This document outlines the plan for the molding and casting assignment, covering both group and individual components. The group assignment involves reviewing Safety Data Sheets (SDS), producing test casts, and comparing mold-making processes. The individual assignment focuses on designing and producing a three-part mold and documenting the casting process.

Objective: Review SDS for molding materials (silicone rubber, urethane rubber) and casting materials (epoxy resin, plaster).

| Material | Example Product | Hazards | Precautions | First Aid | Disposal |

|---|---|---|---|---|---|

| Silicone Rubber | Smooth-On OOMOO 30 | Skin/eye irritation; inhalation risk | Gloves, glasses, ventilation | Wash skin; Rinse eyes 15 min | Cure fully, dispose normally |

| Urethane Rubber | Smooth-On Mold Max 30 | Respiratory sensitization | N95 mask, gloves, ventilation | Fresh air; Wash skin | Cure fully, dispose normally |

| Epoxy Resin | Smooth-On Crystal Clear | Flammable when mixed; irritation | Gloves, glasses, ventilation | Wash skin; Fresh air | Cure fully |

| Plaster | USG Hydrocal White | Dust irritation | Dust mask, gloves | Wash skin; Rinse eyes | Dispose as solid waste |

| Construction Cement (OPC) | General Purpose Cement | Dust irritation; alkaline when wet | Use gloves, dust mask, safety glasses | Skin: rinse with water; Eyes: rinse 15 min; Inhalation: fresh air | Cure completely; dispose as solid waste |

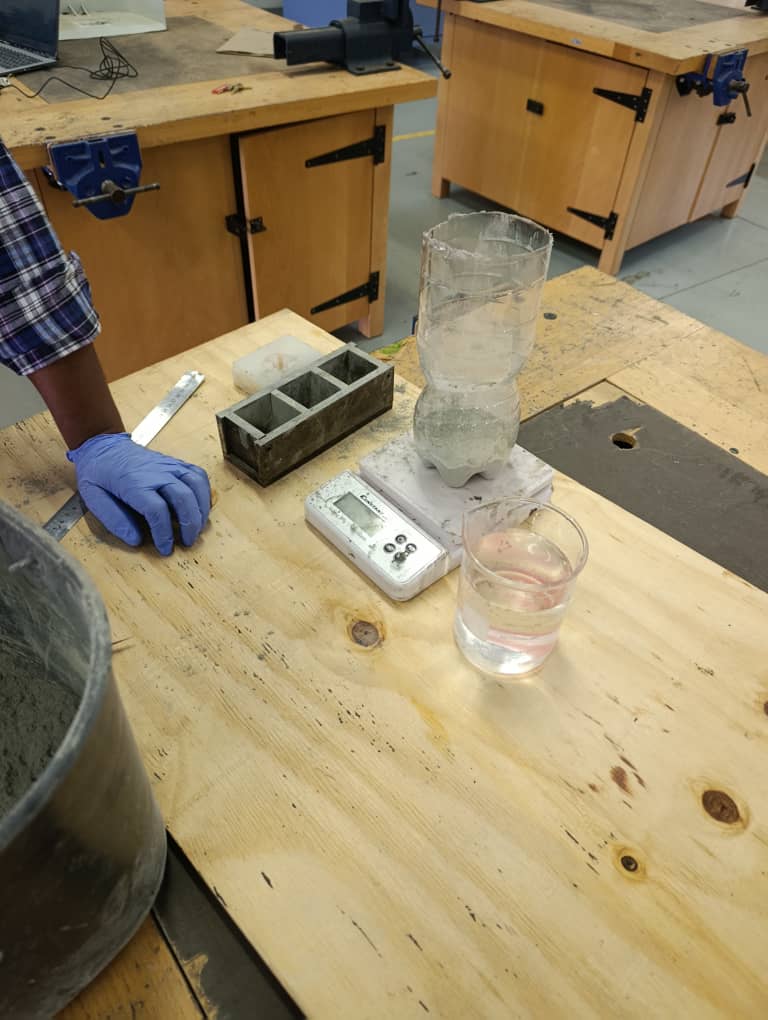

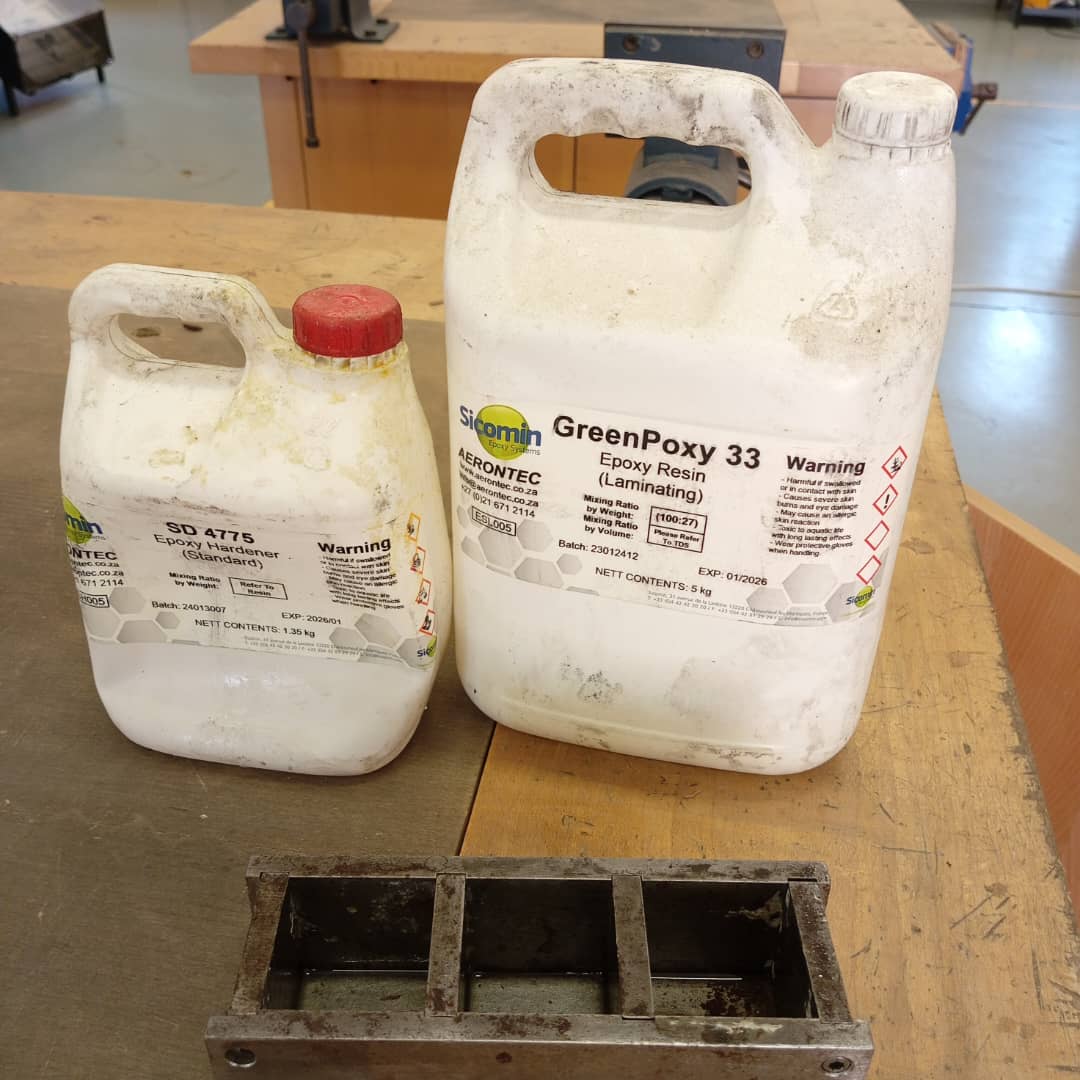

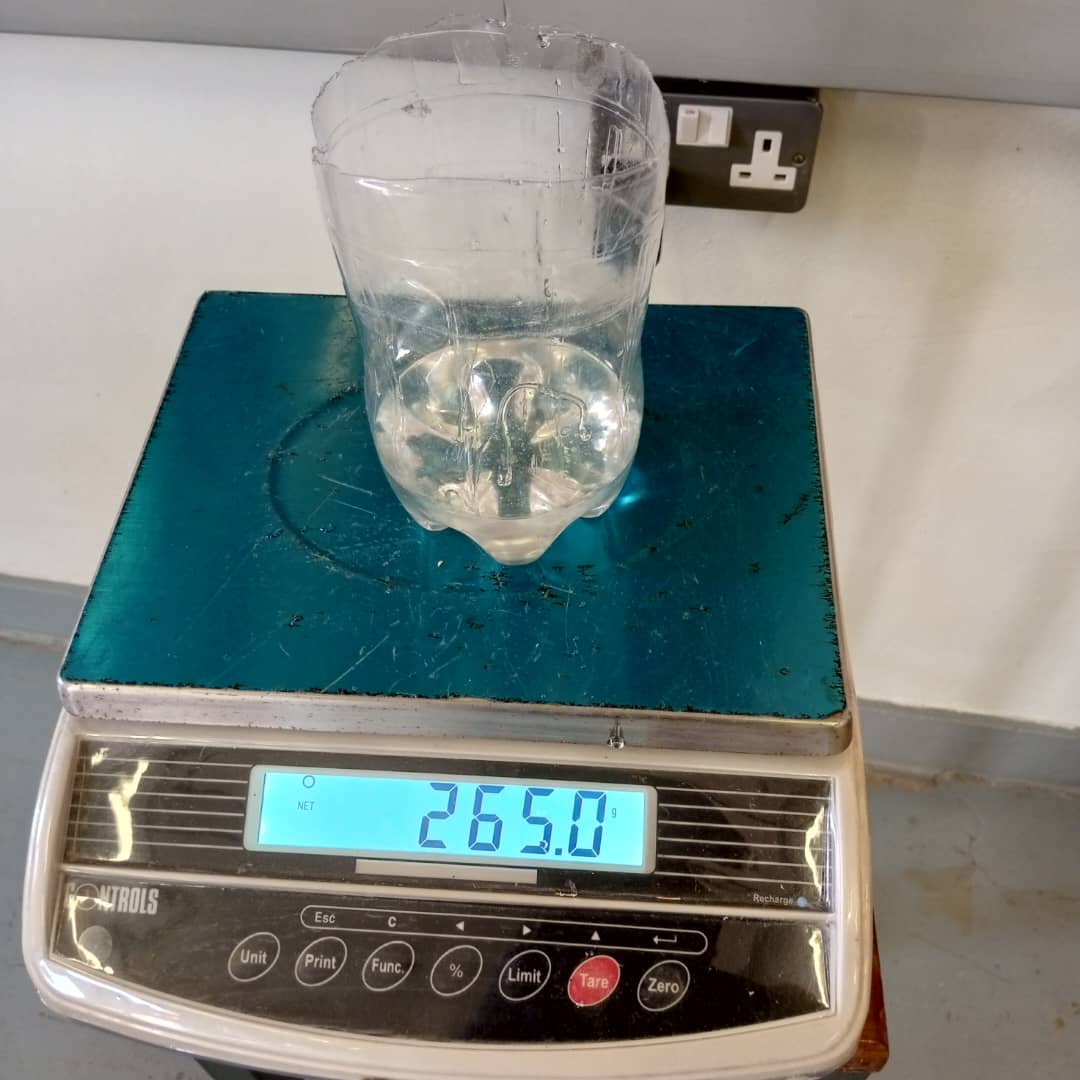

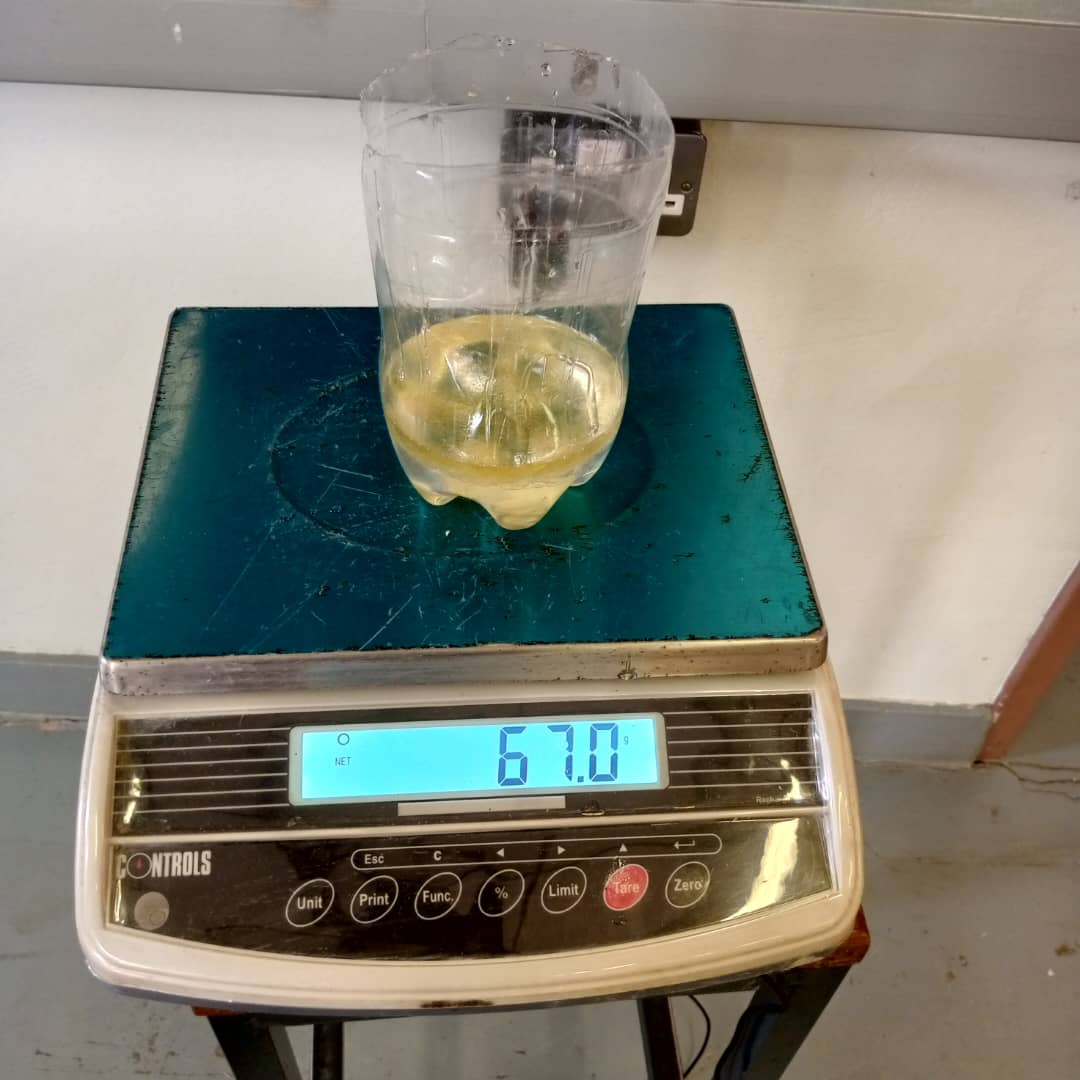

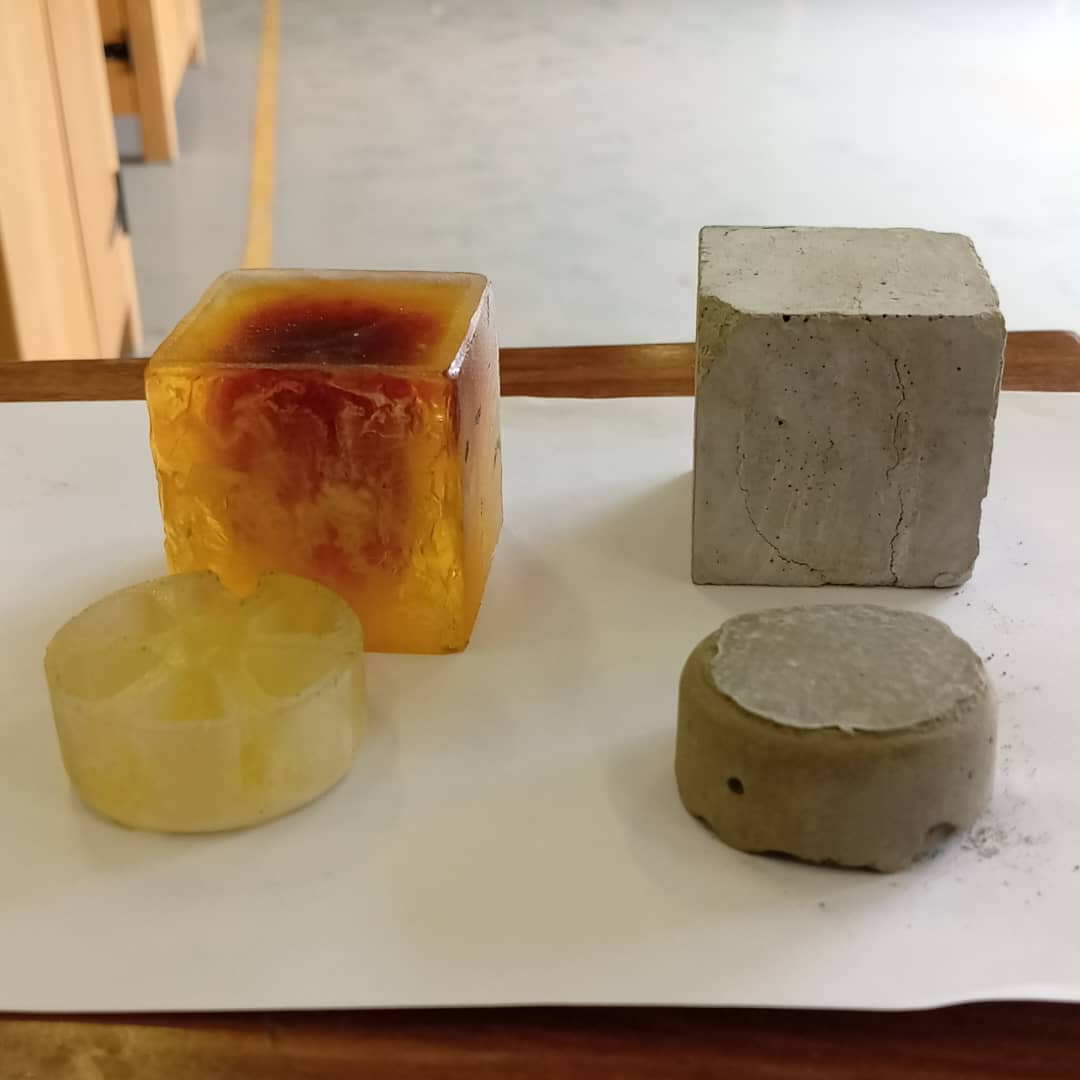

Objective: Create test casts using silicone and Metal Molds with epoxy resin and plaster.

The mold cavity has the following dimensions:

Volume Calculation:

V = π r² h

V = 3.14 × (2.25 cm)² × 3 cm

V ≈ 47.8 cm³

Material Used: Construction cement (Portland-based), not Plaster of Paris.

Density of Portland Cement: 3.15 g/cm³

Theoretical Mass:

Mass = Density × Volume

Mass = 3.15 g/cm³ × 47.8 cm³

Mass ≈ 150 g

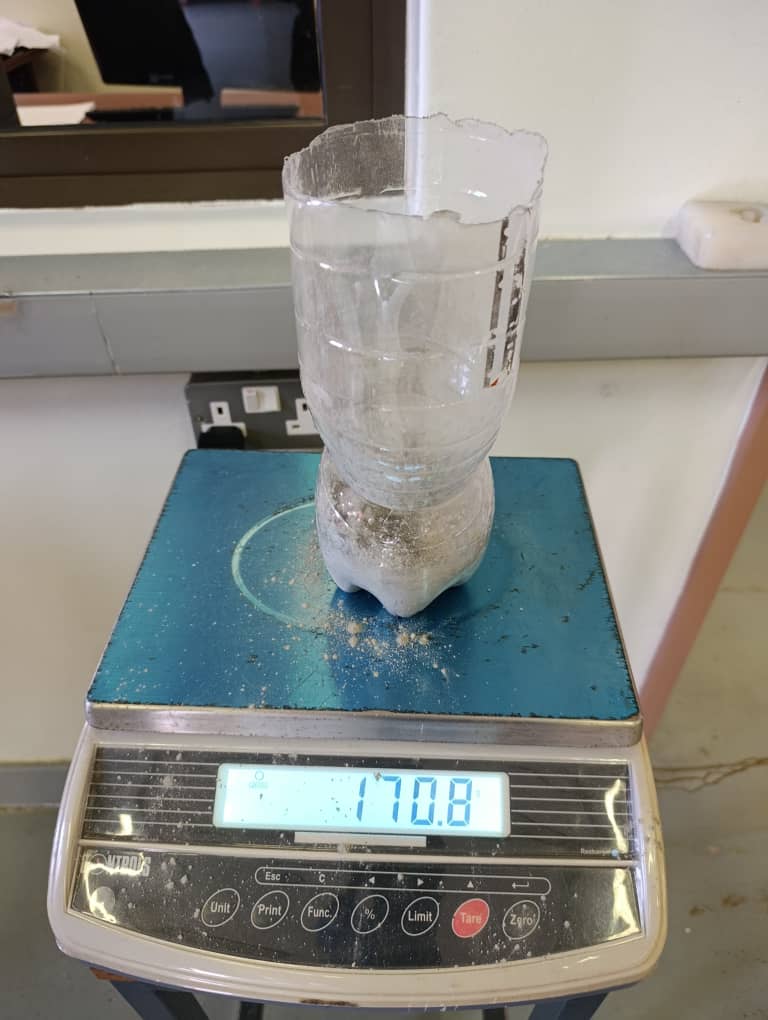

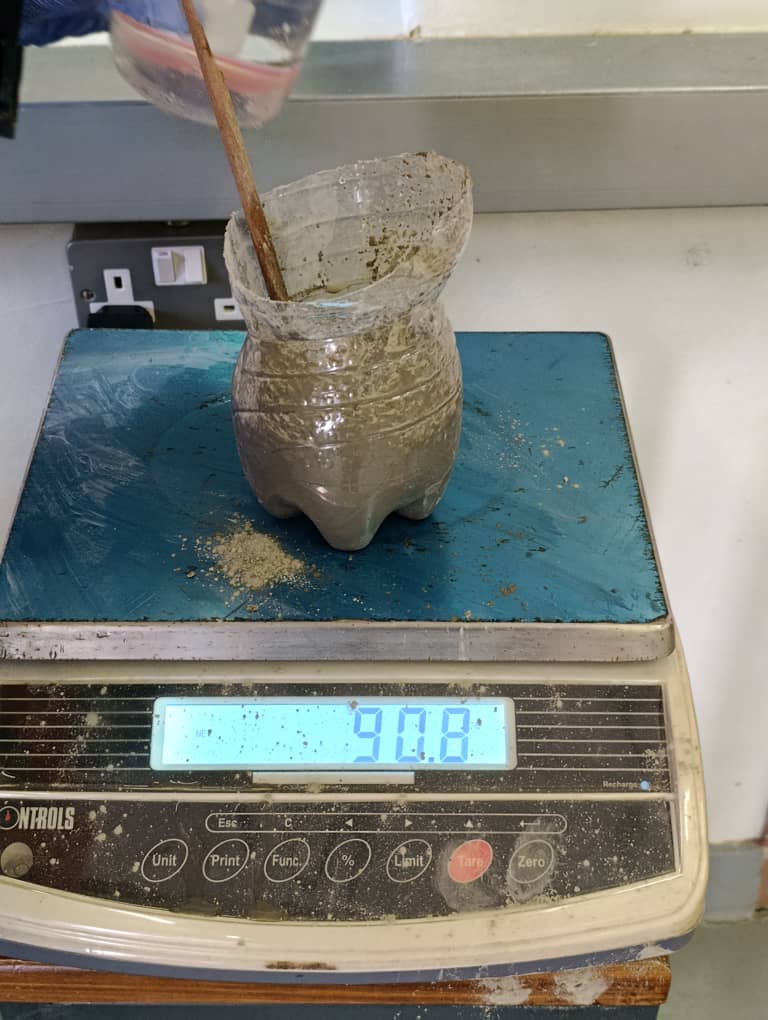

We used a mass of 170g in order to fill metal and silicon molds

Measured Mass: 170 g

This confirms that the cast was made using Portland cement, which has a much higher density than Plaster of Paris. The measured value matches the expected range when using cement instead of POP.

Objective: Compare 3D-printed molds (additive) versus CNC-milled molds (subtractive).

| Process | Tool | Material | Pros | Cons | Surface Finish |

|---|---|---|---|---|---|

| 3D Printing | FDM Printer | PLA | Fast, low cost | Layer lines, needs finishing | Smooth after sanding |

| CNC Milling | ShopBot CNC | Wax / MDF | Precise, smooth | Slower, material waste | Smooth with minimal work |