Invention, Intellectual Property and Income

Invention, Intellectual Property and Income

- Develop a plan for dissemination of your final project.

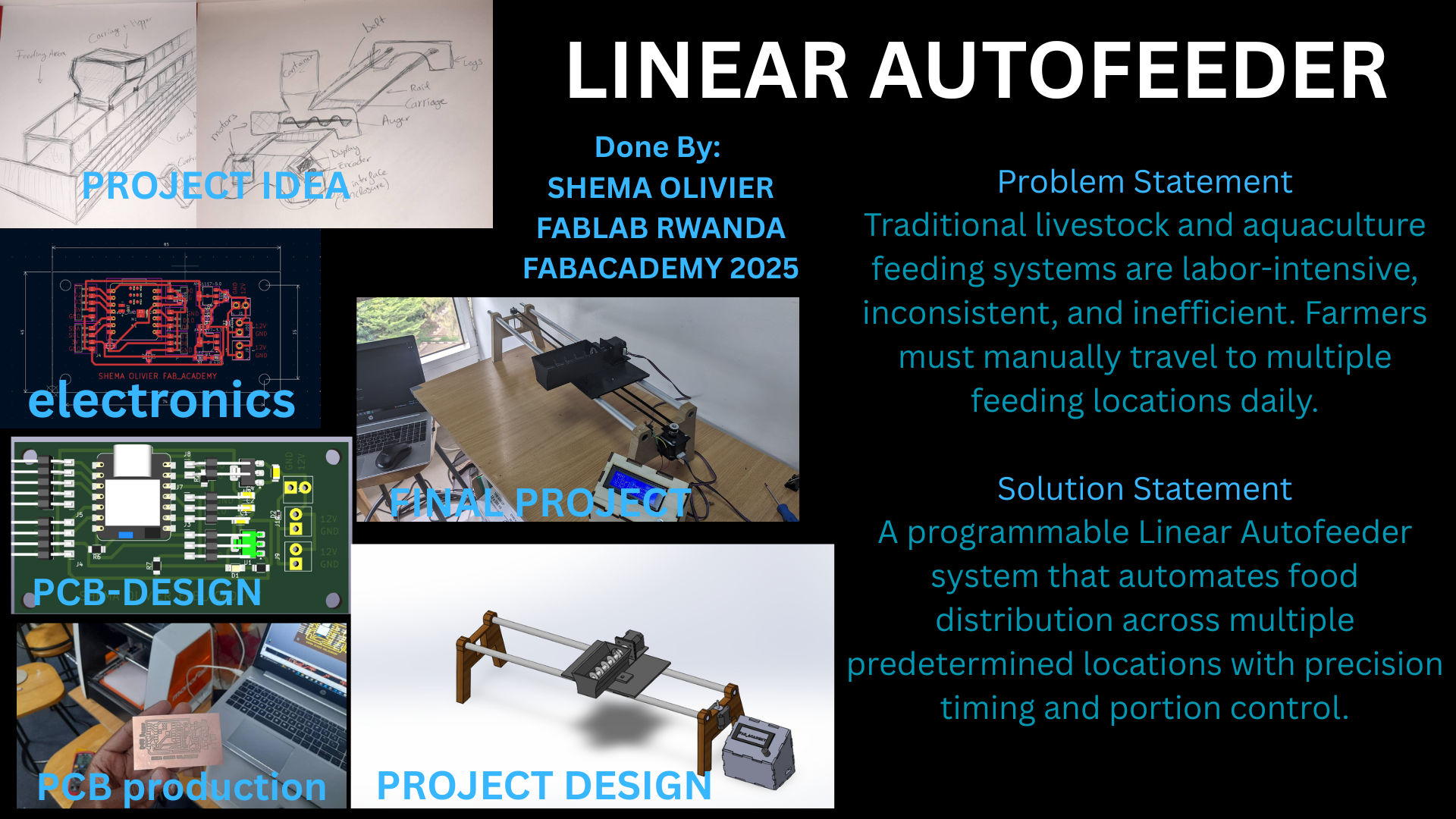

- Prepare drafts of your summary slide (presentation.png, 1920x1080) and video clip (presentation.mp4, 1080p HTML5, < ~minute, < ~25 MB) and put them in your website's root directory

#.Invention, Intellectual Property and Income of The Linear Autofeeder

1. Invention Summary

The Linear Autofeeder is a smart, programmable system designed to move along a rail and dispense food in precise amounts using an auger mechanism. It is intended for use in fish farming, animal feeding, and other fields where automation, timing, and consistency are essential. The project brings together mechanical engineering, electronics, and embedded programming into one efficient system.

Personal Motivation:

This project was inspired by daily life on my family’s cattle farm. We manually feed animals every day, which is time-consuming and physically demanding. I wanted to create something that could automate this repetitive task — not only for us but for other smallholder farmers facing similar challenges.

National Context:

In Rwanda, there is a national push to increase dairy production and aquaculture output to improve food security and economic resilience. With the right modifications, this system could be a valuable tool in supporting those goals by:

- Reducing labor for farmers

- Ensuring consistent feeding schedules

- Improving animal health and productivity

- Supporting the digitalization of agriculture

By using local materials and accessible fabrication methods, the Linear Autofeeder shows how affordable smart farming tools can be created and adapted for Rwanda and beyond.

2. Dissemination Plan

Sharing the Project

To make this project accessible and useful for others, I plan to:

- Publish full documentation (system integration, BOM, firmware, CAD files, usage guide) on my personal Fab Academy site.

- Upload open-source files (CAD, code, design files) on GitLab under a selected open license on my personal Fab Academy site.

- Share video demonstrations on YouTube and social media platforms such as Twitter, Instagram, and LinkedIn for awareness.

- Present the system at local and regional events (e.g., Hanga Hub, agriculture, or innovation expos).

3. Intellectual Property Plan

License Selection

To encourage collaboration and allow others to build on this work while protecting original authorship:

License: [Creative Commons Attribution-NonCommercial-ShareAlike 4.0 (CC BY-NC-SA)]

This license allows others to remix, adapt, and build upon the project non-commercially, as long as they credit me and license their new creations under the same terms.

- If I wish to commercialize the system later, I may shift to a dual-licensing model, keeping a free version for education and a commercial version with added features/support.

4. Income and Business Opportunities

Short-Term Opportunities

- Sell pre-assembled kits or DIY build kits of the Linear Autofeeder.

- Offer customization services for local cattle and fish farmers and cooperatives.

- Consultation and workshops for smart farming automation.

Long-Term Development

Upgrade the system with:

- Wireless connectivity (mobile app or web-based control).

- Battery/solar options for off-grid use.

- Mobile version on wheels for longer-range feeding.

5. Learning Outcomes

Through this project, I have:

- Learned how to integrate and document various fabrication and electronics techniques into one product.

- Explored how open hardware can solve local problems and be shared widely.

- Developed a roadmap for turning a prototype into a scalable, real-world solution.

- Gained confidence in combining technical work with design, communication, and planning for impact.

6. Final Deliverables Prepared

| Deliverable | File Name | Status |

|---|---|---|

| Presentation Slide | presentation.png | Done (1920x1080) |

| Project Video | presentation.mp4 | Done (~1 min, < 25MB) |

| Documentation Website | index.html and folders | Uploaded |

| CAD & Code Files | /files directory | Uploaded |

| BOM + Instructions | /docs directory | Uploaded |

Presentations

7. Conclusion

The Linear Autofeeder is more than a final project — it’s a solution that meets real agricultural needs using digital fabrication. I plan to continue refining it, make it more accessible, and share it openly so others can learn from, build on, or benefit from the work.