Molding and Casting

Assignment: Design a mold around the process you’ll be using, produce it with a smooth surface finish that does not show the production process, and use it to cast parts.

Molding and casting is a two-part fabrication process used to replicate shapes or objects. It involves creating a mold (a hollow impression of an object) and then casting a material into that mold to produce a solid replica. This process is widely used in manufacturing, sculpture, product design, and prototyping.

What is Molding?

Molding is the process of creating a negative cavity that captures the shape of an object. This mold is made using a flexible or rigid material, usually poured or formed around a “master” or “positive” object. After curing, the mold can be used to reproduce the original form by casting.

What is Casting?

Casting is the process of filling the mold cavity with a liquid or malleable material (such as resin, plaster, silicone, or soap). Once the casting material hardens, it is removed from the mold to produce a solid replica of the original object.

Key Terms and Definitions

- Positive Master: The original object or model from which a mold is made.

- Negative Mold: The hollow, reverse shape of the original object, used to create casts.

- Cast: The final object produced by pouring material into a mold.

- Flexible Mold: A mold made from silicone or rubber that allows easy removal of complex shapes.

- Rigid Mold: A hard mold, often made of plastic or plaster, used for simple, non-flexible castings.

- Curing: The process by which a mold or cast material hardens over time through chemical reaction or cooling.

- Demolding: The process of removing the cured object from its mold.

- Draft Angle: A slight angle added to mold walls to help with demolding and reduce friction.

- Undercut: A part of the design that may trap the cast and make demolding difficult or damaging.

- Release Agent: A spray or coating applied to the master or mold to prevent sticking.

Fab Lab Use Case

In the Fab Lab, molding and casting is typically demonstrated by designing a 3D model (like a coin, tag, or shape), fabricating a mold using CNC milling or 3D printing, and casting a material like soap, resin, or plaster into that mold. The goal is to understand material properties, replication techniques, and the advantages of subtractive (mold making) and additive (casting) workflows.

This process not only teaches digital fabrication and traditional manufacturing methods but also reinforces design thinking, attention to tolerances, and iterative testing. Due to scheduling issue I was not able to conduct a machined attempt. However, we will attempt to improve the design using CNC mill.

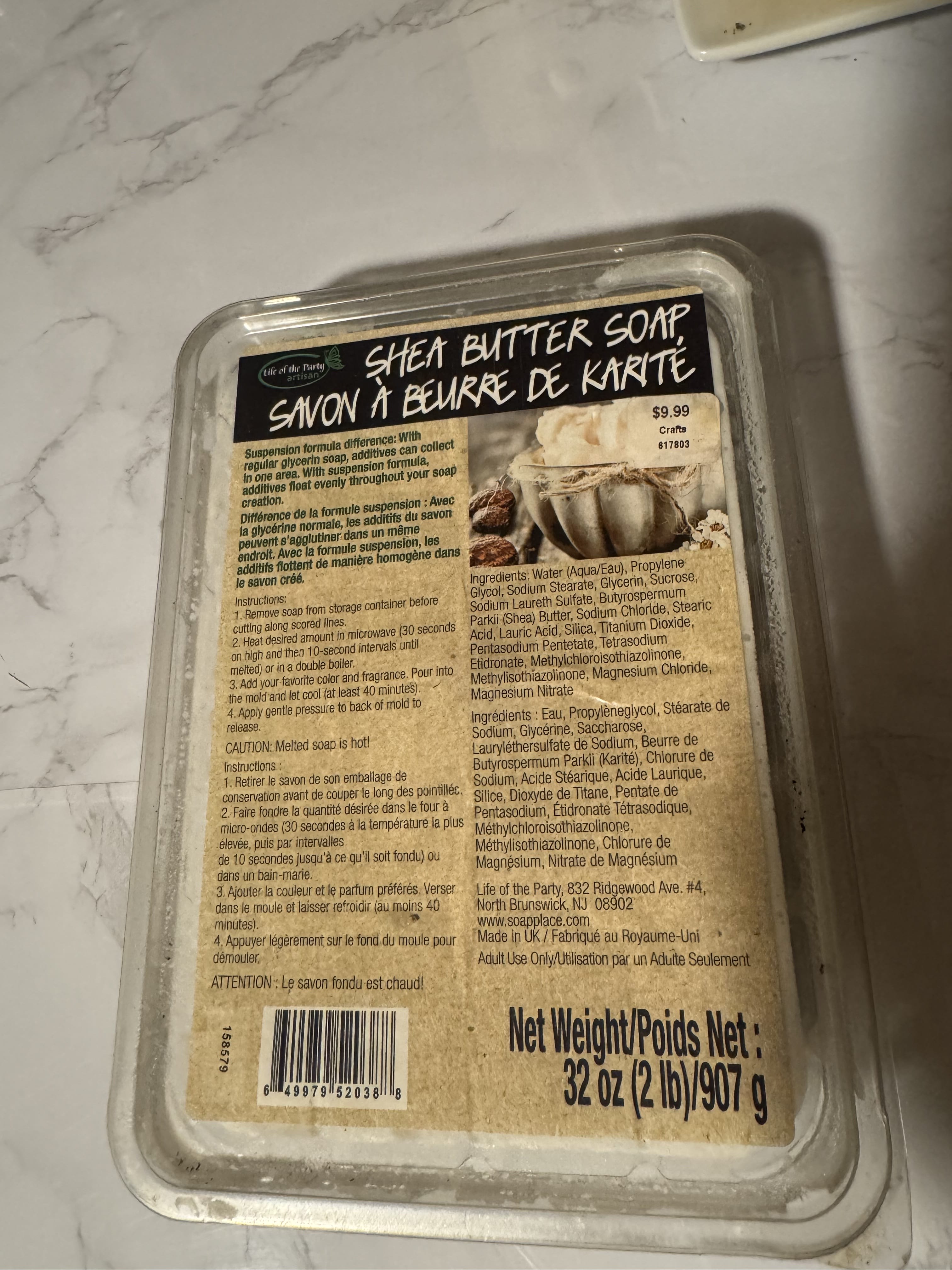

Amazing Mold Maker – Mixing & Molding Guide

(Platinum-Cure Silicone Rubber)

Basic Specs:

- Mix Ratio: 1:1 by volume (Part A : Part B)

- Pot Life: ~20–30 min

- Demold Time: ~4 hours at room temperature

- Cure Type: Platinum (addition-cure silicone)

- Use Case: Soap, resin, wax, plaster, low-temp materials

Step-by-Step Directions:

-

Prep Workspace

Clean surface and avoid latex gloves — they contain sulfur, which can inhibit curing in platinum silicones.

We used polyethylene-based gloves, which are safe and non-reactive.

Use clean, dry cups and stir sticks. -

Measure

Pour equal parts A & B into a mixing cup.

Mix by volume, not weight. -

Mix

Stir for 3 full minutes.

Scrape sides and bottom.

Stir slowly to minimize bubbles. -

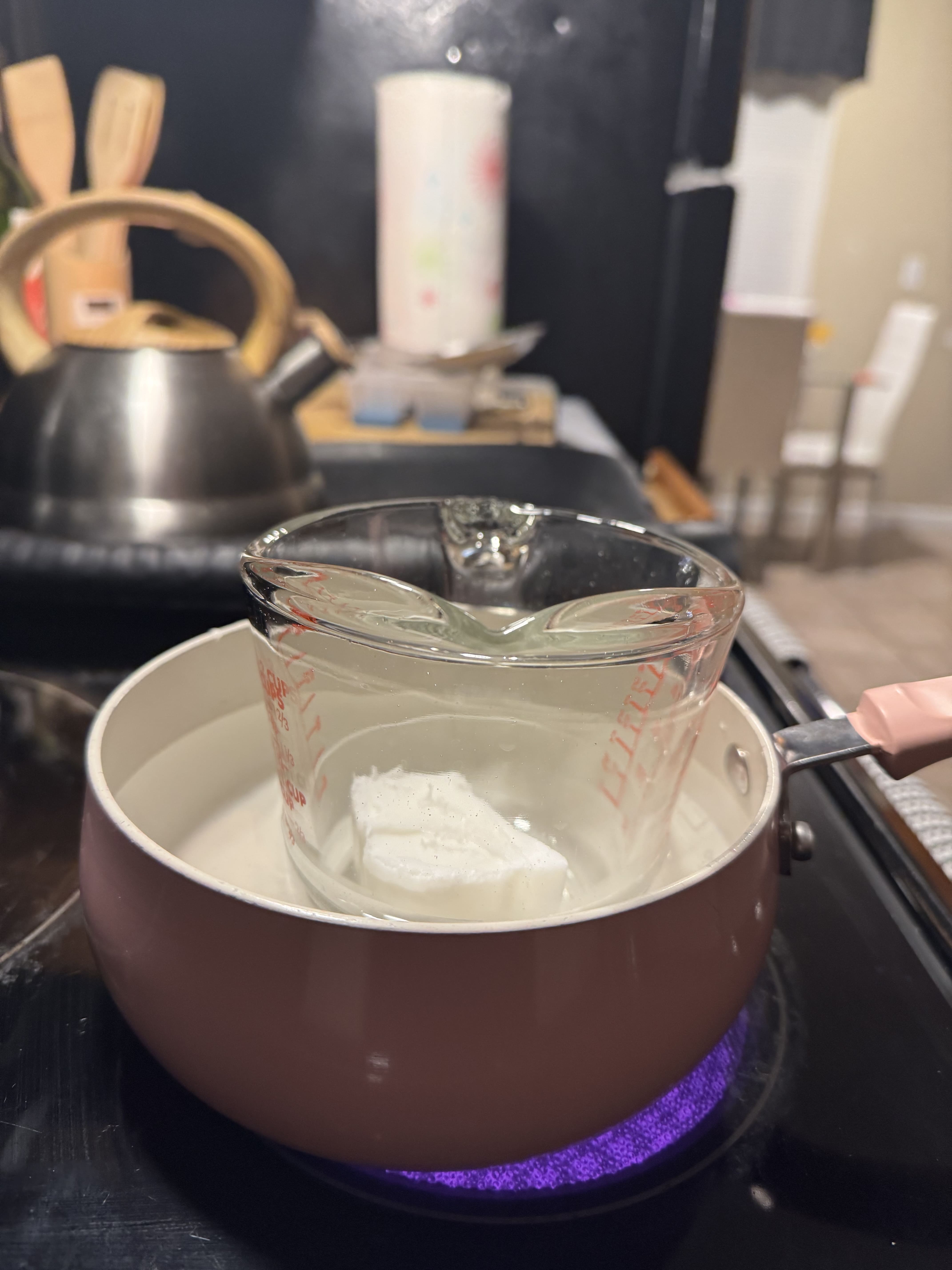

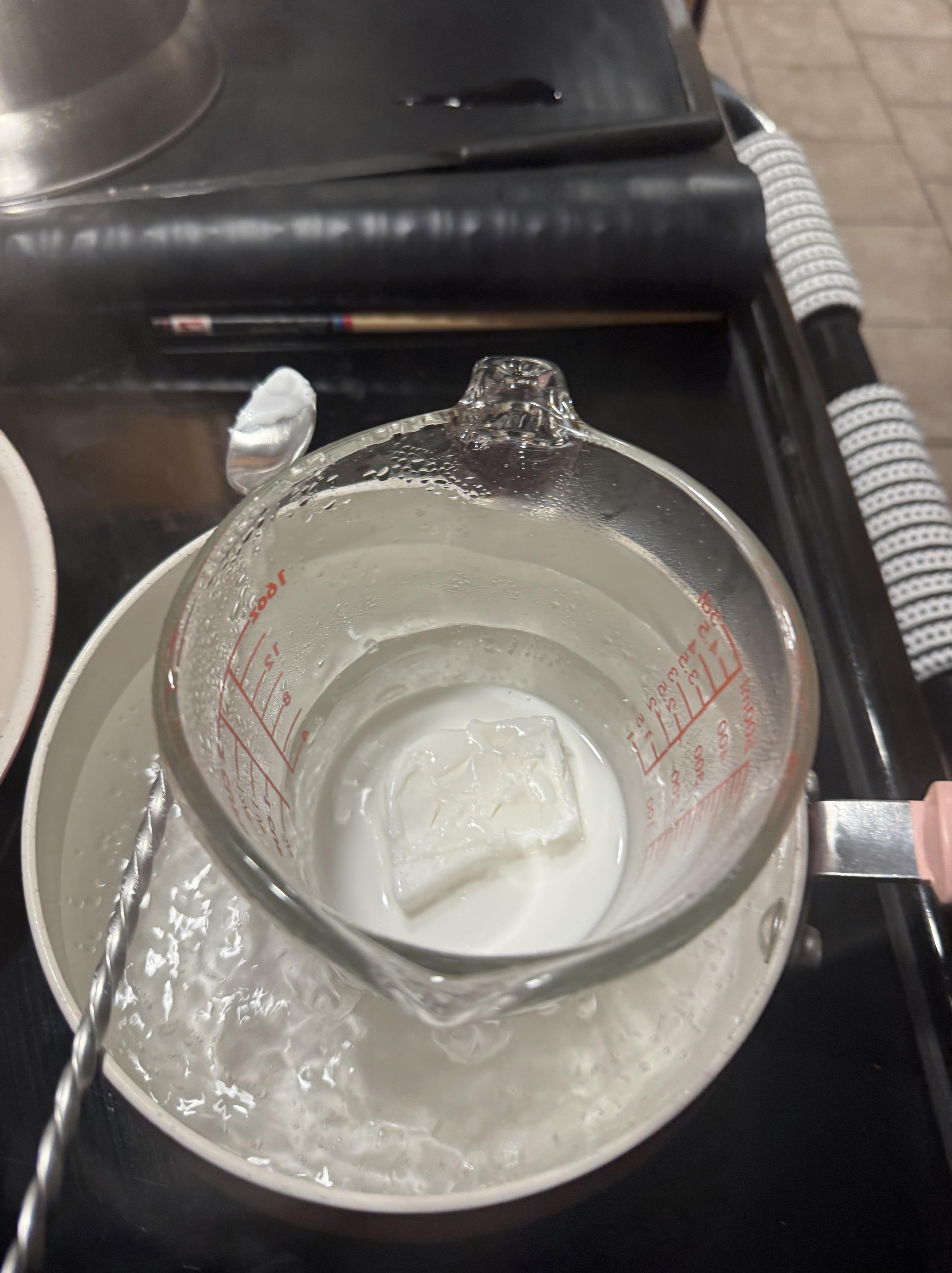

Pour

Pour from a high, thin stream into a mold box corner.

Let silicone rise around the object.

Tap or vibrate gently to release air bubbles. -

Cure

Let sit 4+ hours undisturbed at room temperature.

Check that the mold is firm and non-sticky. -

Demold

Gently peel mold from object.

Wash with soap and water before using for soap casting.

Pro Tips:

- Don’t use sulfur-based clay (prevents curing)

- Store at room temperature, sealed tight

- Optional: use mold release on 3D prints or textured objects

- Post-cure clean: Wash mold before casting soap

- If this is a food grade mold be sure to use food safe materials.

Perfect for:

- Melt-and-pour soap

- Resin charms

- Chocolate & wax molds (if food-safe certified)

- Plaster or concrete minis

Moulding & Casting Decorative Soap