Applications and Implications, Project Development

Applications and Implications:

Propose a final project masterpiece that integrates the range of units covered.

Your project should incorporate

- 2D and 3D design

- Additive and subtractive fabrication processes

- Electronics design and production

- Embedded microcontroller interfacing and programming

- System integration and packaging.

Where possible, you should make rather than buy the parts of your project. Projects can be separate or joint but need to show individual mastery of the skills and be independently operable.

#.Applications and Implications of Linear Autofeeder Project

1. Project Overview

The Linear Autofeeder is a smart, programmable system designed to automatically dispense food along a linear path. It is especially useful for applications such as fish farming, animal feeding, or automated crop watering (with modifications).

This project demonstrates a complete integration of digital fabrication, electronics, programming, and mechanical design to deliver a standalone functional prototype.

2. Integration of Fab Academy Skills

The Linear Autofeeder integrates a wide range of skills developed throughout the Fab Academy. In 2D design, components like the feeder’s control panel and interface housing were created using CAD tools and laser-cutting techniques. For 3D design, tools like SolidWorks were used to model a custom auger, carriage, and food hopper, which were then fabricated using additive manufacturing through FDM 3D printing. Subtractive fabrication methods, including laser cutting, were applied to produce structural parts such as support frames and the protective enclosure.

In electronics design and production, a custom PCB can be developed to host the ESP32C3 microcontroller and essential components like motor drivers and connectors. Embedded microcontroller programming was done using the Arduino IDE with C++, enabling precise control of motor functions, sensor inputs, and user interaction via a rotary encoder. The microcontroller interfaces with various components, including stepper motors, an LCD display, an encoder, and a limit switch, all communicating seamlessly with the ESP32C3. System integration was achieved through clear firmware logic, organized wiring, and mechanical alignment, while the final packaging ensures a tidy enclosure that houses all electronics with proper cable management and a user-friendly interface.

3. Applications

Real-world Use Cases

- Cattle Farming: Automate silage or dry feed delivery along feeding troughs.

- Aquaculture: Feed fish at precise intervals along cages or tanks.

- Poultry Farming: Deliver grain or pellets along coops.

- Greenhouses: Modified to dispense nutrients or water along rows.

- Education & Prototyping: Serves as a demo for motion control, embedded systems, and system integration.

4. Implications

Why It Matters

- Reduces labor and increases consistency in feeding routines.

- Supports precision agriculture and smart farming.

- Encourages local production of automation tools in agriculture.

- Provides a scalable platform: the same logic can be adapted to other linear distribution systems.

5. Has Anyone Done This Before?

Initial Research and Inspirations

Before designing the Linear Autofeeder, I conducted research on similar projects and mechanisms, both for linear motion and automated feeding. This helped shape the concept, understand common approaches, and avoid reinventing the wheel.

Linear Motion Inspiration (Camera Sliders):

- Camera slider projects were a great starting point to understand smooth linear movement using stepper motors and rails.

- These videos provided insight into how to implement motion control, limit switches, and structural design.

Feeding System Inspiration:

- A key turning point in the project came when I found a video of a cattle feeding machine that distributes food along a row.

Automatic Cattle Feeder (YouTube Shorts)

This inspired the concept of adapting that idea to aquaculture and small-scale farming.

Existing Products: King of Feeders

- I also looked at existing commercial solutions, such as King of Feeders, which offers mechanized feeders.

Combined Inspiration: Linear + Feeding:

- Finally, I found a reel that blended both ideas (linear motion and feeding system), confirming that the combination is feasible and practical.

Conclusion:

This body of research validated that while similar concepts exist, this project offers a unique take by emphasizing local fabrication, educational value, and modular integration, with a strong focus on DIY and accessible tools.

6. Personal Contribution and Mastery

- Designed all parts in CAD from scratch.

- Printed and assembled all 3D components.

- Wired and tested all electronics using breadboards and prototypes.

- Wrote firmware to handle motion, display, inputs, and emergency handling.

- Validated system integration through multiple test cycles.

- Documented the full development process, including challenges and solutions.

7. Materials & Components Needed

| Item | Quantity | Source | Cost |

|---|---|---|---|

| XIAO ESP32C3 | 1 | https://www.nyerekatech.com | Fr20,000 |

| NEMA 17 Stepper Motors | 2 | https://www.nyerekatech.com | Fr29,600 |

| TB6600 Motor Drivers | 2 | https://www.nyerekatech.com | Fr30,000 |

| 20x4 LCD Display | 1 | https://www.nyerekatech.com | Fr10.500 |

| Rotary Encoder | 1 | https://www.nyerekatech.com | Fr3,000 |

| AMS1117 Regulato | 2 | https://www.nyerekatech.com | Fr1,000 |

| Wires, Screws, PCB, Capacitors, Resistors, switches | - | Fab Inventory | Fr20,000 |

| PLA Filament and MDF | - | Fab Lab | - |

| Aluminum Rail | 2m | Local Vendor | Fr10,000 |

| Total Approximate Cost: | Fr104,100 |

8. Make vs Buy Philosophy

| Component | Made/Bought | Reason |

|---|---|---|

| Carriage, Hopper, Auger | Made | Custom-designed and 3D printed to fit system specs. |

| Enclosure Panels | Made | Laser-cut from acrylic/wood based on custom design. |

| ESP32C3 Board | Bought | Readily available and reliable platform for IoT/microprojects. |

| Stepper Motors & Drivers | Bought | Standard motors and TB6600 drivers ensure torque and precision. |

| PCB (Optional) | Made | Could design a custom board to host all electronics. |

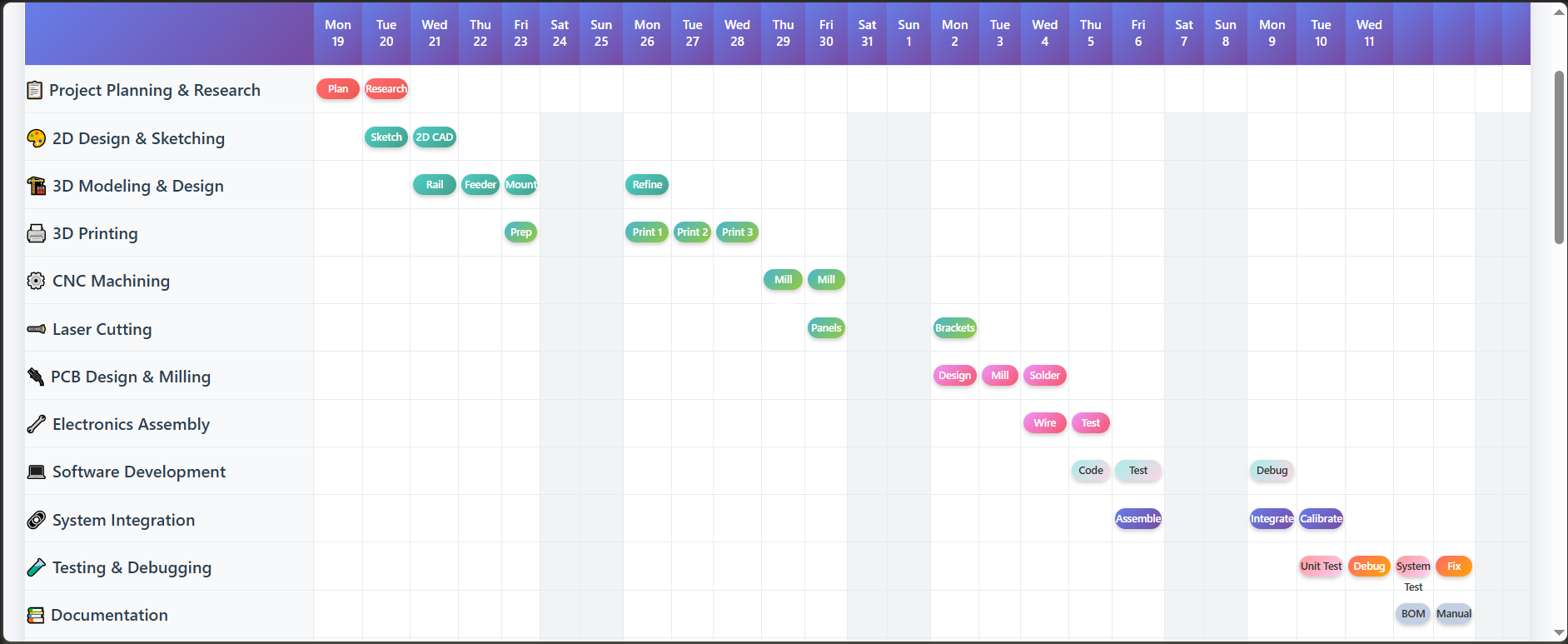

9. Development Roadmap

| Stage | Tasks |

|---|---|

| Planning | Defined scope, researched similar systems, sketched design. |

| Design | Created 2D and 3D models for mechanical and electronic components. |

| Prototyping | 3D printed parts, wired electronics, and built the first firmware draft. |

| Integration | Combined motion, UI, and sensors into a working prototype. |

| Testing & Iteration | Checked accuracy, robustness, and safety features and made improvements. |

| Documentation | Created BOM, system diagrams, firmware structure, and user instructions. |

10. Conclusion

The Linear Autofeeder project is a strong example of how digital fabrication, electronics, and programming can come together to solve real-world challenges. It is modular, functional, and scalable, offering room for future wireless control, solar power, or mobile app integration.