This week we had to measure the power consumption of an output device.

We decided to test a stepper motor since we had one available in our lab and wanted to understand how much power it actually uses.

So basically we took this stepper motor (model 17HS4401S) that we found in the lab and tested how much electricity it uses under different conditions. It was pretty interesting to see the differences!

| What it is | What it means |

|---|---|

| Power Supply | The thing that gives electricity to other stuff. Ours can be adjusted to give different amounts of voltage |

| Voltage (V) | Think of it like water pressure - higher voltage = more "push" for the electricity |

| Current (A) | How much electricity is actually flowing (like how much water is coming out of a hose) |

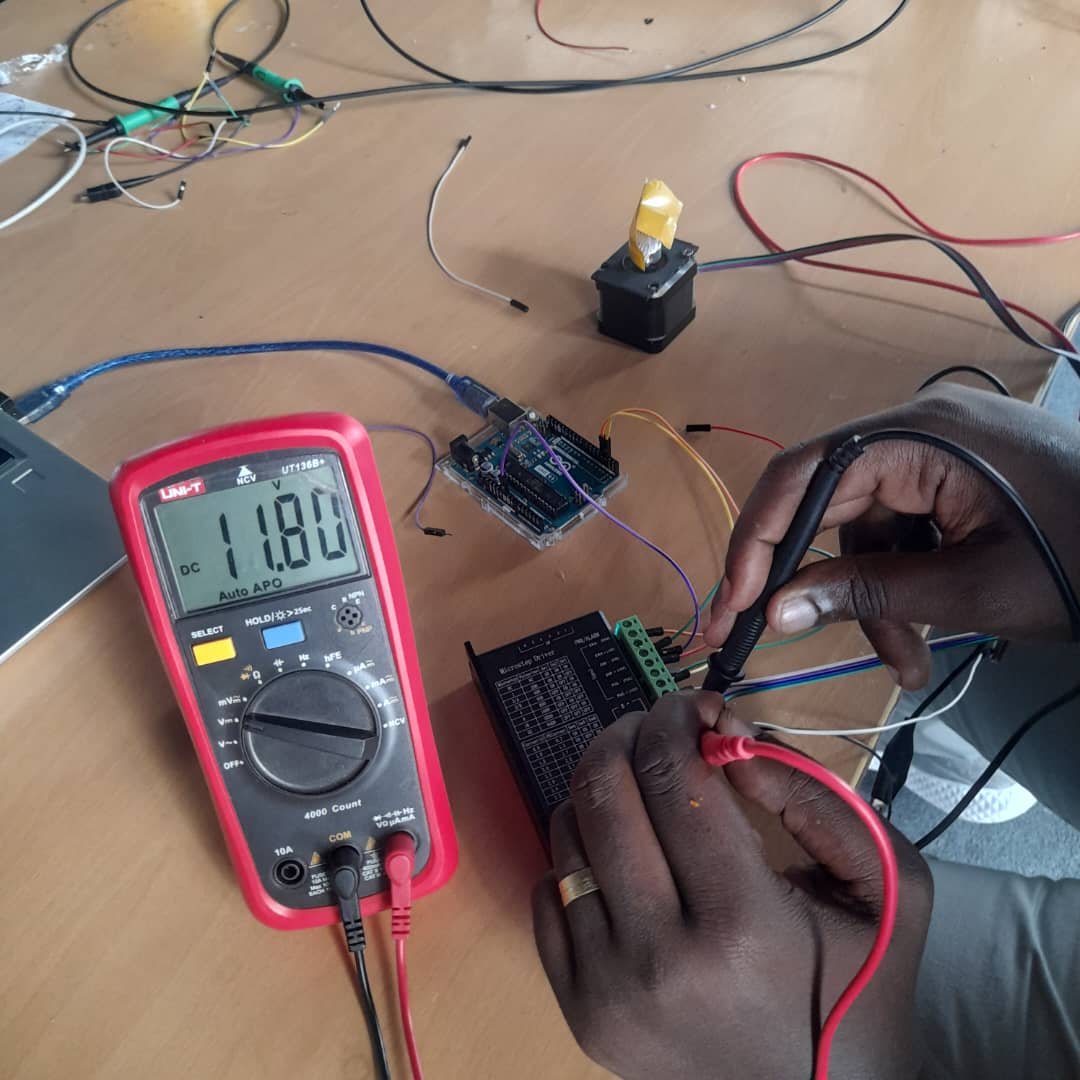

| Multimeter | Tool for measuring electrical stuff - voltage, current, resistance, etc. |

We picked the 17HS4401S NEMA 17 stepper motor. These are pretty common in 3D printers and CNC machines, so it seemed like a good choice for testing.

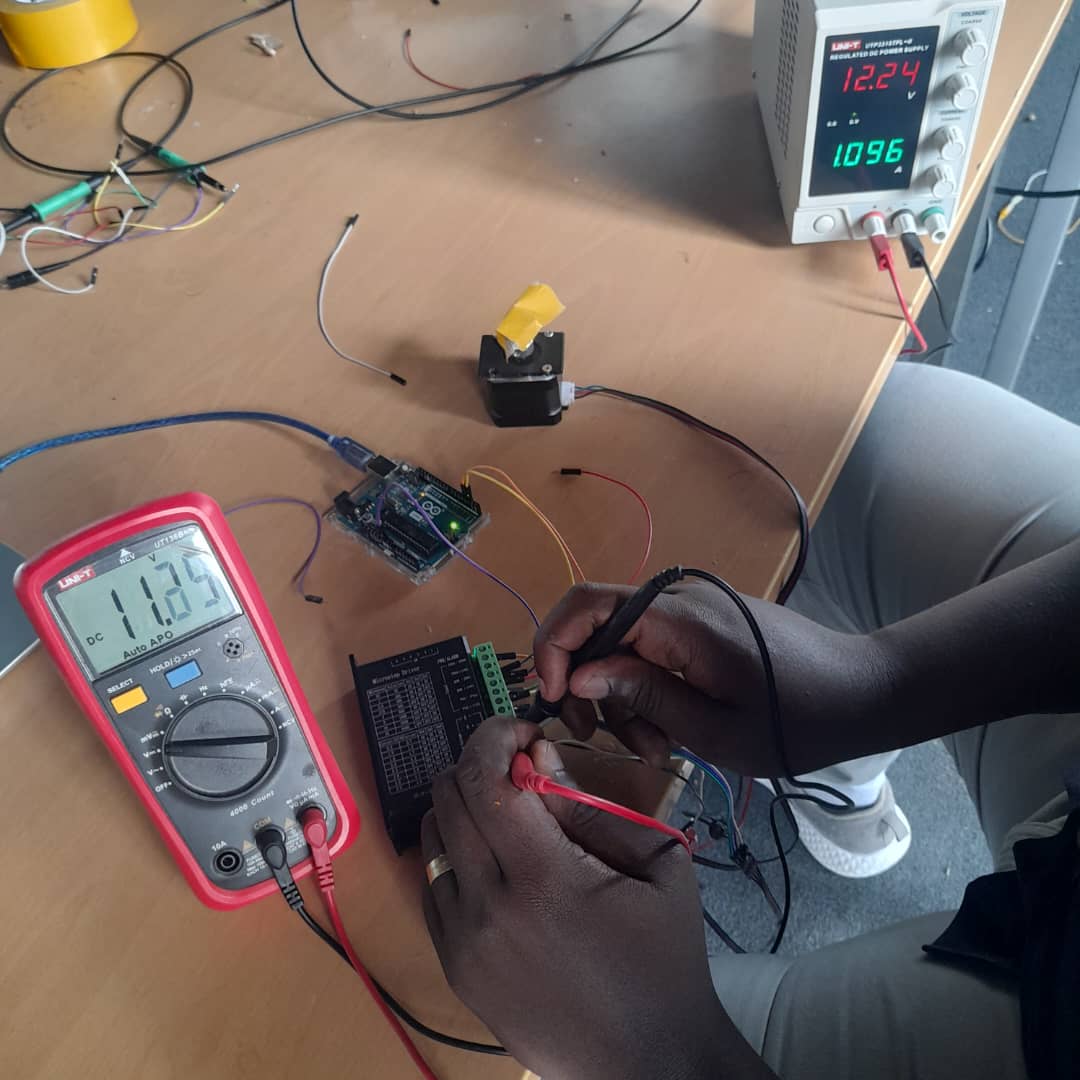

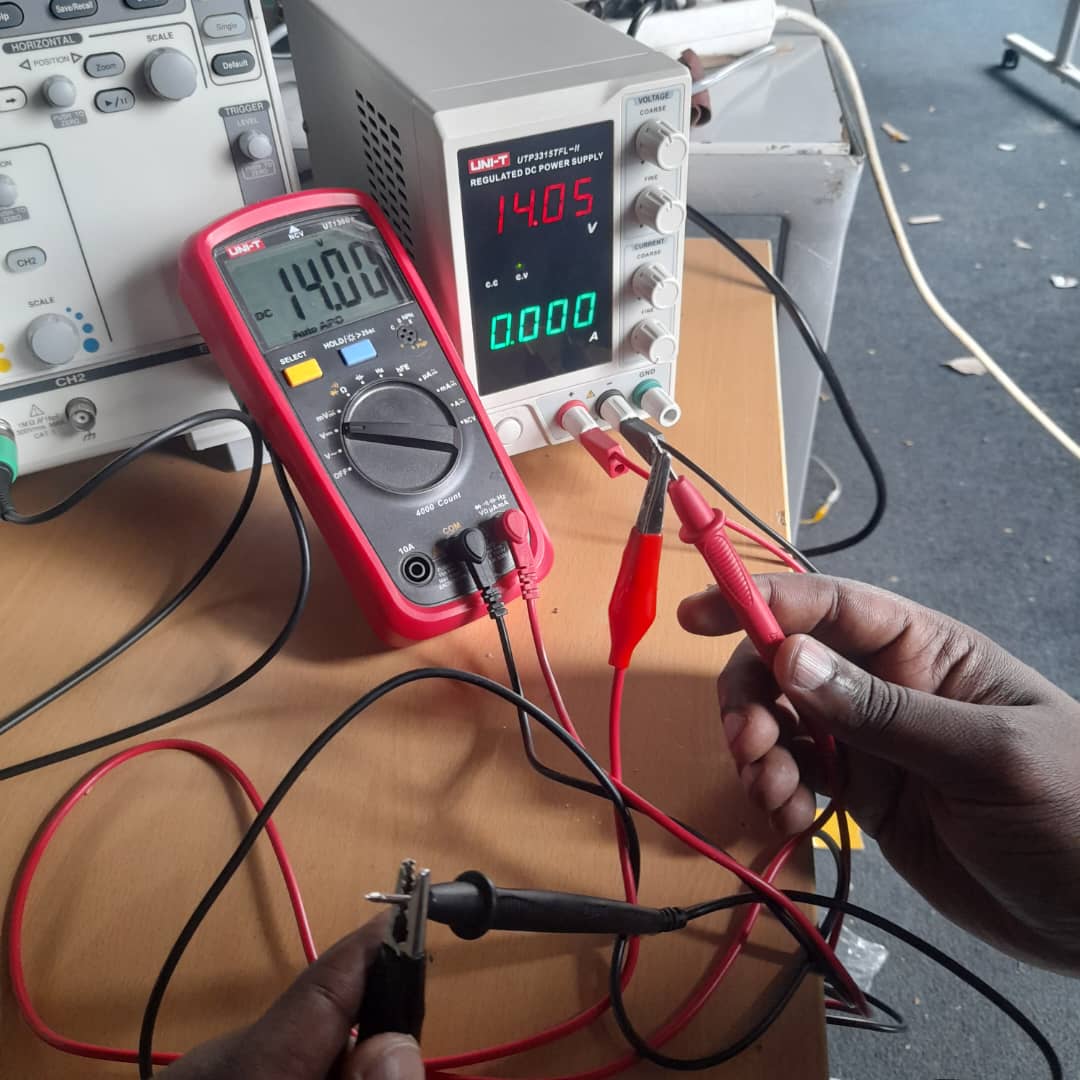

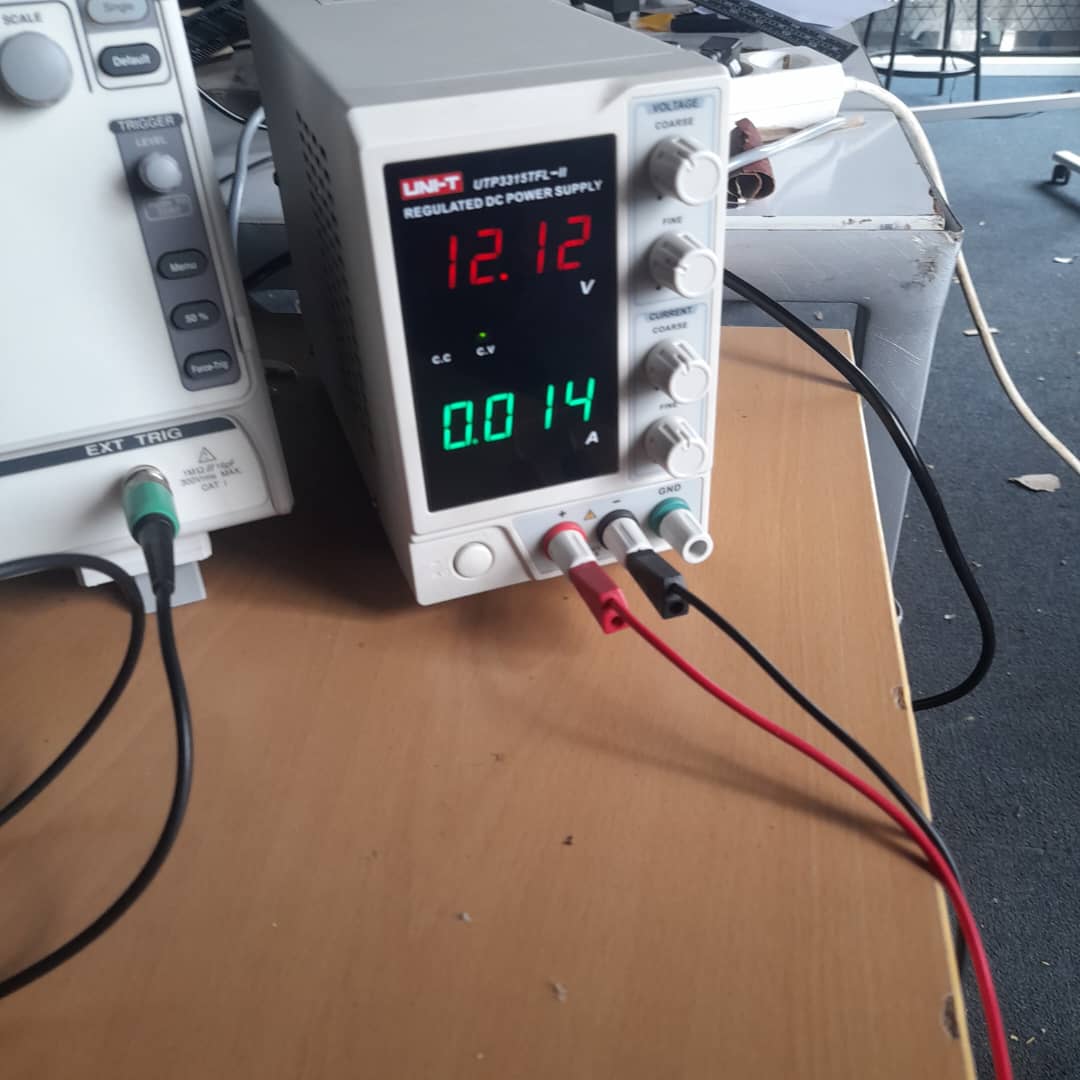

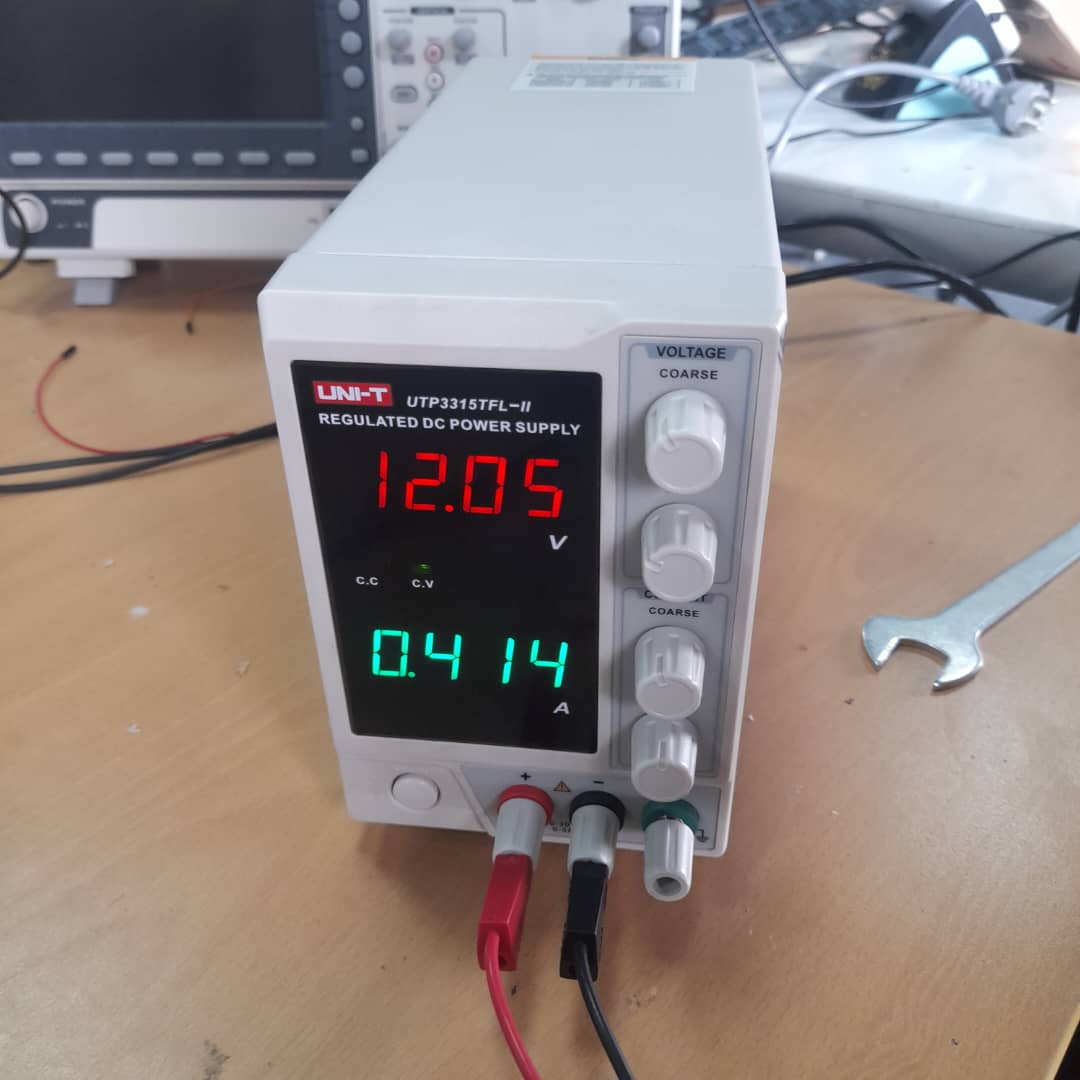

We used this adjustable DC power supply that we have in the lab. It's pretty nice because you can control both voltage and current, plus it shows you what's happening in real time on the display.

The display shows both voltage and current at the same time. There are two sets of controls - "coarse" (moves fast) and "fine" (for precise adjustments). We looked at the motor Specs to figure out we needed 12V.

One thing our instructor told us - always set current limits! If you don't, LEDs can get hot and pull more current until they burn out. Same goes for other components.

What we measured: 12.0V, 0.85A, so that's about 10.2W

What we measured: 11.330V, 0.92A, so about 11.0W

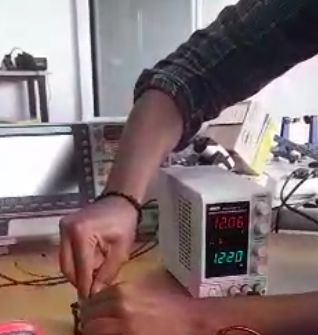

Then we tried holding the motor shaft while it was trying to turn, making it work harder. As expected, it needed more power to fight against our resistance.

What we measured: 12.0V, 1.22A, so about 17.0W

| What the motor was doing | Voltage | Current | Power |

|---|---|---|---|

| Just sitting there (holding position) | 12.0V | 0.45A | 4.8W |

| Spinning freely | 12.0V | 0.92A | 10.8.0W |

| Working against resistance | 12.0V | 1.22A | 14.64W |

Some interesting things we noticed:

Overall this was a pretty useful exercise. We didn't expect the motor to use so much power just sitting there, but now we understand why stepper motor drivers often have features to reduce holding current when the motor doesn't need to move.