For this week's assignment we tried various test prints. These tests are crucial for ensuring quality, reliability, and efficiency in the 3D printing process, particularly for applications where functionality and durability are critical. They also help identify issues early, leading to cost and time savings, and ultimately, more reliable and consistent results.

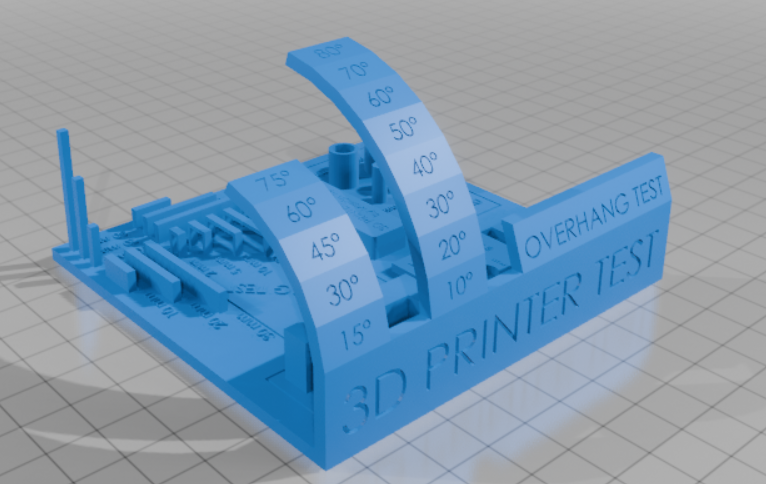

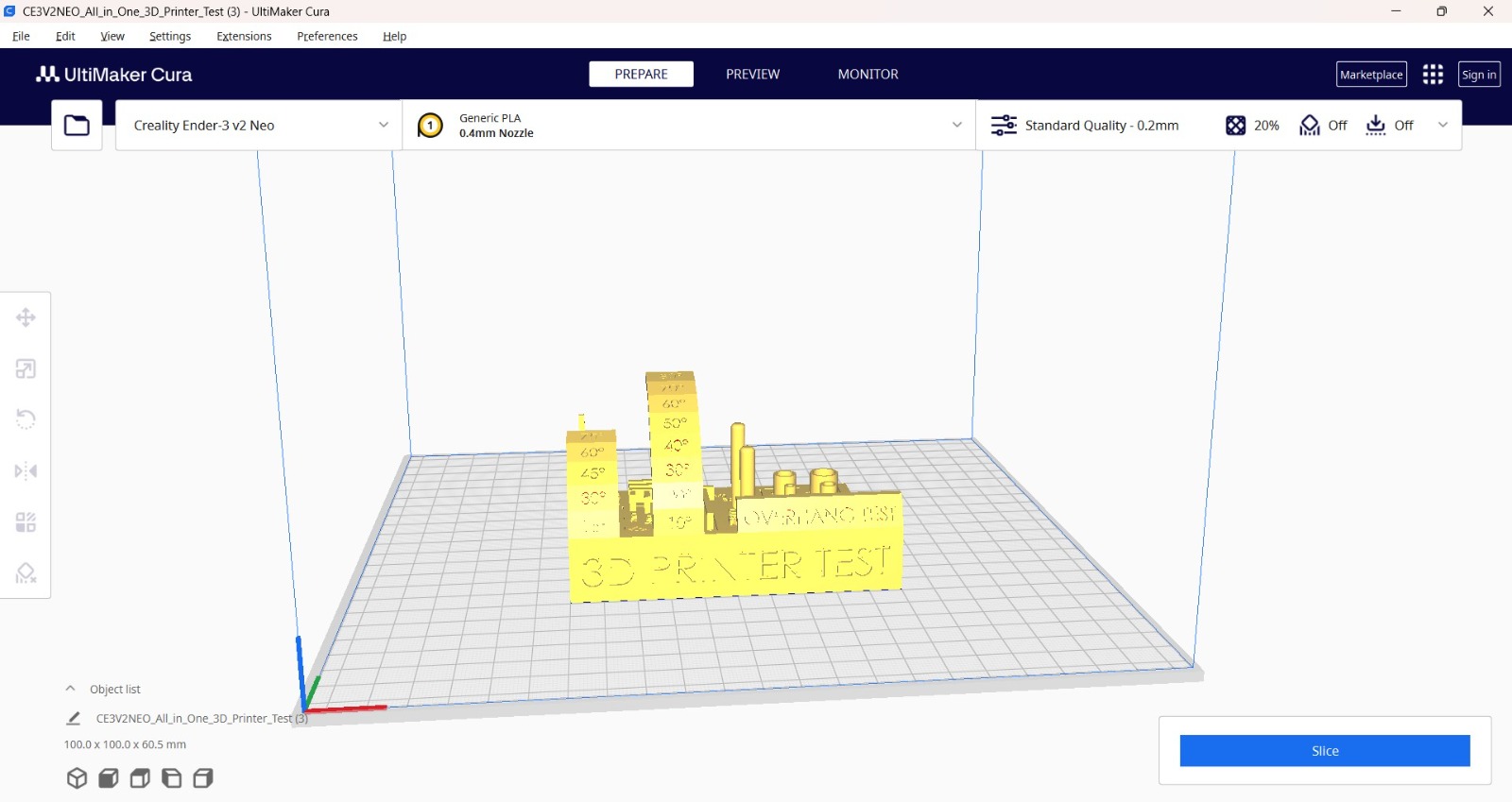

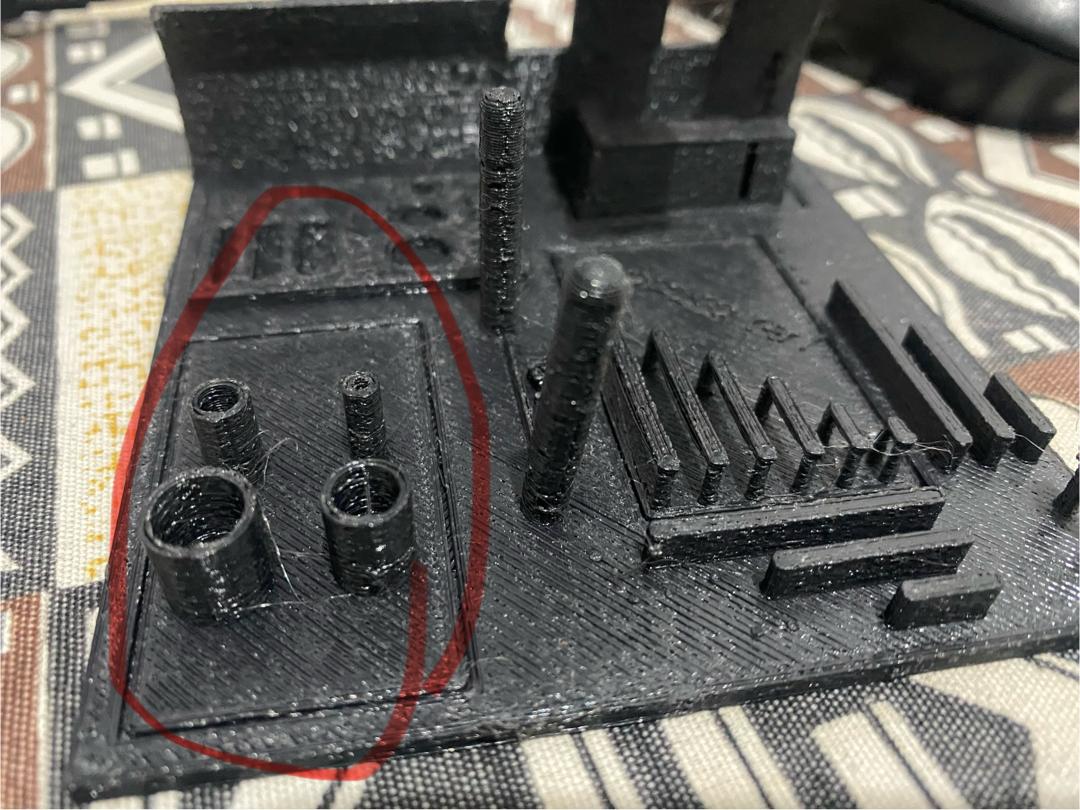

The first test we carried was the all in one print test of which we downloaded the file from THINGIVERSE, and sliced it using UltiMaker Cura slicer. The test file print included the following tests, stringing test, bridging test, tolerance test and scale test.

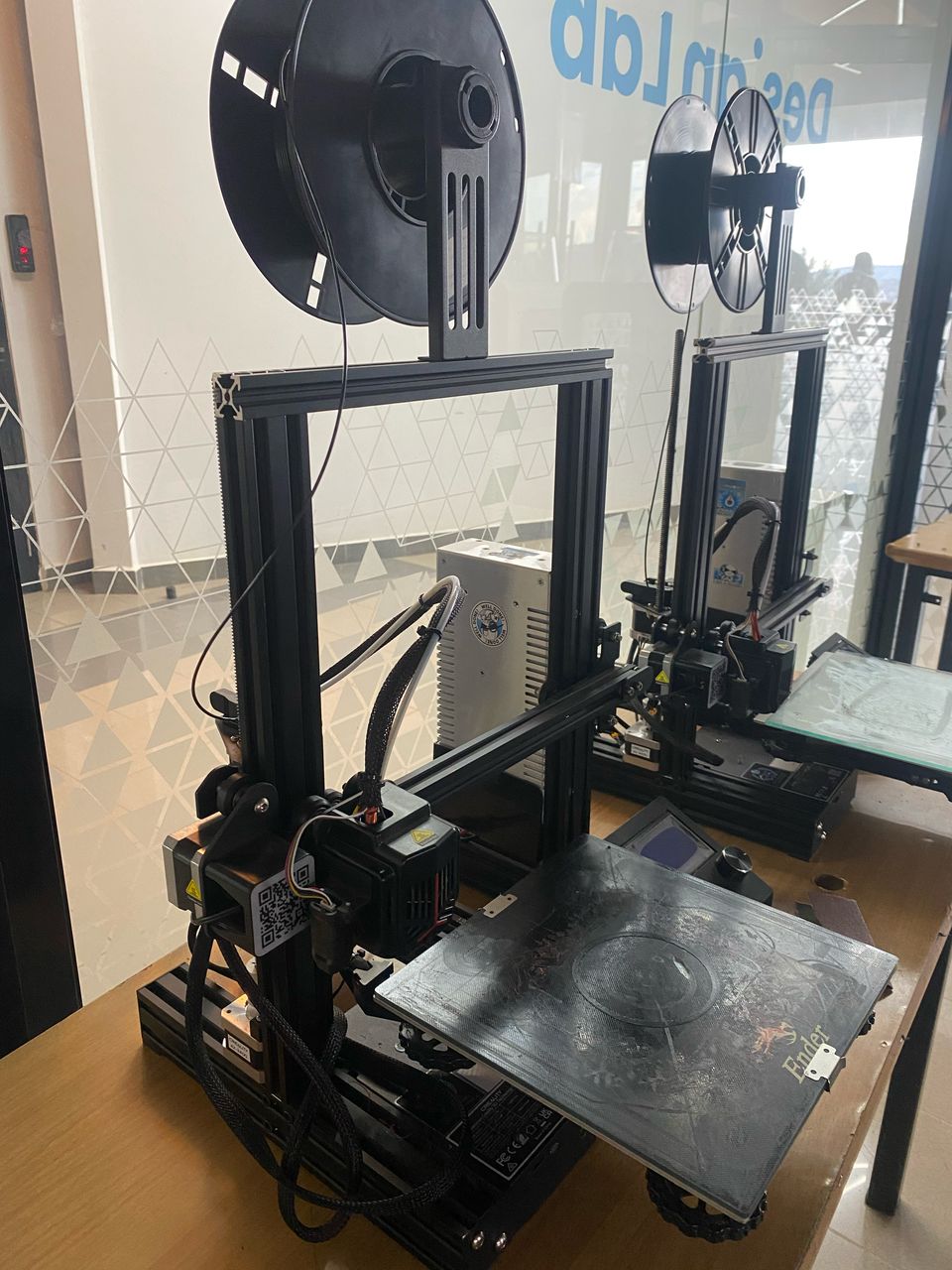

To print this file we used Ender3 3D printer machine, using a PLA filament of 1.75mm.

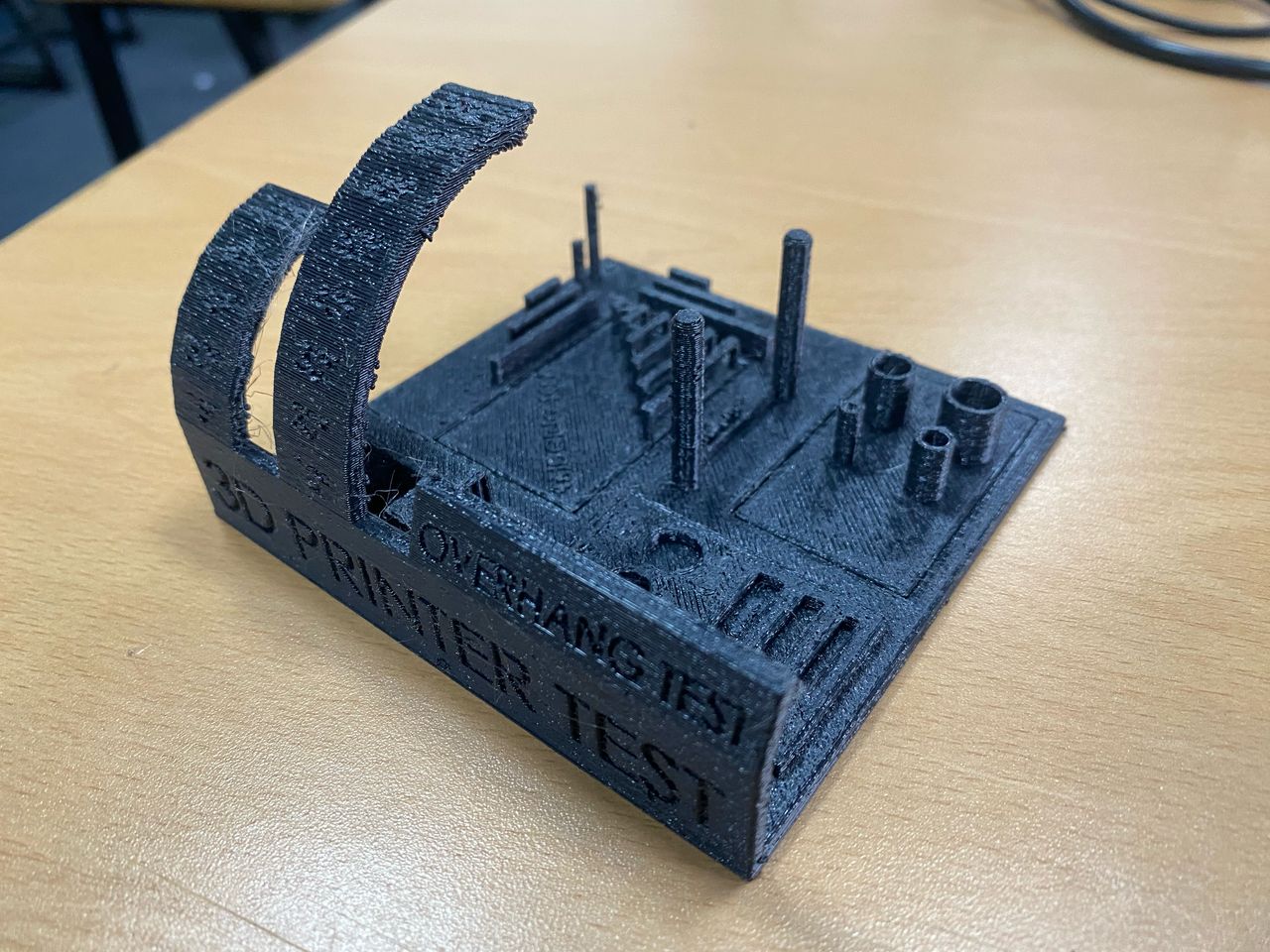

The final results

There is visible stringing (thin, wispy threads) especially around the arch structures. This was maybe because of higher temperature and lower speed. To fix this, we should slightly lower the temperature and increase the speed.

There is a minor sagging on the bridges, and steep overhangs are sharp, but there is some noticeable blobbing and slightly droopy ends. We can improve this by lowering bridge speed and increasing fan speed, for bridging and for overhangs by reducing the print speed.

There is a decent clearance between the gaps in the vertical blades printed and they are not fused at the base, which shows the tolerance is good.

The cylindrical holes are round but have slight over-extrusion on the walls, reducing their inner diameter. To fix this we have to make sure the extruder axes are properly calibrated for accurate movement and extrusion.

The surface shows a lot of micro bumps and slight inconsistencies in layer lines possibly due to over-extrusion or poor temperature control.

We can conclude that the 3D printer needs to be properly calibrated, with the focus being on the retraction and temperature settings to eliminate stringing, improving cooling and bridge speed for better overhang performance and extrusion and dimensional accuracy to enhance fit and finish on tolerance-dependent features. With these targeted adjustments, the printer can reach a much higher standard of quality.