Week 12 - Mechanical design & machine design

In this week's group assignment, our task was to design a machine that includes mechanism, actuation, automation, and application.

Here is our 1 minute presentation video:

Design Process

We began by brainstorming ideas for our group project. I suggested creating a mechanical movement for a handheld massage device, and we decided to move forward with that concept.

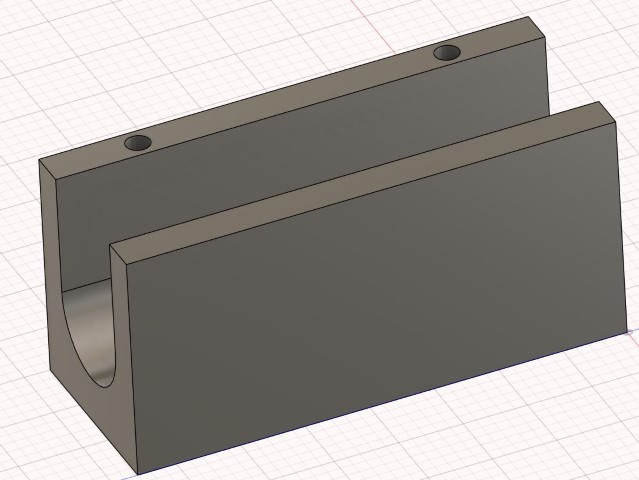

First, I designed a holder for a commercial KiCa A3D handheld massage device. I measured its dimensions with a caliper and added vertical rails (holes) for the vertical bars to slide freely in.

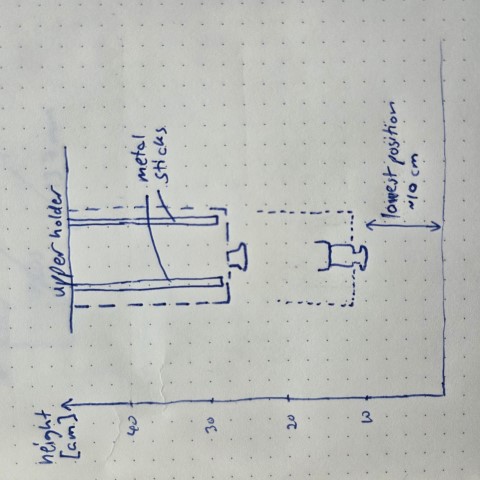

This worked well, but I wanted to make a taller version. The goal was for the holder to rest inside the vertical metal rods when at its lowest position (held by strings) and still have enough clearance to move freely upward, giving room for the massagee.

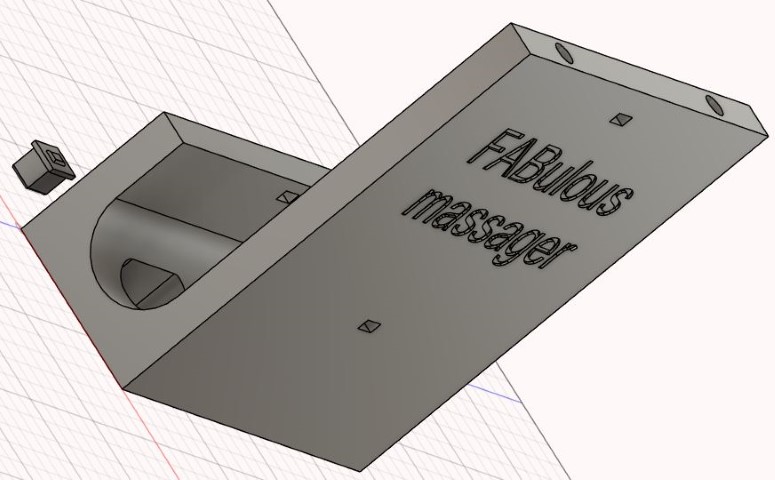

Based on the above plan, I decided to go with a 20 cm tall holder piece. I also added a button extender so the device can be turned on through the holder.

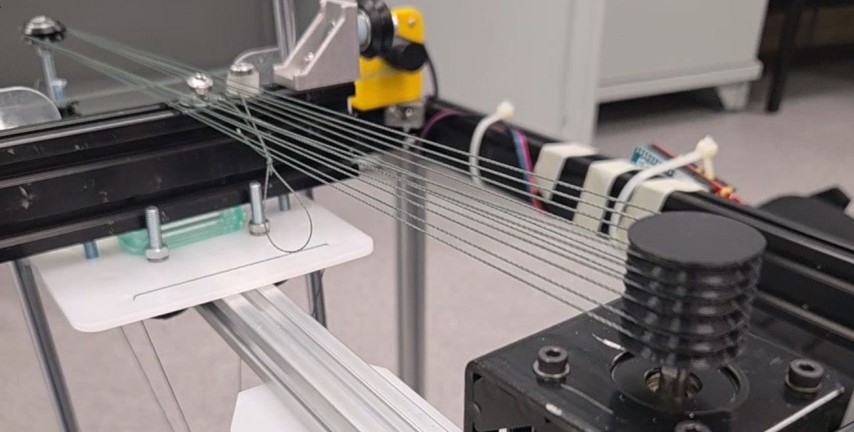

To guide the XY movement, I laser-cut some suitable acrylic pieces with some help from Shahmeer:

We decided to use a string pulley system because the belts we had were too long for our setup. With Shahmeer, we designed and 3D-printed string pulley attachment pieces for the stepper motors. On the other end, the strings were attached to a slotted wheel with ball bearings.

Shahmeer handled the coding for the stepper motors, including joystick control and automation. Together, we also adjusted the stepper motor shield current settings.

In the end, we were quite happy with how well it worked, especially given that this was a side project on a tight schedule.

More details about this week's work can be found on the group assignment page.