System Integration

Individual assignment: Design and document the system integration for your final project

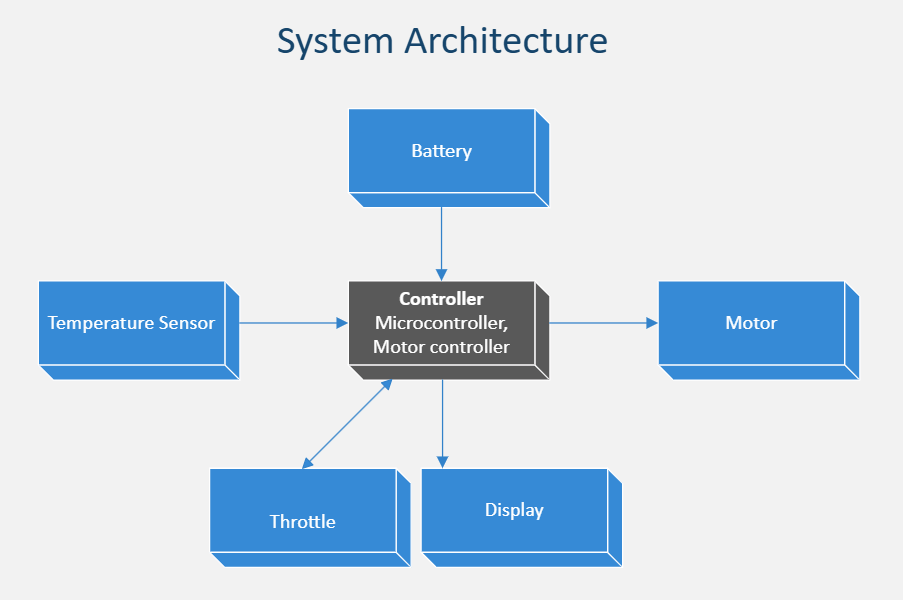

This assignment covers System Architecture that outlines all major subsystems and how they interact in an electric bike

System OverviewThe E-Bike project integrates power electronics, mechanical systems, embedded control, and user interfacing to build a functional electric bicycle. The architecture consists of key systems: Power Supply, Motor Drive, Motor Control, User Interface, Safety Monitoring, and Mechanical Mounting.

1. Power Supply System

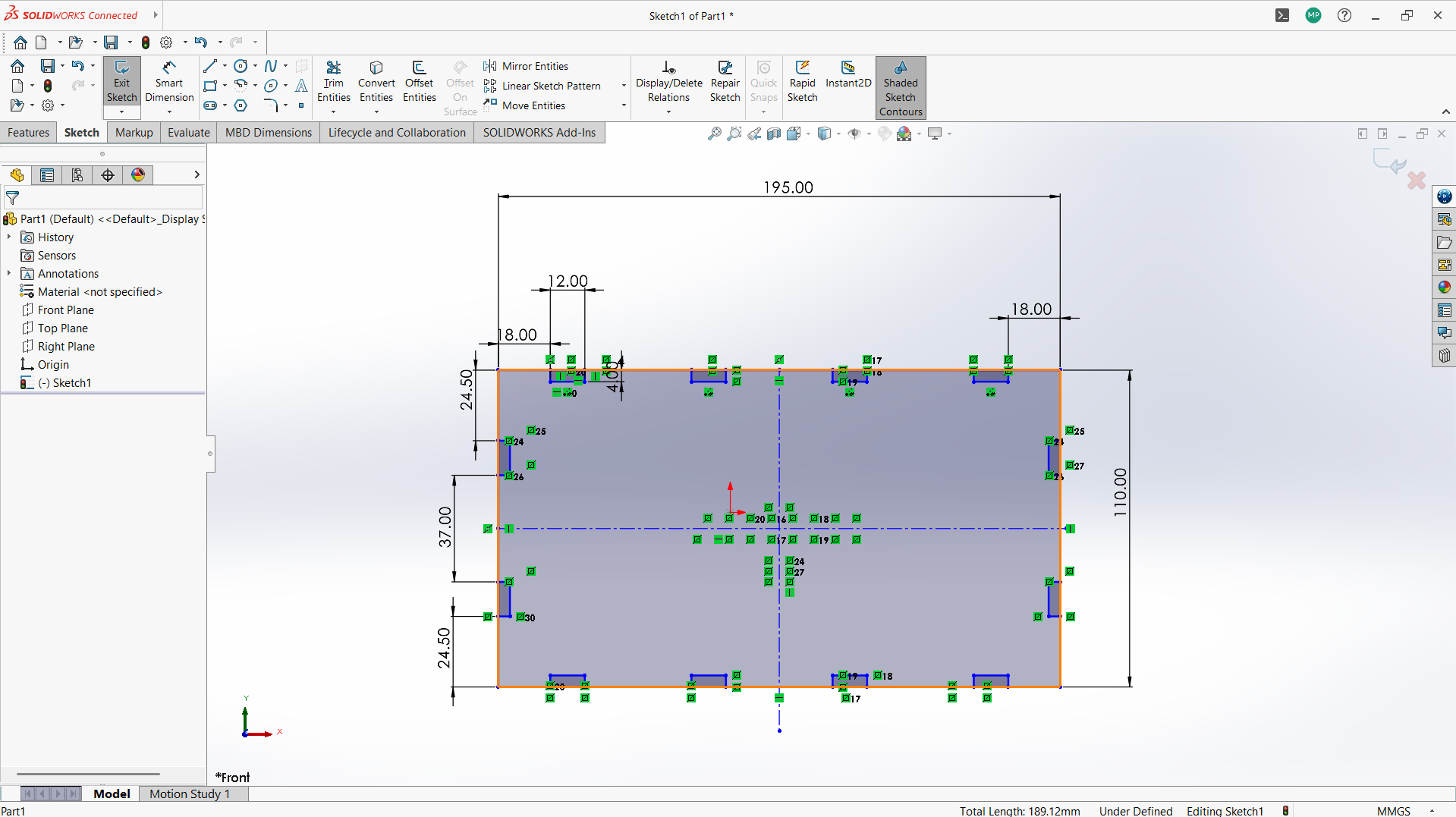

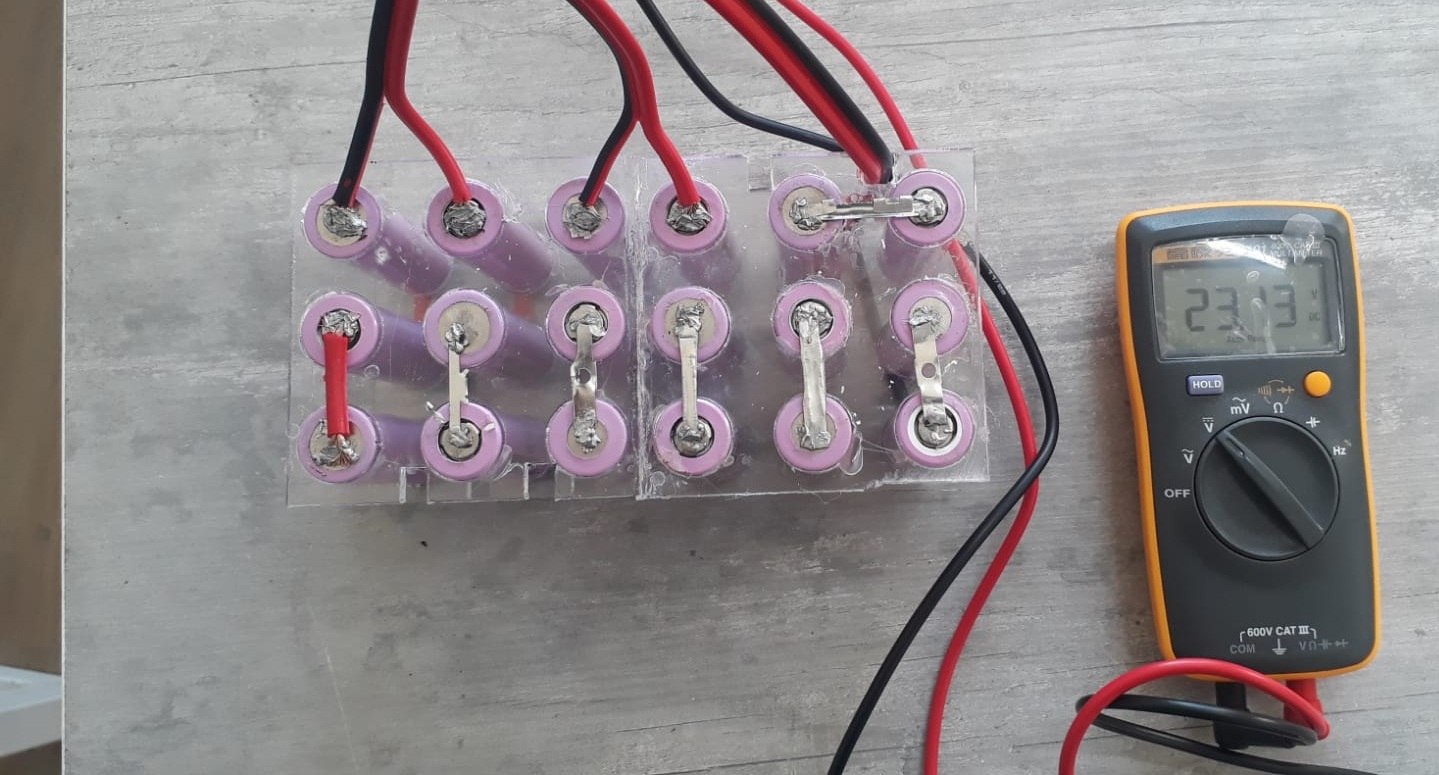

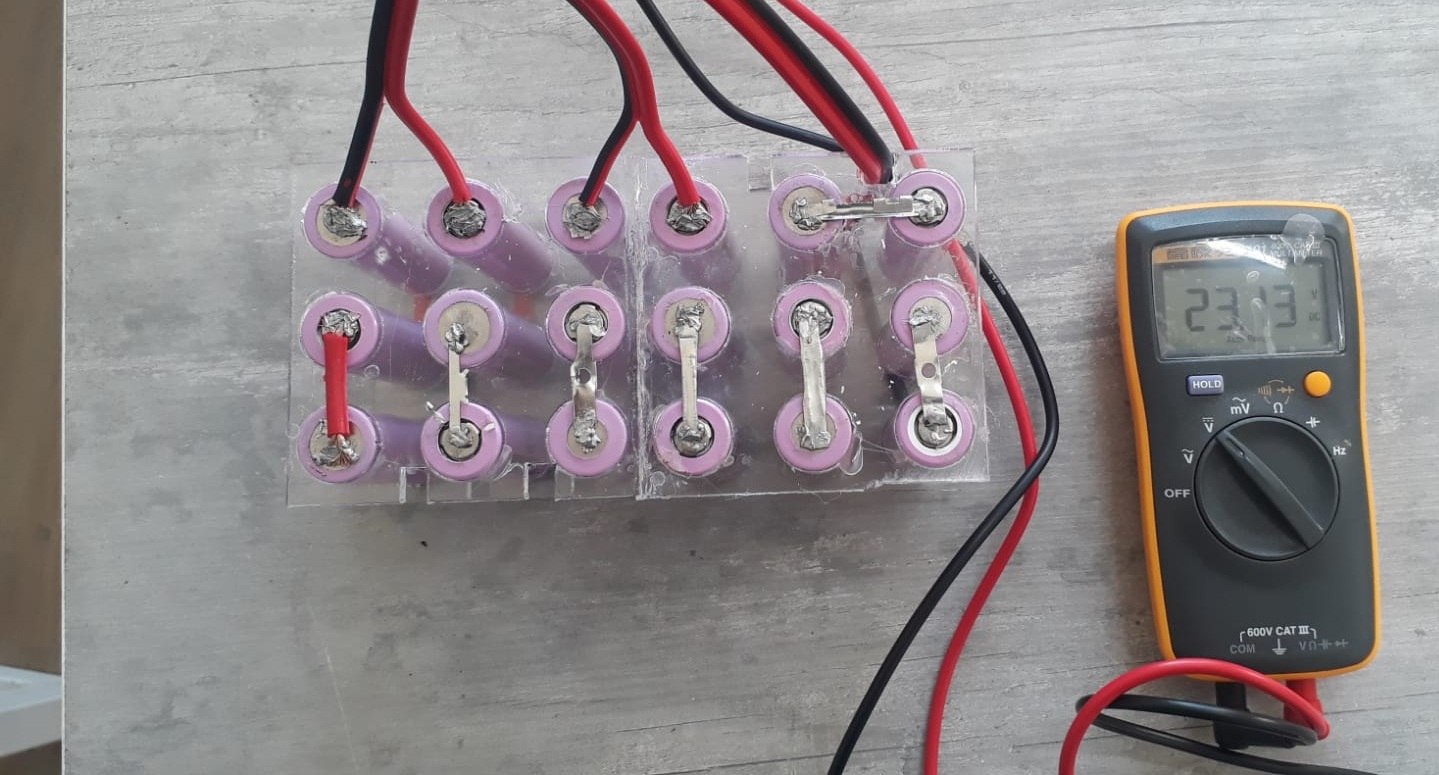

- Battery Pack (24V Li-ion): Provides the primary power source. Composed of multiple 3.7V cells connected in series and parallel to reach the desired voltage and current capacity. Custom-designed bracket that securely attaches the battery to the bicycle frame, preventing movement during rides.

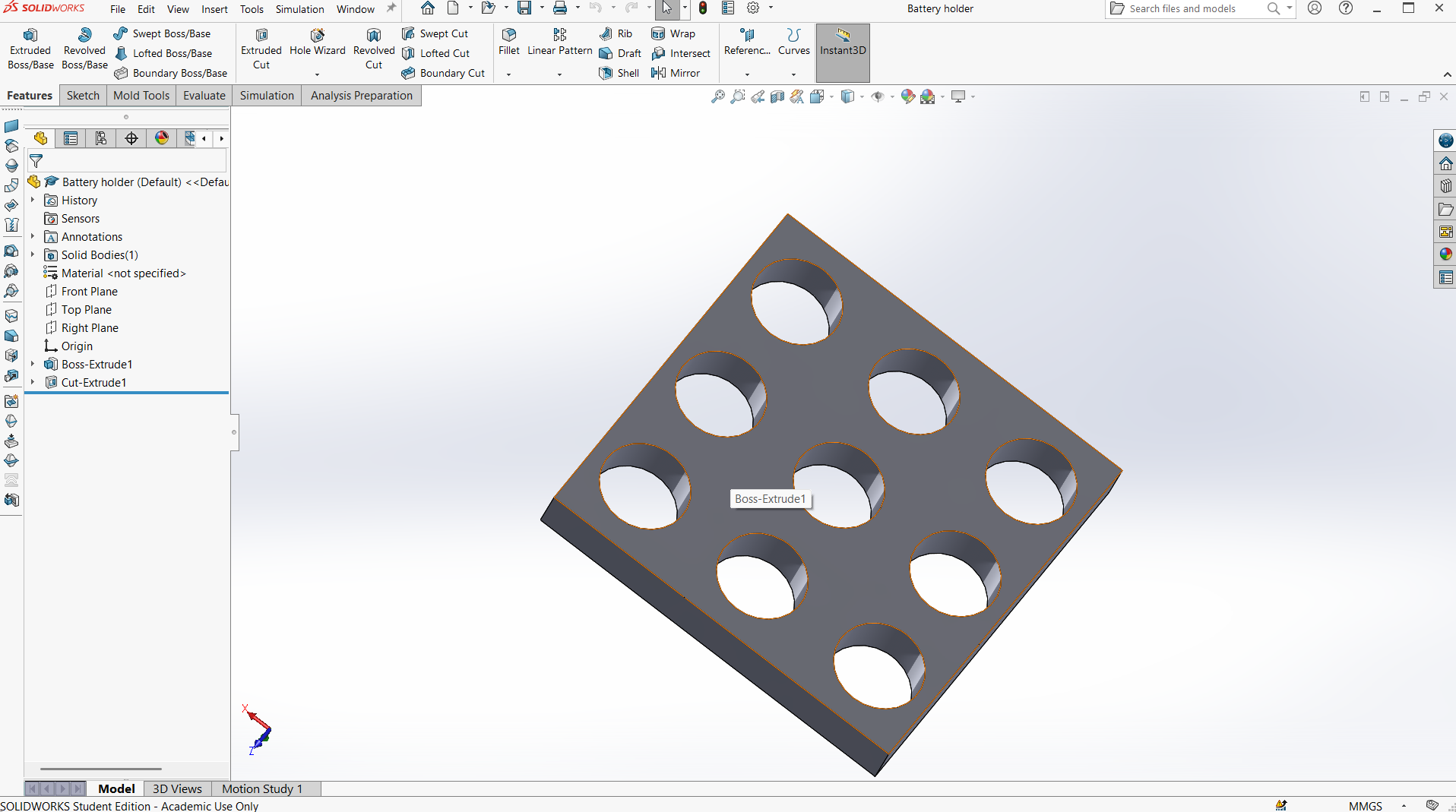

- Battery Cells Holder: Plastic grid layout for organizing the cylindrical cells, ensuring easy wiring and structural integrity.

- Hub Motor: A DC hub motor mounted in a way to drive the rear wheel with a drive chain. It provides direct drive without transmission systems, enabling efficient power transfer and reduced maintenance.

- Temperature Sensors: Installed on controller to monitor MOSFET overheating. Automatically shuts off or limits power if temperature exceeds safety thresholds.

- Voltage Sensors: Continuously measure battery voltage to prevent deep discharge and ensure optimal performance.

- Throttle: Analog 0–5V signal or Hall-effect sensor. User controls acceleration by twisting the handlebar throttle.

- LCD Display: Real-time display of speed, battery level, temperature, and power status. Also includes odometer functionality.

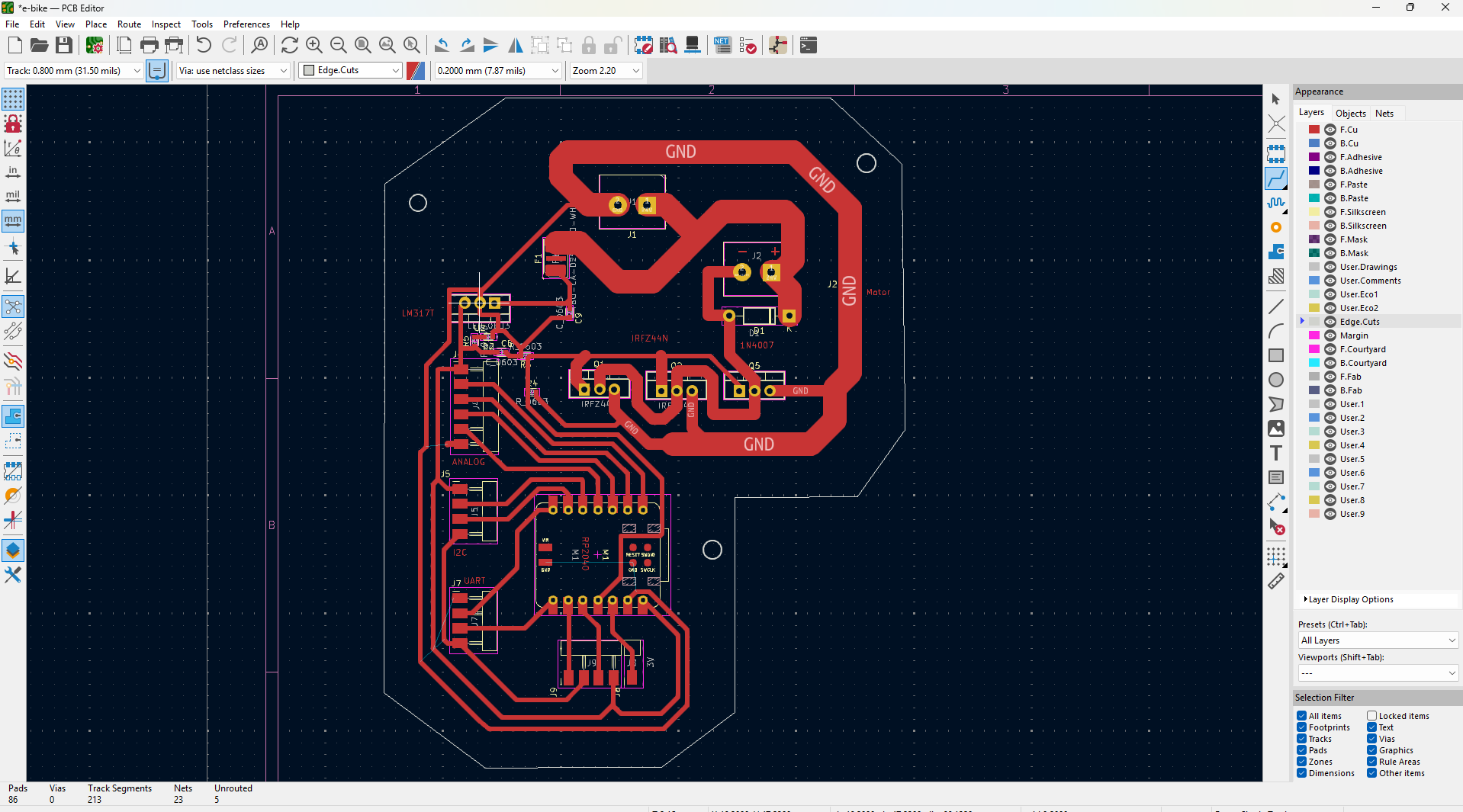

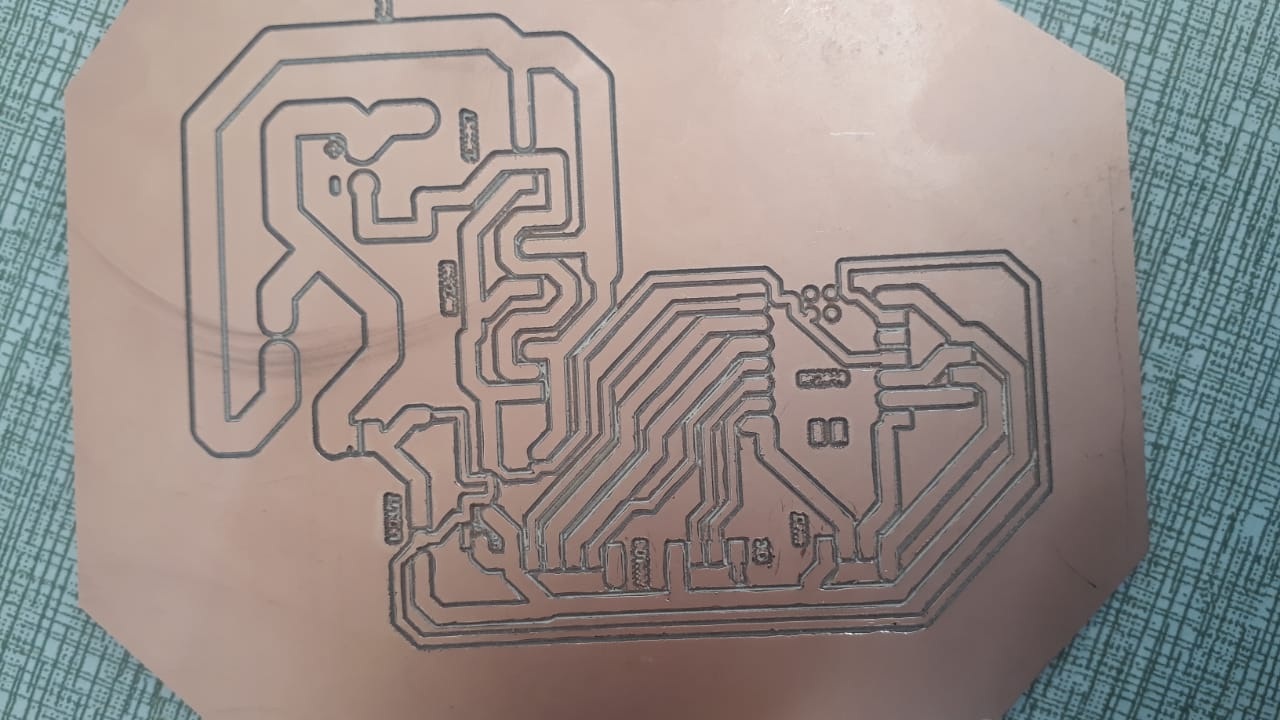

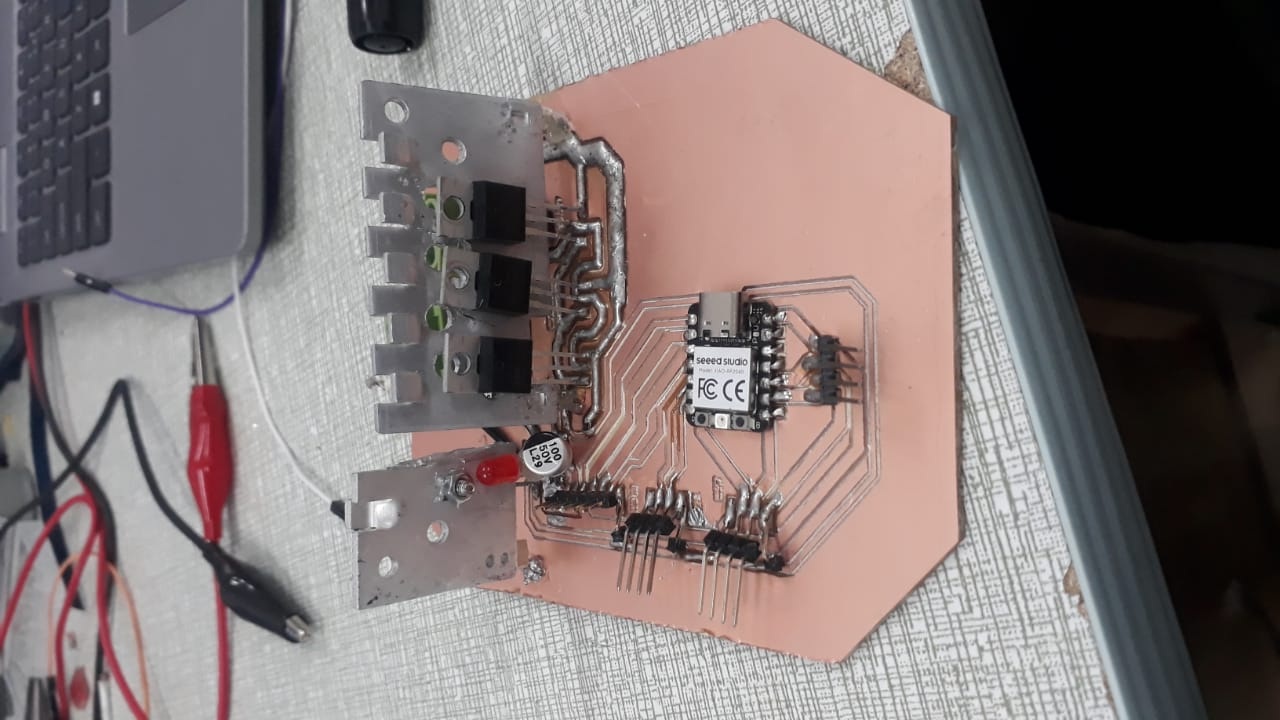

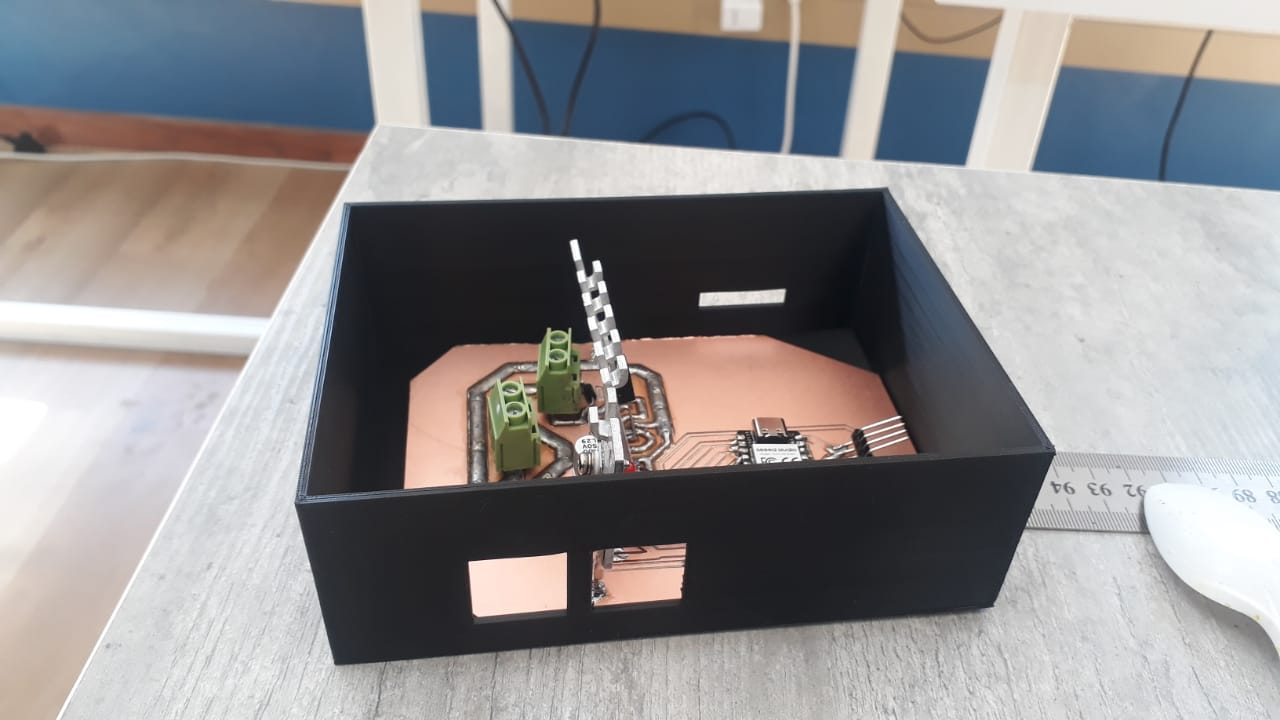

- Motor Controller: Custom PCB for DC motor control. Receives throttle and drives the motor accordingly.

- Outputs: High-current PWM signals for motor drive, safety interrupt signals.

- DC-DC Converter: Steps down the 24V battery voltage to 5V for microcontroller and display operation.

- Features: Soft start to avoid jerks, smooth braking, current limiting to protect motor and battery.

- Motor Driver PCB: Combines a microcontroller (e.g. Seeed Xiao RP2040) and IRFZ44 driver circuitry. Interfaces with sensors and display modules.

- Battery Enclosure: Waterproof case to house the battery pack. Mounted on the down tube.

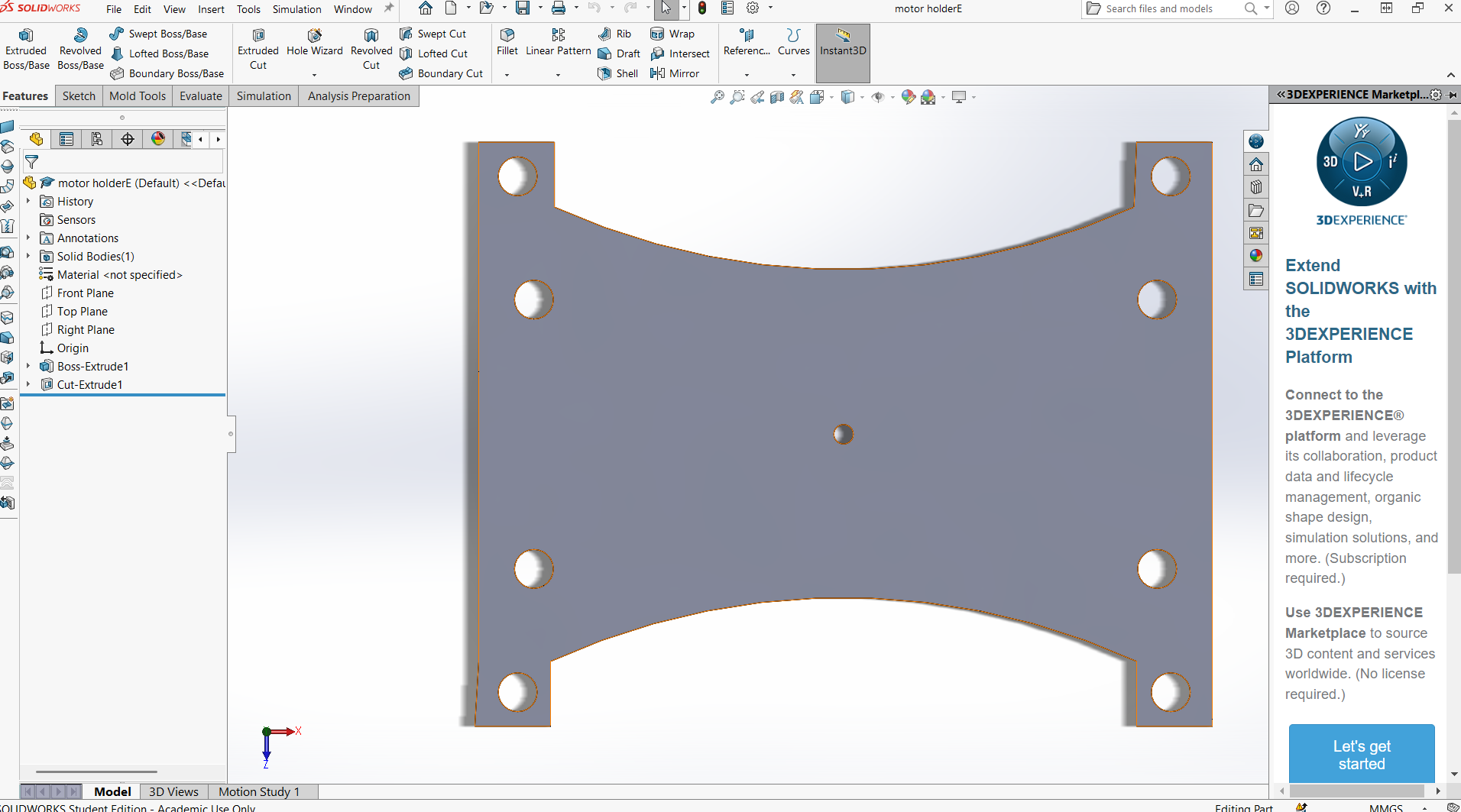

- Motor Mount: Reinforced dropouts and torque arms to hold the motor securely.

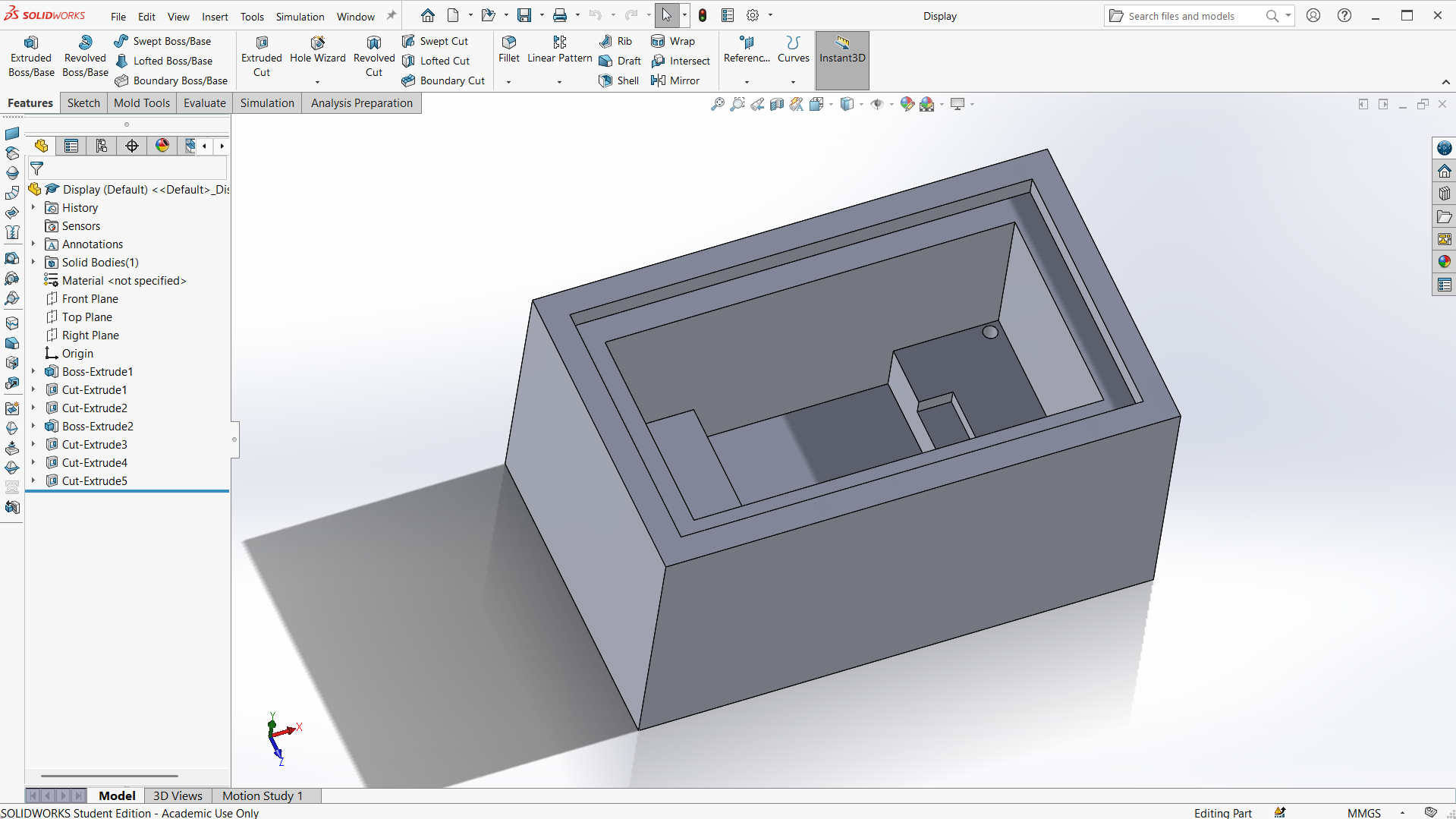

- Controller Mount: 3D-printed mounted to the frame. Ensures airflow and easy access.

- Wiring Management: Sleeving, zip ties, and routing channels to keep wires organized and safe from wear.

- Torque Arms: Prevent motor axle from rotating under torque. Essential for high-power hub motors.

- Fasteners: Anti-vibration stainless steel bolts for mounting all components securely.

- Waterproofing: Rubber gaskets, silicone sealant, and conformal coating to protect electronics from moisture.

- All subsystem connected and assembled.

Code and Interface Files

The following files are included as part of the project: