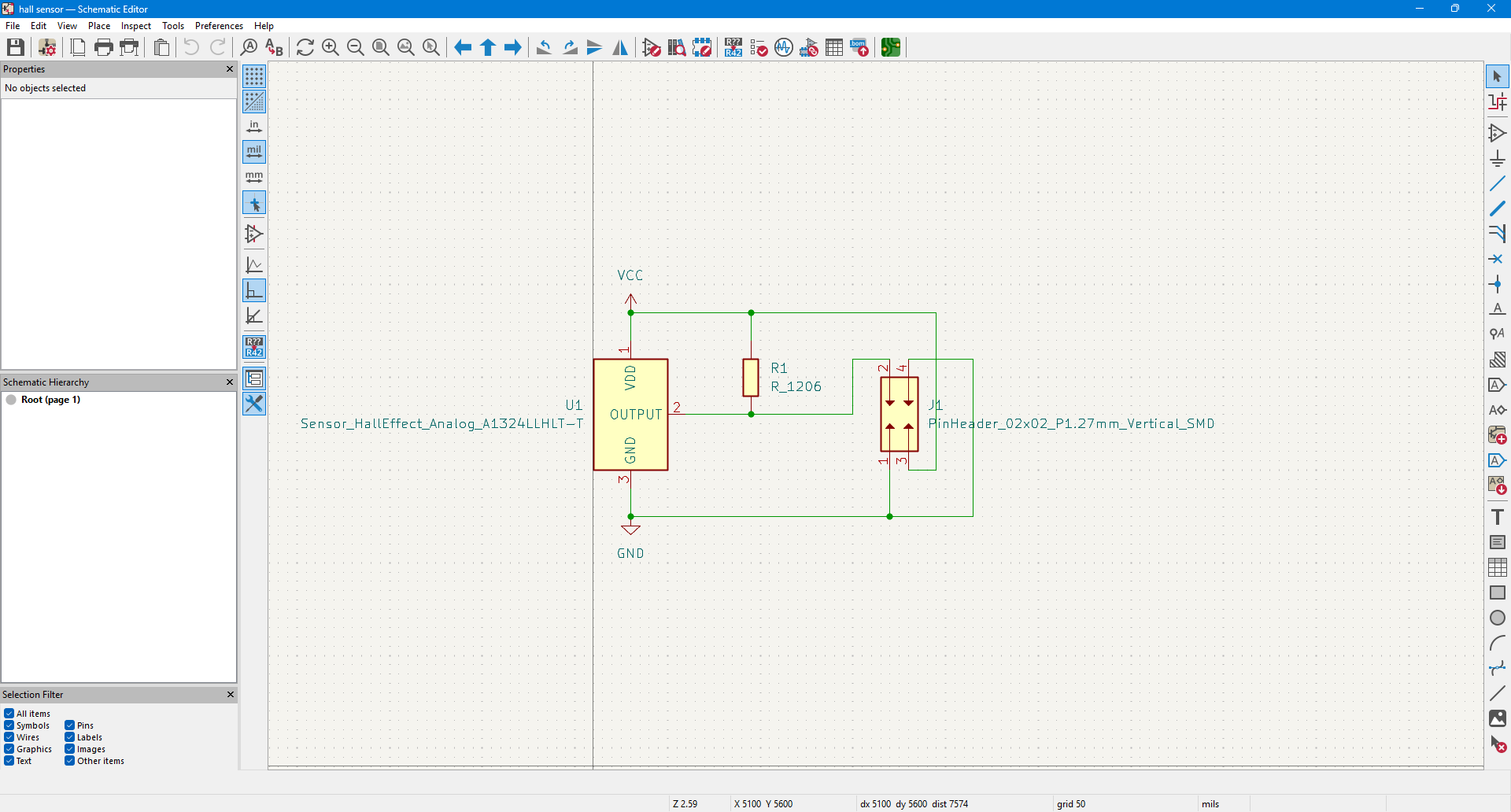

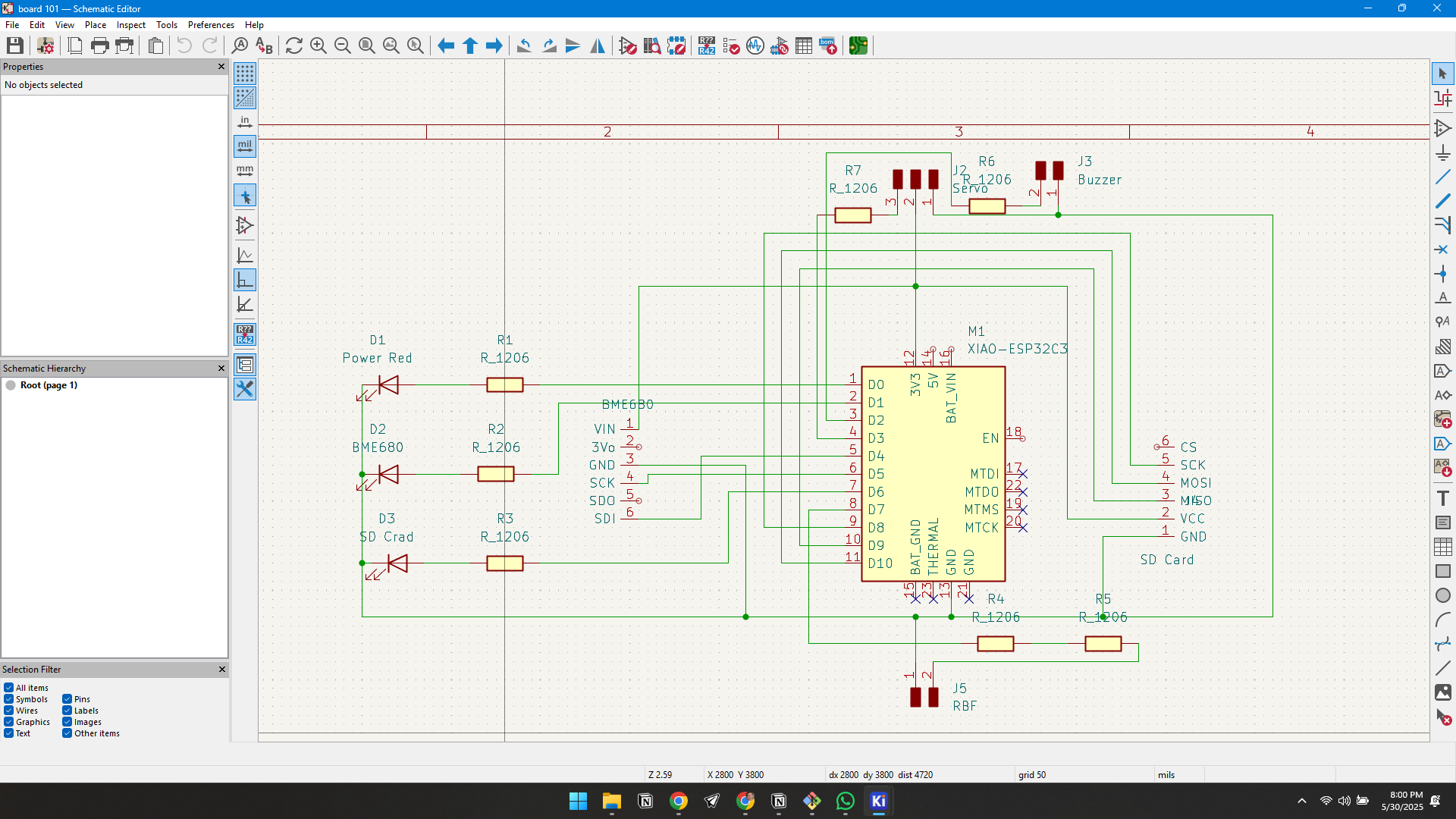

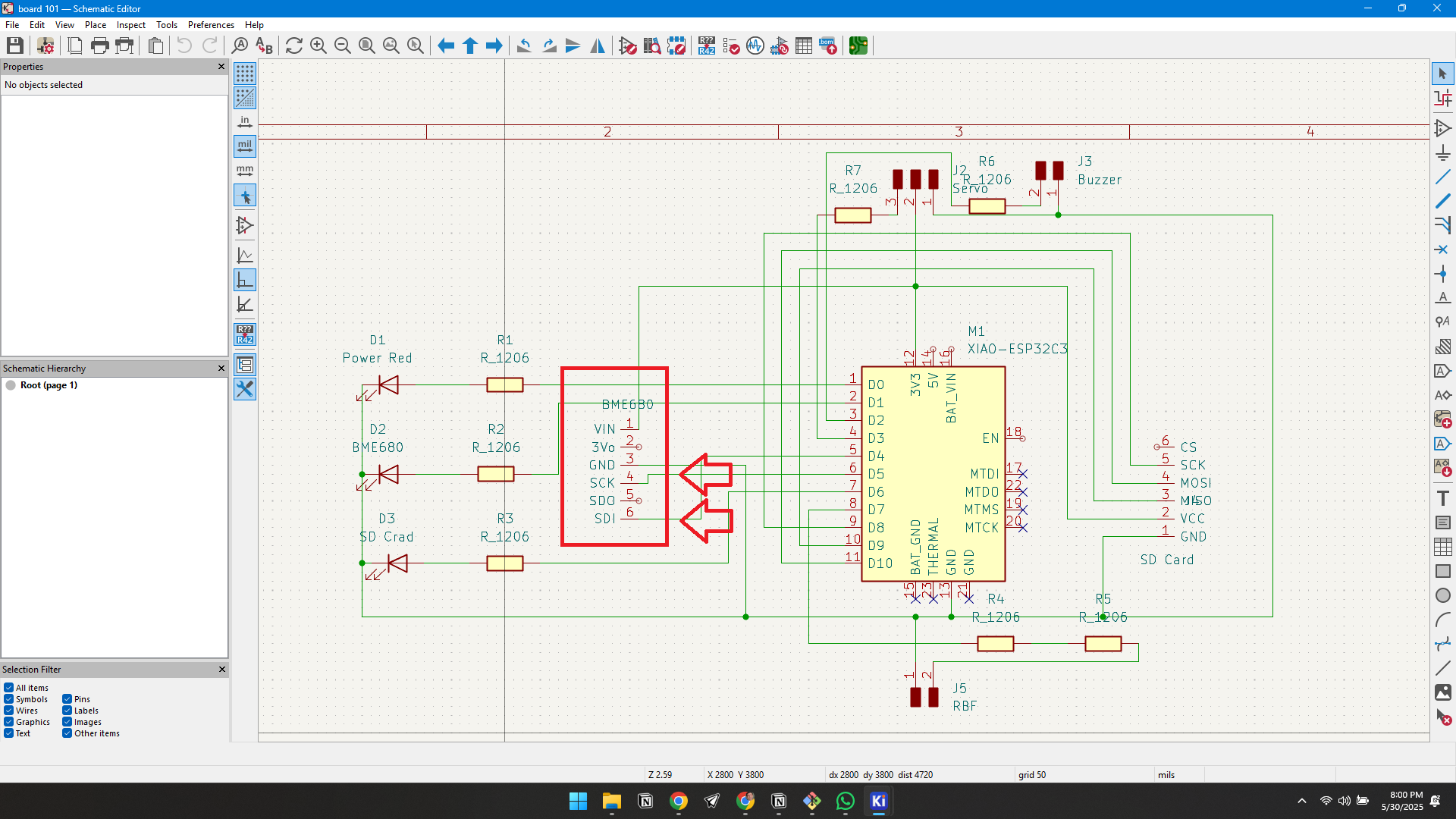

1.Schematic Design in KiCad

- Opened KiCad and designed the schematic for the Hall Effect sensor circuit.

- Ensured the schematic aligned perfectly with the available Fab Lab inventory components (using correct footprints and symbol libraries).

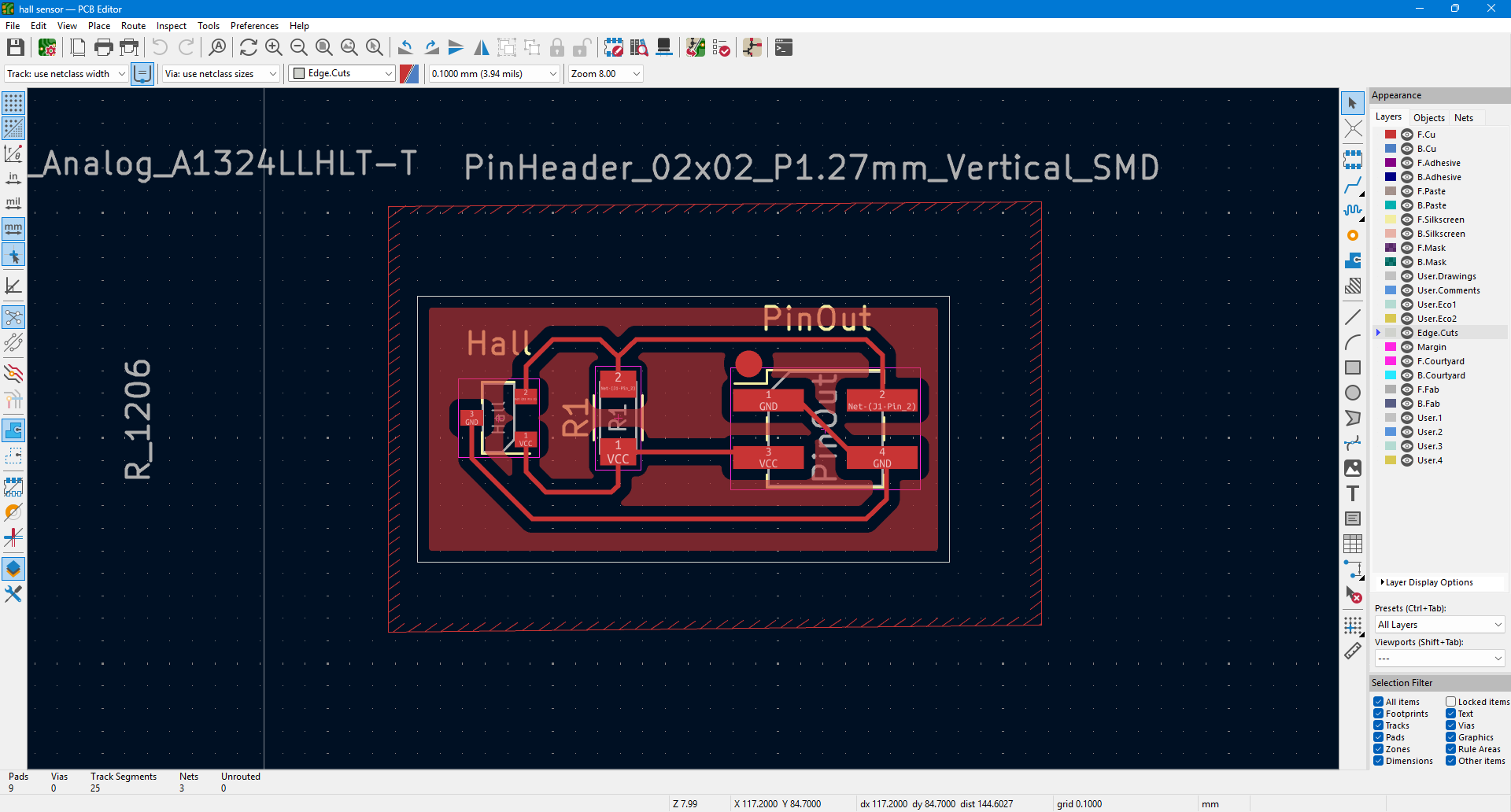

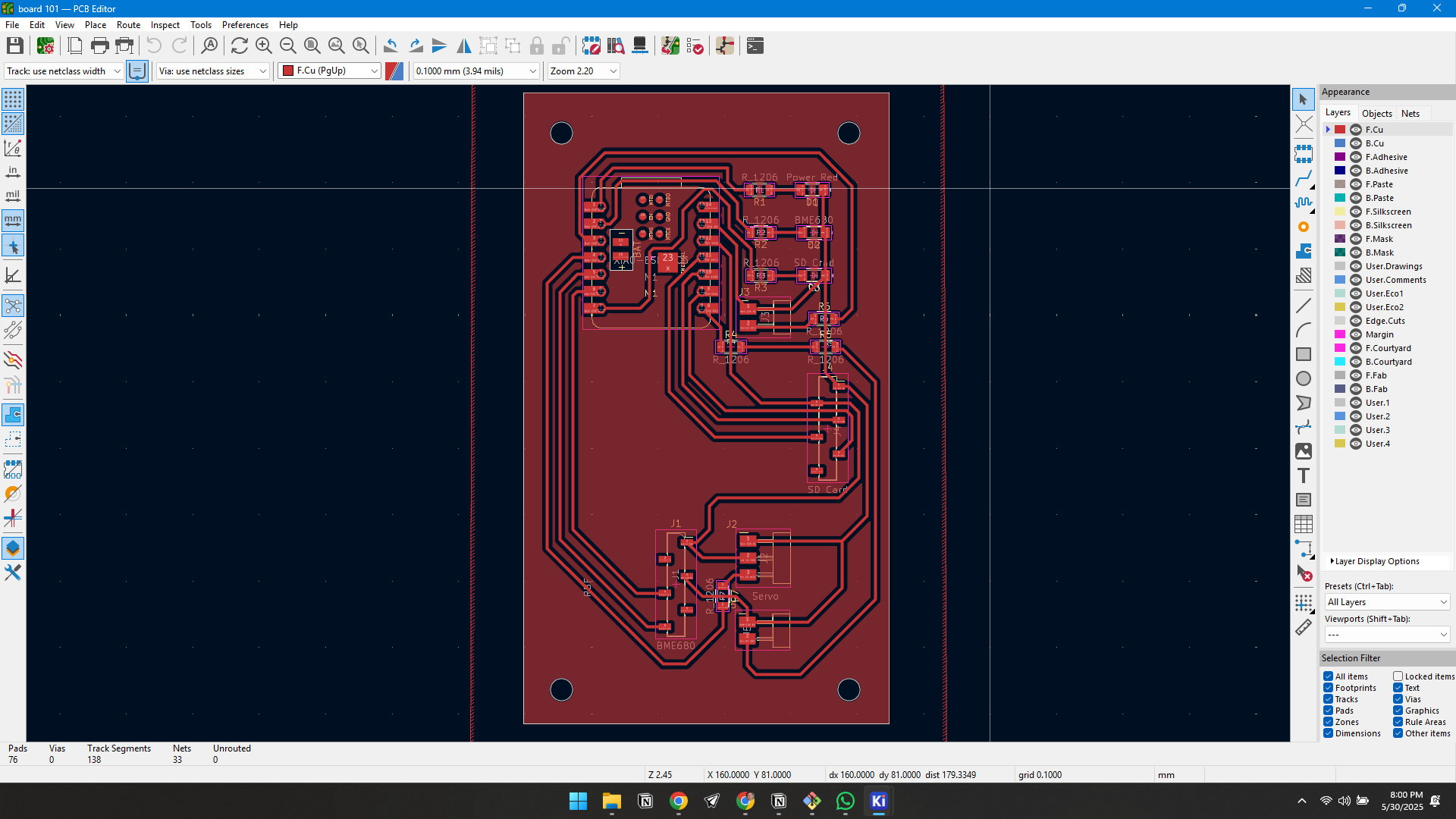

2. PCB Layout

- Moved to the PCB Editor in KiCad.

- Placed and routed components carefully, optimizing for small size and flexibility.

- Verified footprint alignment and proper net connections.

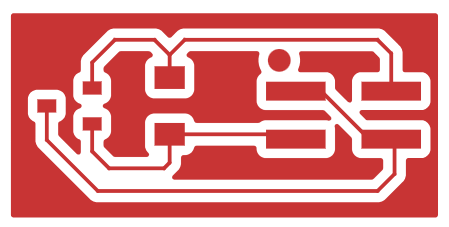

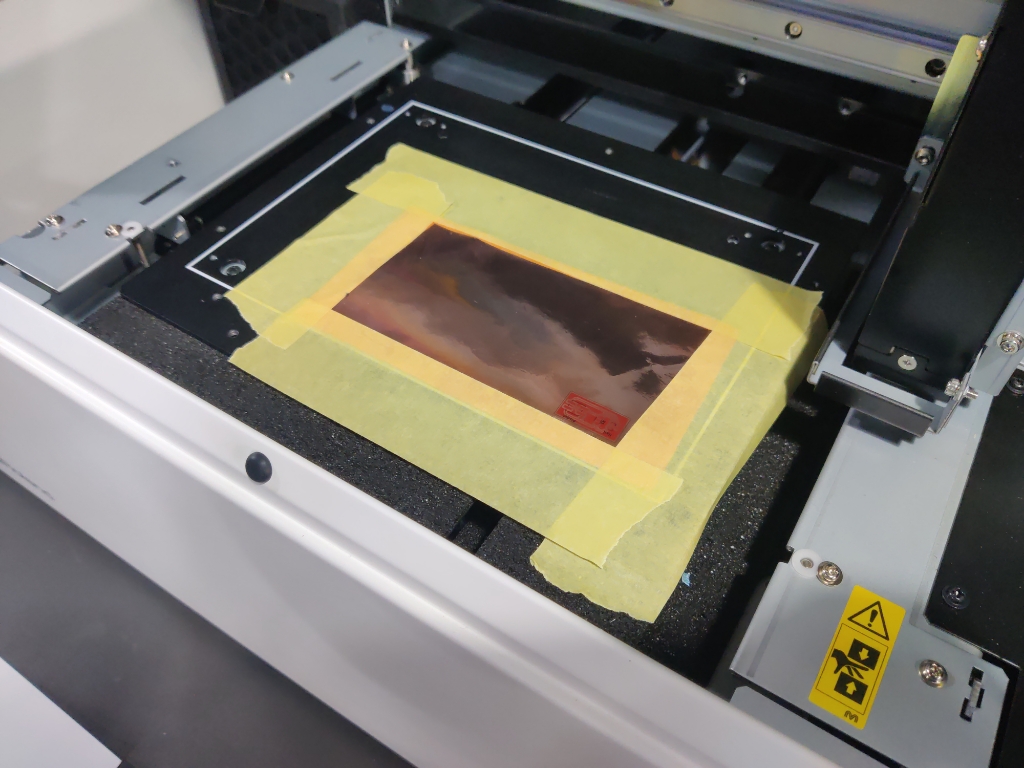

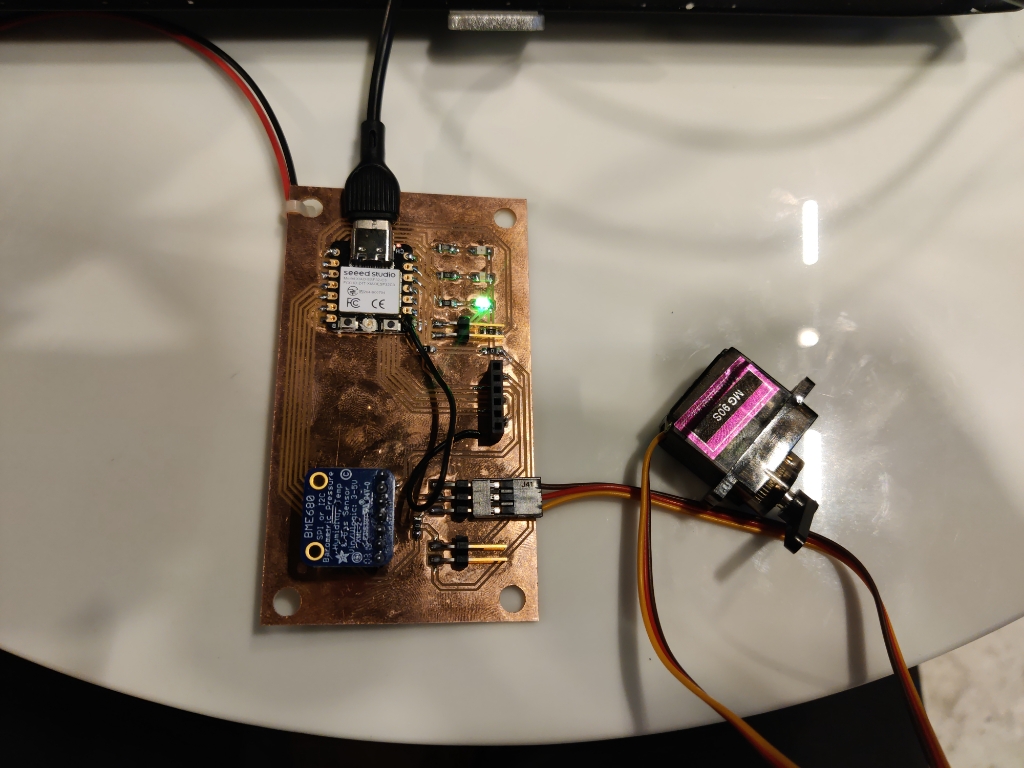

3. Printing the Flexible PCB

- Exported the PCB design and printed it using a UV printer onto copper tape.

- This method allowed the board to be flexible and lightweight, perfect for compact or curved applications.

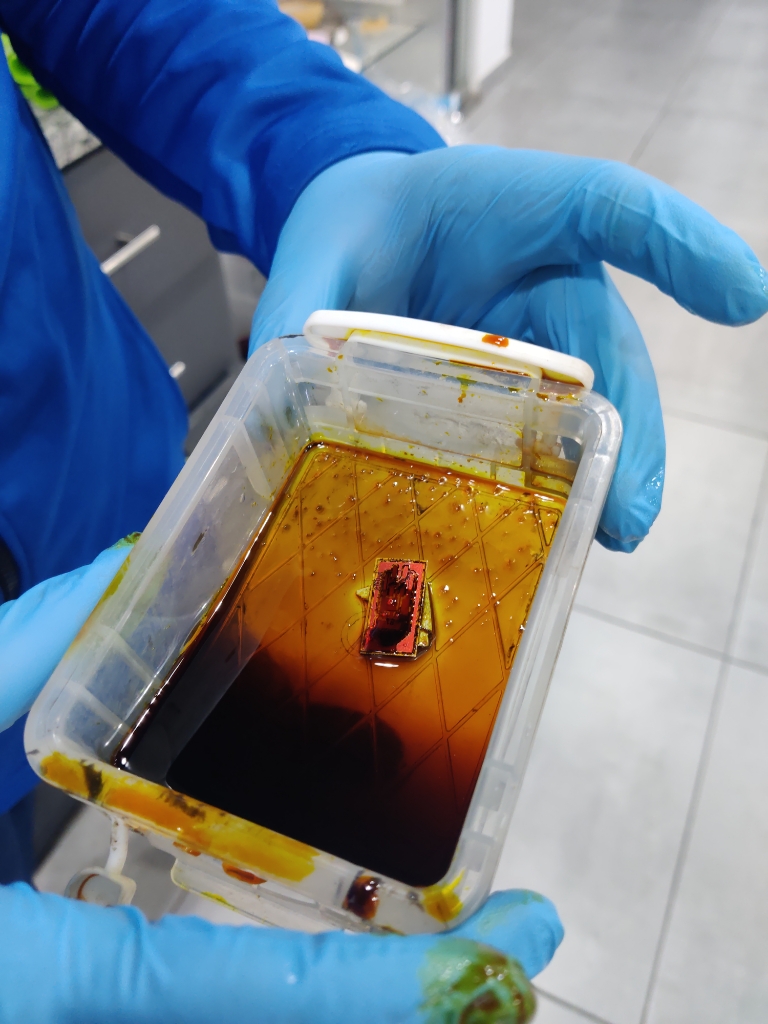

4. Etching Process

- Cut the printed copper tape to the exact required size.

- Performed chemical etching to remove the unwanted copper, leaving only the circuit traces.

- Carefully cleaned and prepared the etched flexible board for soldering.

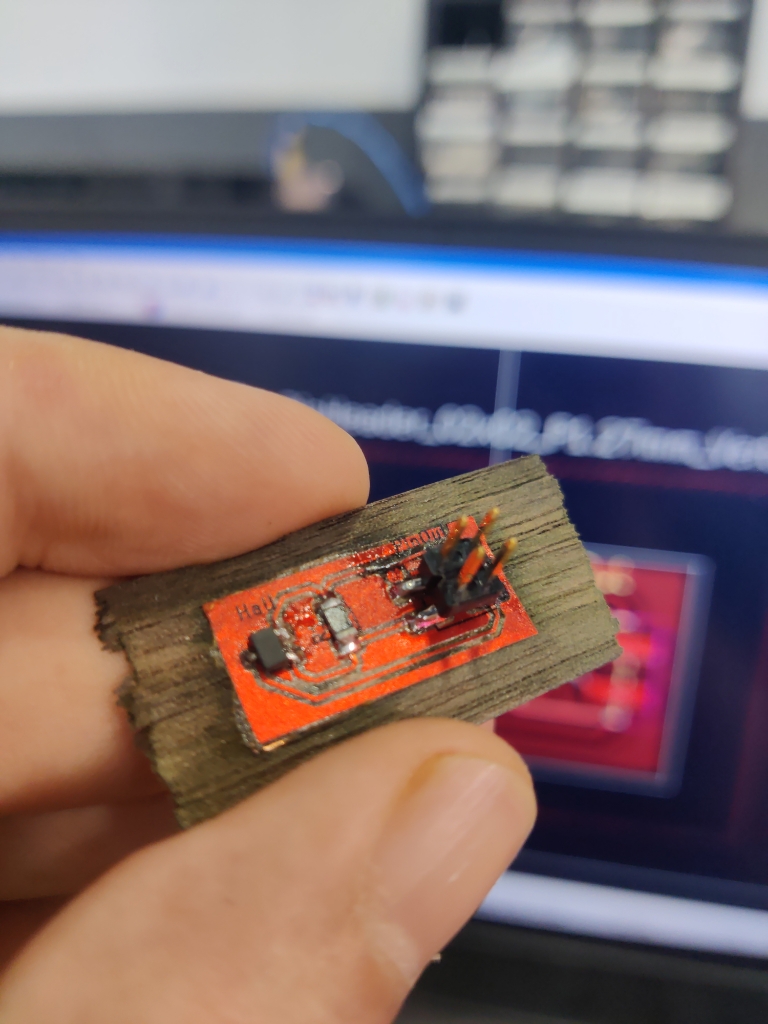

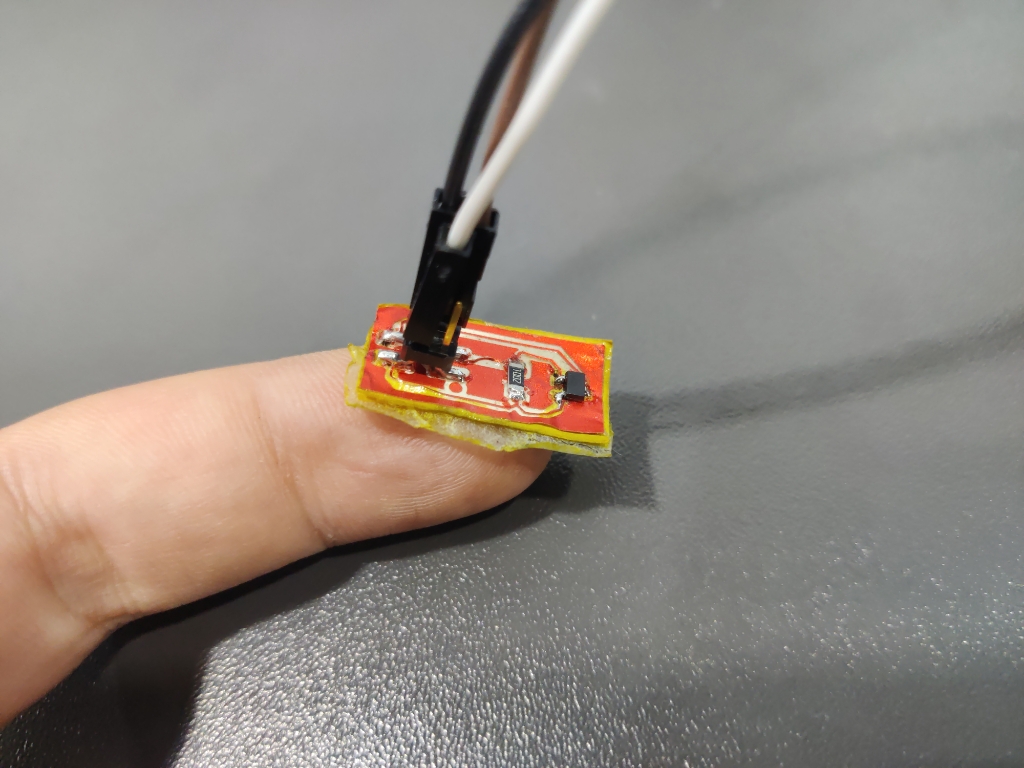

5. Component Assembly

- Soldered the Hall Effect sensor and supporting components directly onto the flexible PCB.

- Ensured connections were solid despite the flexible substrate by using proper soldering techniques.

6. Testing

- Verified circuit functionality using basic magnetic field tests.

- As shown in the video, the flexible PCB performed well, withstanding bending and mechanical stress without impacting performance.

7.Final Project Input Sensor Integration with a Microcontroller:

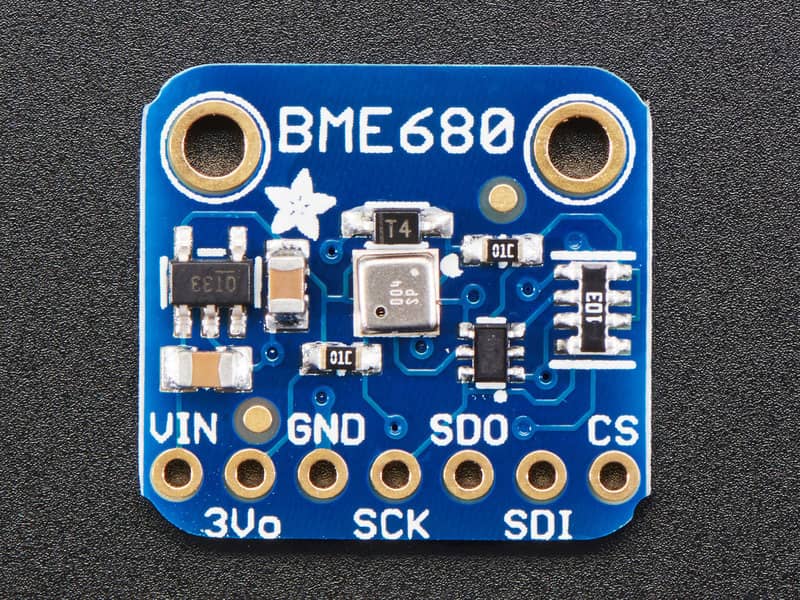

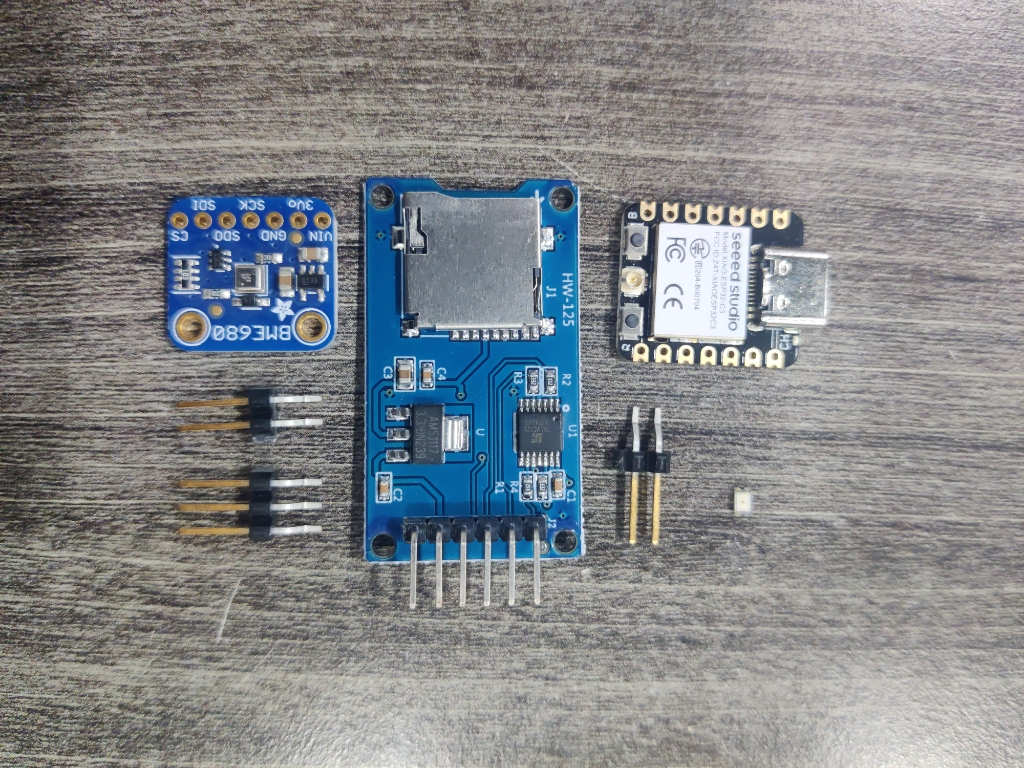

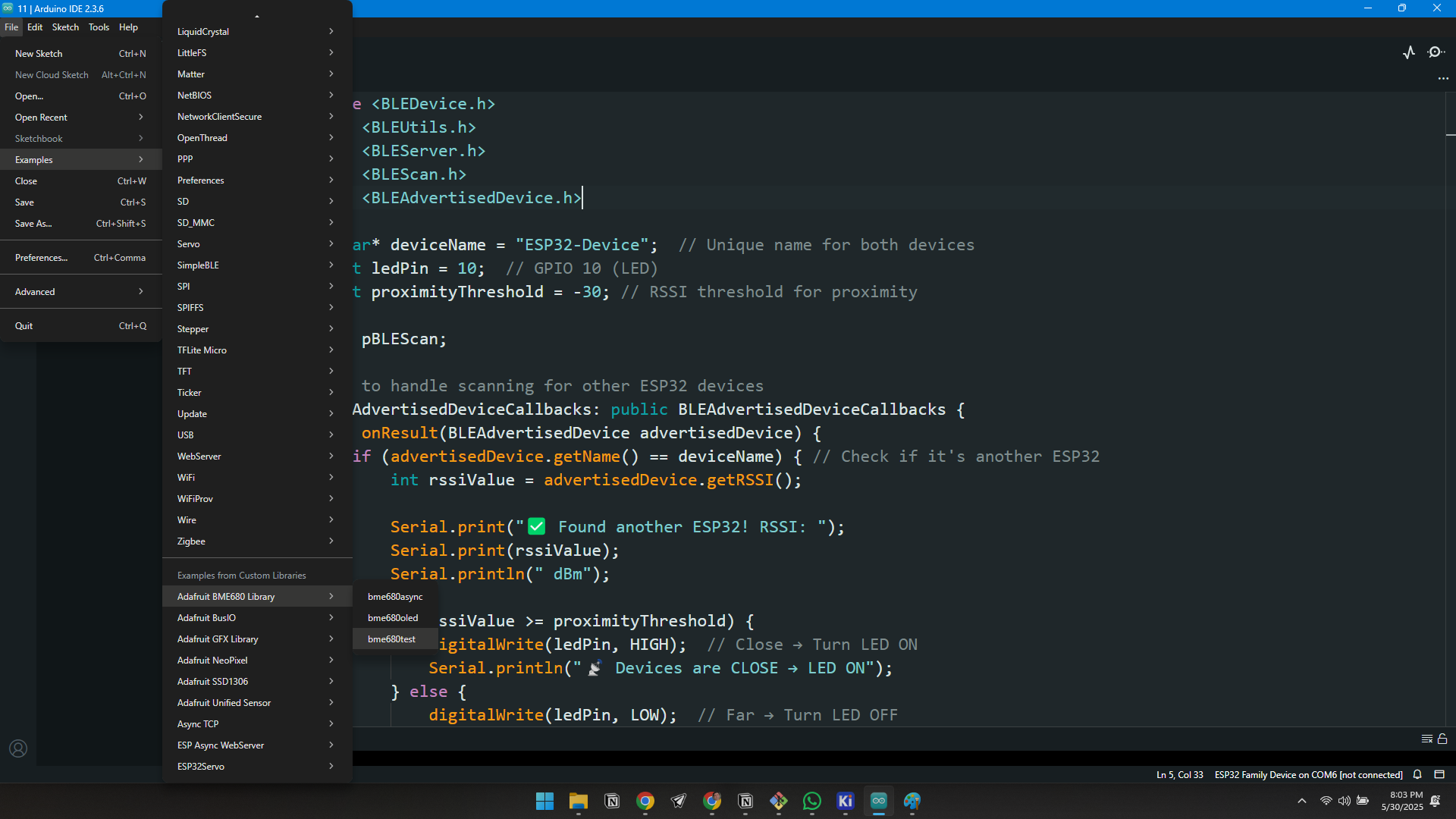

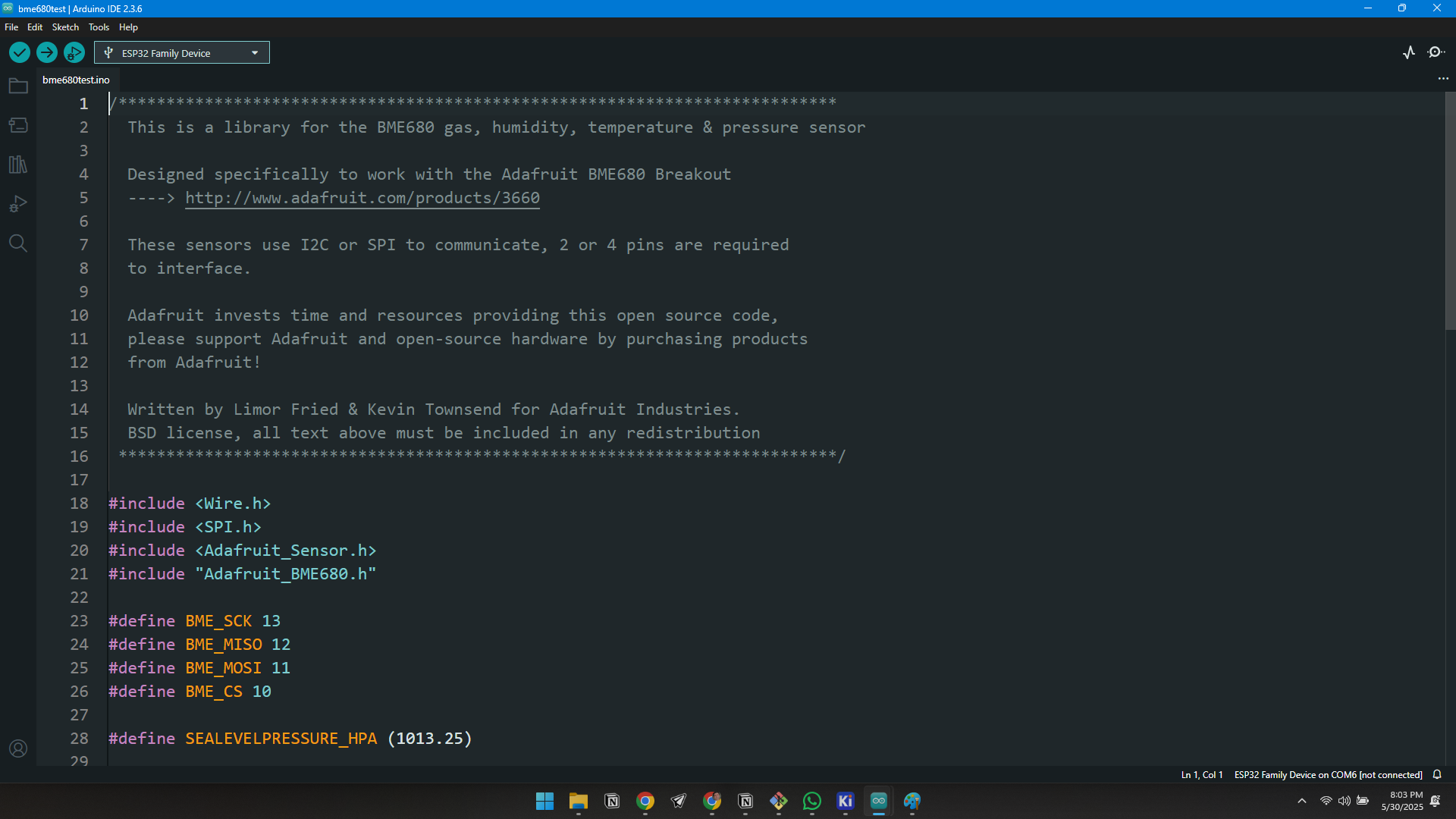

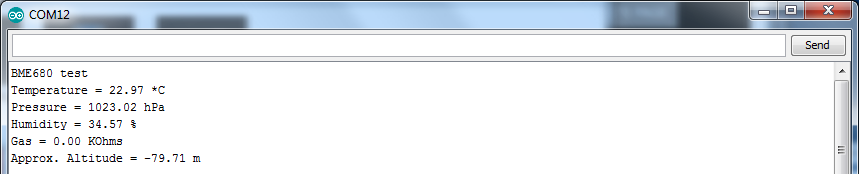

To expand this week’s work, I integrated a barometric pressure sensor (BME680) with the XIAO ESP32-C3 microcontroller. The goal was to measure altitude and air pressure in real-time, which will be a core part of my final project’s parachute deployment logic.

- Designed a custom PCB that accommodates the BME680 sensor and pin headers compatible with the XIAO ESP32-C3.

- Used the Adafruit BME680 Arduino Library to simplify sensor communication via I2C.

/***************************************************************************

This is a library for the BME680 gas, humidity, temperature & pressure sensor

Designed specifically to work with the Adafruit BME680 Breakout

----> http://www.adafruit.com/products/3660

These sensors use I2C or SPI to communicate, 2 or 4 pins are required

to interface.

Adafruit invests time and resources providing this open source code,

please support Adafruit and open-source hardware by purchasing products

from Adafruit!

Written by Limor Fried & Kevin Townsend for Adafruit Industries.

BSD license, all text above must be included in any redistribution

***************************************************************************/

#include <Wire.h>

#include <SPI.h>

#include <Adafruit_Sensor.h>

#include "Adafruit_BME680.h"

#define BME_SCK 13

#define BME_MISO 12

#define BME_MOSI 11

#define BME_CS 10

#define SEALEVELPRESSURE_HPA (1013.25)

Adafruit_BME680 bme(&Wire); // I2C

//Adafruit_BME680 bme(&Wire1); // example of I2C on another bus

//Adafruit_BME680 bme(BME_CS); // hardware SPI

//Adafruit_BME680 bme(BME_CS, BME_MOSI, BME_MISO, BME_SCK);

void setup() {

Serial.begin(9600);

while (!Serial);

Serial.println(F("BME680 test"));

if (!bme.begin()) {

Serial.println("Could not find a valid BME680 sensor, check wiring!");

while (1);

}

// Set up oversampling and filter initialization

bme.setTemperatureOversampling(BME680_OS_8X);

bme.setHumidityOversampling(BME680_OS_2X);

bme.setPressureOversampling(BME680_OS_4X);

bme.setIIRFilterSize(BME680_FILTER_SIZE_3);

bme.setGasHeater(320, 150); // 320*C for 150 ms

}

void loop() {

if (! bme.performReading()) {

Serial.println("Failed to perform reading :(");

return;

}

Serial.print("Temperature = ");

Serial.print(bme.temperature);

Serial.println(" *C");

Serial.print("Pressure = ");

Serial.print(bme.pressure / 100.0);

Serial.println(" hPa");

Serial.print("Humidity = ");

Serial.print(bme.humidity);

Serial.println(" %");

Serial.print("Gas = ");

Serial.print(bme.gas_resistance / 1000.0);

Serial.println(" KOhms");

Serial.print("Approx. Altitude = ");

Serial.print(bme.readAltitude(SEALEVELPRESSURE_HPA));

Serial.println(" m");

Serial.println();

delay(2000);

}- Connected the SCL, SDA, GND, and VCC lines properly between the sensor and the microcontroller.

Official Adafruit Tutorial :

https://learn.adafruit.com/adafruit-bme680-humidity-temperature-barometic-pressure-voc-gas/overview

- Verified communication using Serial Monitor and confirmed live readings of temperature, pressure, altitude, and gas resistance.

- Programmed the ESP32-C3 to log data at 1-second intervals for real-time monitoring.

- This integration will serve as the main sensing unit in my rocket’s data acquisition and parachute deployment system.

Learning Outcome

Through this project, I enhanced my skills in:

- KiCad schematic and PCB design workflows.

- Flexible electronics fabrication using UV printing and etching techniques.

- Precision soldering on flexible materials.

- Understanding the practical integration of Hall Effect sensors for magnetic field sensing in lightweight, flexible applications.

Additionally, I learned how to adapt the manufacturing process to produce innovative, durable designs suitable for real-world dynamic environments.