Week 7

Assignment: Computer-Controlled Machining

Group assignment

The Link of Group assignments.

Individual assignment

- make (design+mill+assemble) something big (~meter-scale)

- extra credit: don't use fasteners or glue

- extra credit: include curved surfaces

Introduction

For this week’s assignment on Computer-Controlled Machining, I chose to design and fabricate an African Birth Chair. I selected this project because it combines cultural significance with practical functionality. The chair is traditionally used during childbirth, symbolizing support and strength. I wanted to explore large-scale CNC machining while also creating a meaningful and usable object that reflects craftsmanship and tradition.

CAD File

I designed the structure in SolidWorks, focusing on a simple yet strong interlocking system. The design includes two main parts that intersect at 90°, forming a cross-locking structure without the need for glue or screws.

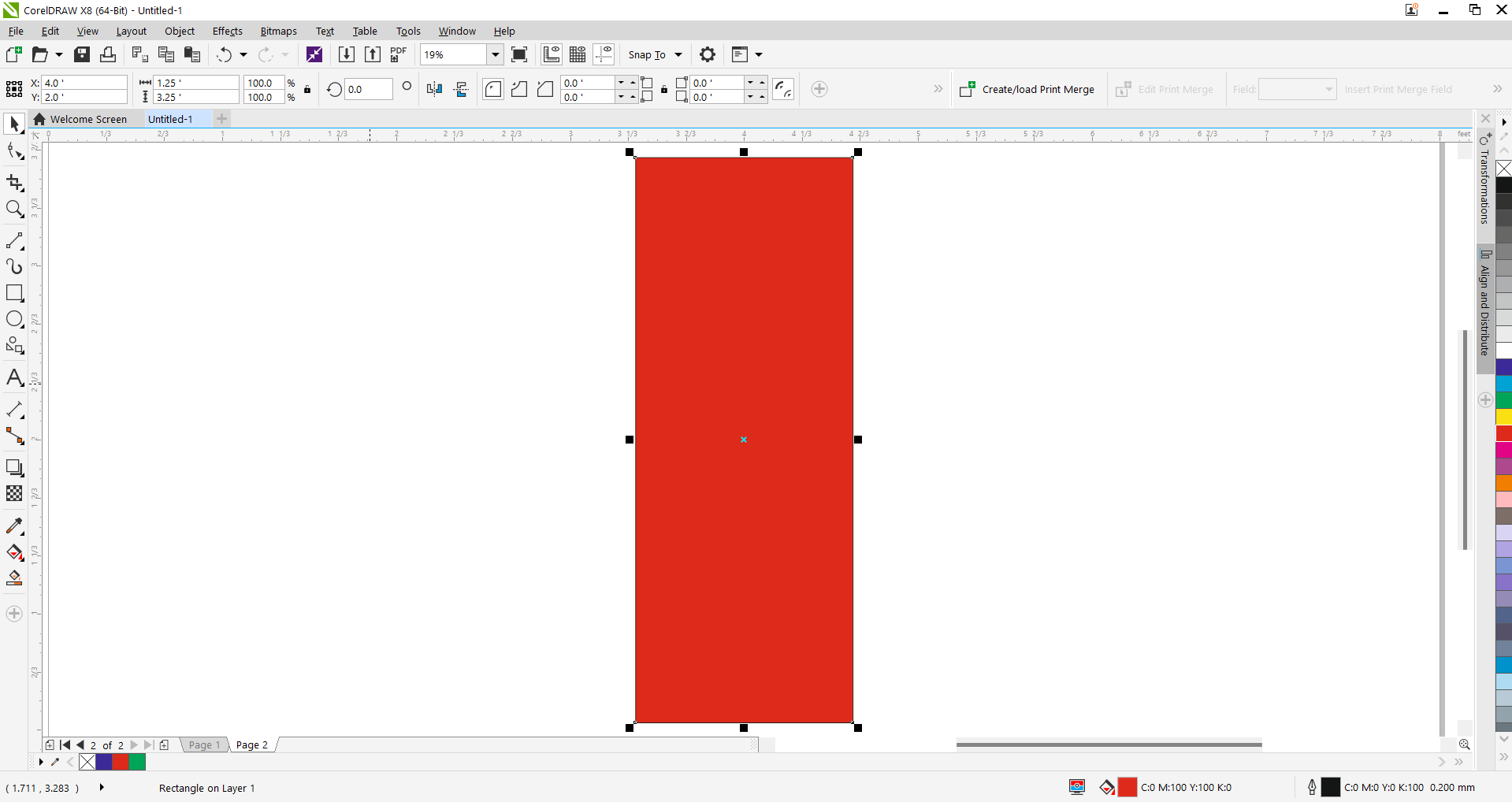

Step 1 - Initial Base Design:

Started with a basic vertical rectangle in CorelDRAW, forming the foundation of the chair's side panel.

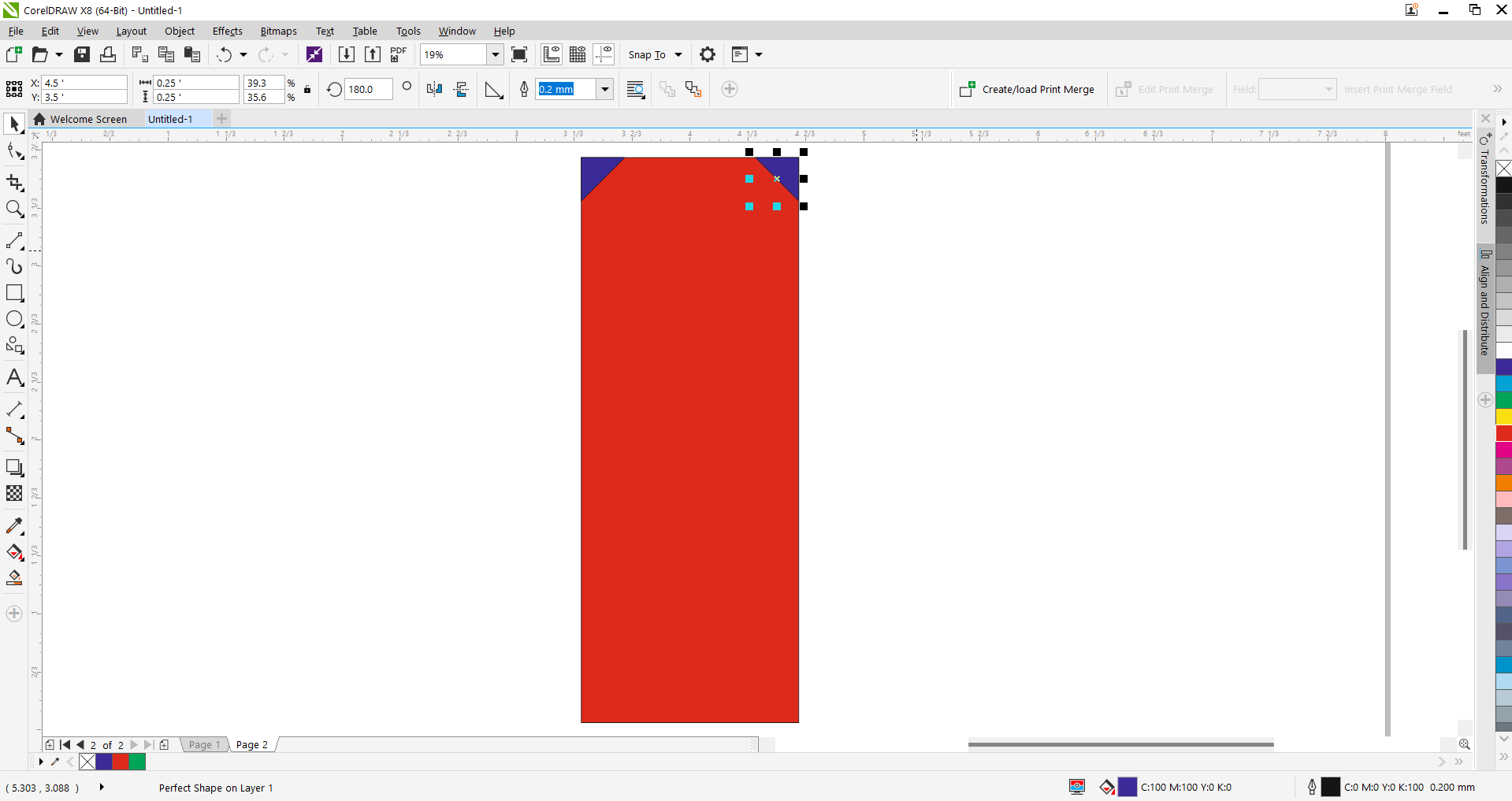

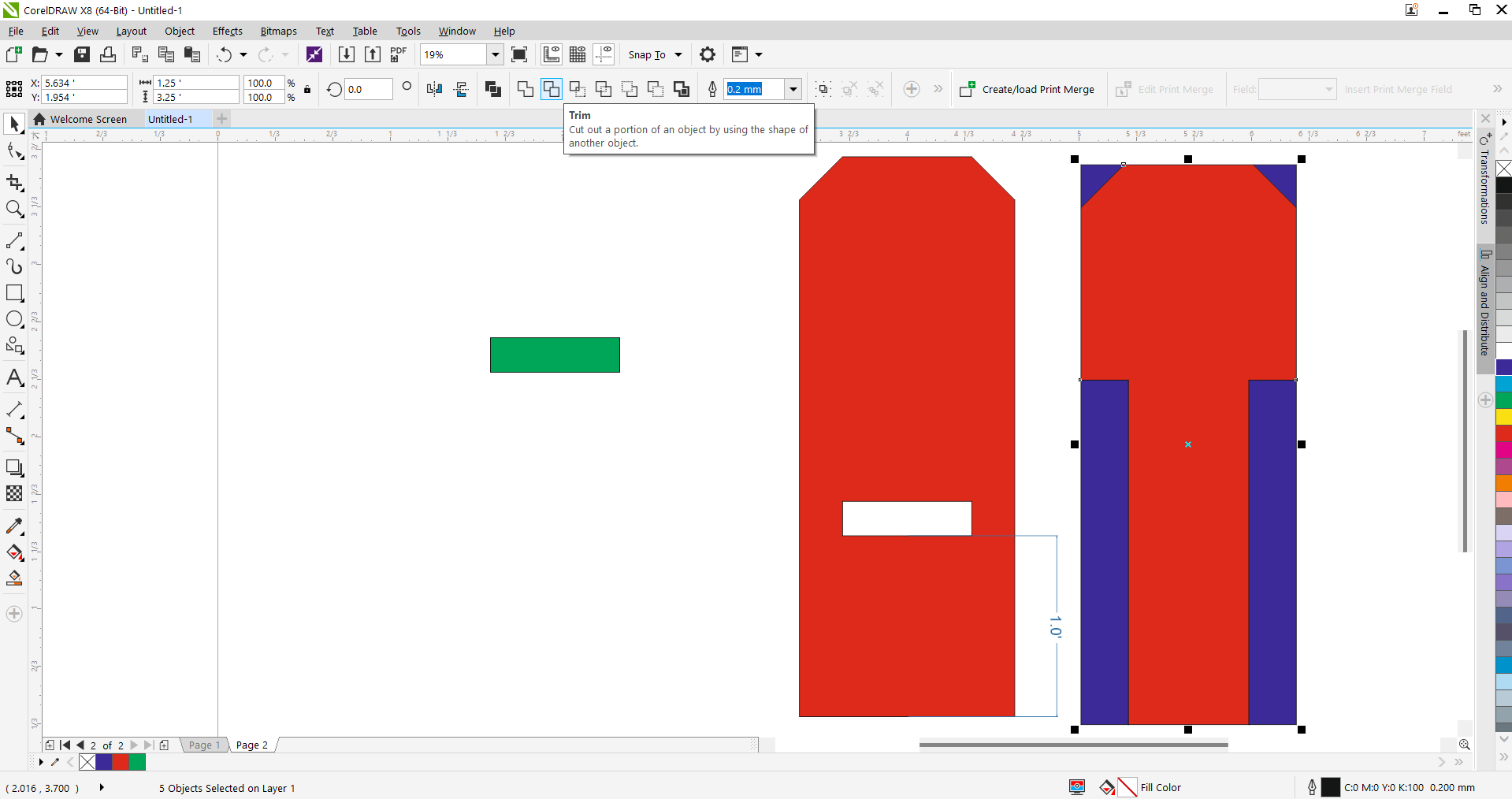

Step 2 - Corner Trimming Setup:

Placed triangle shapes at the top corners to trim the edges and add a stylized chamfer effect to the backrest.

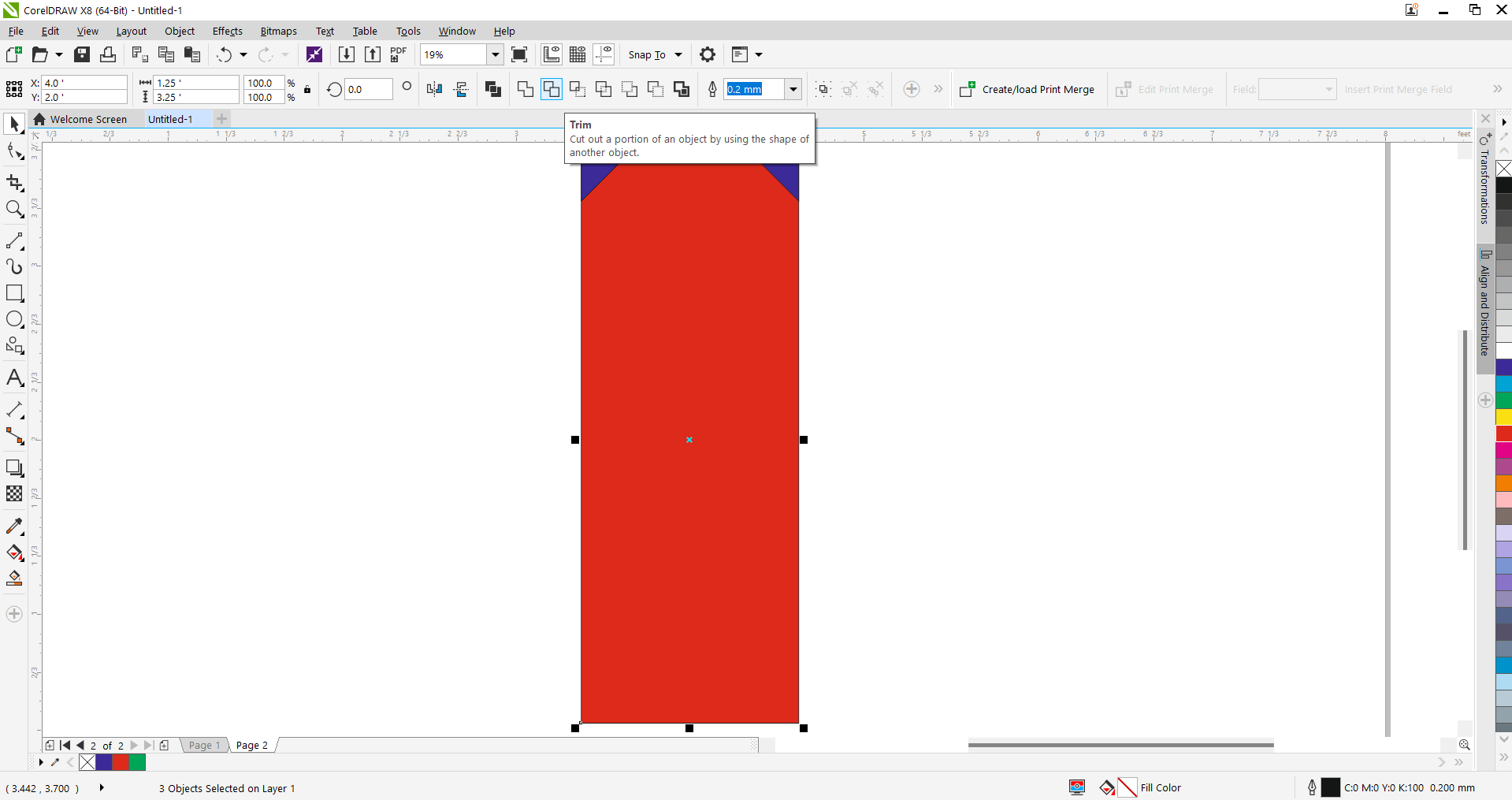

Step 3 - Applying the Trim Tool:

Used CorelDRAW’s Trim feature to cut the corner triangles from the main rectangle, shaping the backrest profile.

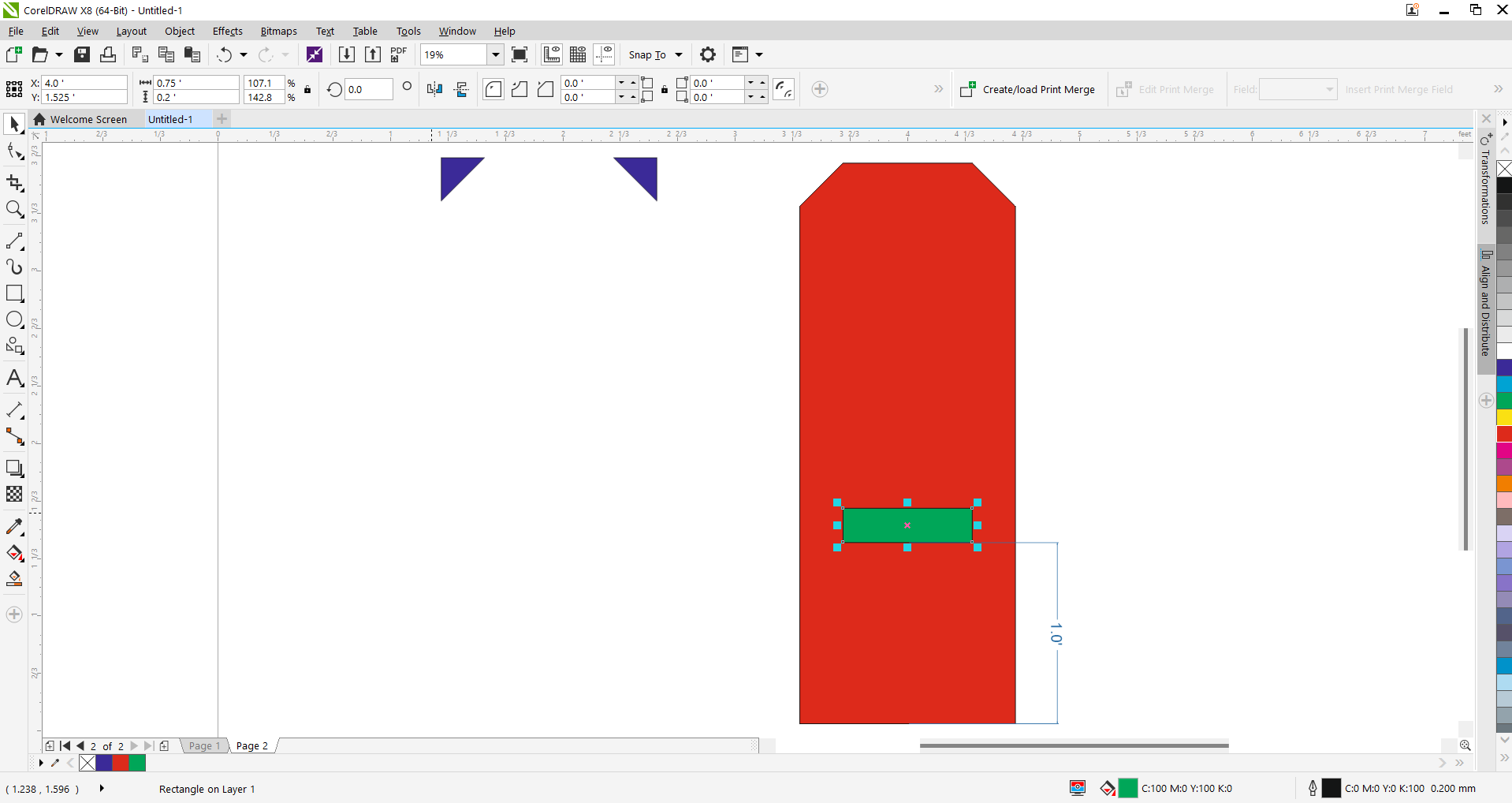

Step 4 - Slot Rectangle Design:

Inserted a small green rectangle to act as the seating slot in the side panel of the chair for fitting the seat.

Step 5 - Full Part Layout:

Duplicated the design and created additional parts including connectors, seat pieces, and support columns.

Step 6 - Final Fitment & Alignment:

Refined the alignment and spacing of the components. The green parts represent slot-fillers and connectors.

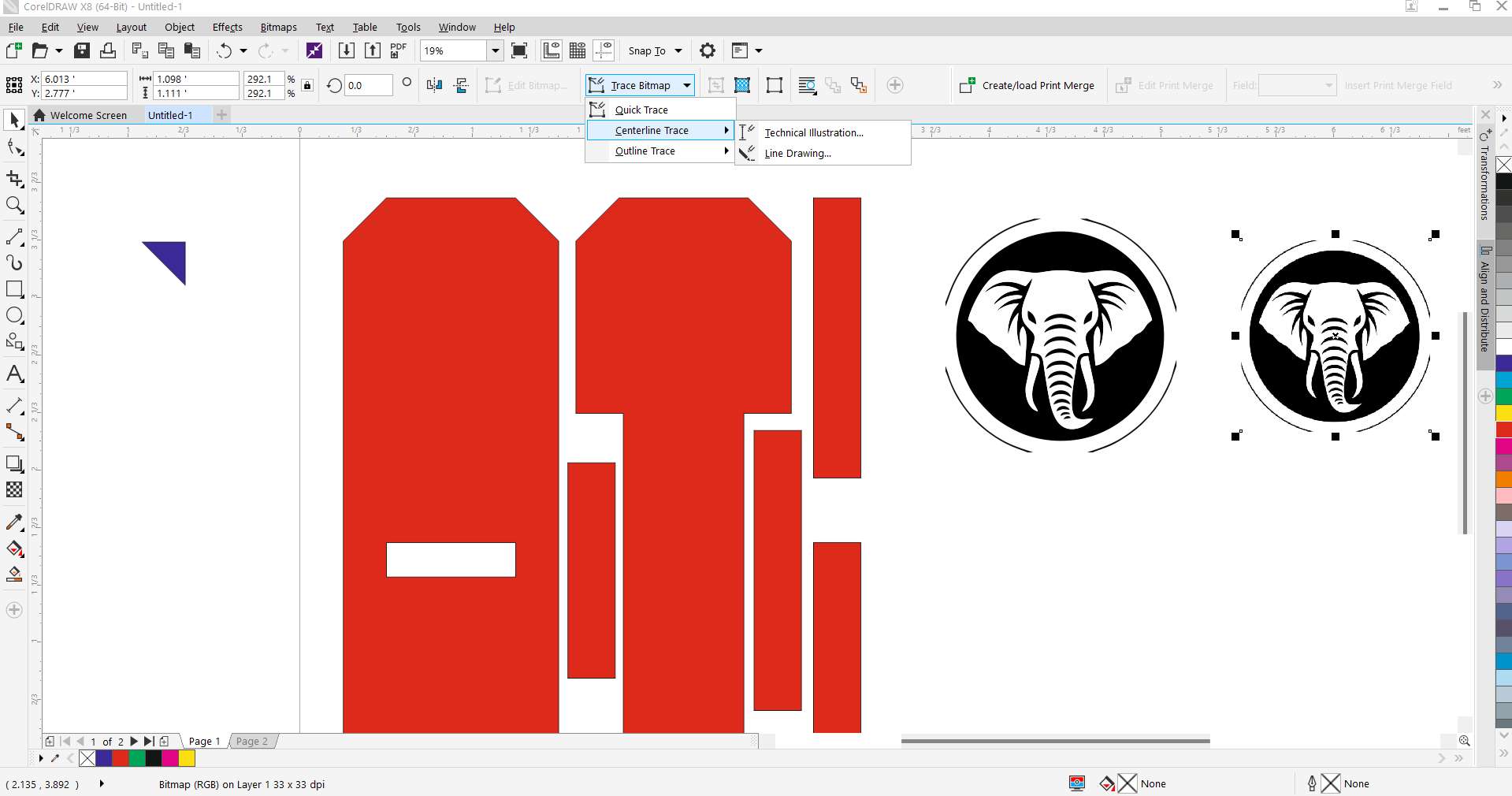

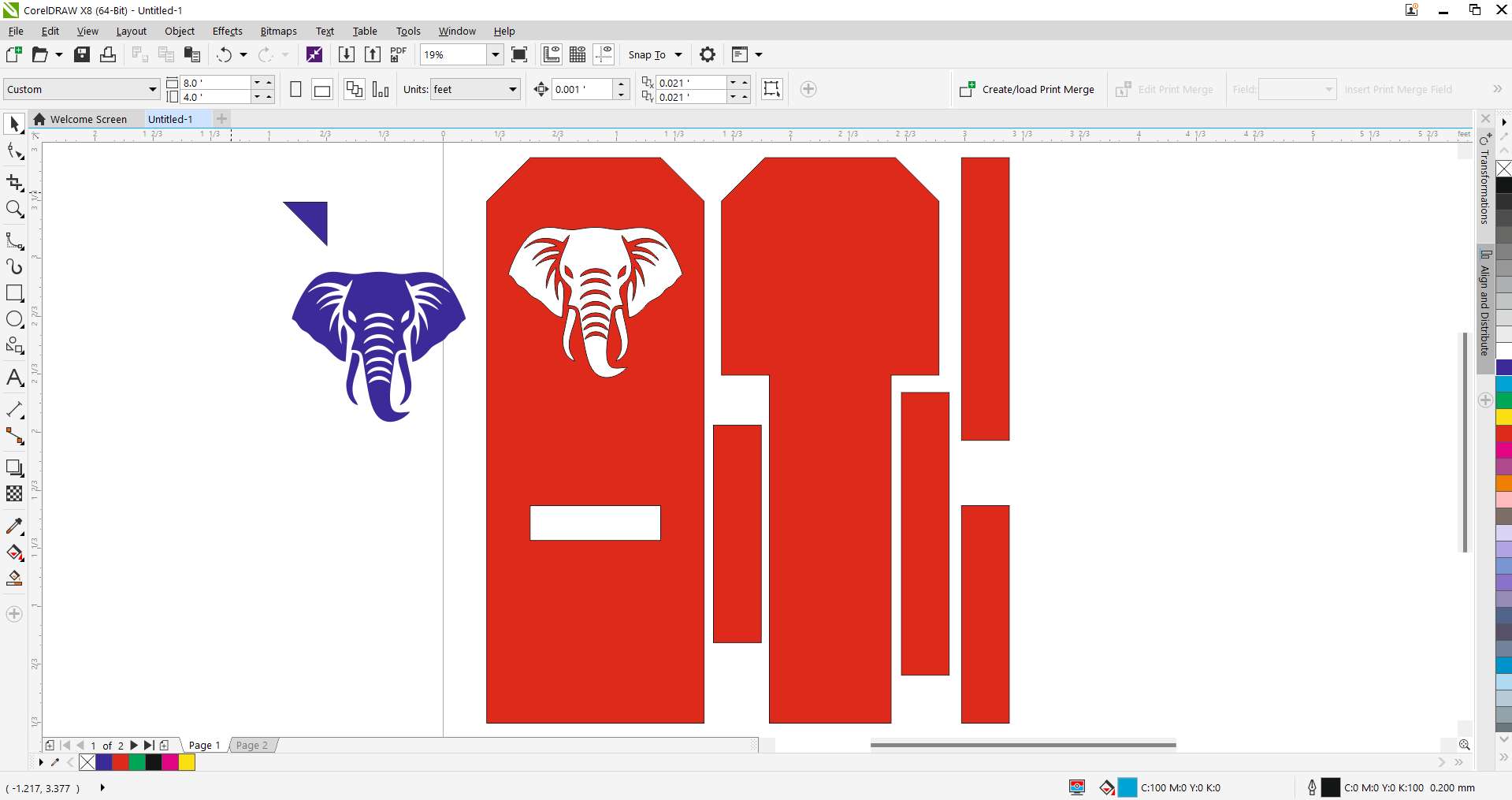

Step 7 - Importing Elephant Artwork:

Imported an elephant head image for engraving. This graphic symbolizes strength and cultural roots.

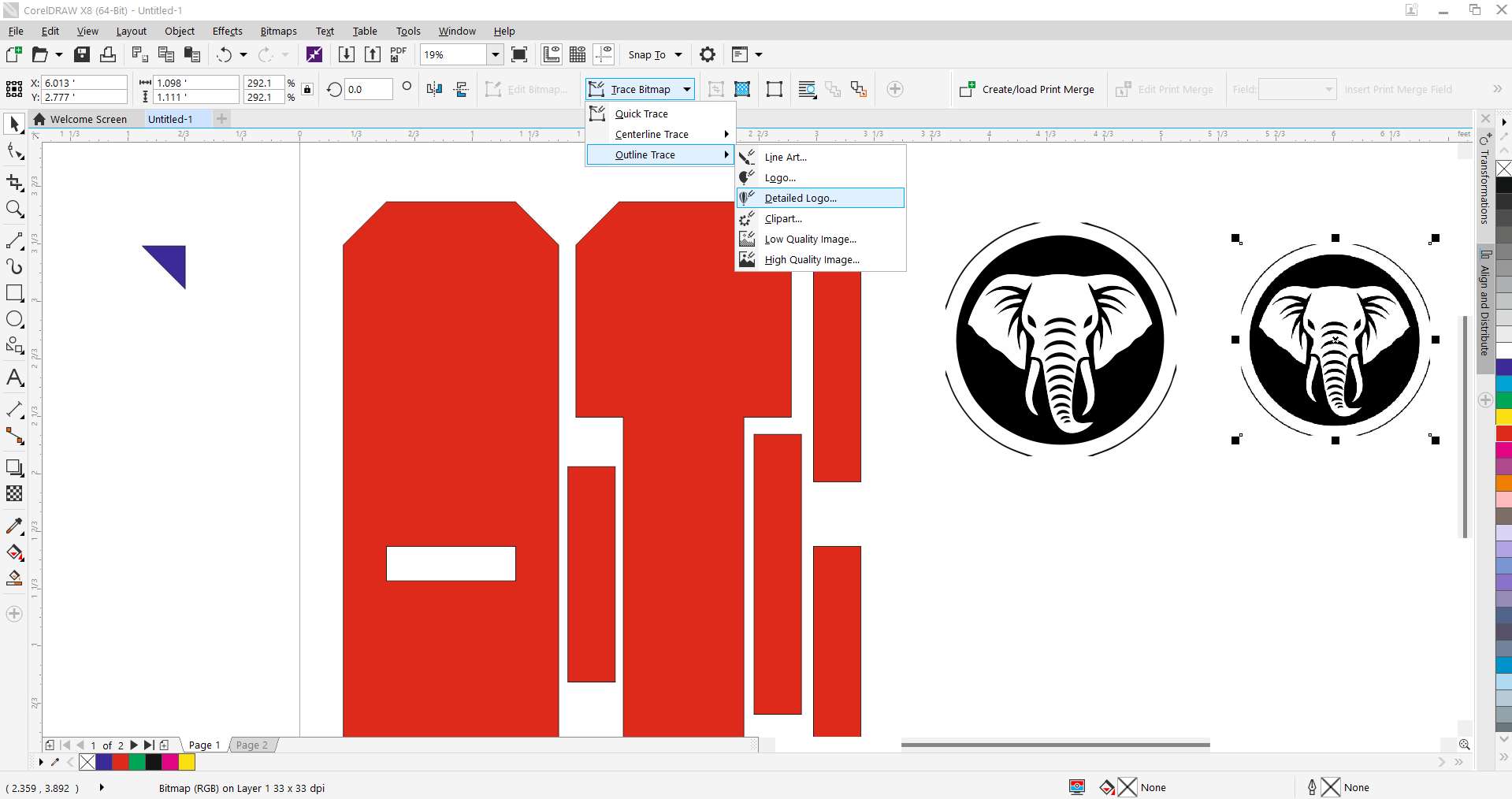

Step 8 - Tracing Bitmap to Vector:

Used the ‘Outline Trace > Detailed Logo’ feature to convert the bitmap image into editable vector lines.

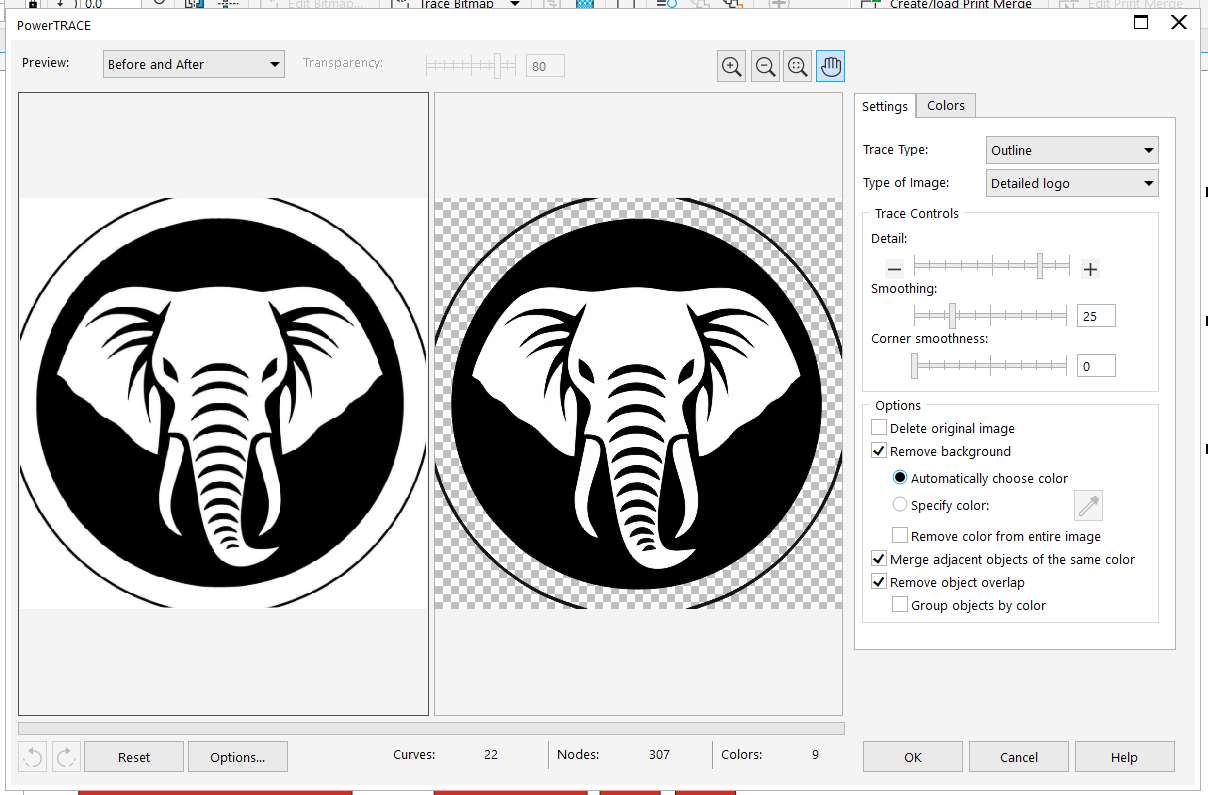

Step 9 - PowerTRACE Cleanup:

Adjusted detail, smoothing, and background removal settings to generate clean vectors from the image.

Step 10 - Final Vector Placement:

Placed the traced elephant head vector onto the backrest. This engraving became the centerpiece of the chair.

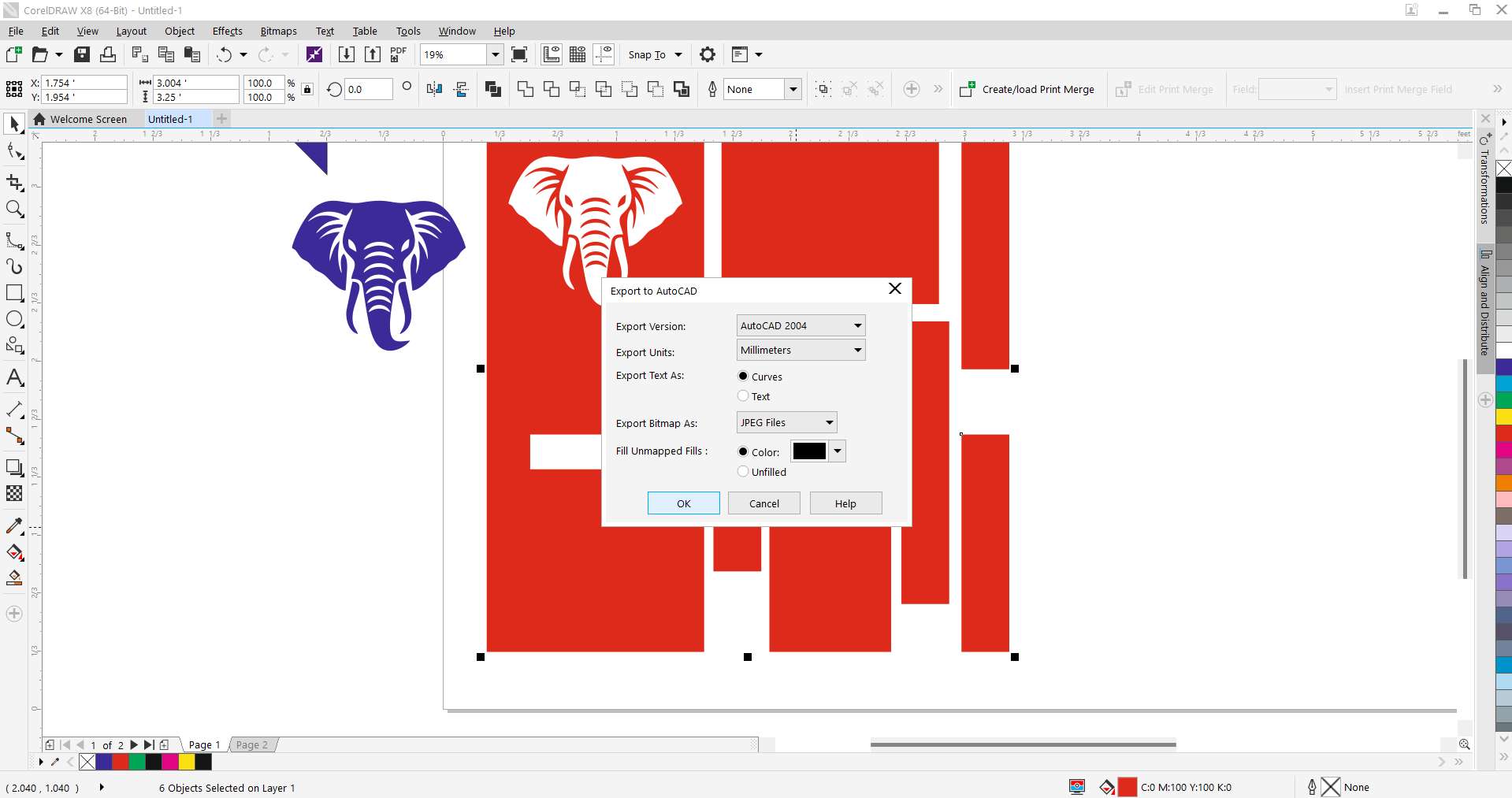

Step 11 - Export to DXF for ArtCAM:

Exported the entire layout as a DXF file with millimeter units to be imported into ArtCAM for toolpath creation.

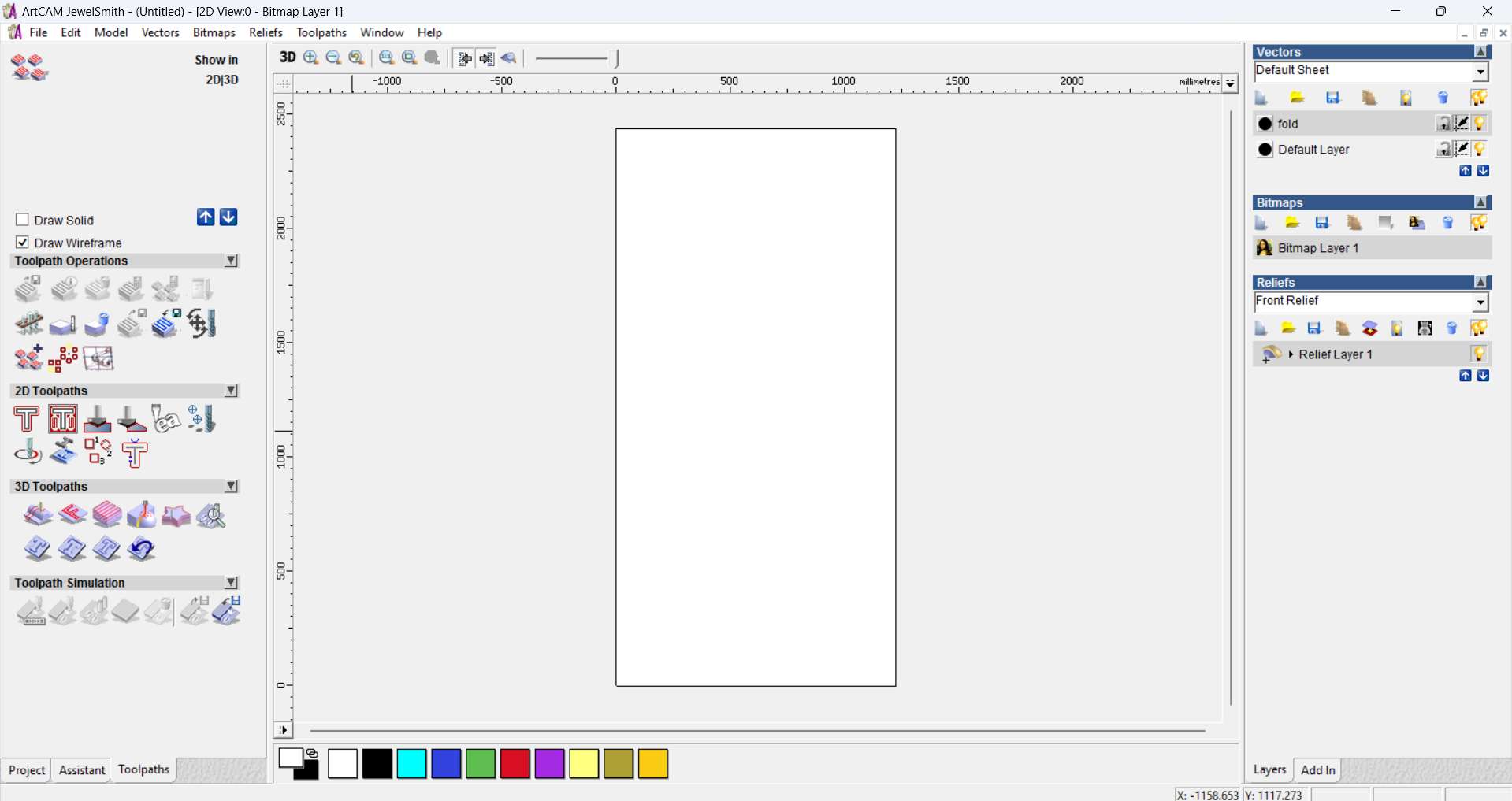

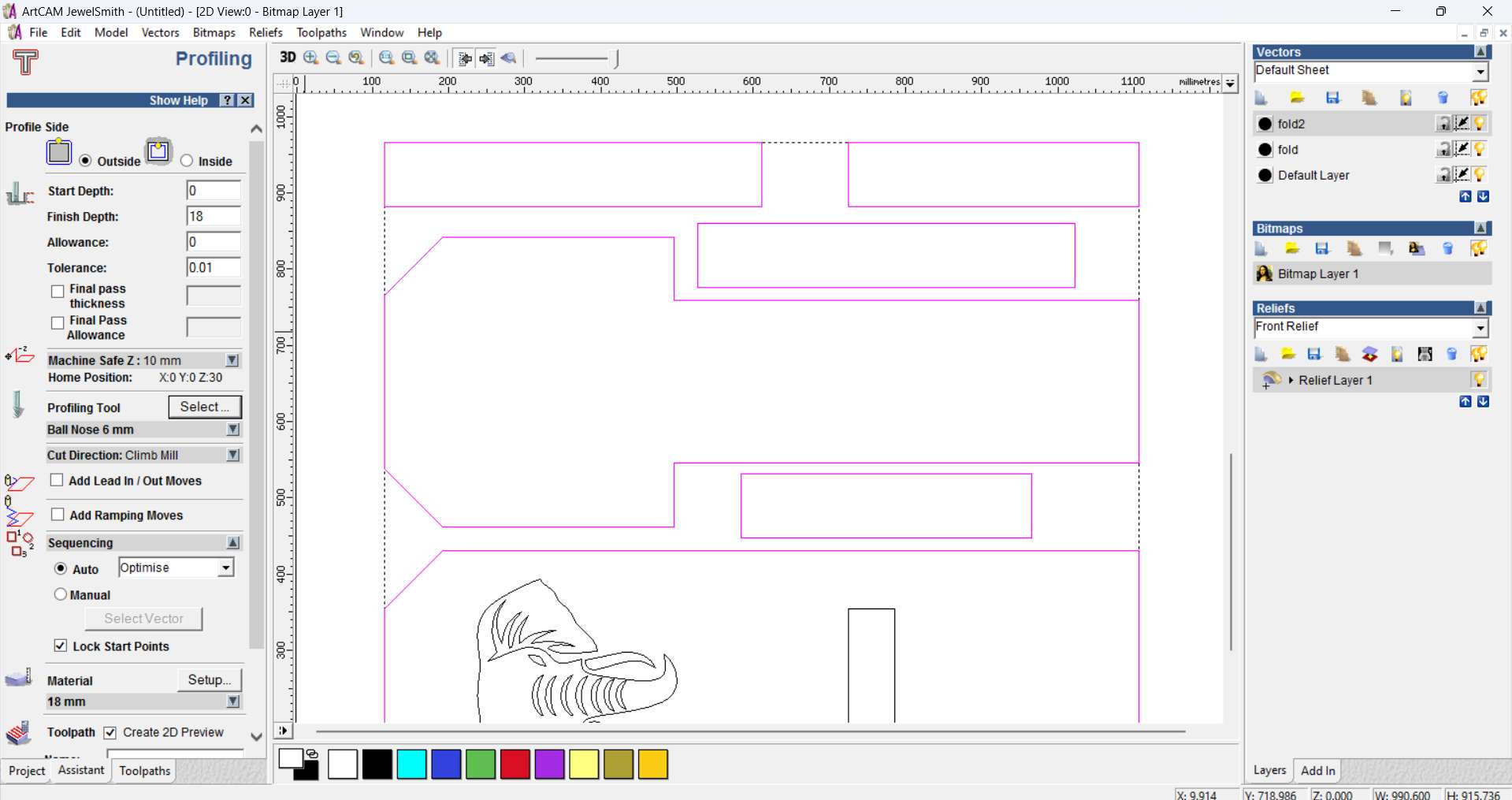

Step 12 - ArtCAM Setup:

Initialized the ArtCAM interface and loaded the DXF layout for 2D and engraving toolpath operations.

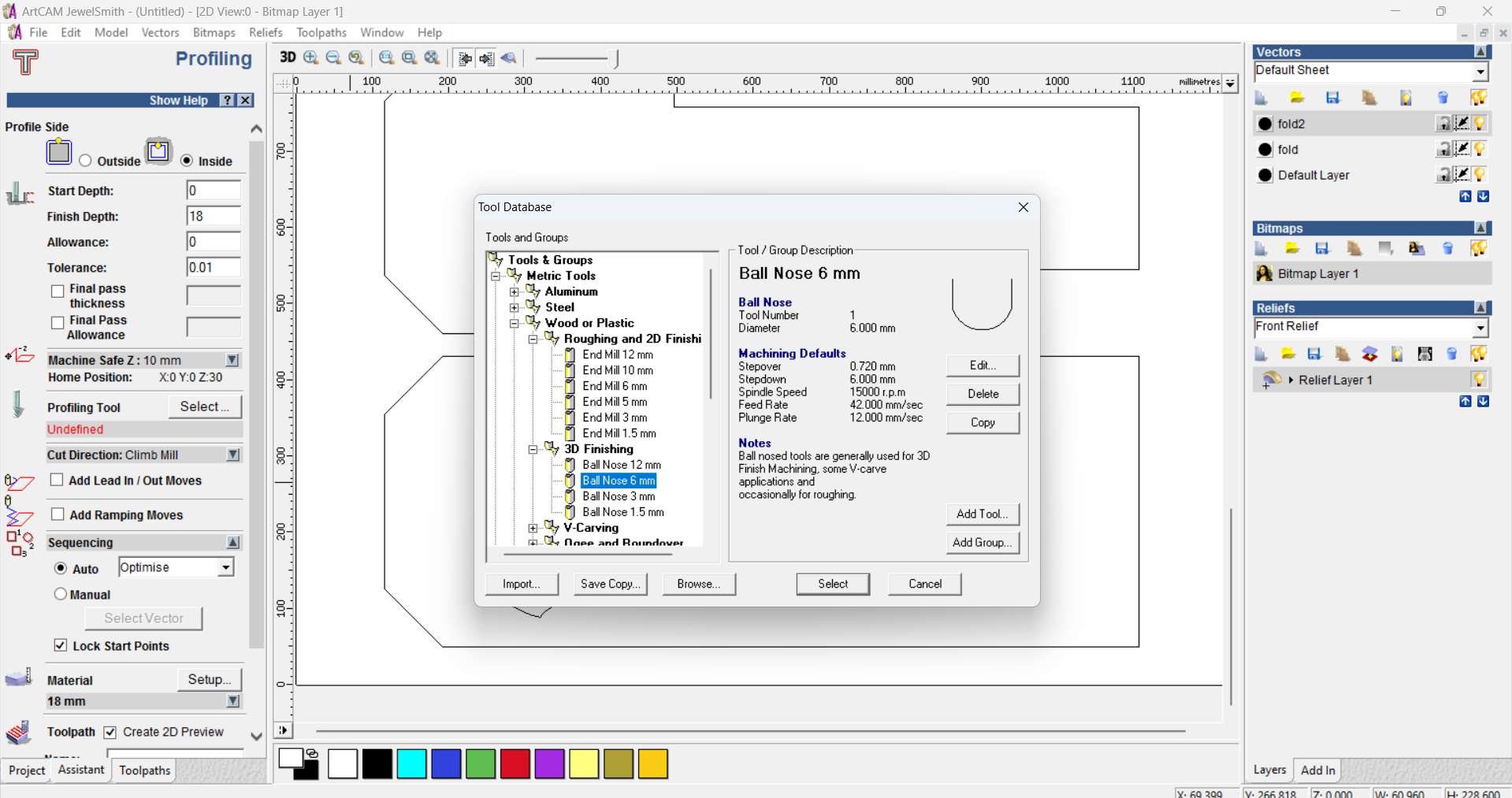

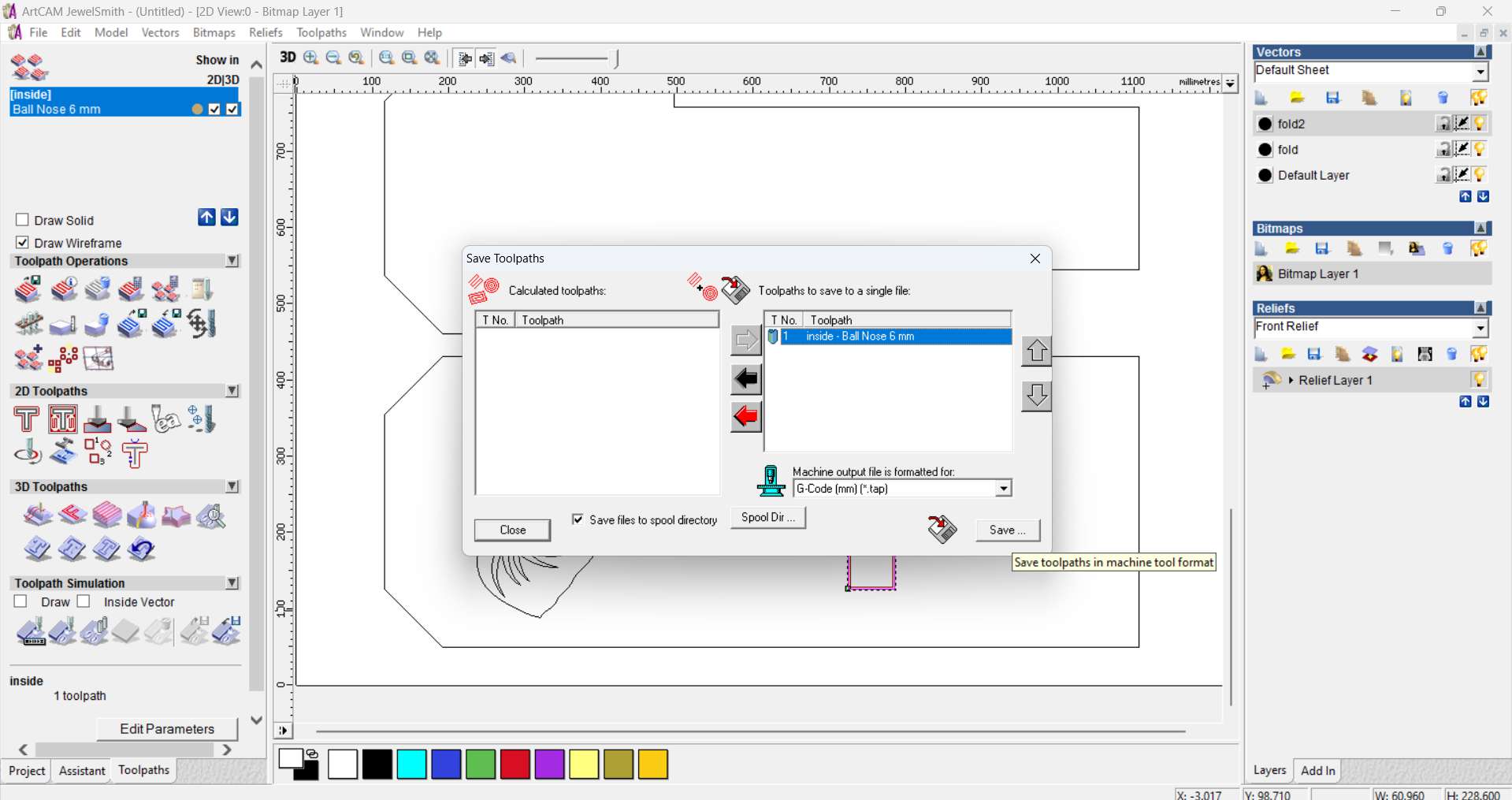

Step 13 - Tool Selection & Parameters:

Selected a 6mm Ball Nose tool with defined stepdown, stepover, and feedrate for both cut and engraving paths.

Step 14 - Saving Profile Toolpath:

Generated and saved the profile cutting path using inside cut method and enabled lead-in/out moves.

Step 15 - Toolpath Preview in ArtCAM:

Previewed the full toolpath outline including the profile cut and the position of the engraved elephant vector.

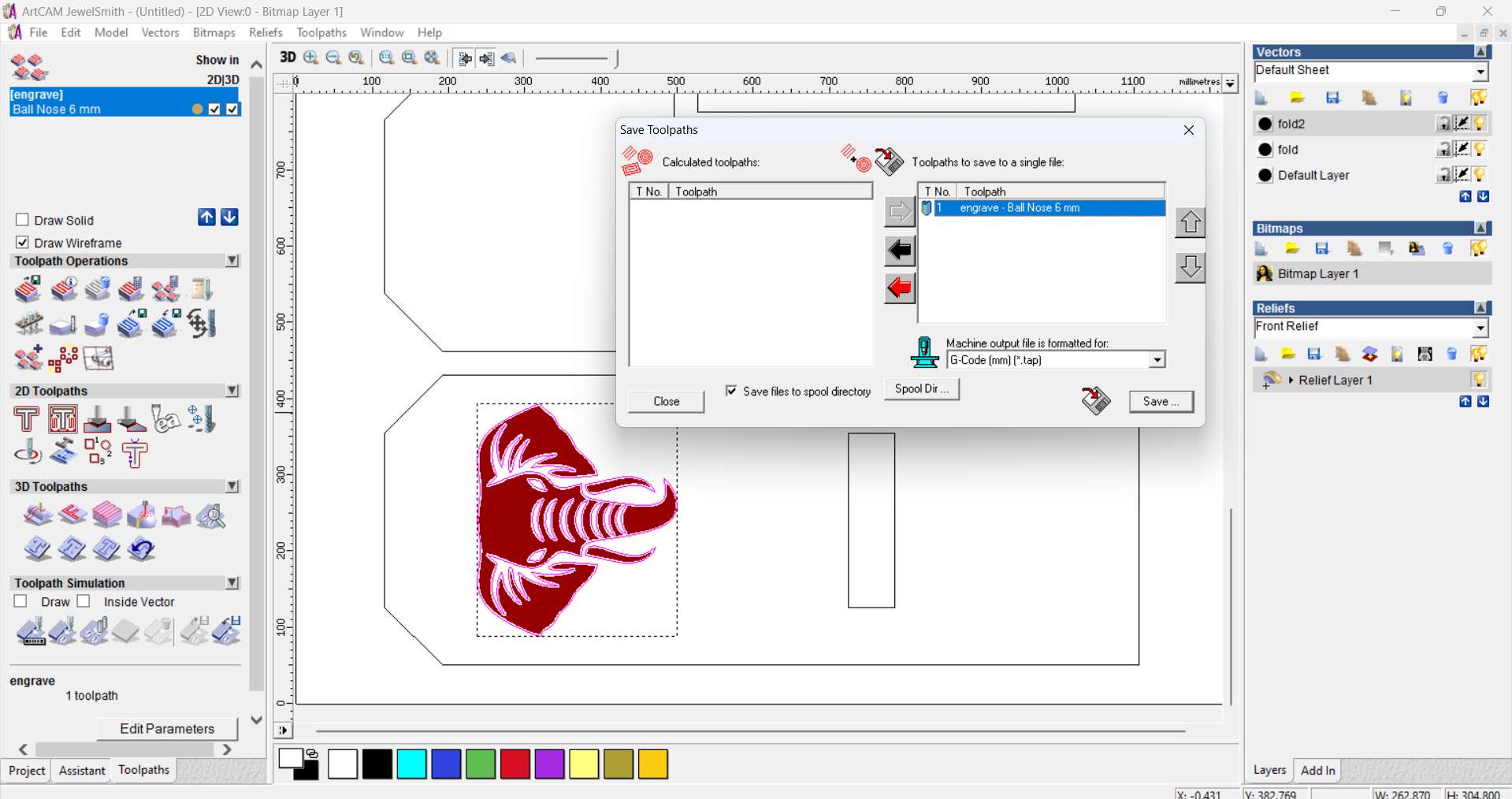

Step 16 - Saving Engraving Path:

Saved a separate G-code toolpath for the elephant head engraving using the same 6mm Ball Nose bit.

Step 17 - Machine Details & Safety Precautions

For this assignment, I used the STM 1325 CNC router, a robust and precise machine suitable for large-format cutting tasks.

Safety Precautions Followed:

PPE Usage: I wore safety goggles, ear plugs, and a dust mask to protect against flying debris, loud noise, and fine dust particles.

Emergency Preparedness: Familiarized myself with the emergency stop button and the main power switch before starting.

Workspace Check: Cleared the work area of any loose tools or obstructions.

Material Clamping: Ensured the plywood sheet was tightly secured to the bed with clamps to prevent movement during cutting.

Bit Safety: Confirmed the correct tool bit was installed and firmly tightened in the spindle.

Step 18 - Machine Setup Steps (STM 1325)

1. Design Preparation:

Created the design in Fusion 360 (or mention your software).

Exported it as a DXF file and imported into ArtCAM for toolpath generation.

2. Material Used:

12mm plywood sheet chosen for its strength and wide availability.

3. Toolpath Creation in ArtCAM:

Generated profile and pocket toolpaths with appropriate depth and clearance.

Added dogbone fillets for joints where necessary.

4. Machine Zeroing:

Set the X, Y, Z zero points at the corner of the material using the machine's control panel.

5. Machining Process:

Monitored the cutting process carefully.

Paused midway to clear dust and check alignment.

6. Post-Cutting Tasks:

Removed the finished parts from the board.

Cleaned up the tabs, sanded edges, and started the assembly process.

Working Image

Step 19 - CNC Milled Components:

Cut plywood parts ready after CNC milling. This includes the backrest, base, seat, and support elements.

Step 20 - Fully Assembled Chair:

Assembled the African Birth Chair with a slot-fit design. The engraved elephant head adds cultural depth.

Step 21 - User Testing:

The final chair was successfully tested by sitting. It proved to be structurally sound and comfortable.

Table of Contents

- 1. Initial Base Design

- 2. Corner Trimming Setup

- 3. Applying the Trim Tool

- 4. Slot Rectangle Design

- 5. Full Part Layout

- 6. Final Fitment & Alignment

- 7. Importing Elephant Artwork

- 8. Tracing Bitmap to Vector

- 9. PowerTRACE Cleanup

- 10. Final Vector Placement

- 11. Export to DXF for ArtCAM

- 12. ArtCAM Setup

- 13. Tool Selection & Parameters

- 14. Saving Profile Toolpath

- 15. Toolpath Preview in ArtCAM

- 16. Saving Engraving Path

- 17. CNC Milled Components

- 18. Fully Assembled Chair

- 19. User Testing