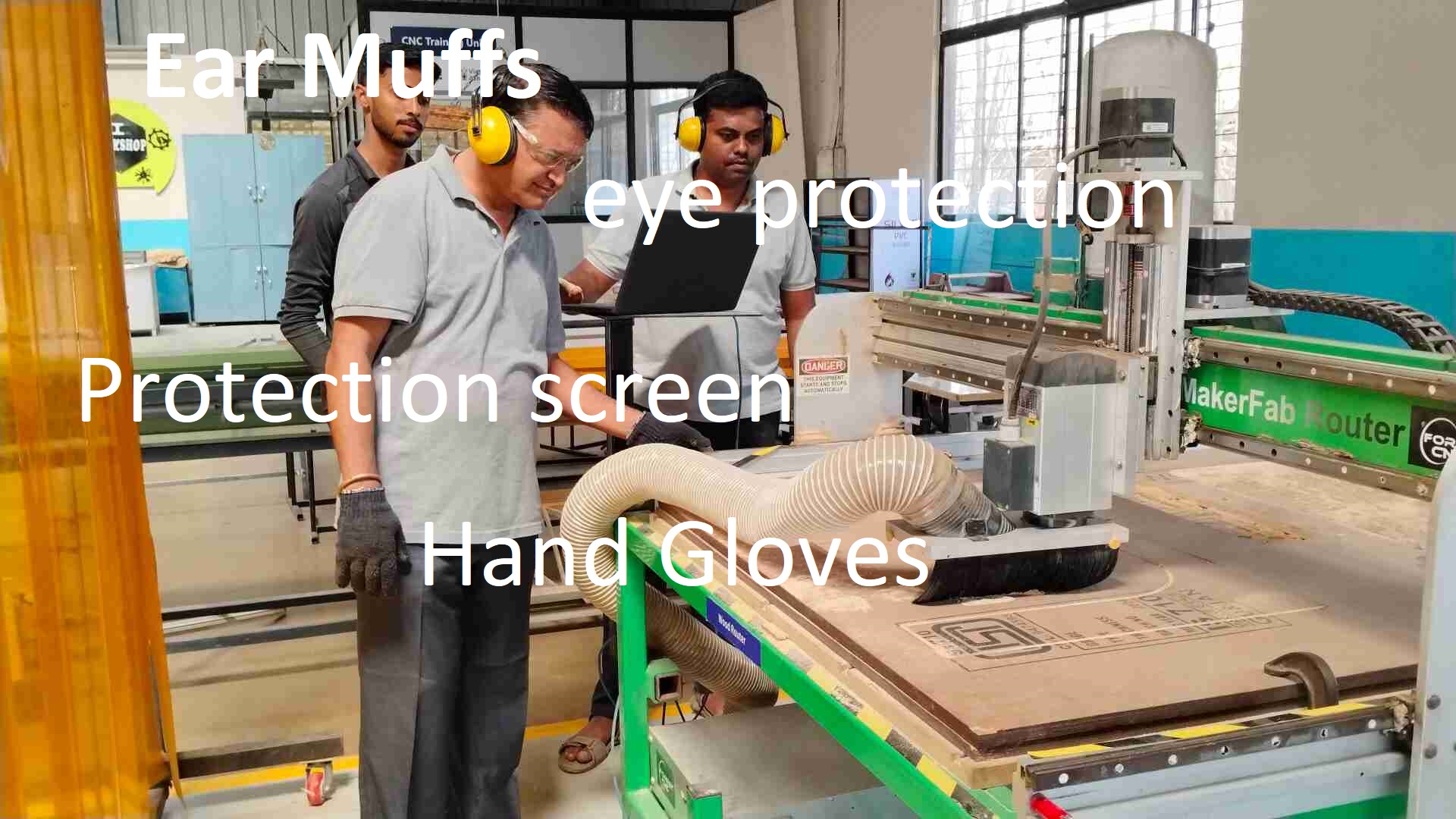

Group Assignments -Lab Safety Requirements and Training

(A) Personal Protective Equipment:

- Safety Glasses/Goggles:- Protect your eyes from flying debris and dust.

- Hearing Protection:- Use earplugs or earmuffs to protect against high noise levels.

- Dust Masks/Respwirators:- Wear these to avoid inhaling fine dust particles.

- Gloves:- Use gloves when handling materials, but never while operating the machine as they can get caught in moving parts.

- Close-Fitting Clothing:- Avoid loose clothing, jewelry, and tie back long hair to prevent entanglement.

(B) Machine Operation:

- Training:- Only trained and authorized personnel should operate the CNC router.

- Pre-Operation Checks:- Inspect the machine for any damage or issues before use. Ensure all safety guards and covers are in place.

- Setup:- Securely clamp the workpiece and ensure it is properly supported. Check that all tools and fixtures are properly installed.

- Software Checks:- Double-check the CNC program for errors before running the machine.

(C) During Operation:

- Stay Alert:- Remain focused and avoid distractions while the machine is running.

- Emergency Stops:- Know the location of emergency stop buttons and how to use them.

- Safe Distance:- Maintain a safe distance from the machine while it is in operation. Never reach into the machine while it is running.

- Ventilation:- Ensure proper ventilation to reduce the buildup of dust and fumes.

(D) Post Operation:

- Power Down:- Always turn off the machine and disconnect the power before performing any maintenance or adjustments.

- Clean Up:- Remove dust, debris, and waste materials from the machine and surrounding area.

- Tool Maintenance:- Regularly inspect and maintain tools and equipment to ensure they are in good working condition.

(E) General Safety:

- Know Emergency Procedures:- Be familiar with the lab’s emergency procedures, including the location of fire extinguishers, first aid kits, and emergency exits.

- Avoid Crowding:- Limit the number of people around the CNC router to prevent accidents and ensure a clear workspace.

- Report Issues:- Immediately report any safety hazards, equipment malfunctions, or accidents to the lab supervisor.

Maker Forest CNC Router

Machine Specification is Maker CNC Router (8x4 bed size) i.e.2400mm x 1200mm bed size - The MakerFab Routers are cost effective heavy duty machines made of a welded steel frame with 2” tubular steel. The extra rigidity is great for handling the abuse of students and will last for years. Includes Control Computer, CAD/CAM software, tooling set, MDF Table with Aluminum T Slots, Clamping system, curriculum, 3-1/2 HP Router, wrenches, operates on 110V 20A.

A computer-controlled device for accurate cutting, engraving, and creating is the Forest CNC Router. It can be used on light metals, composites, wood, and plastic. Fabrication, prototyping, signage, furniture manufacturing, and industrial applications are its primary uses. More information is available on this website

MakerFab Routers

The MakerFab Routers are cost-effective, heavy-duty CNC machines constructed with a welded steel frame featuring 2” tubular steel. This design ensures enhanced rigidity, making them suitable for educational environments and capable of withstanding rigorous use.

More information availabe in the website about Forest Scientific MakerFab Router🔧 Included Components

- Control Computer

- CAD/CAM Software

- Tooling Set

- MDF Table with Aluminum T-Slots

- Clamping System

- Curriculum

- 3-1/2 HP Router

- Wrenches

- Operates on 110V 20A

📏 Available Models

- RMF 24″ x 20″ CNC Router

- RMF 48″ x 20″ CNC Router

- RMF 48″ x 48″ CNC Router

- RMF 48″ x 96″ CNC Router

- RMF 60″ x 120″ CNC Router

✅ Key Features

- Heavy-duty welded structural steel construction

- Complete turnkey package

- True 3D with continuous contouring and smoothing

- Auto Z sensing for part zero

- Unlimited file size for complex 3D parts

- Homing sensors on X, Y, & Z axes

- 3-year, on-site parts & labor warranty

🔌 Optional Upgrades

- Vacuum Table Systems

- Spindle Upgrades (e.g., 2.5 HP, 6 HP, 12 HP)

- 3D Digitizing Probe

- 6″ Fourth Axis

- Wireless Jog Pendant

- Desiccant Dryer System for ATCs

- Pneumatic Cooler for Plastics & Metals

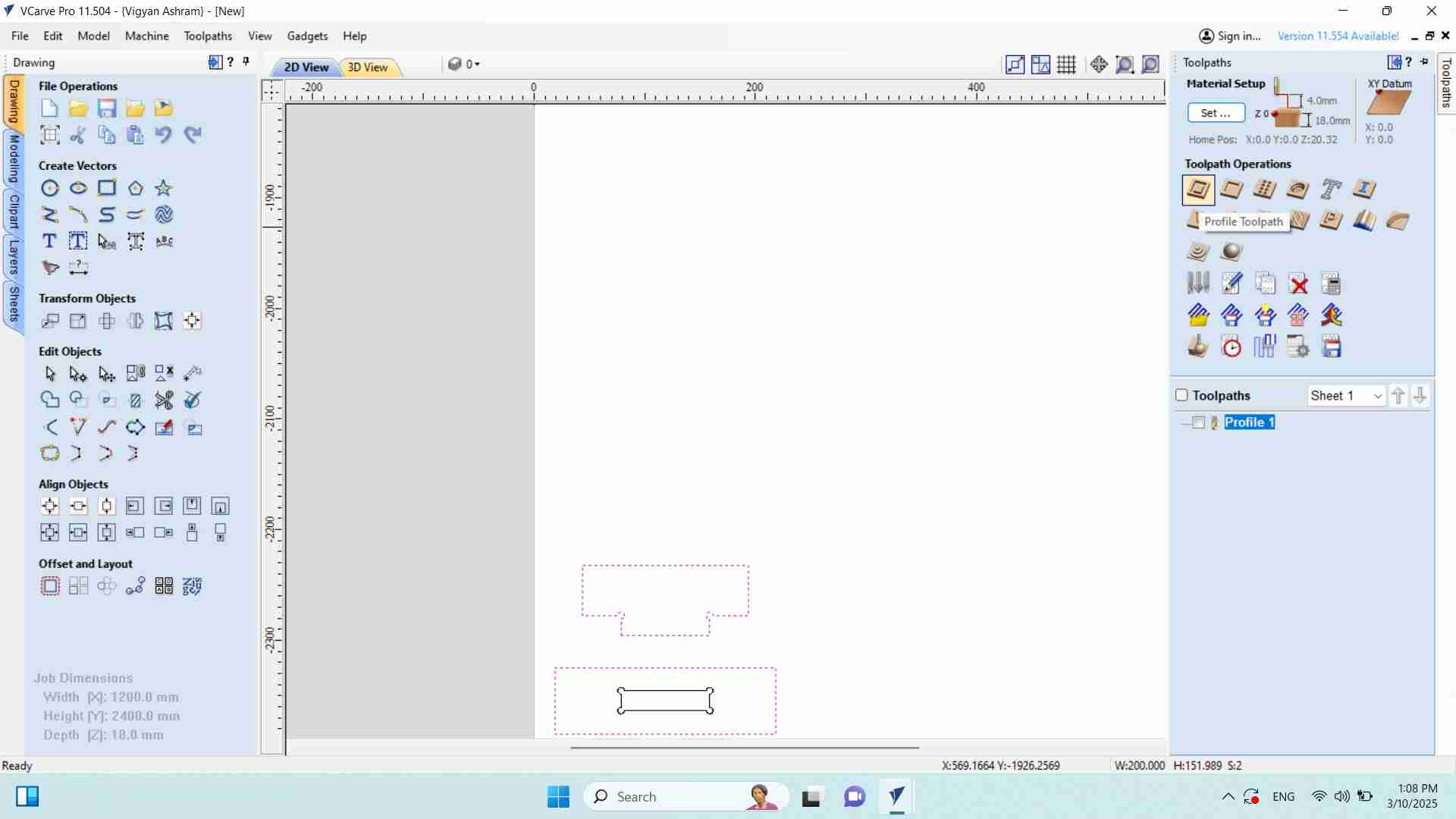

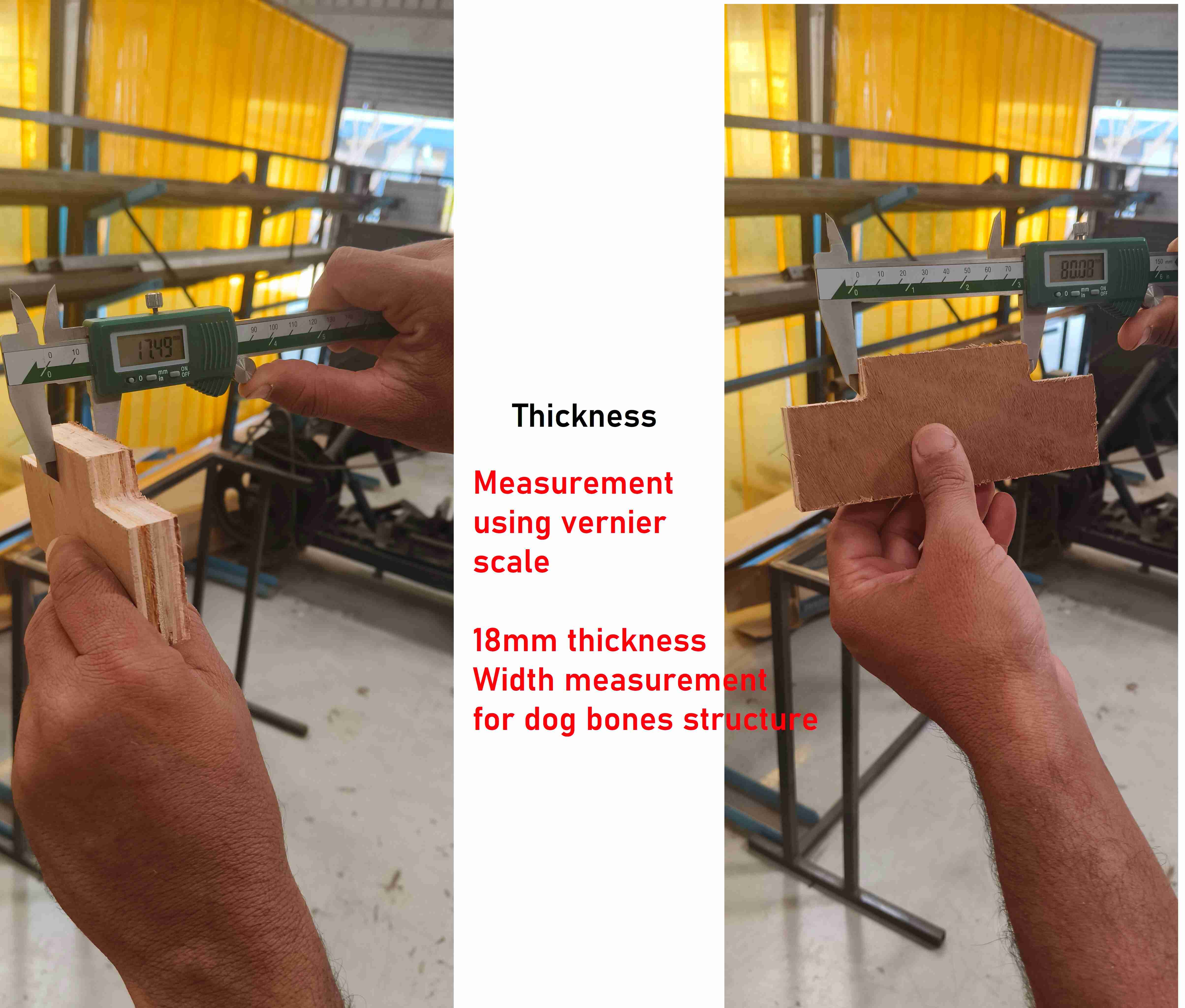

we used plywood measuring 2400mm in height and 1200mm in width equal to same bed size, with a thickness of 18mm for the Individual Assignment

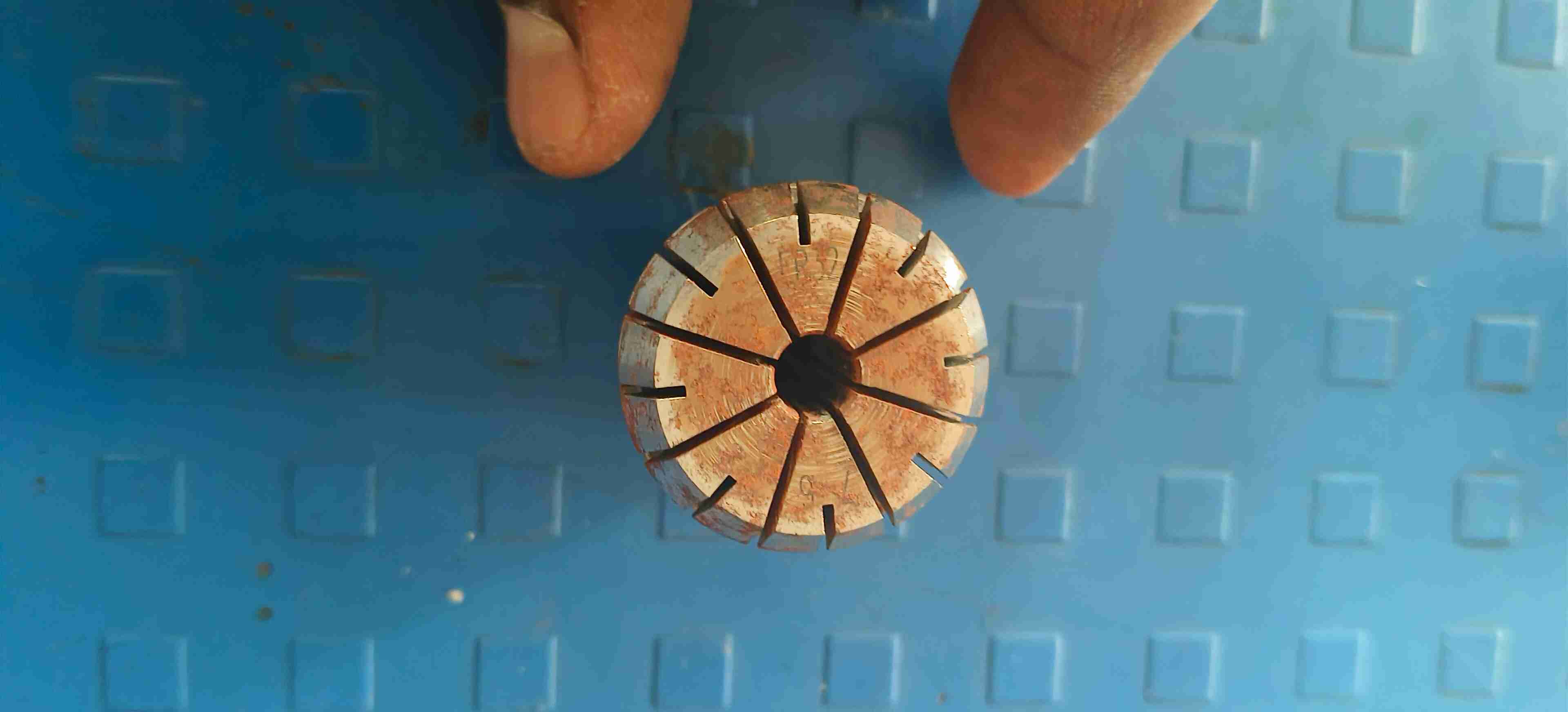

understand the usage of clamp holder

The CNC router operates with basic tools such as end mill with different flute faces, which determine the cutting efficiency and material removal rate. The number of faces on the tool affects the cutting finish and speed. Tools are securely held in place using a collet, which ensures precision during operation. The machine operates on three axes (X, Y, and Z), allowing for versatile movement and intricate designs.

The number of flutes on a CNC router tool refers to the cutting edges present on the tool. Commonly, tools have 1, 2, or 3 flutes, with each configuration offering distinct advantages:

Single-Flute Tools: Ideal for softer materials like plastics or aluminum, as they provide ample chip clearance and prevent clogging.

Two-Flute Tools: Provide a balance between chip clearance and cutting speed, making them suitable for a wide range of materials.

Three or More Flutes: Designed for harder materials or applications requiring a smoother surface finish, as they provide more cutting edges per rotation.

Flat End Mill (Square End Mill): Has a flat cutting edge with sharp corners.

Ball Nose End Mill : Features a rounded tip for smooth, contoured cutting.

Tapered End Mill :Tapers down towards the tip, combining the features of ball nose and flat end mills.

In a CNC router, a collet is a cylindrical sleeve used to hold the cutting tool securely in place within the spindle. It plays a critical role in ensuring precision and stability during machining operations.

we fixed the flute in collet and used the fout flute tool cutter for our assignments

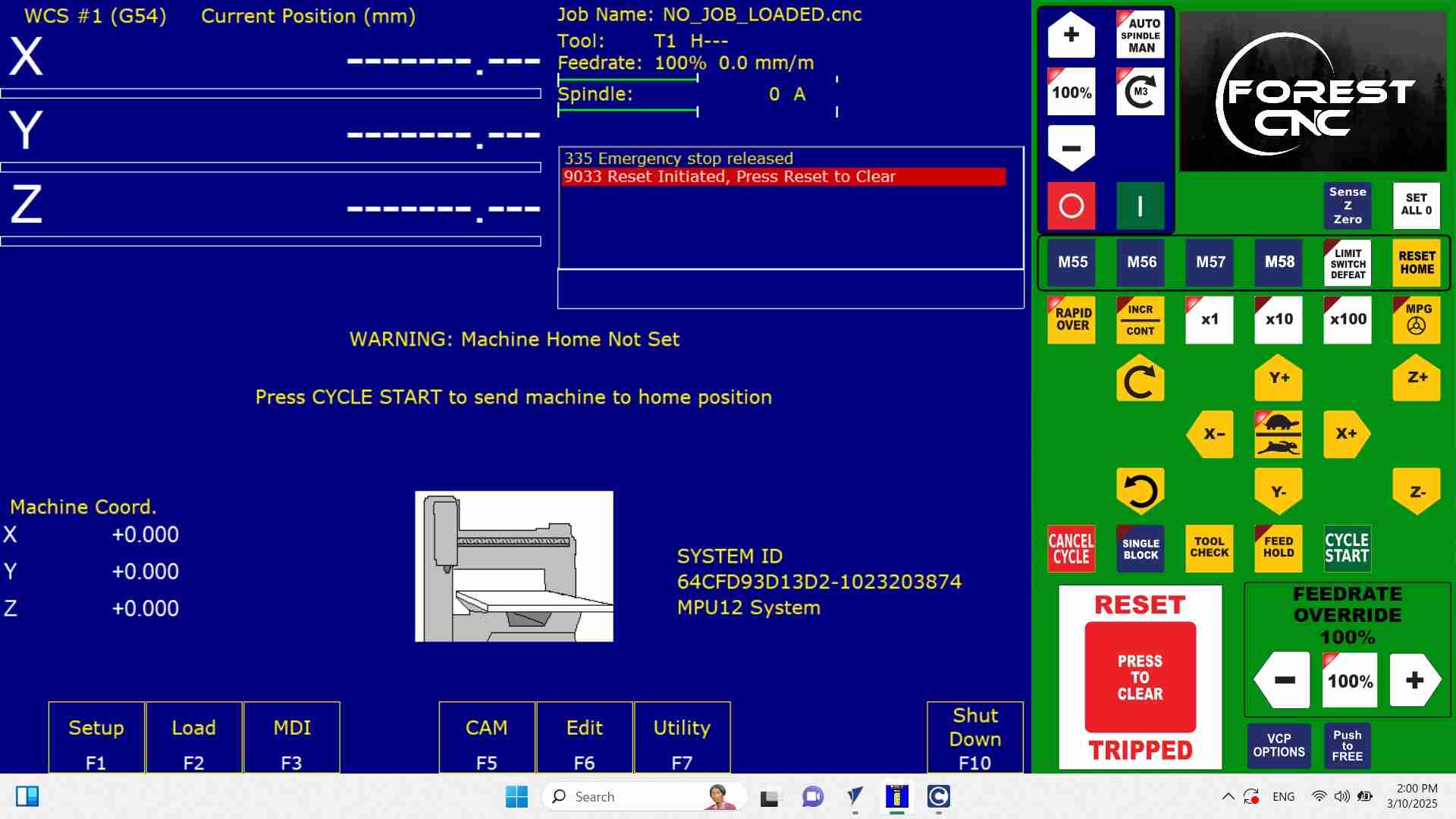

CNC routers are equipped with various protection instruments to ensure the safety of the machine, the operator, and the workpiece. Here are some key protection mechanisms commonly found in CNC routers:

Emergency Stop Button: Purpose: Allows the operator to instantly stop the machine in case of an emergency. Location: Positioned prominently on the machine for easy access.

Limit Switches: Purpose: Prevent the machine from exceeding its designated working area by stopping the motion at the axis limits.

Coolant Flow Monitoring: Ensures proper coolant flow to the cutting area, preventing overheating of tools and workpieces.

Understanding forest cnc router software to operate the machine for cutting plywood

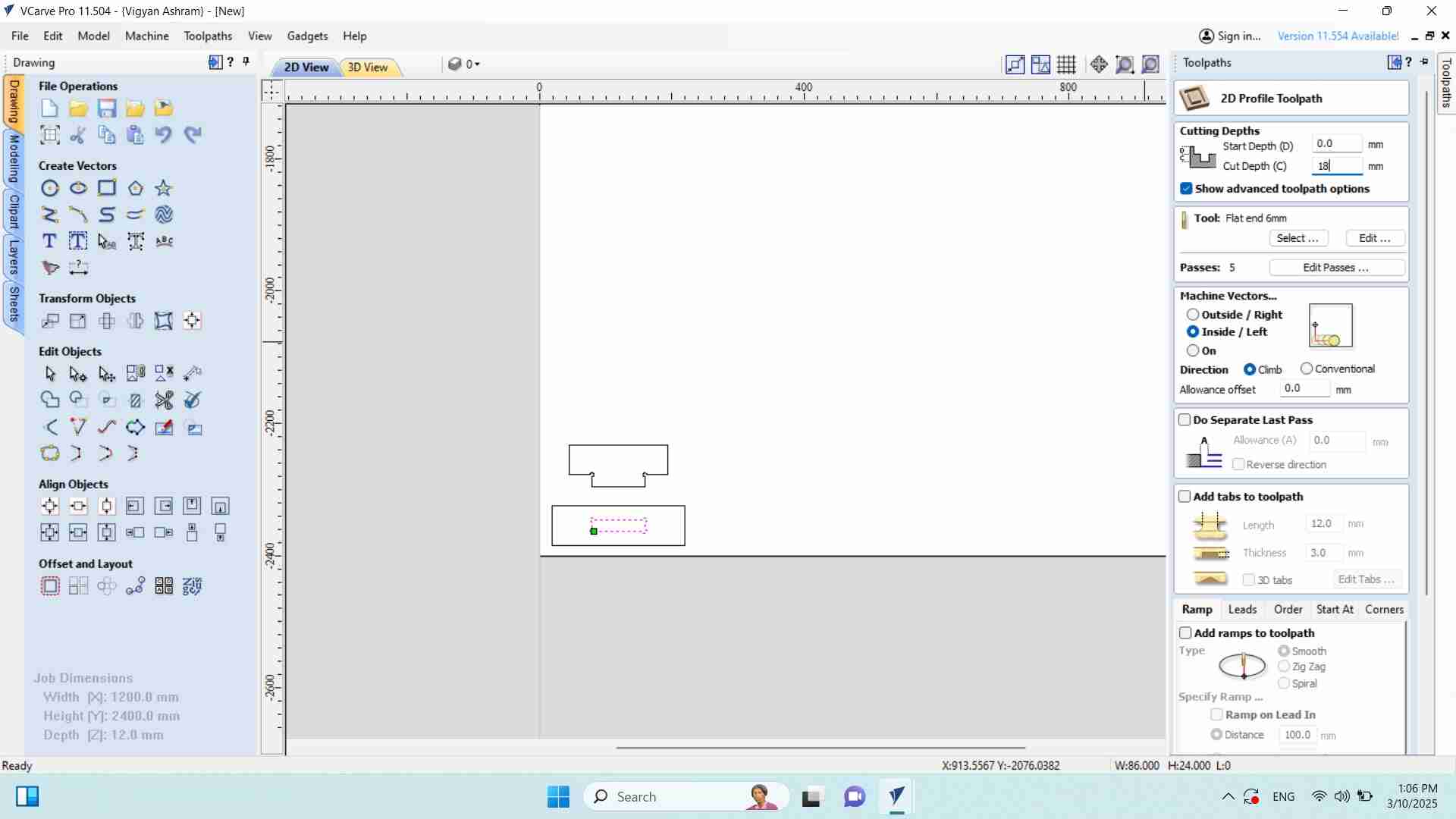

Assign the appropriate tools (e.g., end mills, V-bits) and set the cutting parameters (feed rate, spindle speed, depth of cut). we set the default feed rate of 100% and spindle speed 100% and cutting depth of 18mm

Seeting of home origing and Set origin in CNC router

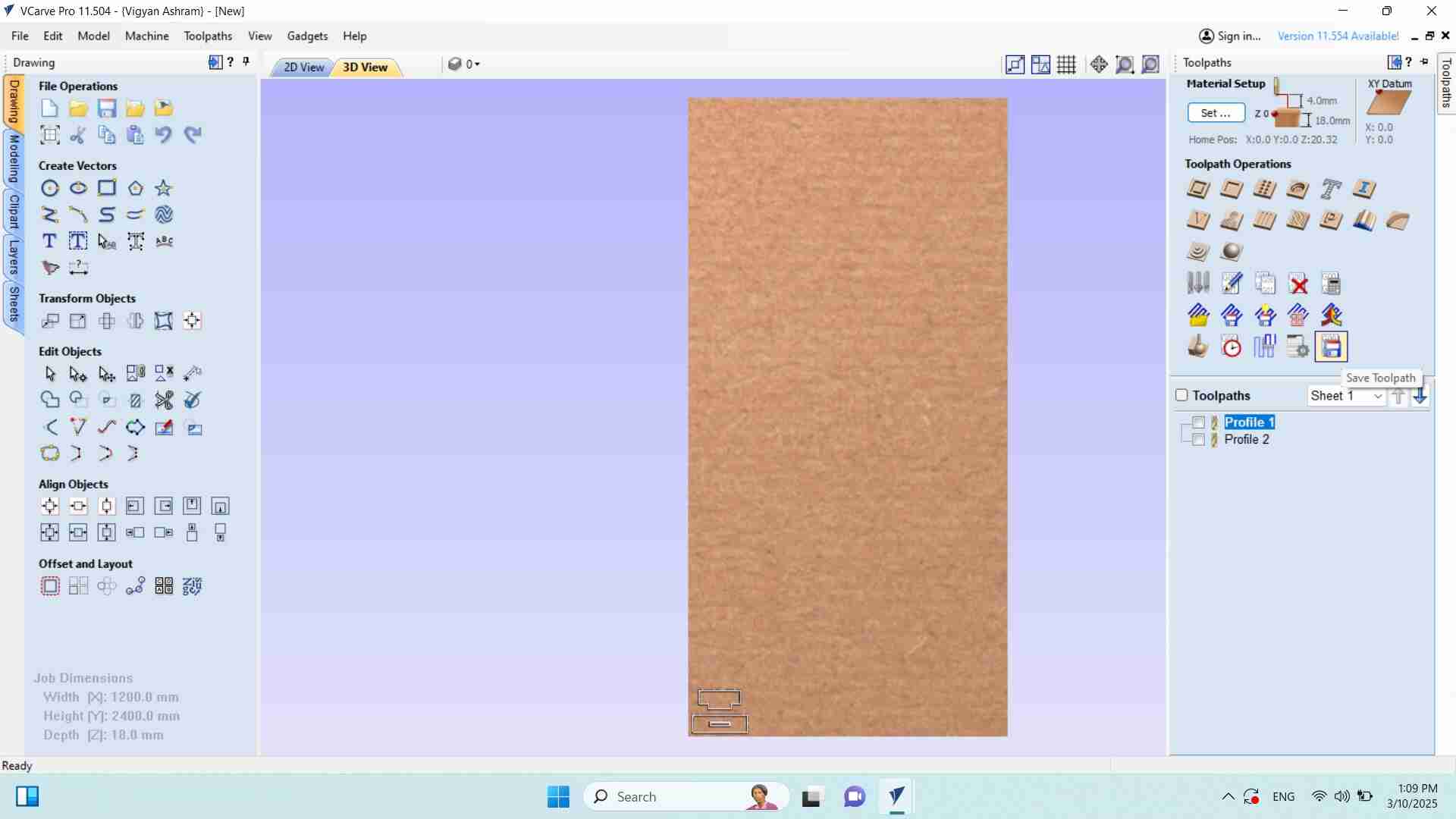

Solidworks 3d files is converted ---> .dxf file ---> uploaded in vcare pro ---> convert to .cnc format for uploading in Forest CNC machine

Profile for outcut layer is smulated and saved according to choosen size with width of 18mm

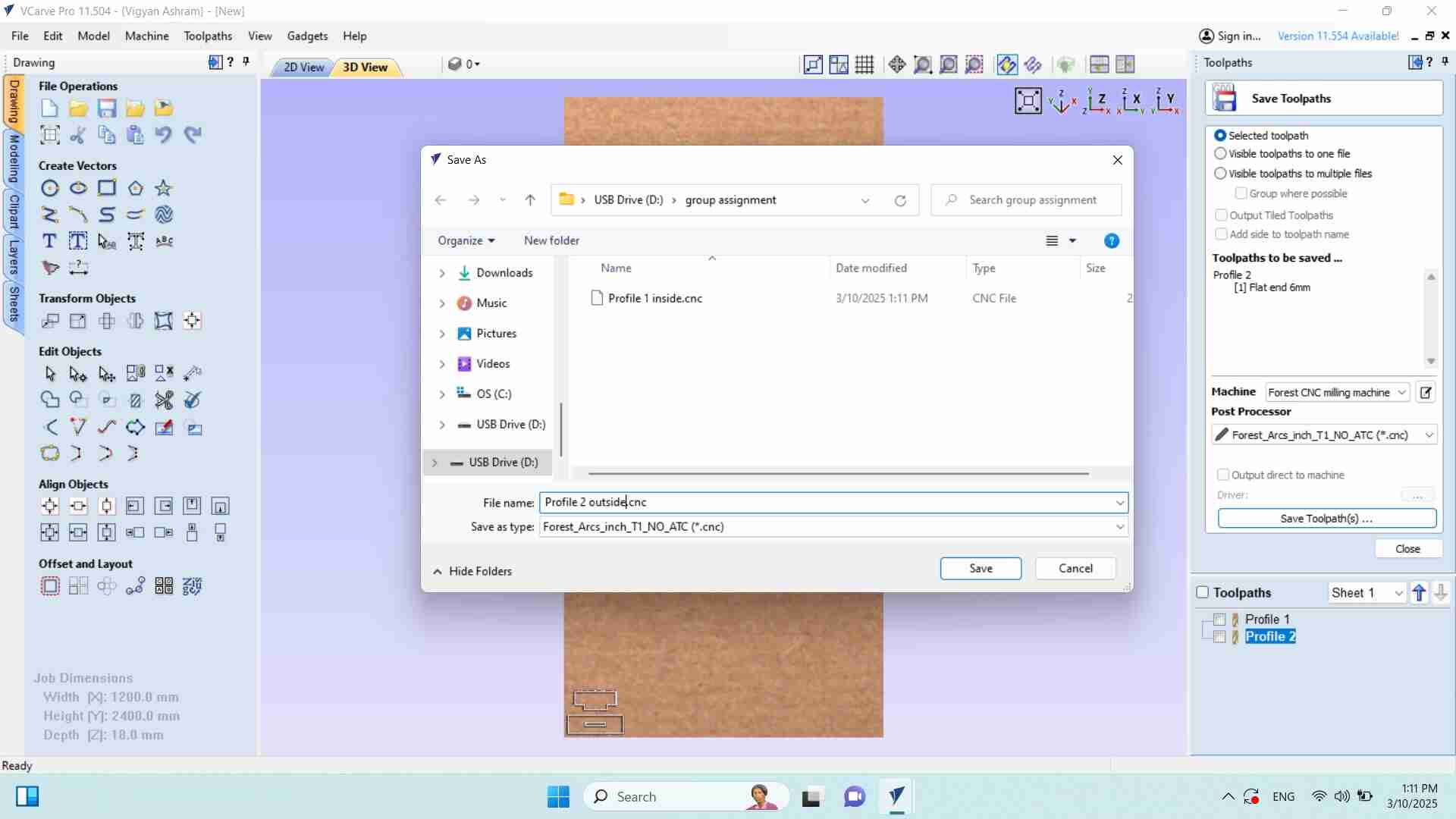

Profile for out layer is smulated and saved according to choosen size with width of 18mm

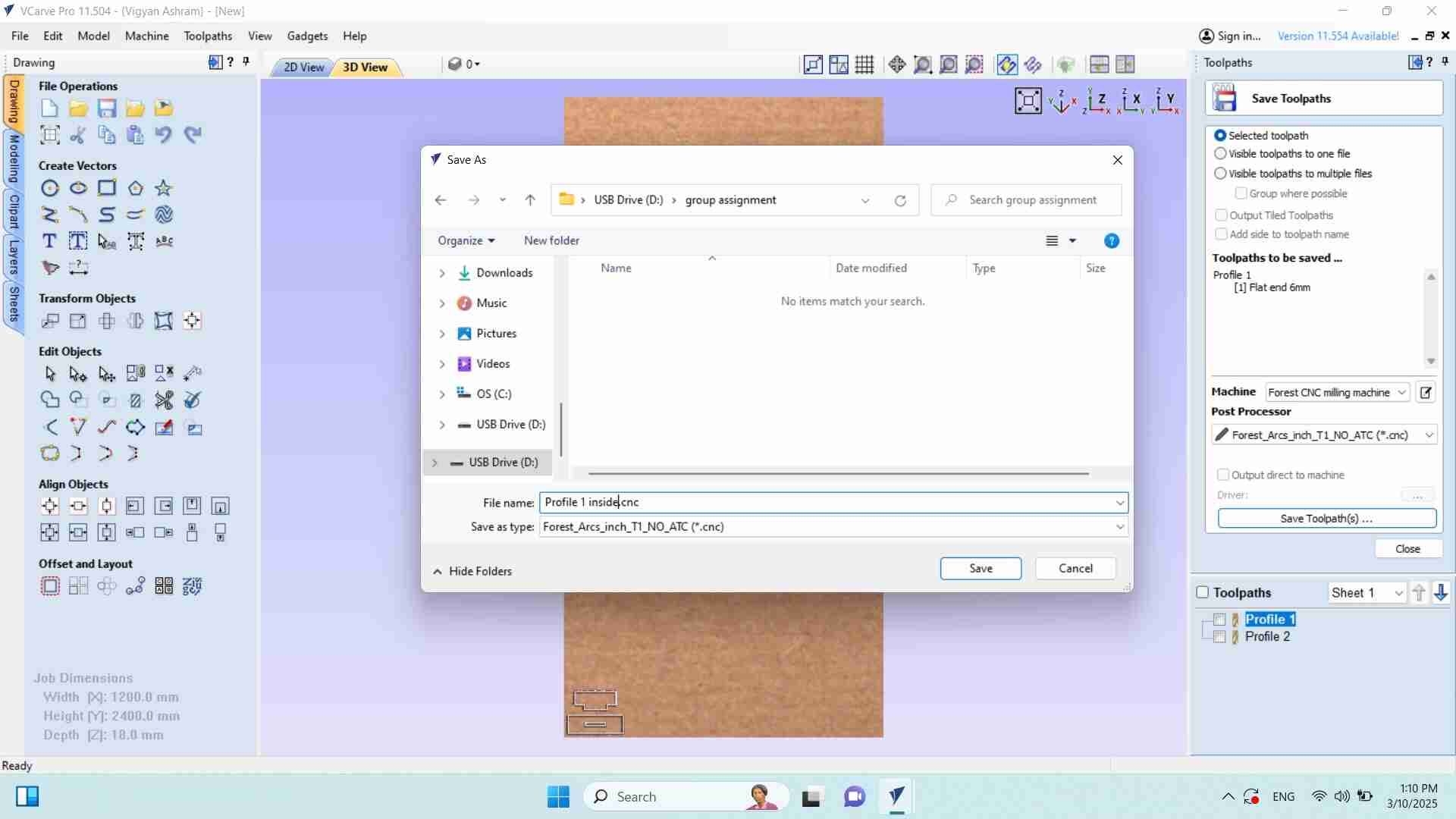

Profile for inside cut layer is smulated and saved according to choosen size with width of 18mm

Using tool path option to export the profile to cnc machine

Tool Path file for uploading in CNC Router machine

Uploaded the .cnc file in machine for cutting the plywood

Assigned 4 flute end mill with a 6 mm collet and set the default feed rate of 100% and spindle speed 100% and cutting depth of 18mm

After Cutting of shapes

Measurement incut and outcut thickness and width using vernier scale

Group Assignment file for undesrtadning the machine cutting and evaluation

At the time of uploading of cnc file to the machine

CNC Router Machine Cutting

Mistakes done in origin setting

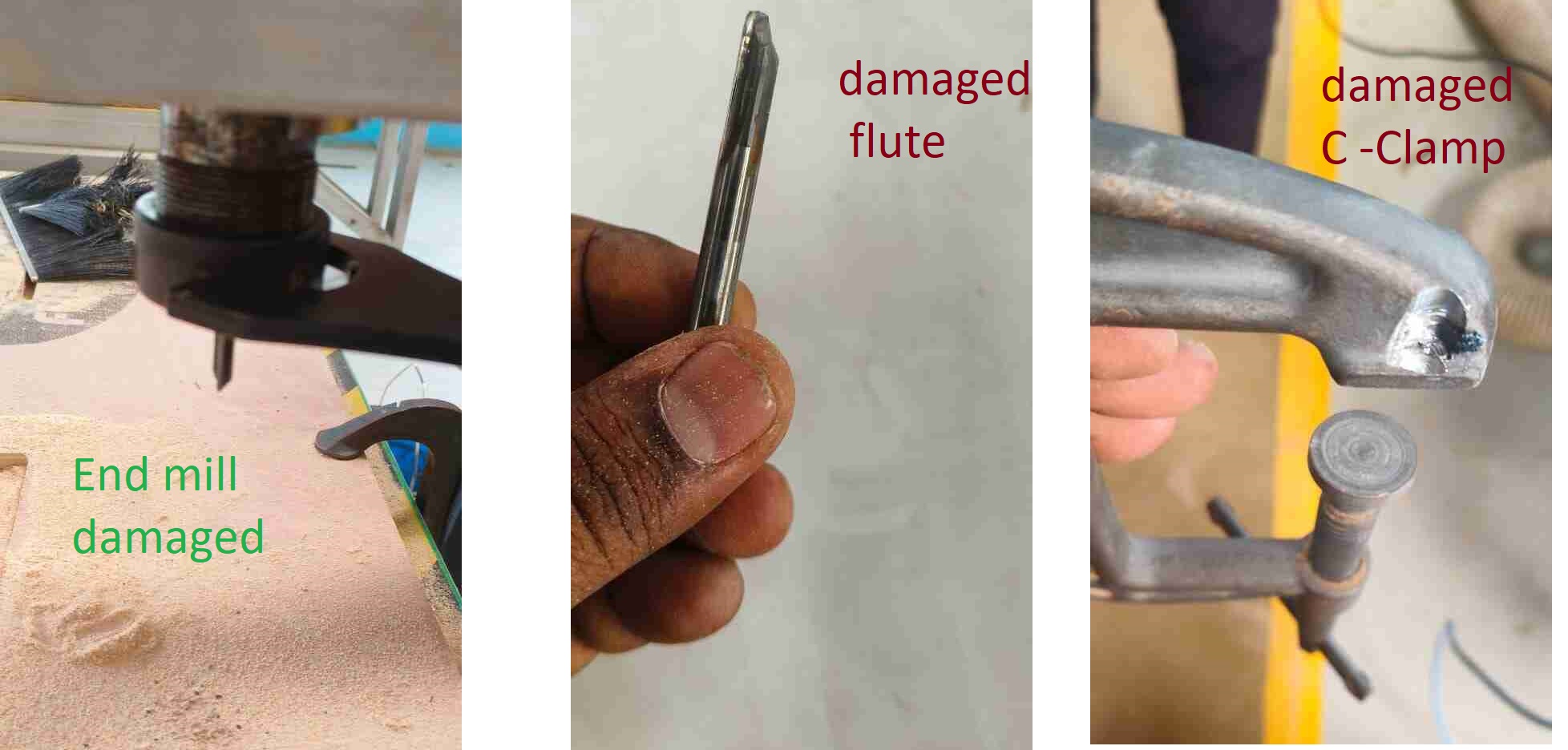

While cutting the assignment, our pc went to sleep mode unexpectedly, suddenly machine get stopped. After that again initiated the operation by setting the origin, end mill moved in different directions, unexpectedly, without expecting anythingm it hits the C-clamp and flute get damaged, fire sparkle is generated , immediately , kadam sir hit the emergnecy stop button to stop the machine, after that checked the flute and replaced the four face flute in the collet

😀 Learned to understand how to use the CNC Wood Router Machines 😀

😀 Understand the Collet size for holding flute and flute faces for cutting 😀

😀 real experience happen with end mill damages 😀

😀 Thanks to Vigyan Ashram and Instructor Mr.Akash Mhais for providing support 😀