17. Applications and Implications, Project Development

Task of this week

Propose a final project masterpiece that integrates the range of units covered.

Your project should incorporate:

- 2D and 3D design

- Additive and subtractive fabrication processes

- Electronics design and production

- Embedded microcontroller interfacing and programming

- System integration and packaging.

Where possible, you should make rather than buy the parts of your project. Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.

See Final Project Requirements for a complete list of requirements you must fulfil.

Project: BMI Calculator

1. What the project will do:

My project is BMI (body mass index) Calculator. It measure the height and mass of a person and automatically display BMI of the person. Additionally; when user type their ID, the machine will store data and send them to sever. This will help to keep track of user especially children.

2. Who has done what beforehand?

Machines almost similary to this are commerially available. For example Afton Fitness Equipent have made it. What I have added is the ability to keep and track change of the users where necessary.

3. What will design?

- Structure (stand)

- Metal frame to hold load cell

- PCB

- Enclosure to hold electronic components

- 3D printed adapters used to mount parts together

4. What materials and components will be used?

| Items | Quantity | Price/unit | Total price | Link |

|---|---|---|---|---|

| Load cell (200kg) | 1 | 39.00 $ | 39.00 $ | amazon.com |

| HX711 Load Cell Amplifier | 1 | 3.50 $ | 3.50 $ | amazon.com |

| HC-SR04 Ultrasonic Sensor | 3 | 3.50 $ | 3.50 $ | amazon.com |

| 9mm MDF board | 1 | 25.00 $ | 25.00 $ | Local hardware store |

| 40x40 metal tube | 1 | 6.00 $ | 6.00 $ | Local hardware store |

| LCD Screen | 1 | 9.96 $ | 9.96 $ | amazon.com |

| Keypad | 1 | 3.00 $ | 3.00 $ | amazon.com |

| PLA Filament | 1 | 30.00 $ | 30.00 $ | amazon.com |

| Total | 89.96 $ |

4. What parts and systems will be made?

- Stand will be cut from MDF board using CNC machine

- Metal frame: welding

- Control board (PCB) for all electronic components

- Power management system to control and supply microcontroller

- Enclosure for screen will be 3D printed

5. What processes will be used?

- CAD with SolidWorks for structural design

- 3D printing

- PCB design and milling

- Soldering and circuit assembly

- Embedded programming (Arduino IDE)

- Wireless communication between microcontrollers(ESP-NOW)

6. What questions need to be answered?

- Is load cell secured enough to hold person's weight?

- Can the microcontrollers reliably communicate send data?

- Is load cell well calibrated to take accurate measurement?

7. How will it be evaluated?

This machine should be able to:

- Take accurate heaght measurement

- Take accurate mass

- Send data to cloud

8. What tasks still need to be completed?

- Integrate keypad so that user can put their ID

- Finetune design

- Test the limit of load cell

9. What has worked?

- Stand is now assembled

- Metal frame to hold load cell is complete and strong enough to a lot of weight

10. What has not worked yet?

- Obtained values are slighly not the same even for an object with the same weight

- Screen keeps shouting down

11. What have you learned?

- Use of CAD Software

- Designing reliable circuits using custom PCBs

- CNC Machining

- Metal welding

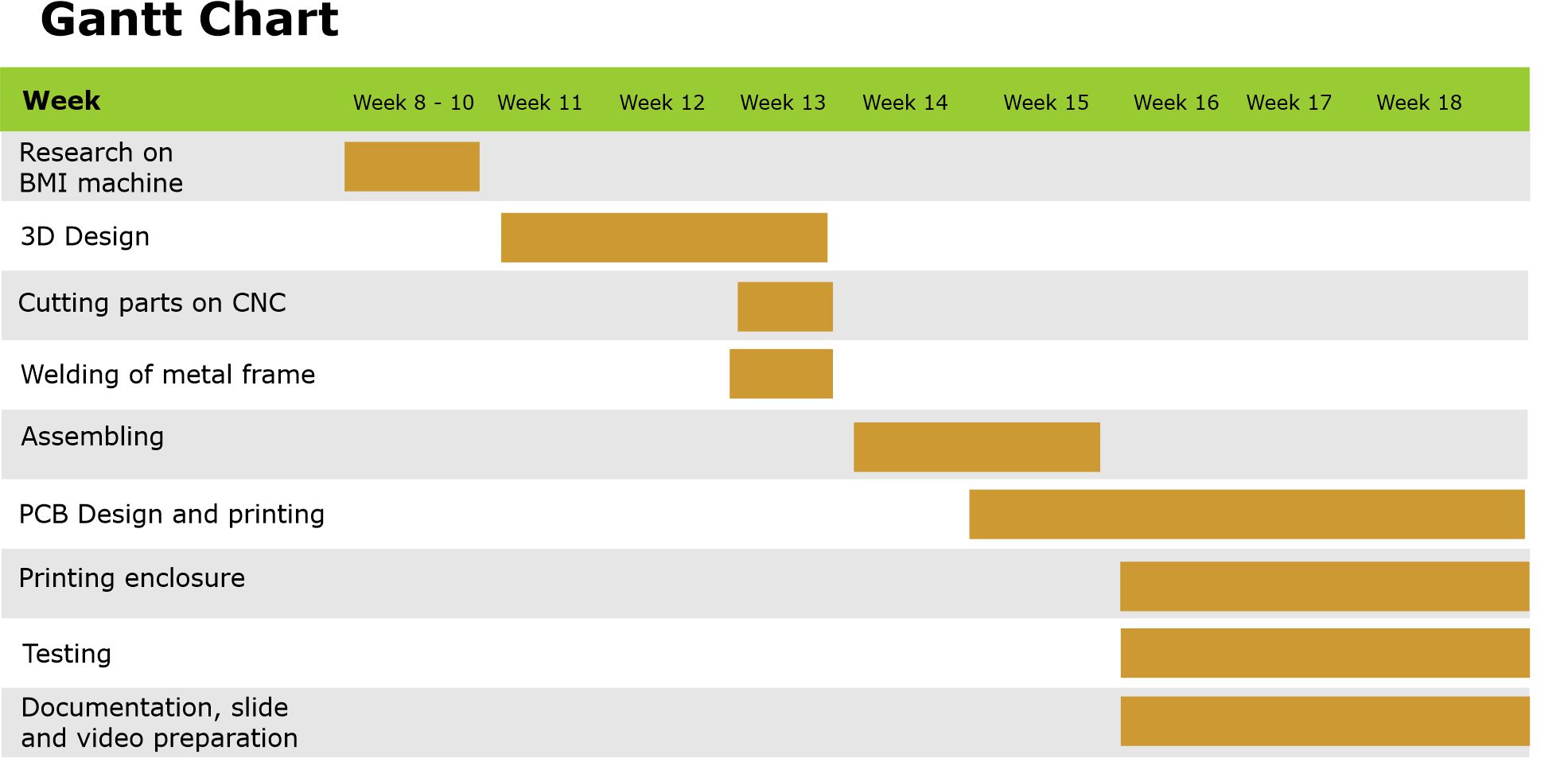

12. Gratt chart