Individual Assignment:

- Design a machine that includes mechanism+actuation+automation+application

- Build the mechanical parts and operate it manually

- Document the group project and your individual contribution

- Actuate and automate your machine

- Document the group project and your individual contribution

To see the full extent of this project, please visit the link below and hit CTRL+F then type "Week 12." Any documentation not provided here is either because Vicky did that portion or because we both figured out and contributed to a specific portion of the project together. -

Moonlighter 2025 Group Assignments

We both did some research and looked to Stoccafisso; a well known automata maker; for reference and inspiration. While his work tends to be more hand carved and highlights the simplicity in the mechanics of his design, we wanted to get a little more technical with the design and function of the mechanics.

As far as subject matter, after rolling around a couple of ideas we landed on creating a dragon that would flap its wings when triggered by a motion sensor. We both are into fantasy, the arts, and films and both of our fab labs host camps/classes for kids. This could be a great project to teach kids about animation, film making, and animatronics.

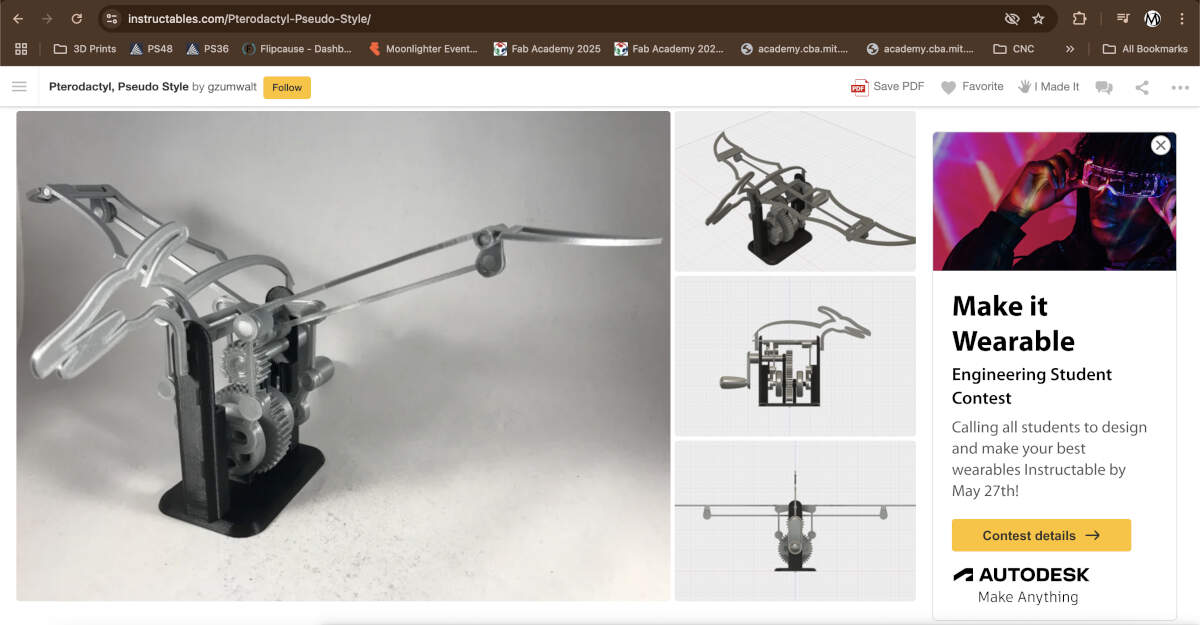

To get our bearings and figure out how to actually construct our machine, we looked for a template on instructables to print a test sample. Together, we found a sample that had flapping wings and immediately went to print this file.

Pterodactyl, Pseudo Style Tutorial

After sending the sample file to print, we constructed it together and started to get a better understanding of the mechanical components and construction.

From this point forward, I will be speaking about my contributions to this project. The text above is in place to show where it all started.

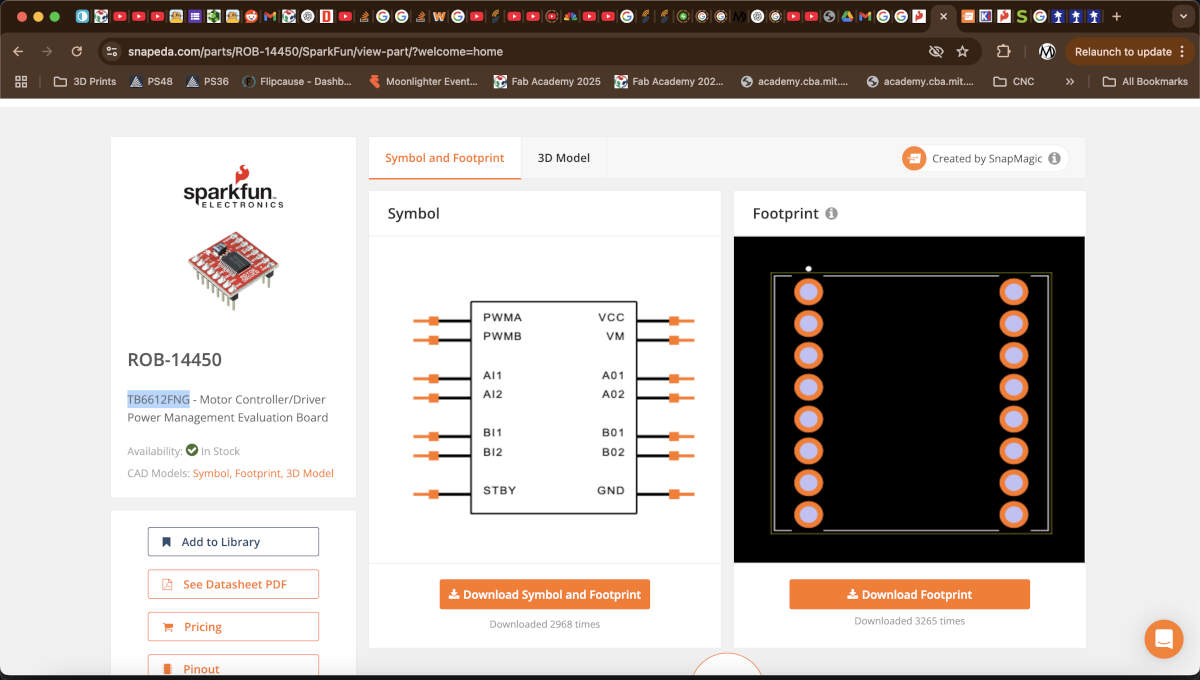

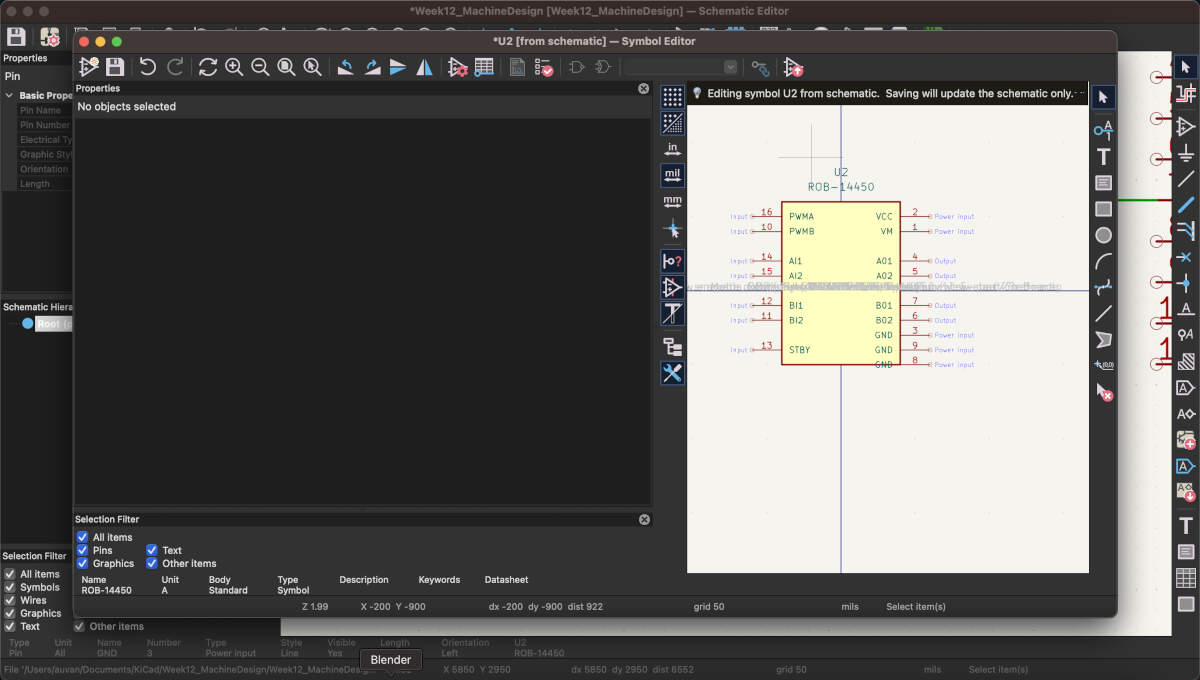

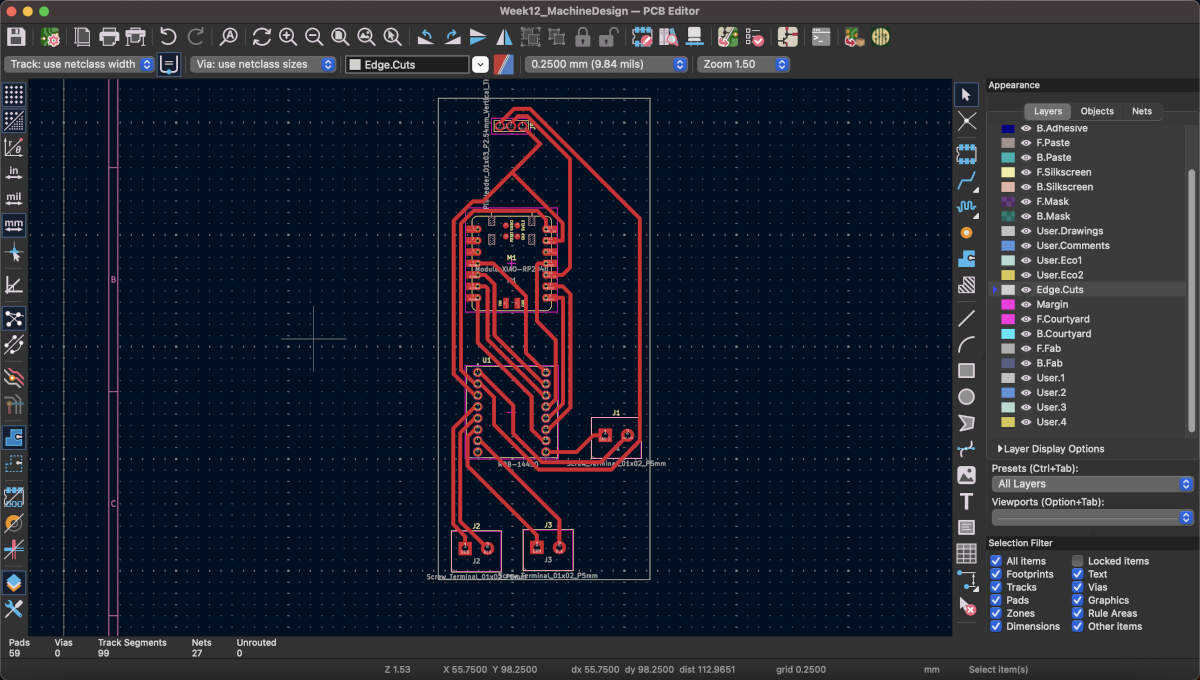

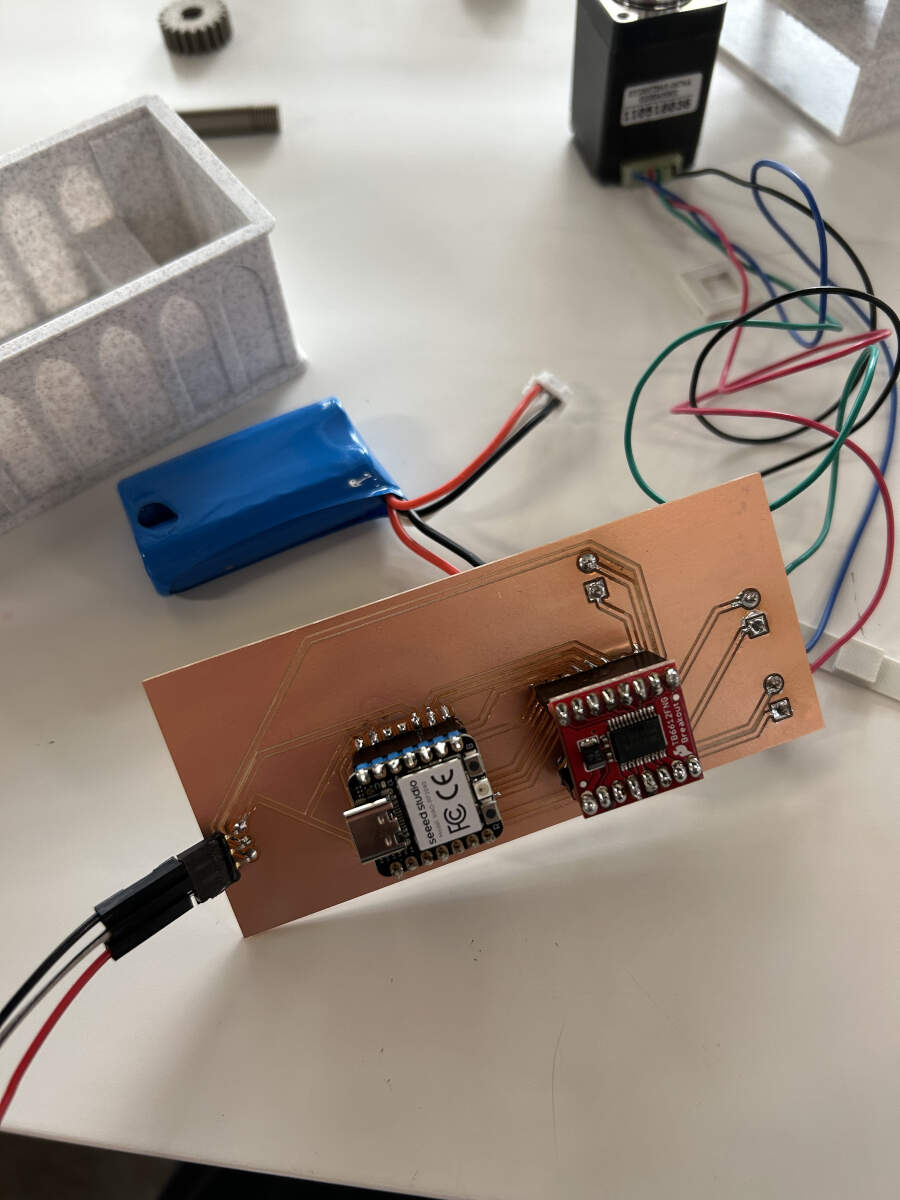

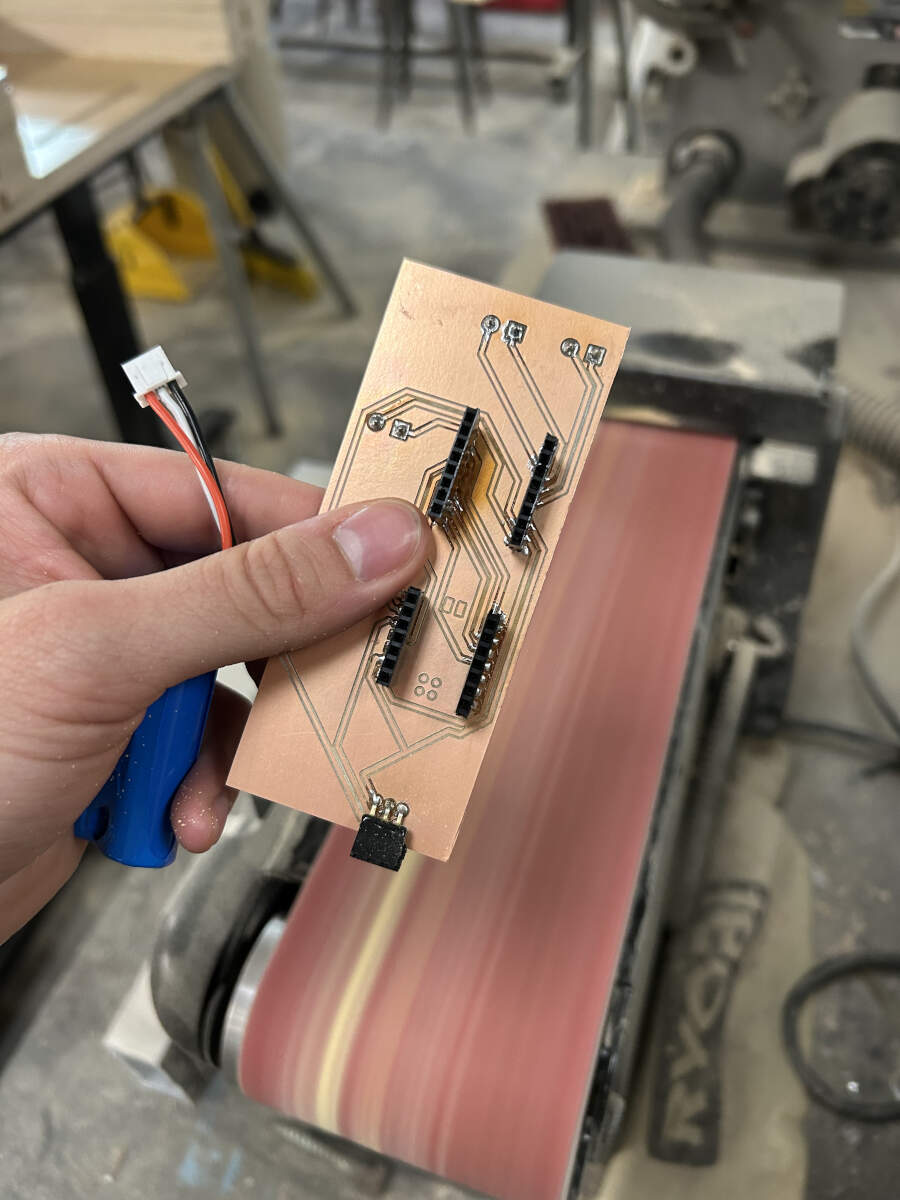

Already having gone over the connections with Vicky, Augusto got to work designing the PCB board on KiCad. The first step to complete was locating a footprint for the motor driver online. Thankfully SnapEDA had both the symbol and footprint on their website.

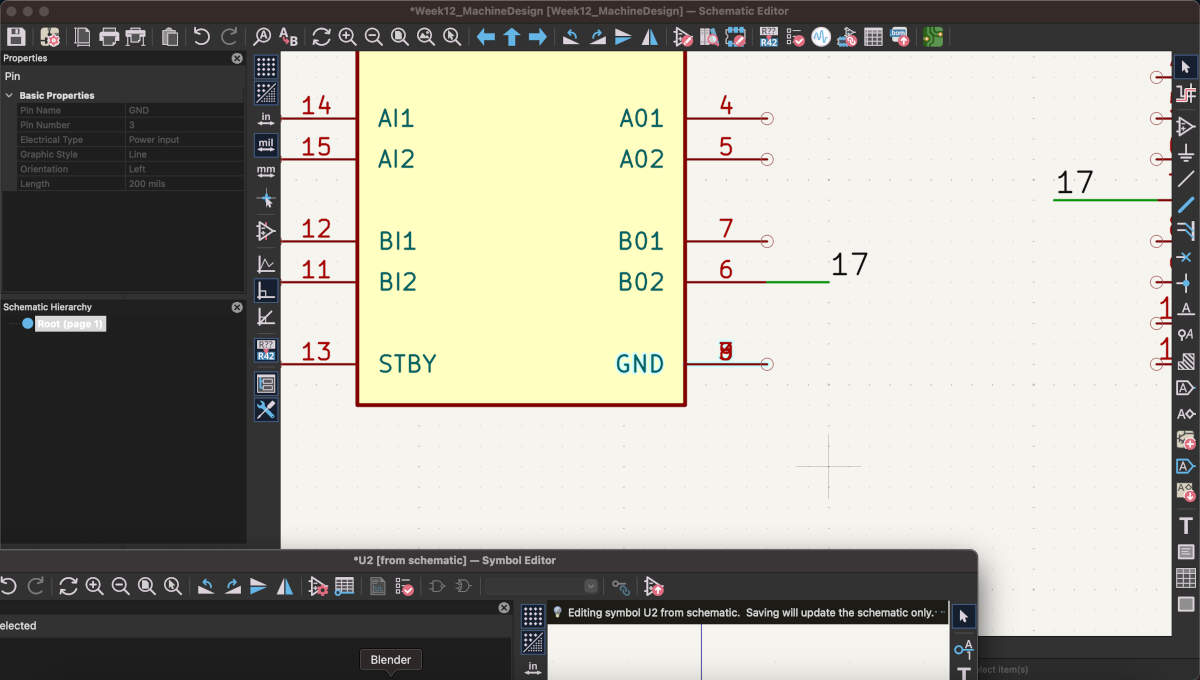

Unfortunately for Augusto, the symbol for the schematic portion of the design needed editing because 3 of the pins were overlapping each other.Augusto was able to move those three pins away from each other so that they could be read and connected to other parts of the board.

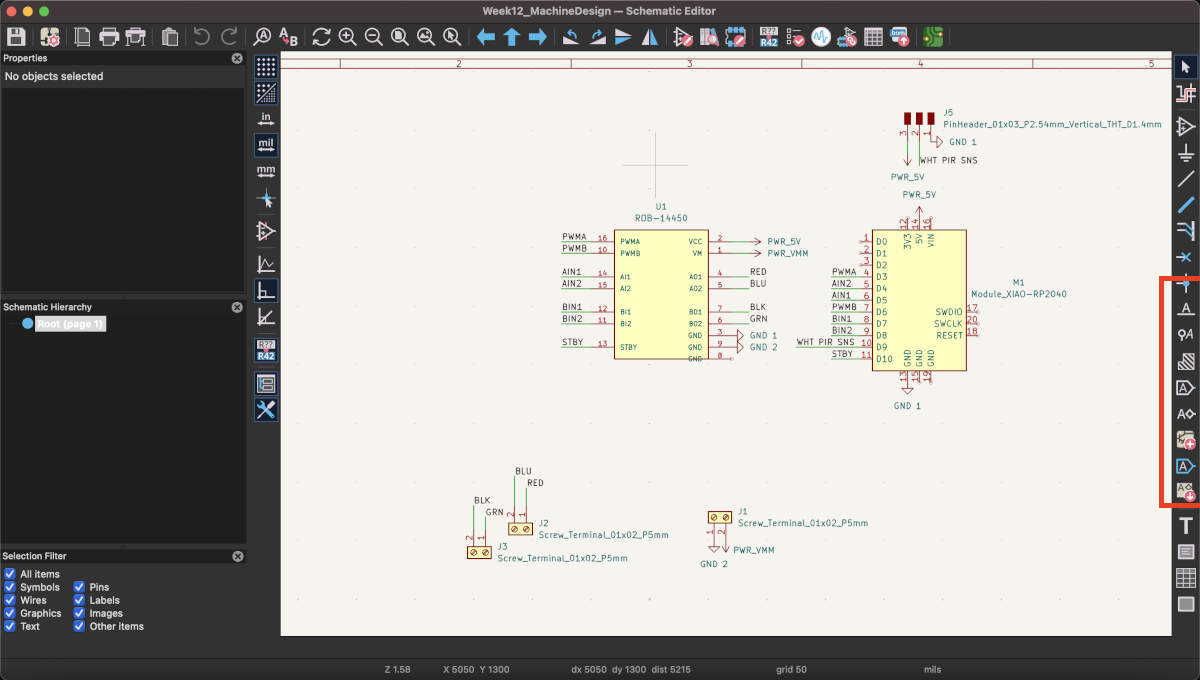

The schematic portion was finalized using a heavy amount of tags to signify what was connected to what otherwise it would have been too much visual clutter.

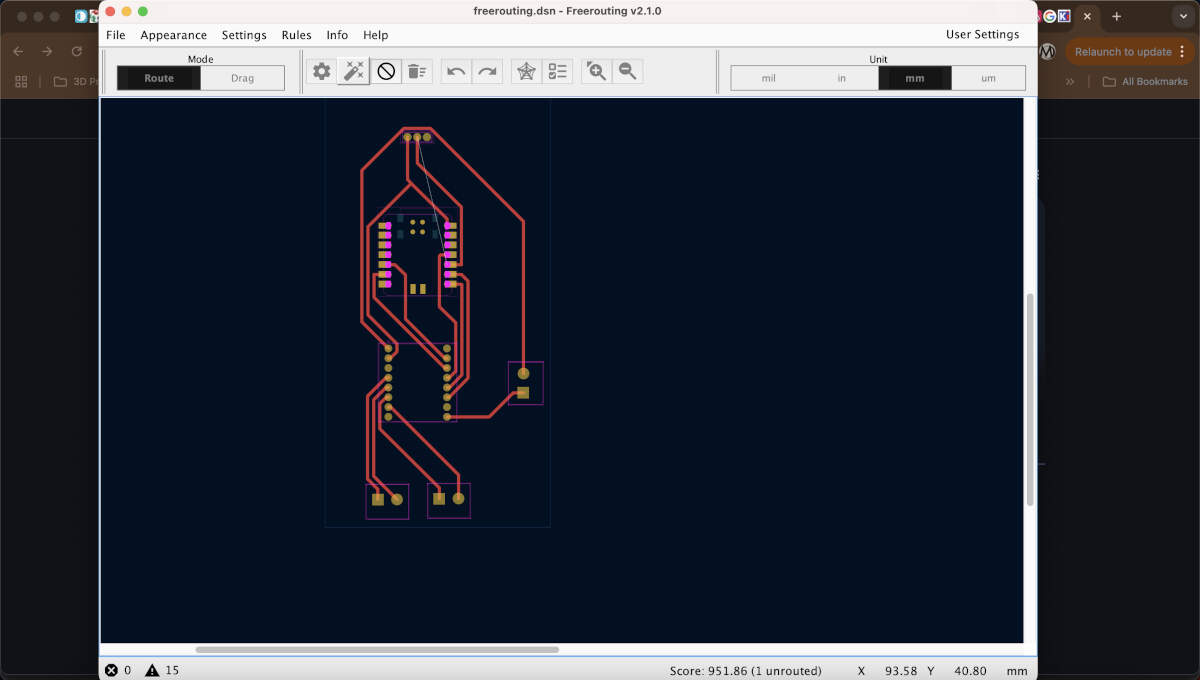

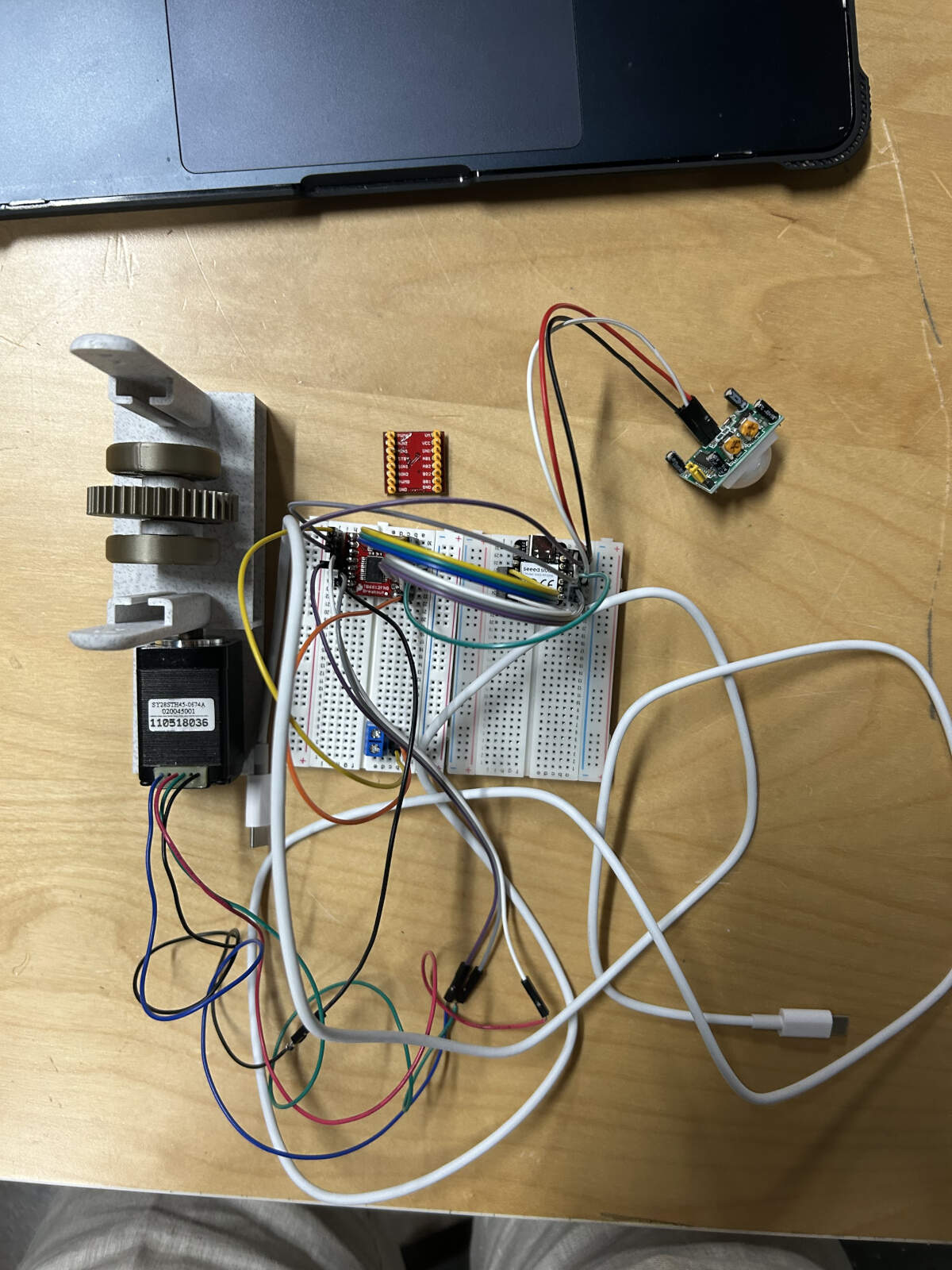

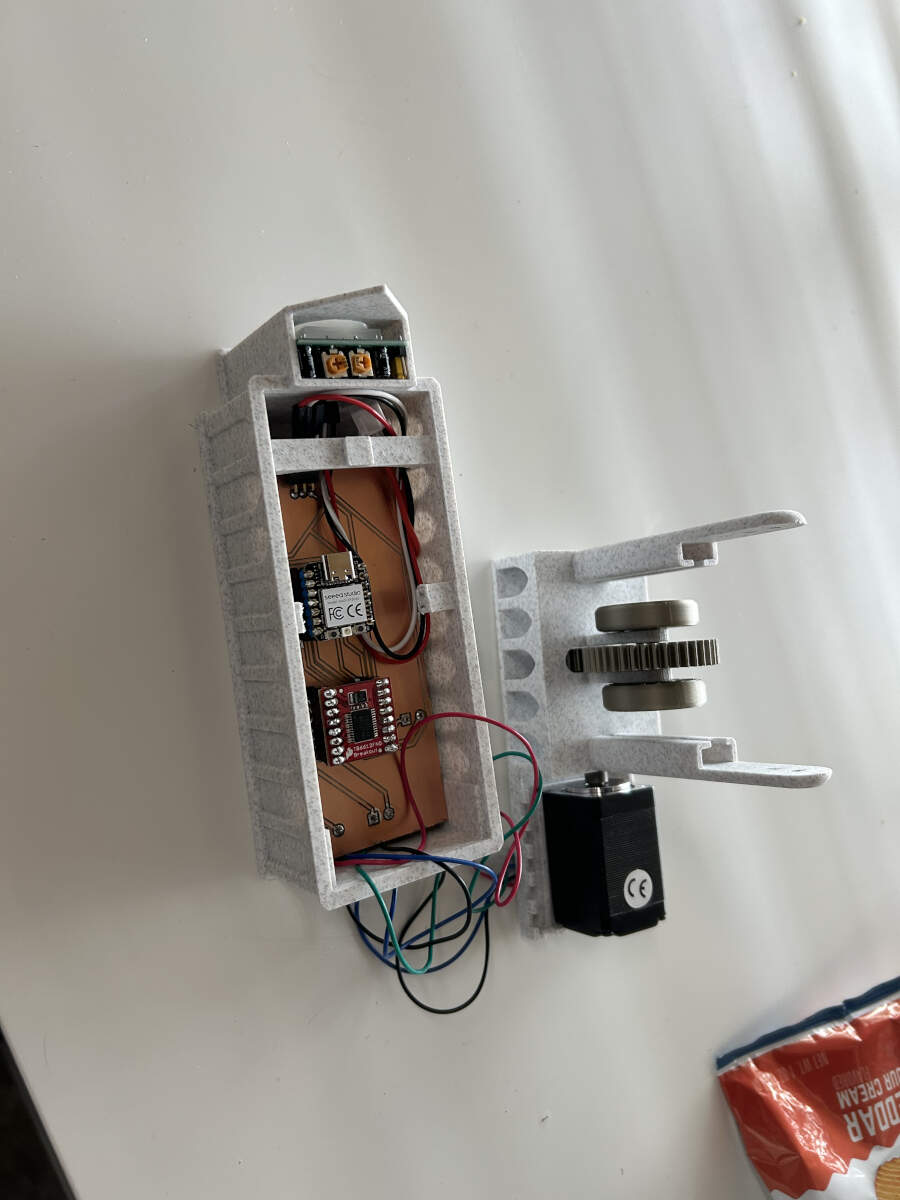

Augusto proceeded to lay out the footprints/components in a linear fashion that made sense for the soon-to-be redesigned model. One end would connect to the PIR sensor with the microcontroller being closest to it , the other end connected to the stepper motor which lead directly to the motor driver as suggested by the earlier mentioned ChatGPT log. To save on time, Augusto tried FreeRouter for the first time and was able to generate a perfect set of paths for the board after generating a few different designs/seeds.

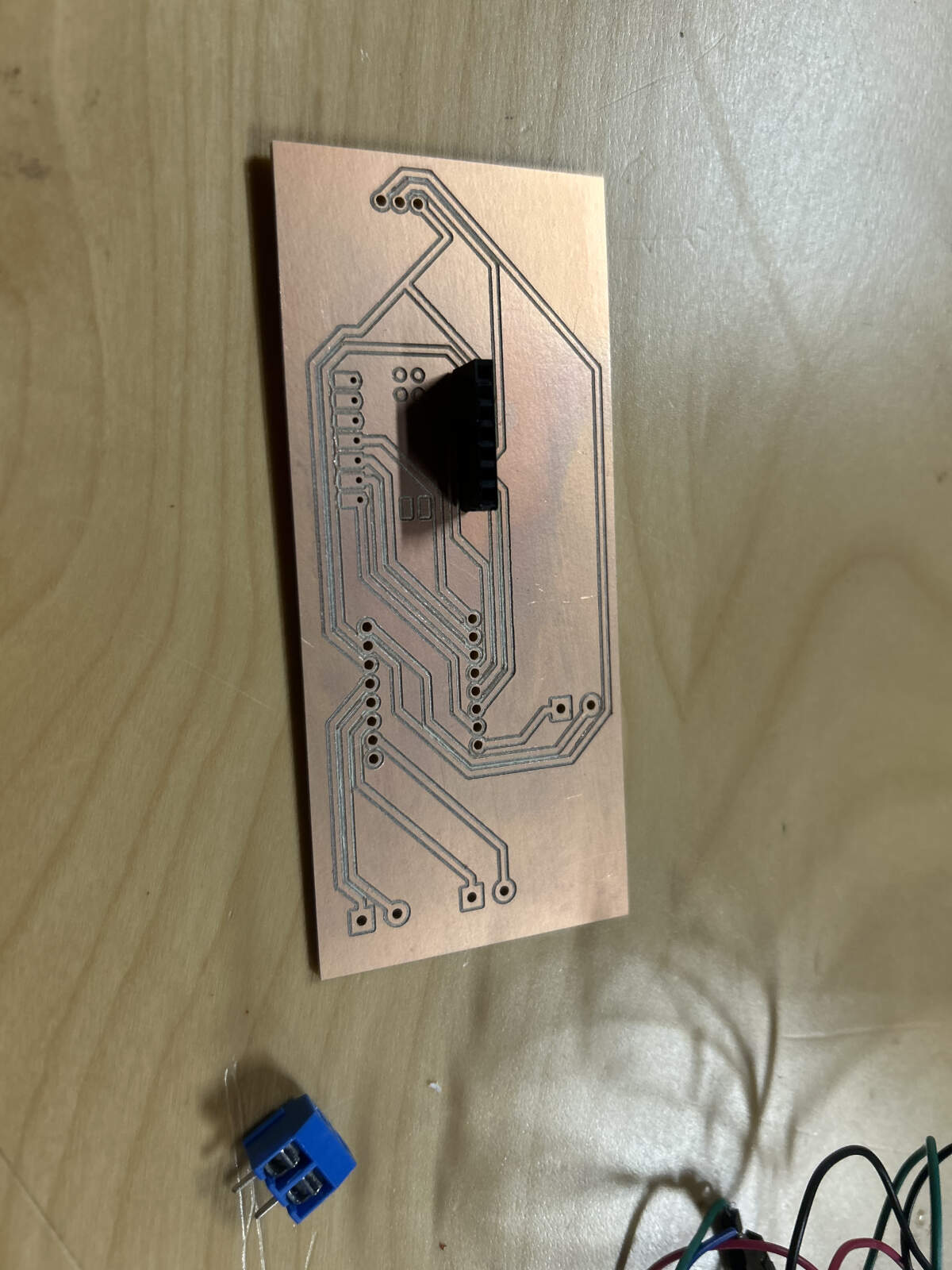

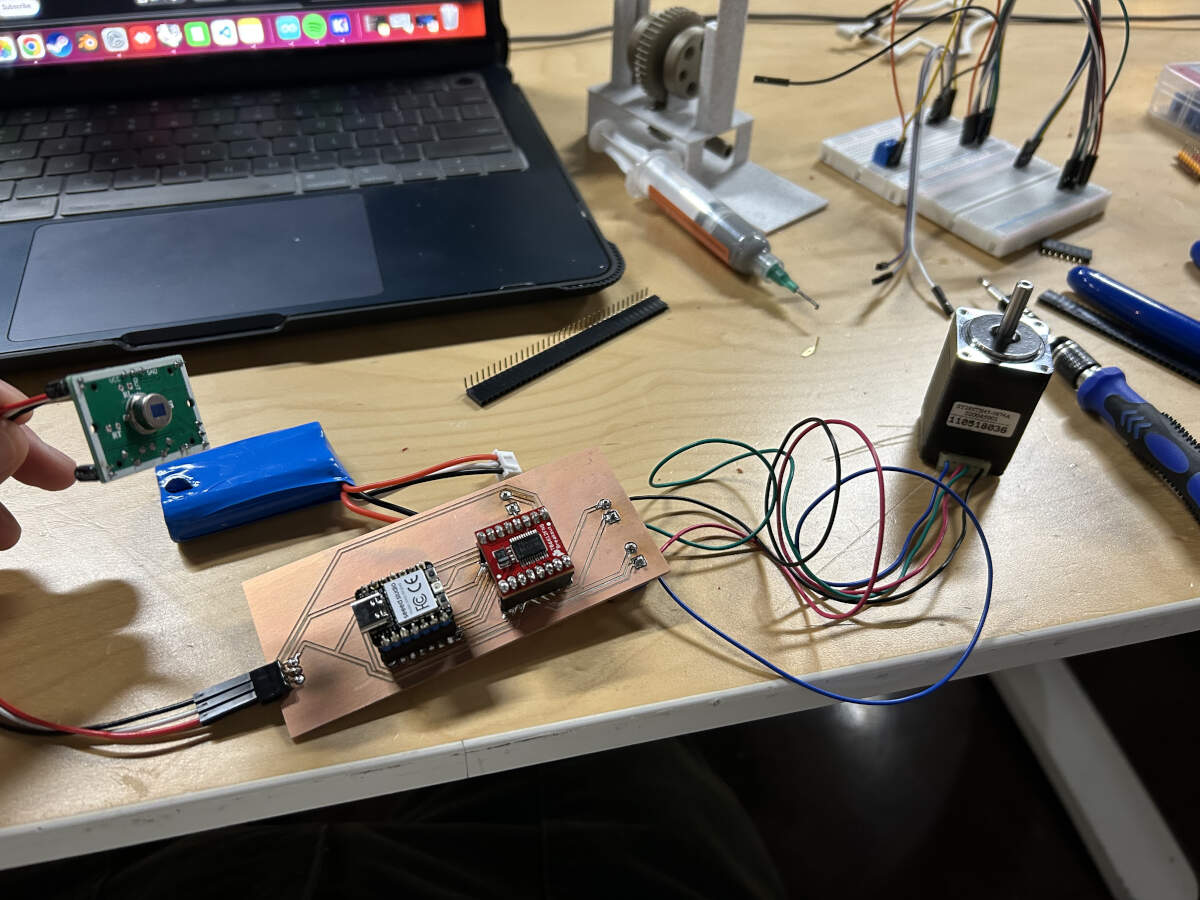

Once Augusto finished the PCB board design, he sent the files over to Vicky who proceeded to mill the board. Once milled, Vicky started to solder the pin headers to the board to make it easier to test and switch out microcontrollers, inputs and outputs if needed. Augusto finished soldering the connections for the additional power, inputs and outputs.

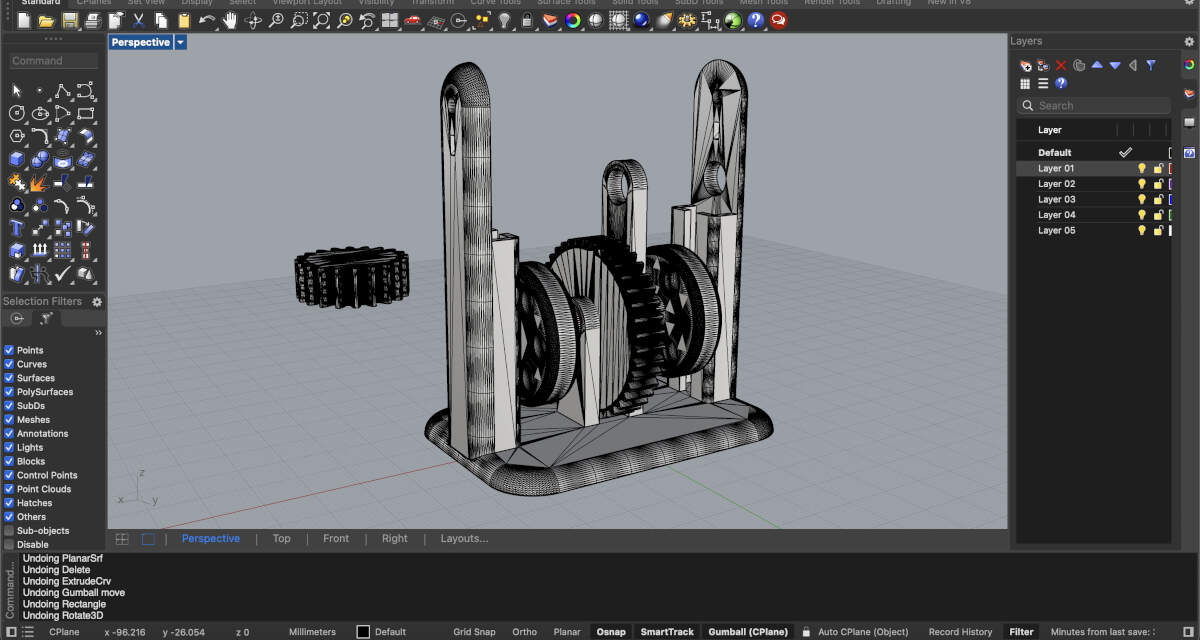

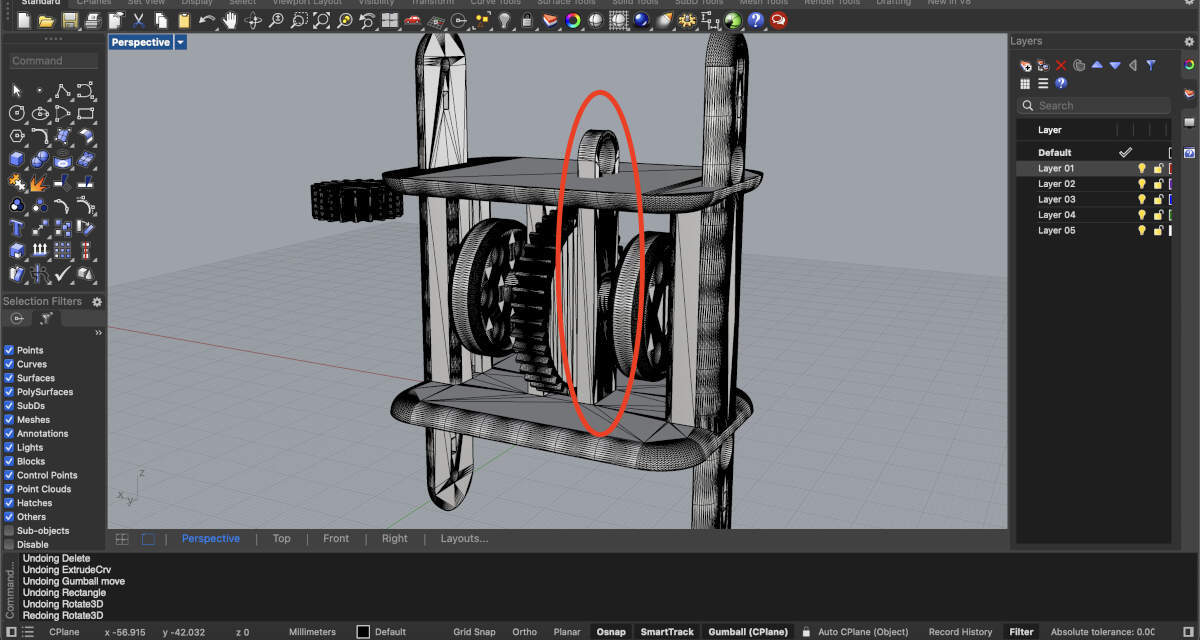

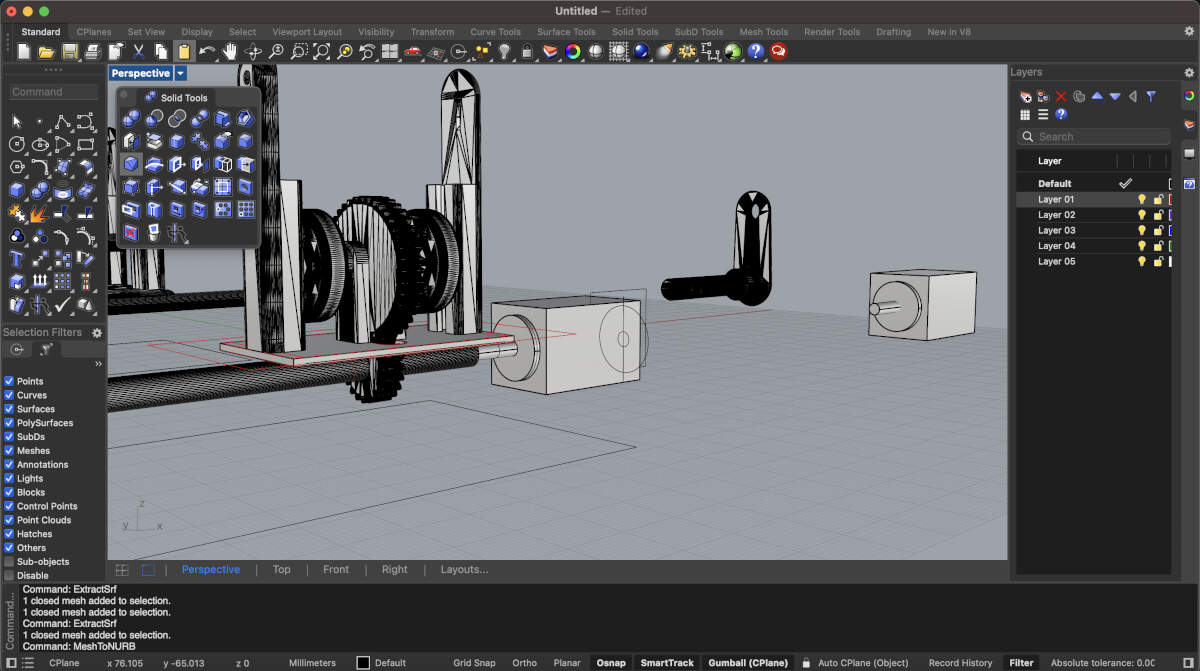

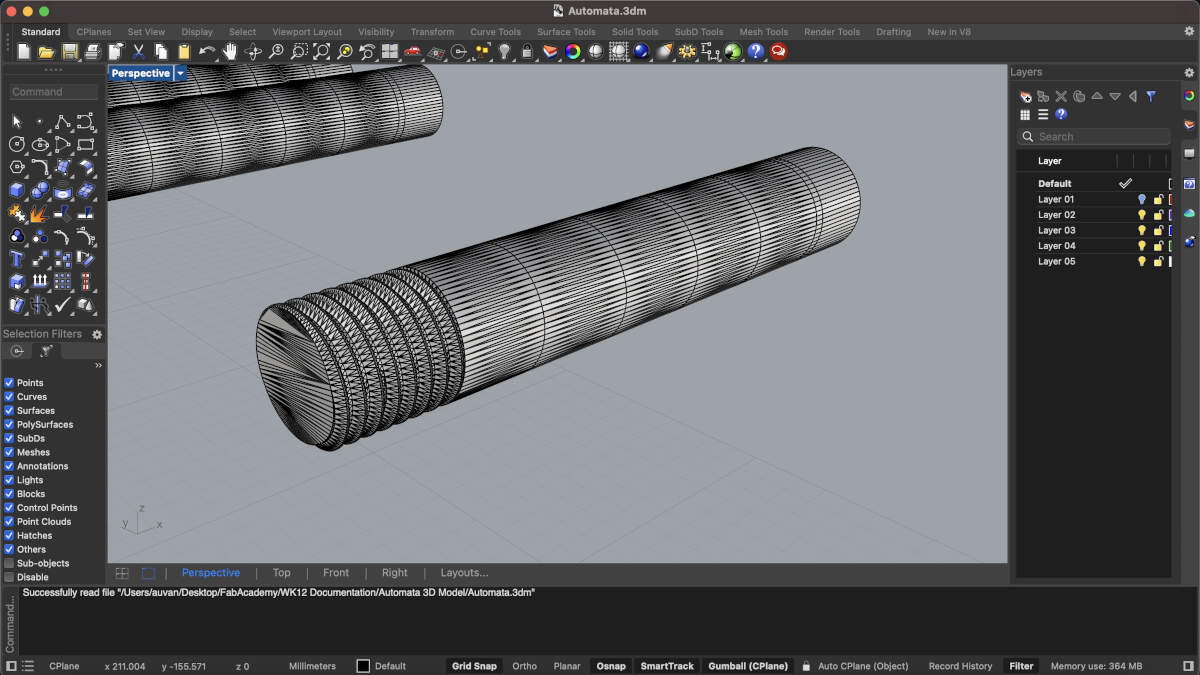

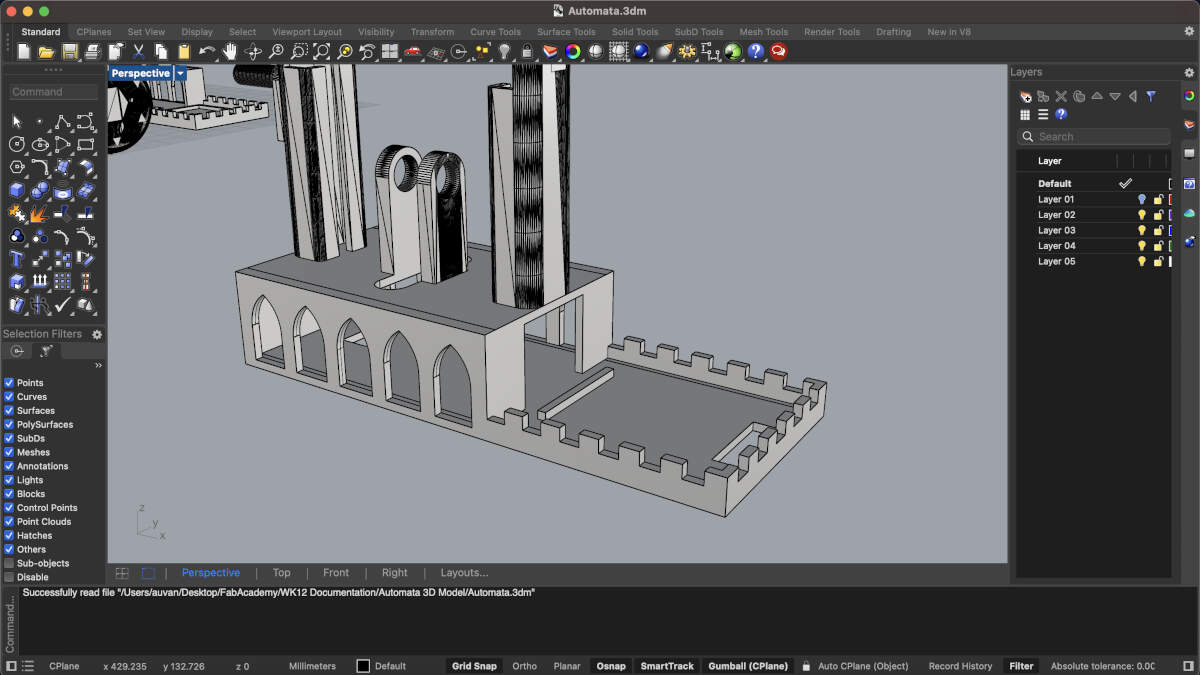

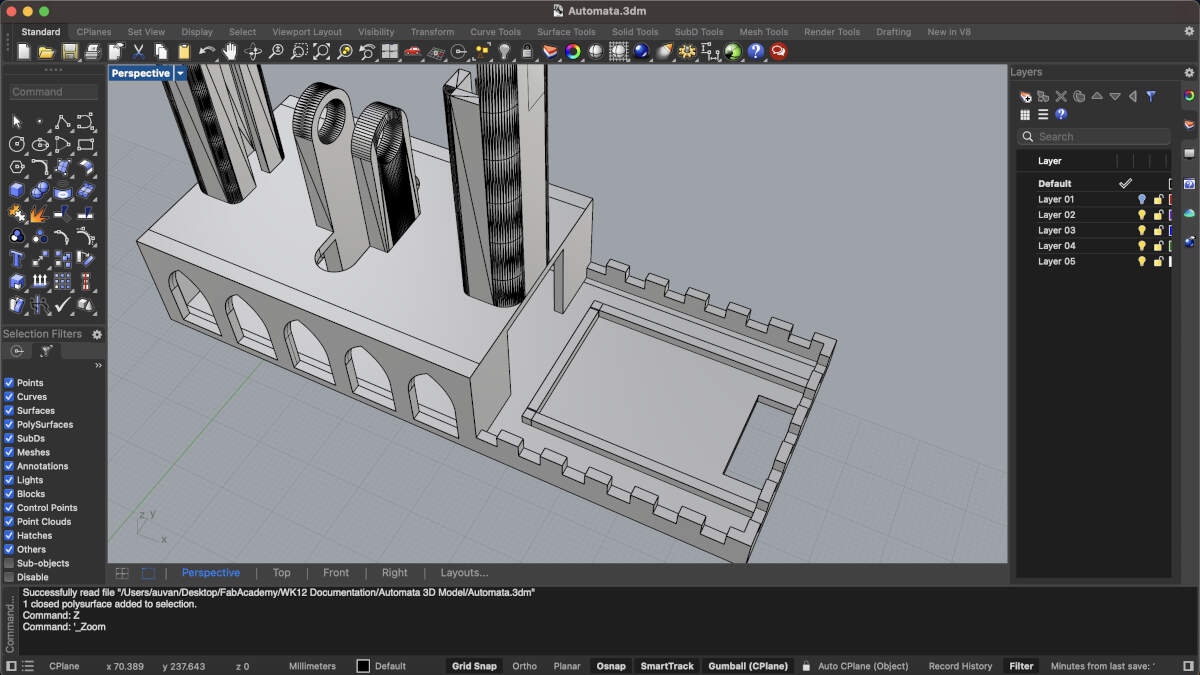

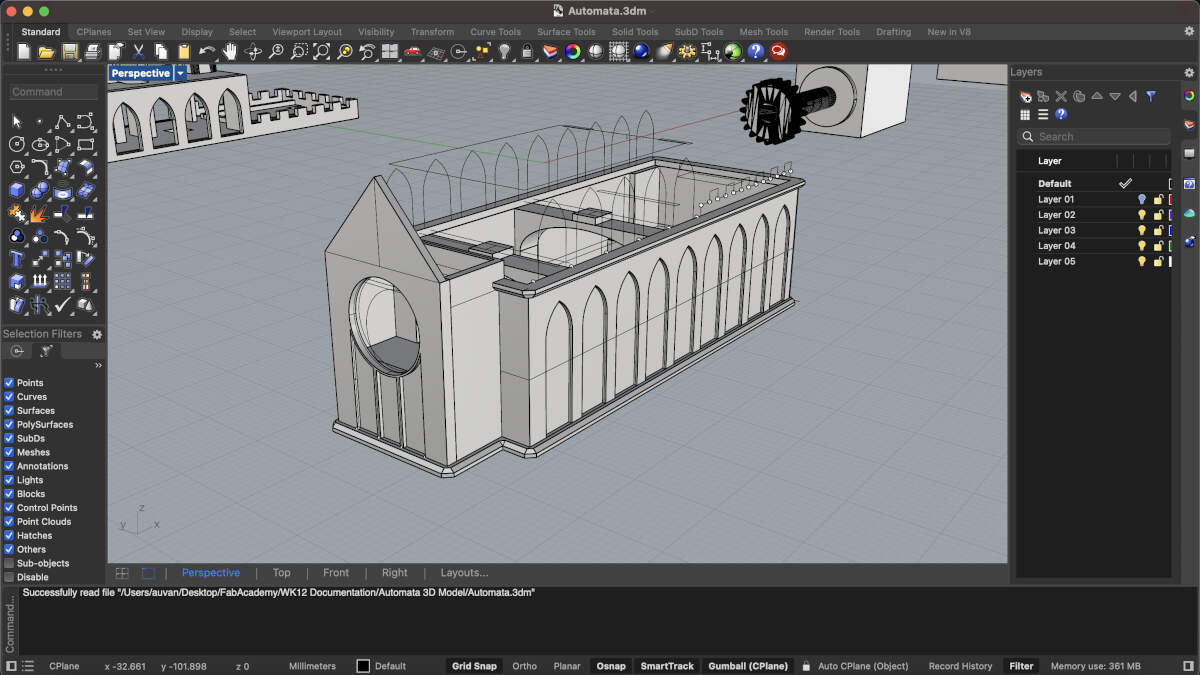

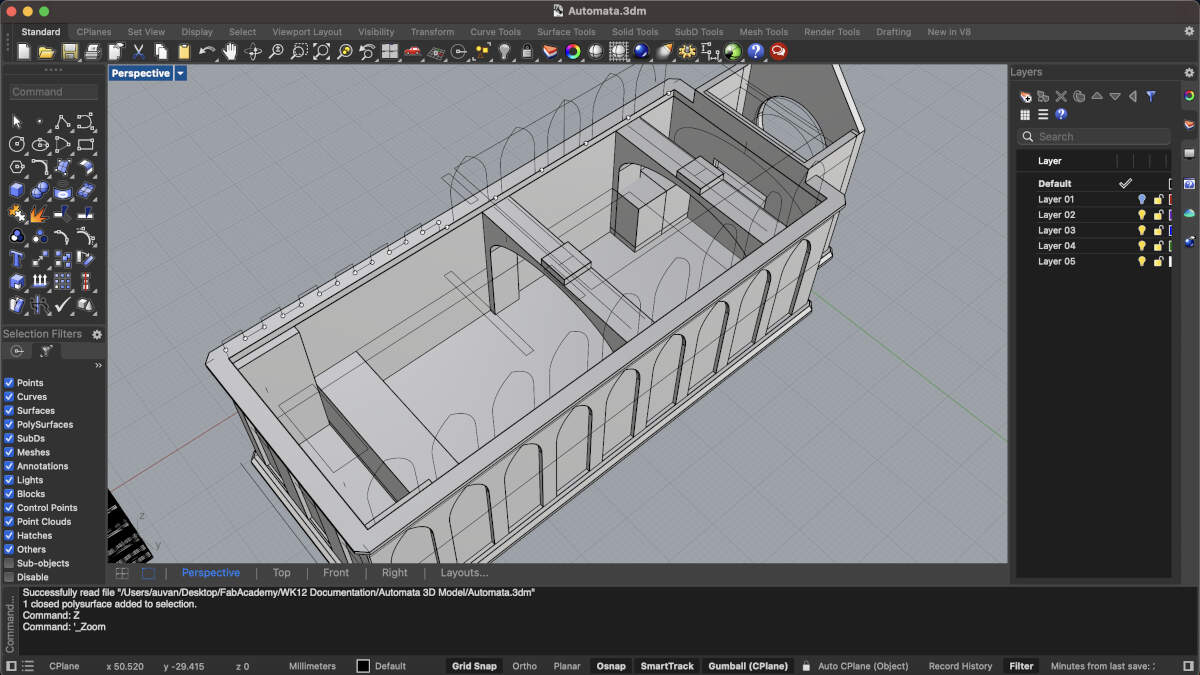

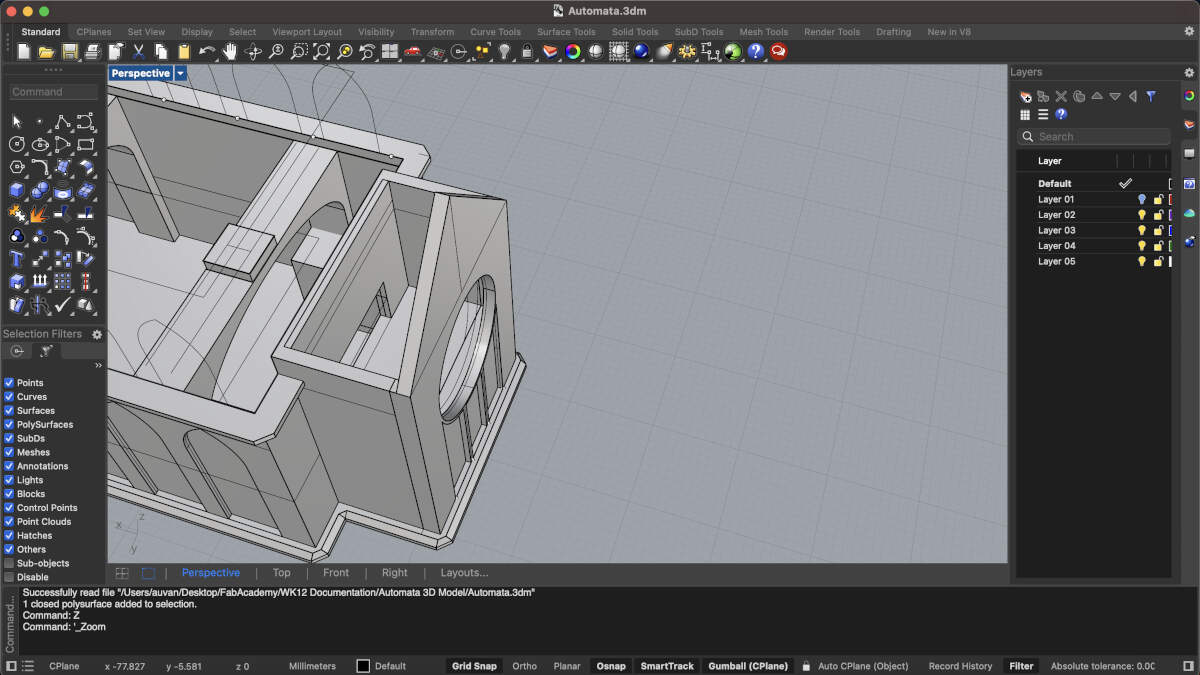

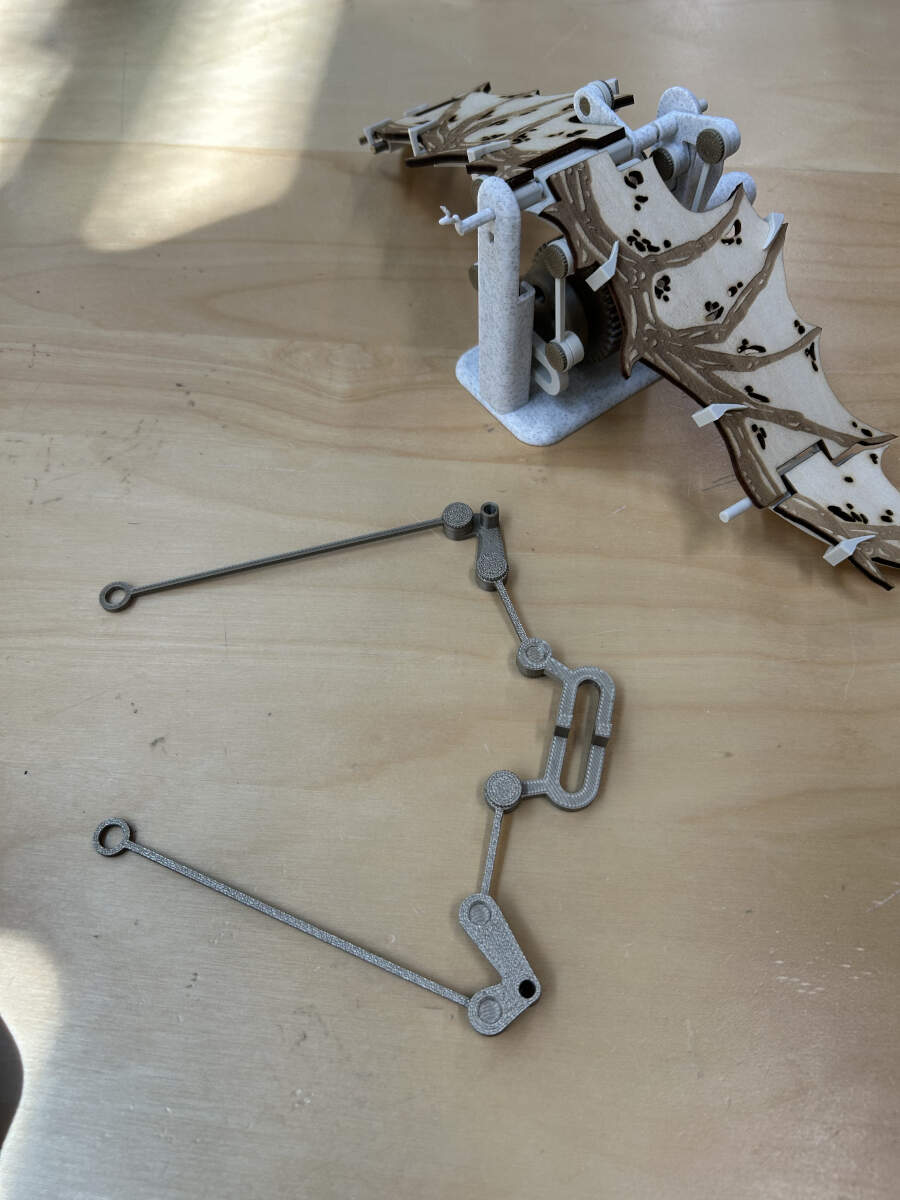

To redesign the base and mechanism of the automata, Augusto decided to import the most relevant aspects of the model into Rhino3D. With the relevant pieces on display it became easier to see how Augusto could alter the model. To redesign the mechanism we essentially had to flip it so that the smallest gear responsible for moving the rest was underneath the base but still in contact with the other gears. To ensure this gear would always have the same function, the entire base was copied and flipped on its head using the holes holding all the big gears in line as a central rotating axis. That way the smallest gear would have the same distance it has on top as it would then have on the bottom.

This circled piece is the affected, edited, and mirrored bit of the model.

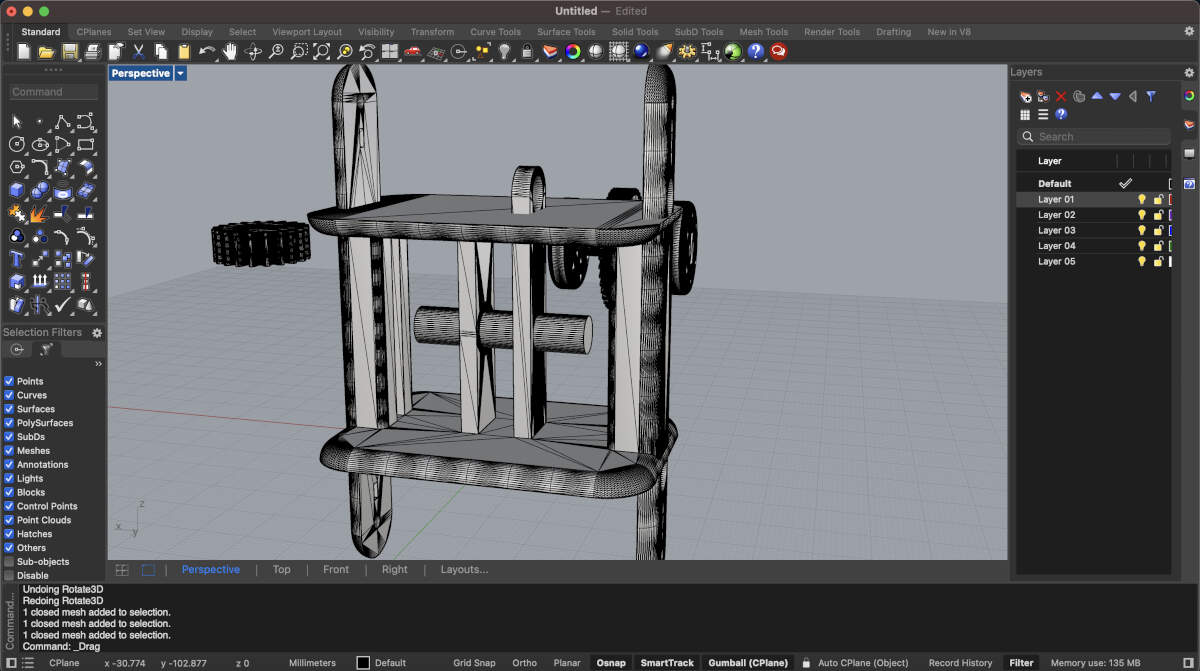

The rod here displays using that portion of the model where the gears were formerly at as the central rotating axis.

The base is being reduced to accommodate the smaller gear that will now be located at the bottom.

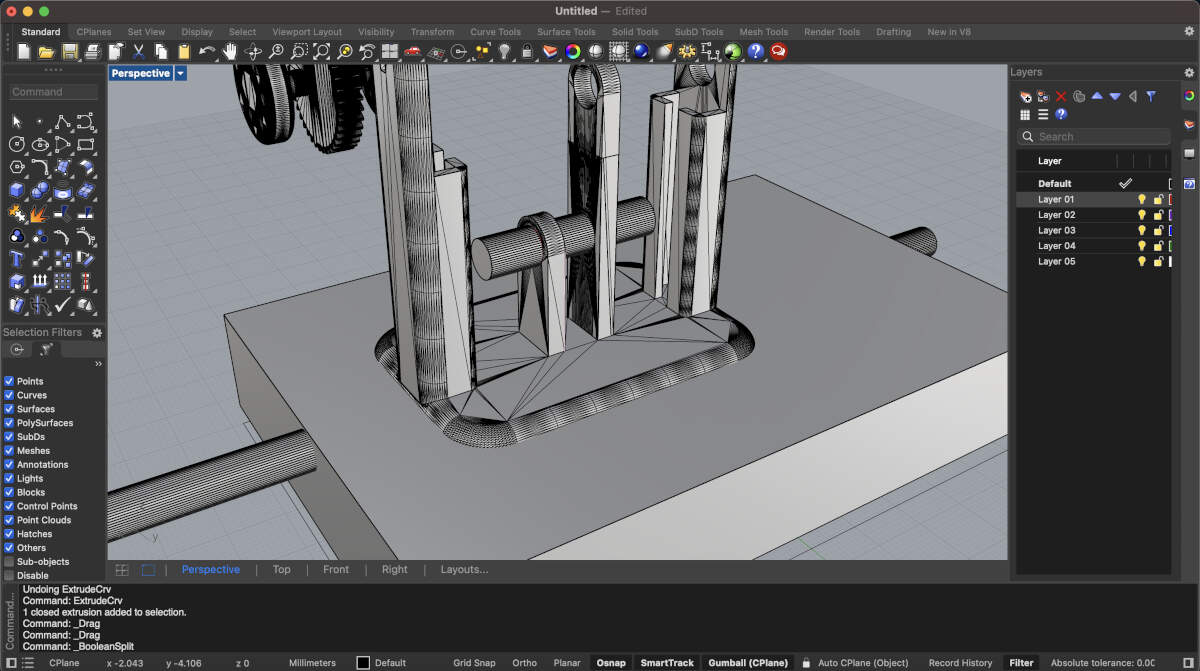

This is the end result for the flipped piece.

This altered version of the base is nearly complete.

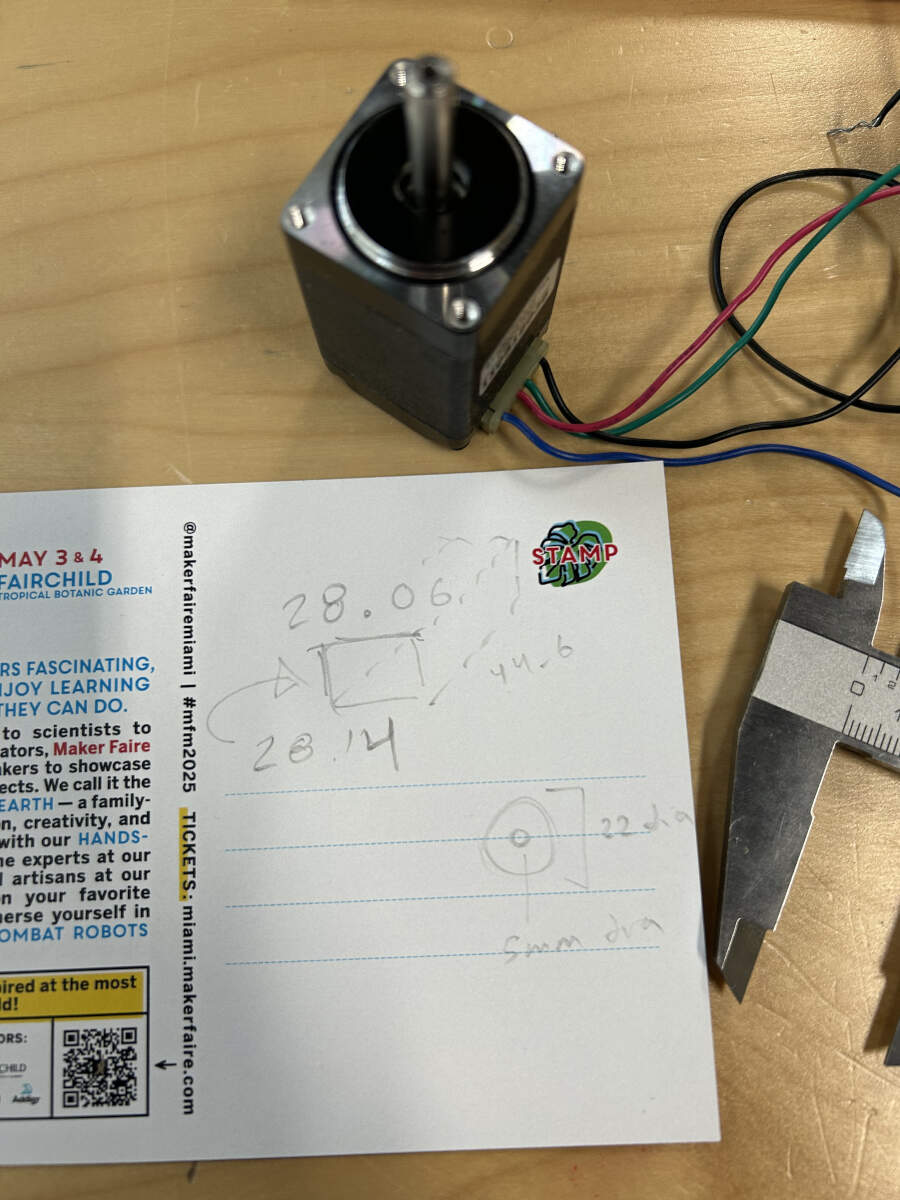

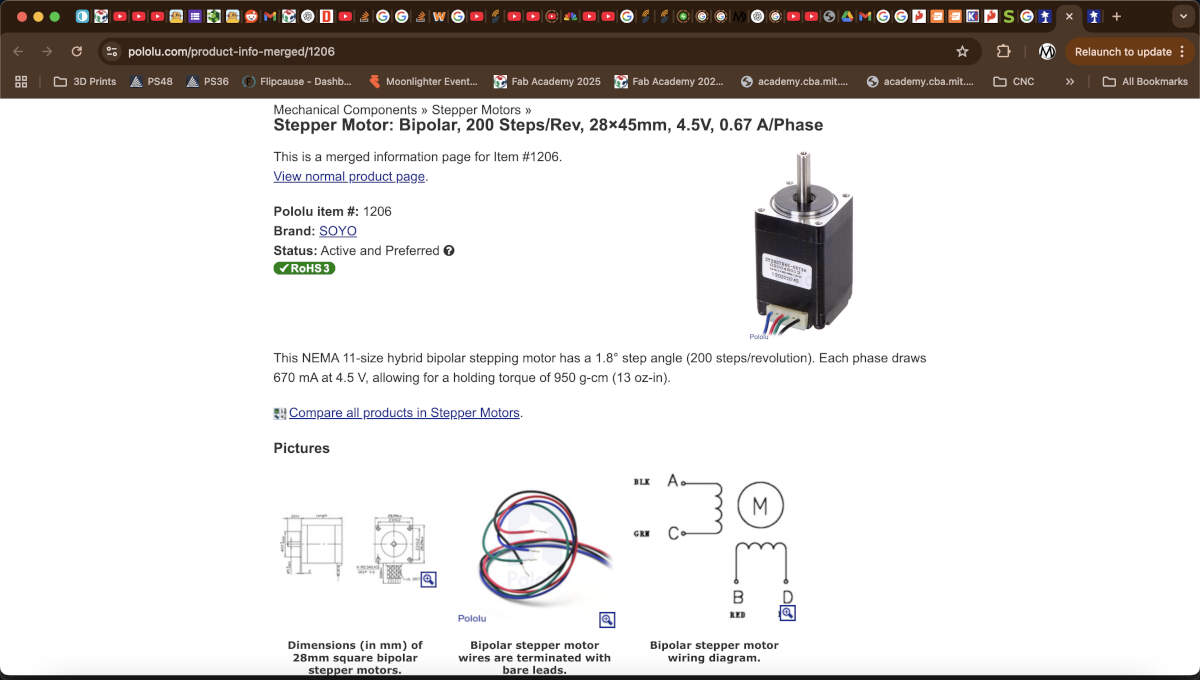

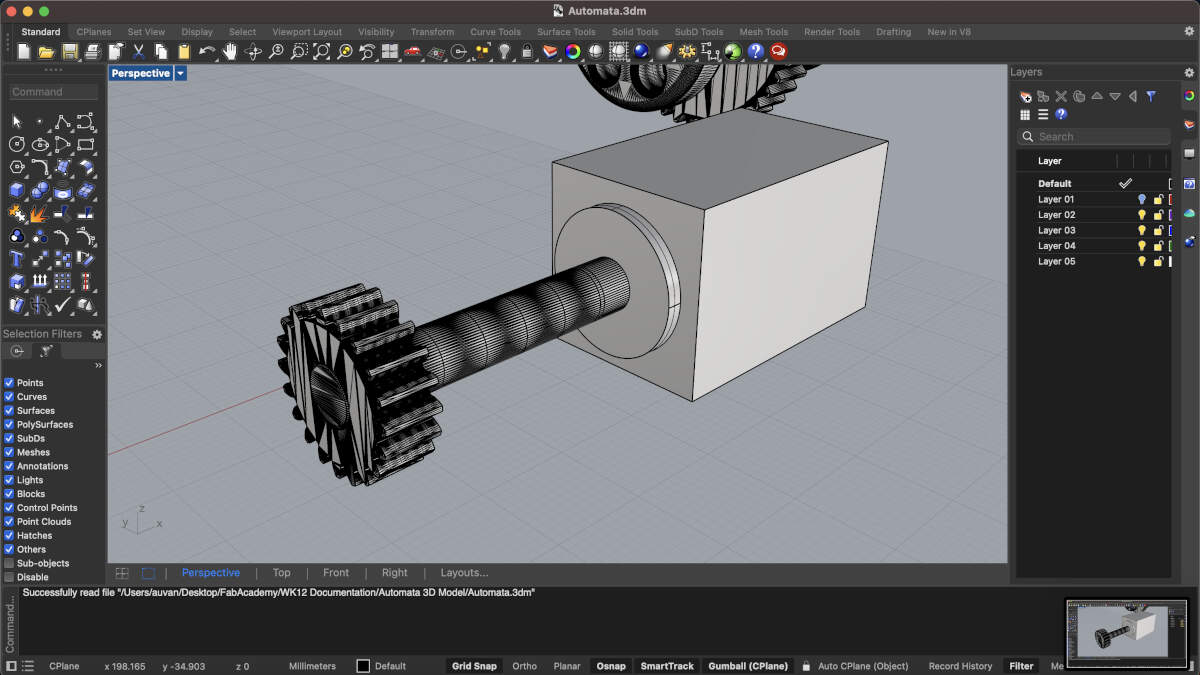

The stepper motor chosen was measured using a pair of calipers.

With its dimensions established a digital copy was made to easily visualize its place in the model.

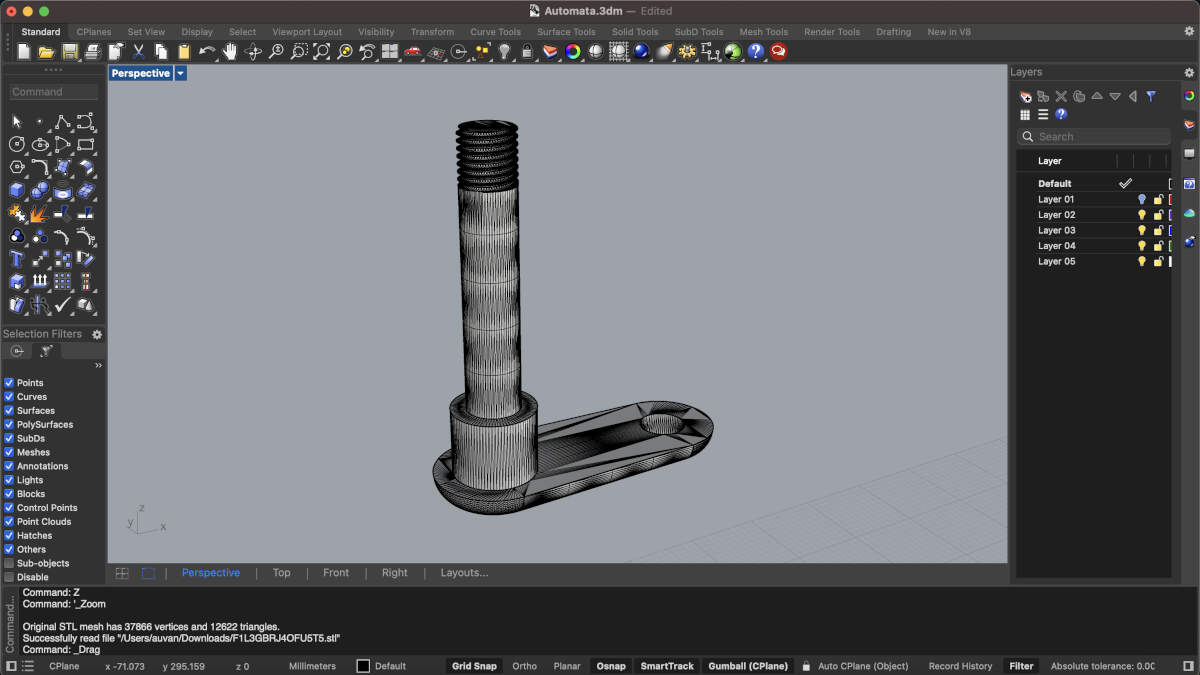

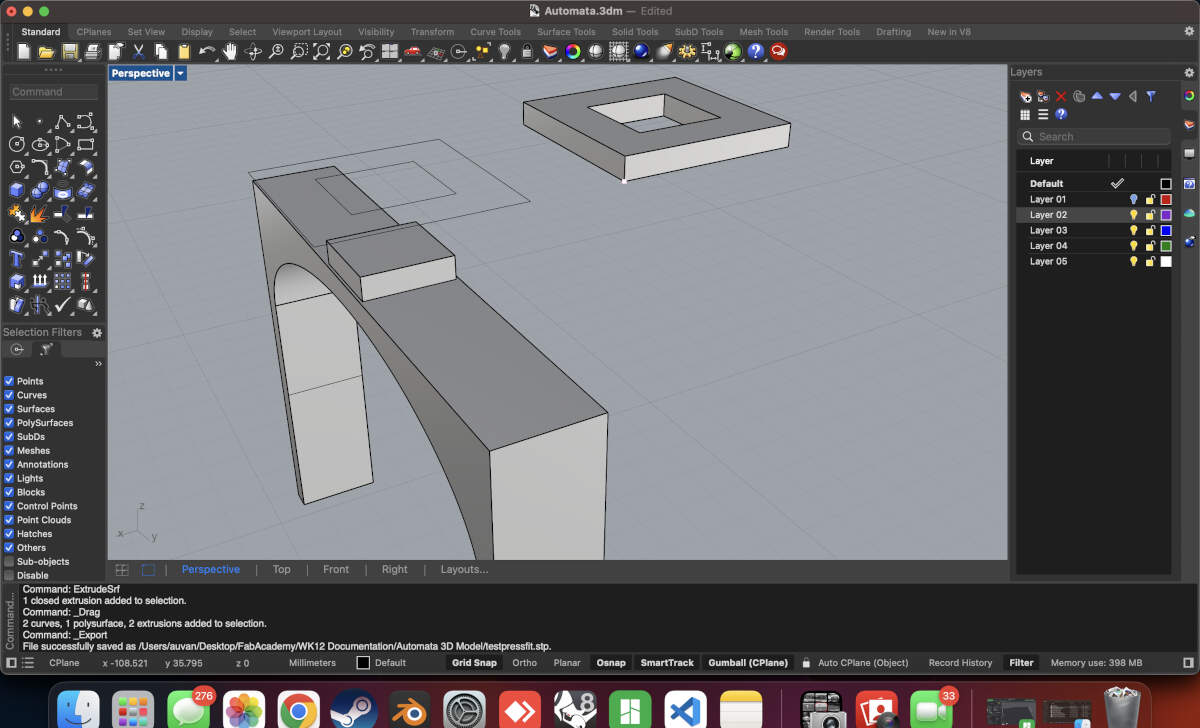

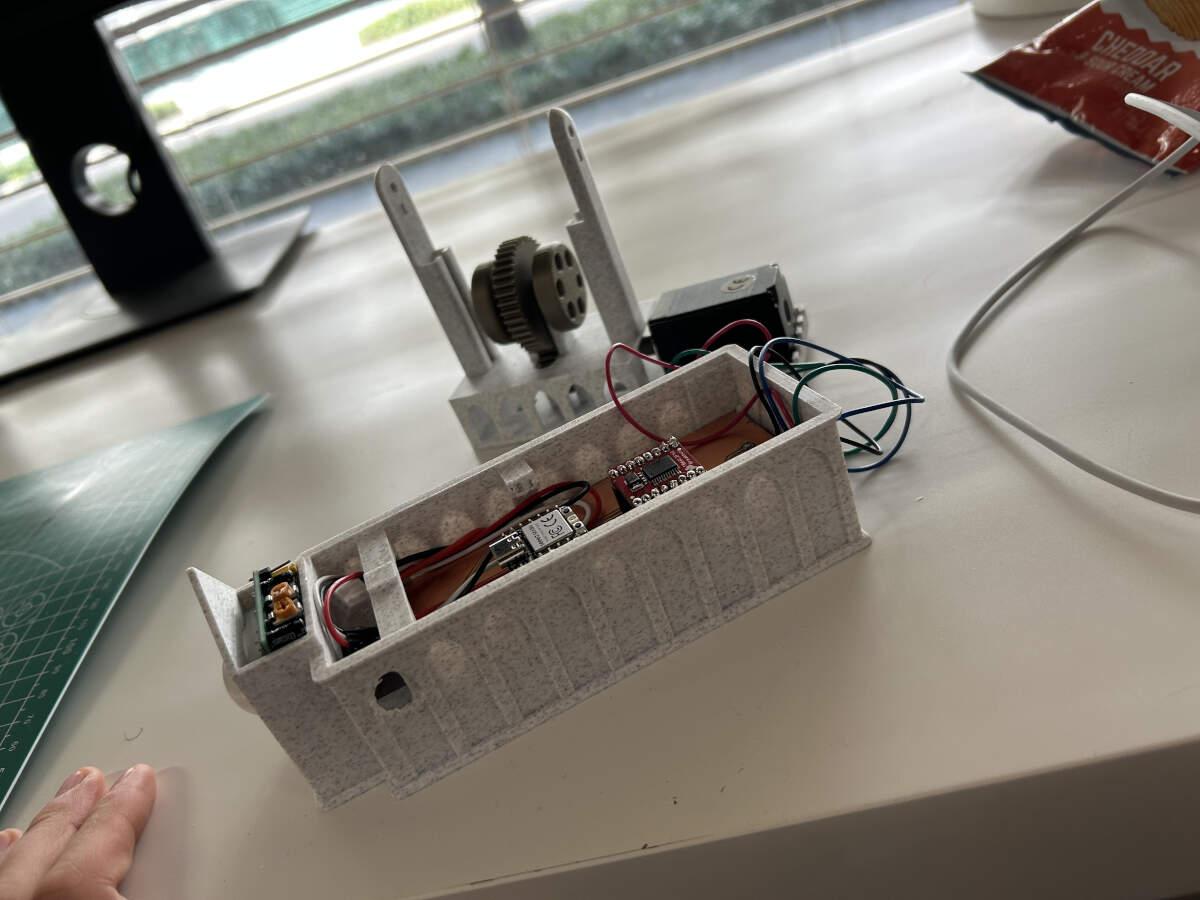

We altered the original handle and modified it so that it could be press-fit onto the stepper motor. The handle’s screw was sliced off, hollowed out using an internal extrusion and then slid onto our motor. Playing with the tolerances was a must given that our first few prints did not fit onto the motor but at least it worked in some sense.

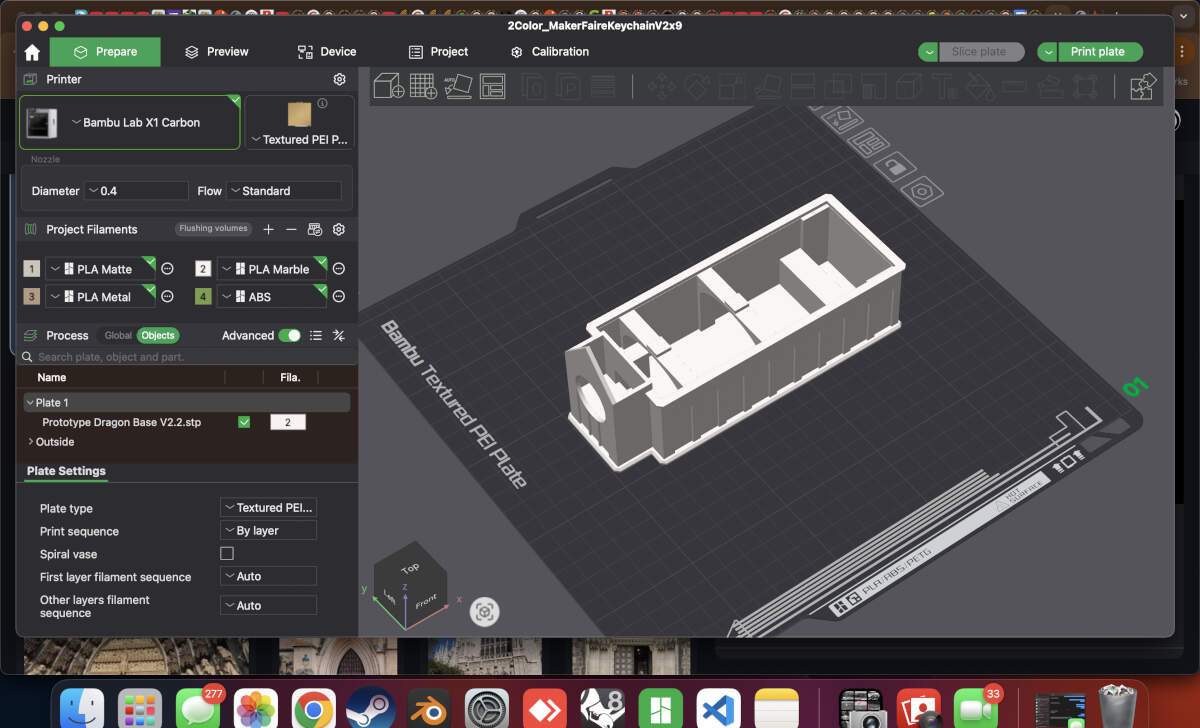

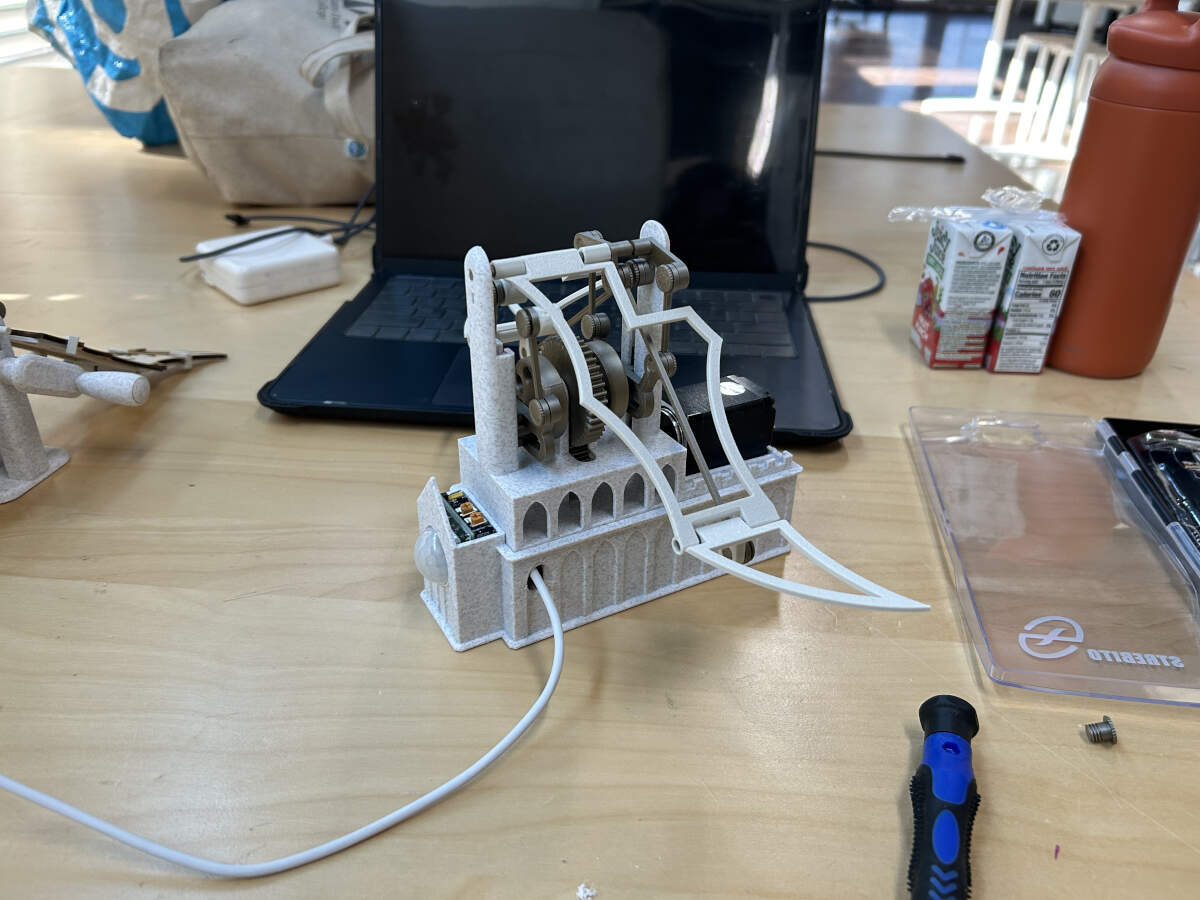

With the mechanism modified, I quickly put together an easy first draft or prototype of the base to test the modified mechanism with the stepper motor. With our connections and electronics already having worked it was no surprise seeing it work perfect with the modified base/mechanism. From that point forward it was easy to create the rest of the model.

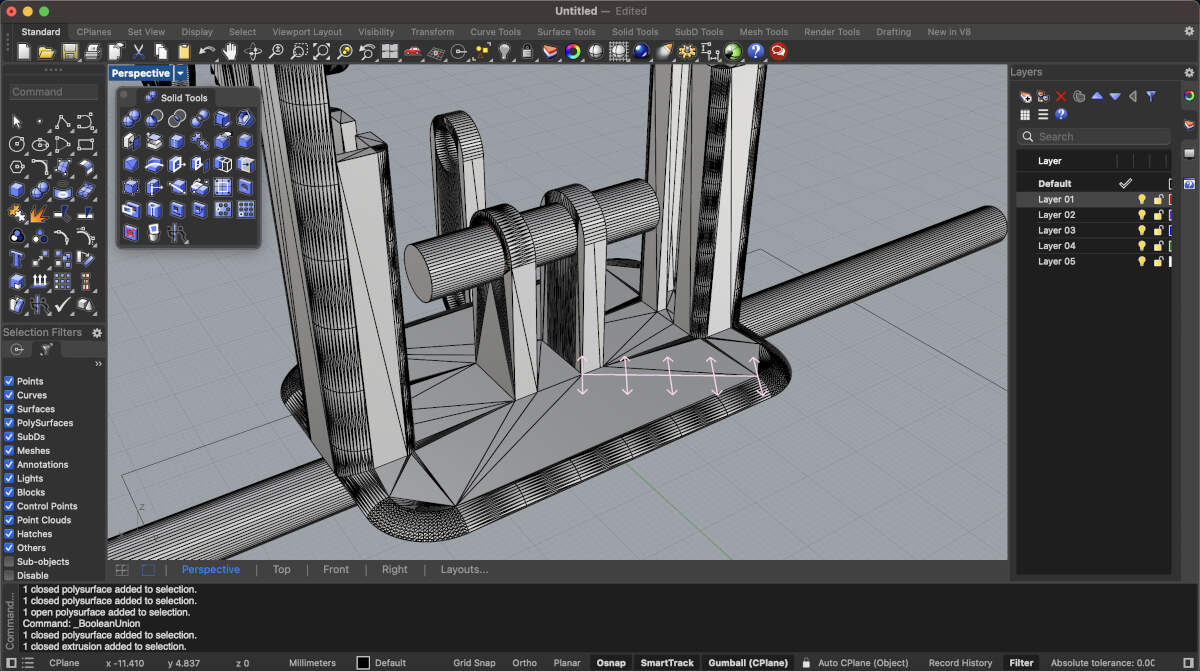

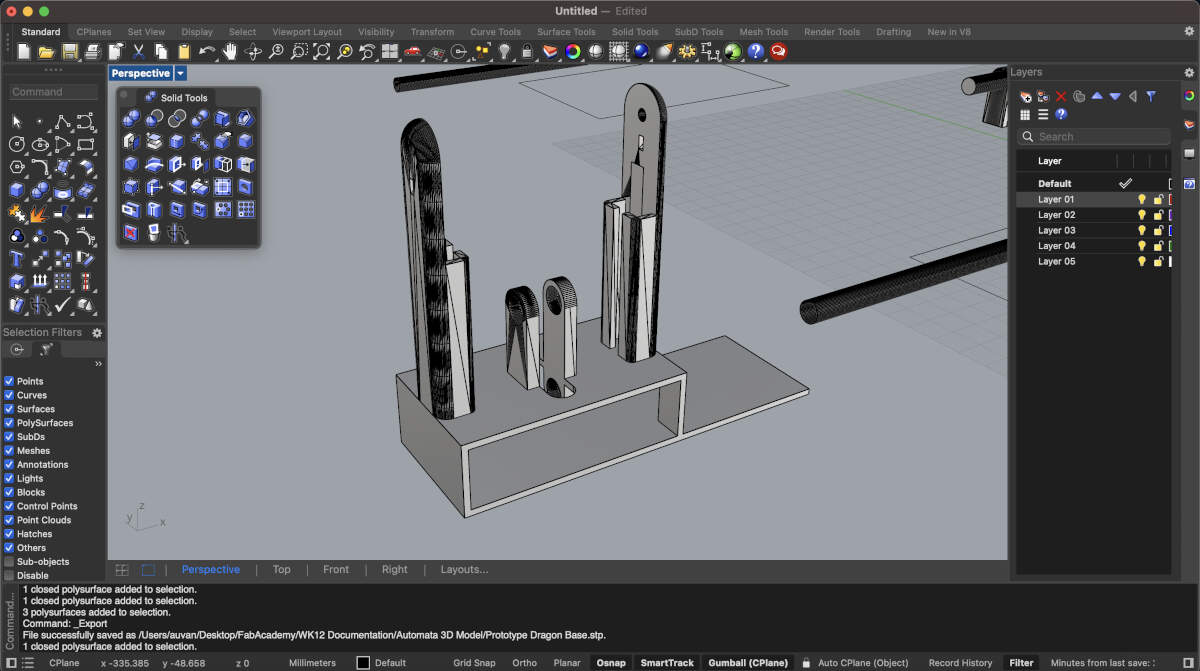

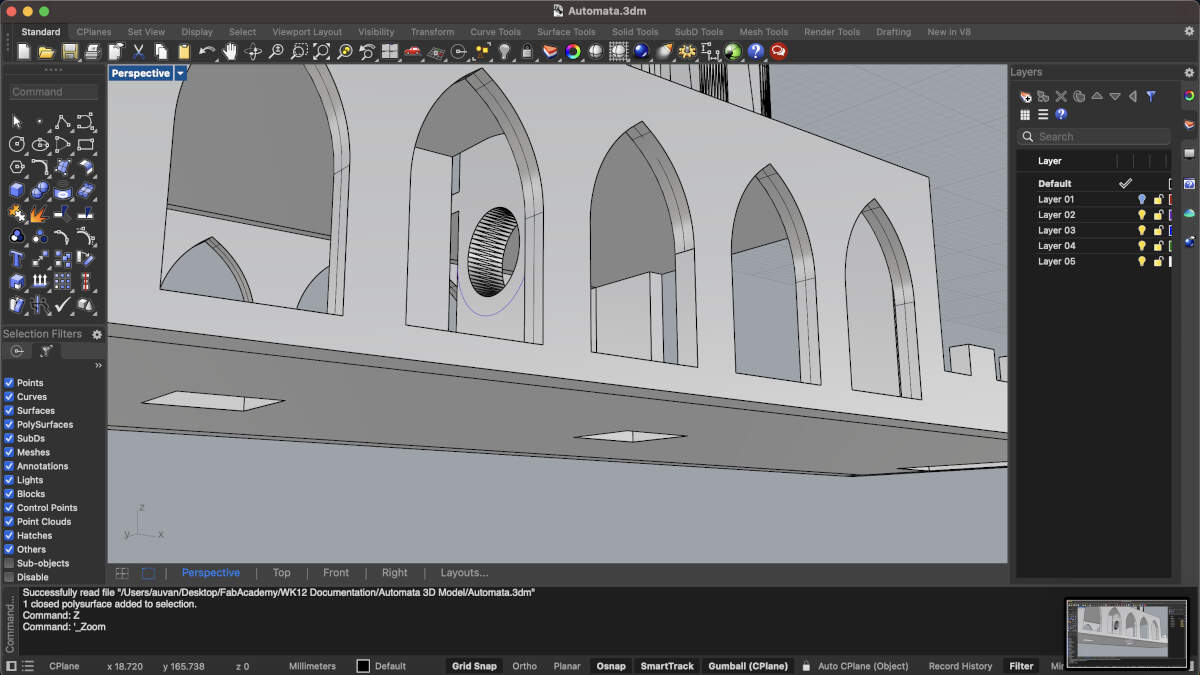

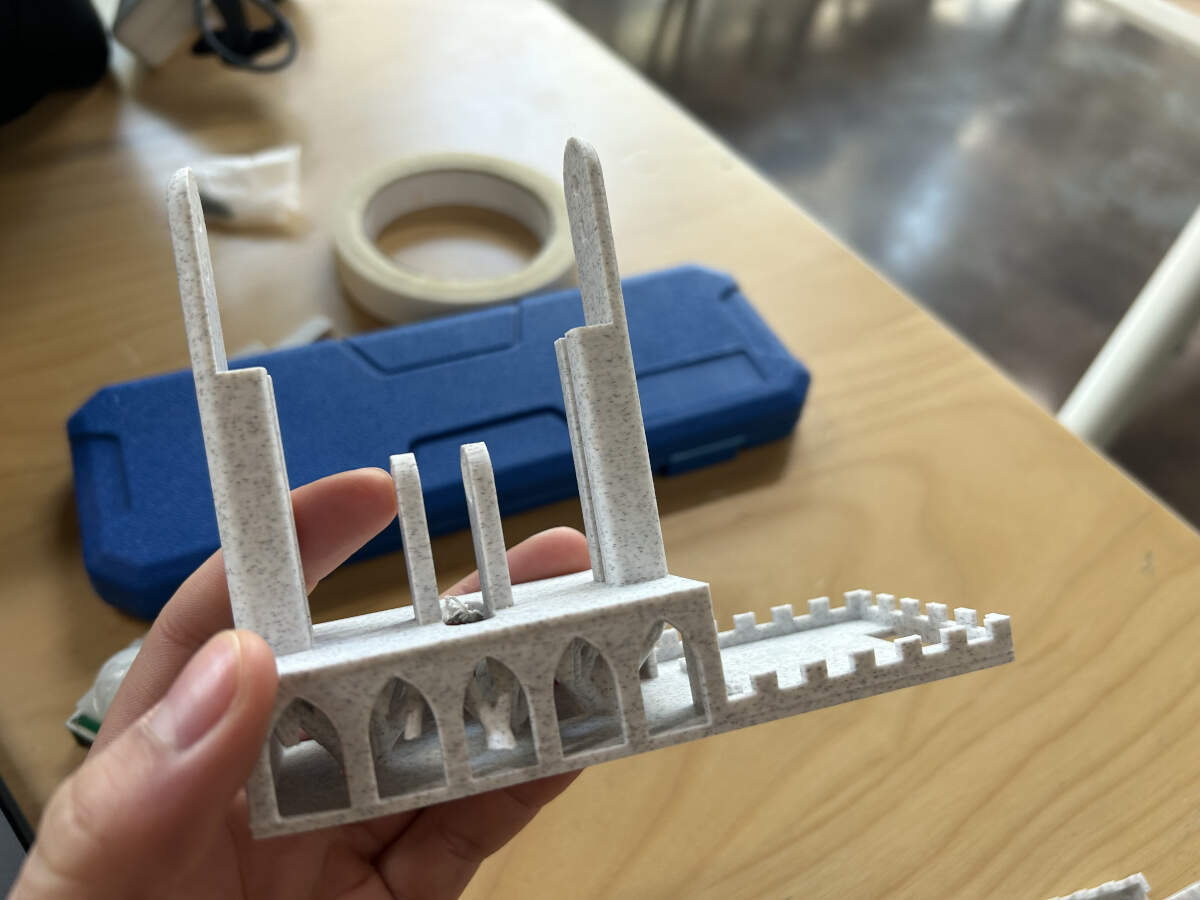

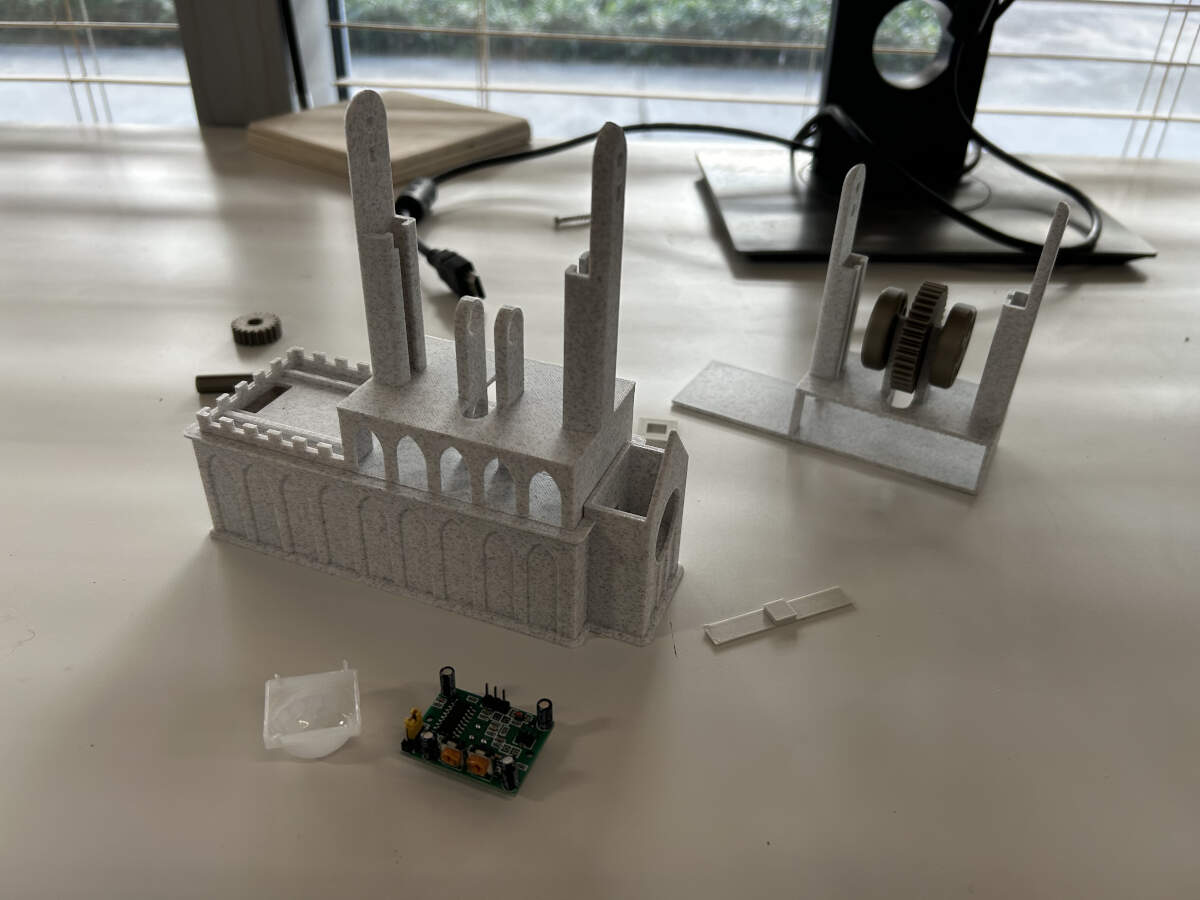

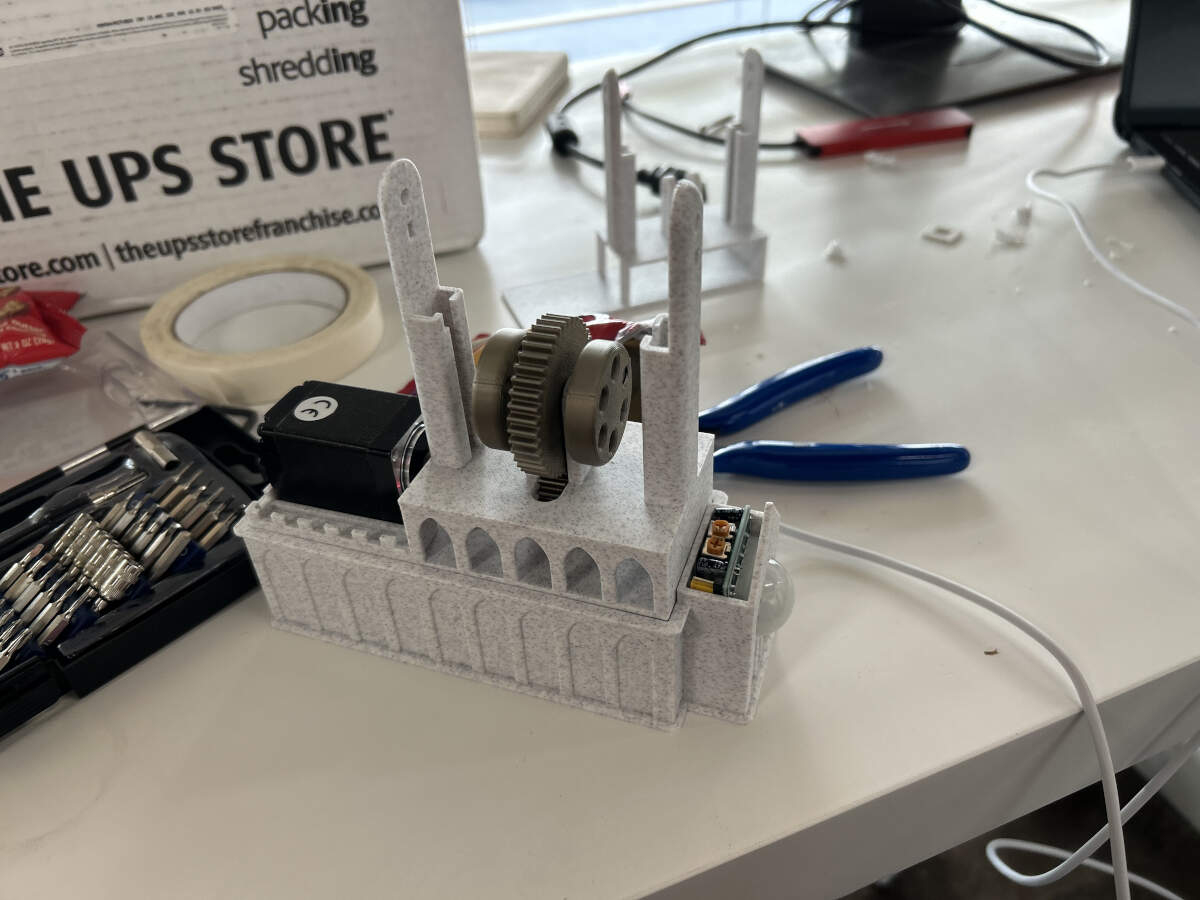

Arches and crenellations were added. Since we were going with dragon imagery and this is typically tied to medieval imagery, we decided to move forward with modifying the base and electronics housing to make them look like a gothic cathedral.

Extruded lines added around the area where the stepper motor will be located. These will hold it in place.

The center of the base features two smaller “pillars” that go through the first floor of the base. These pillars were extended to now reach the second floor of the base so that way they did not require any support.

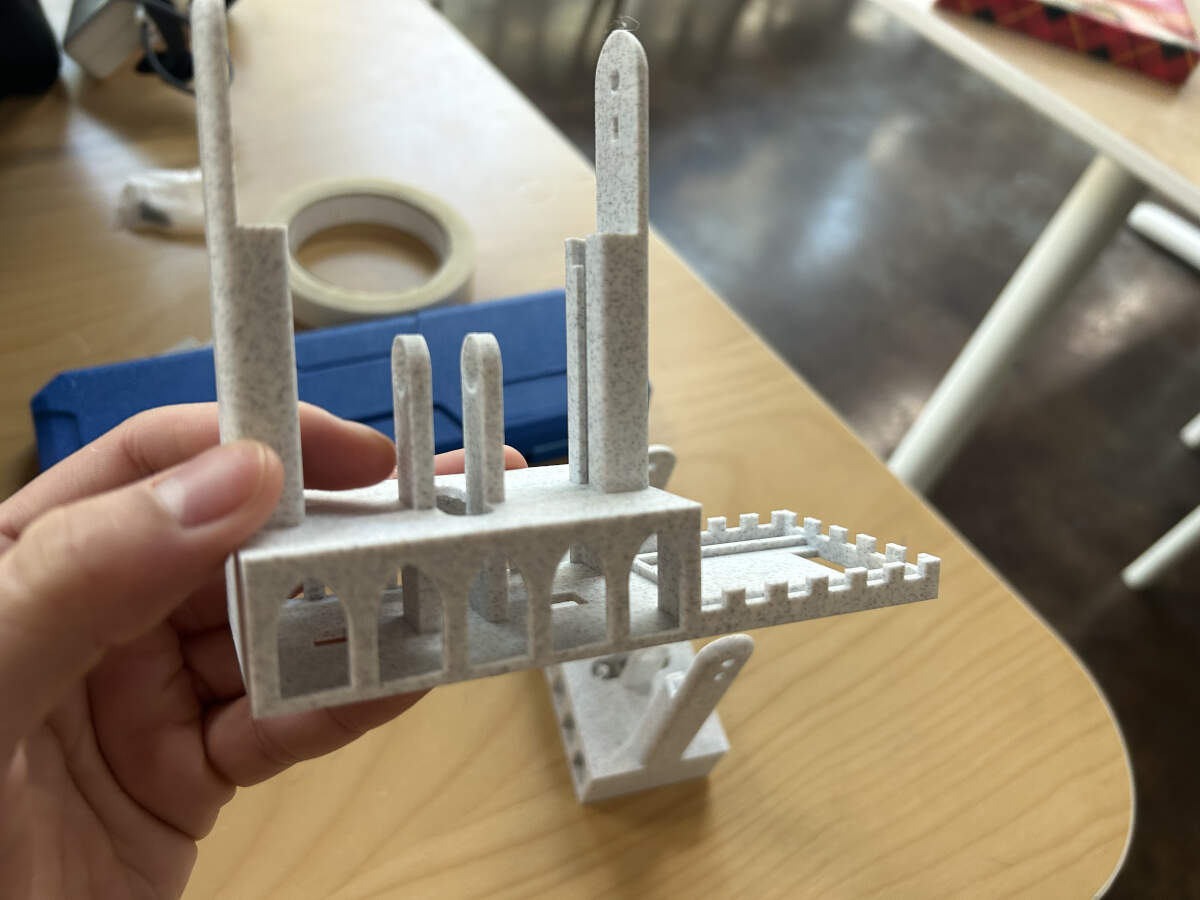

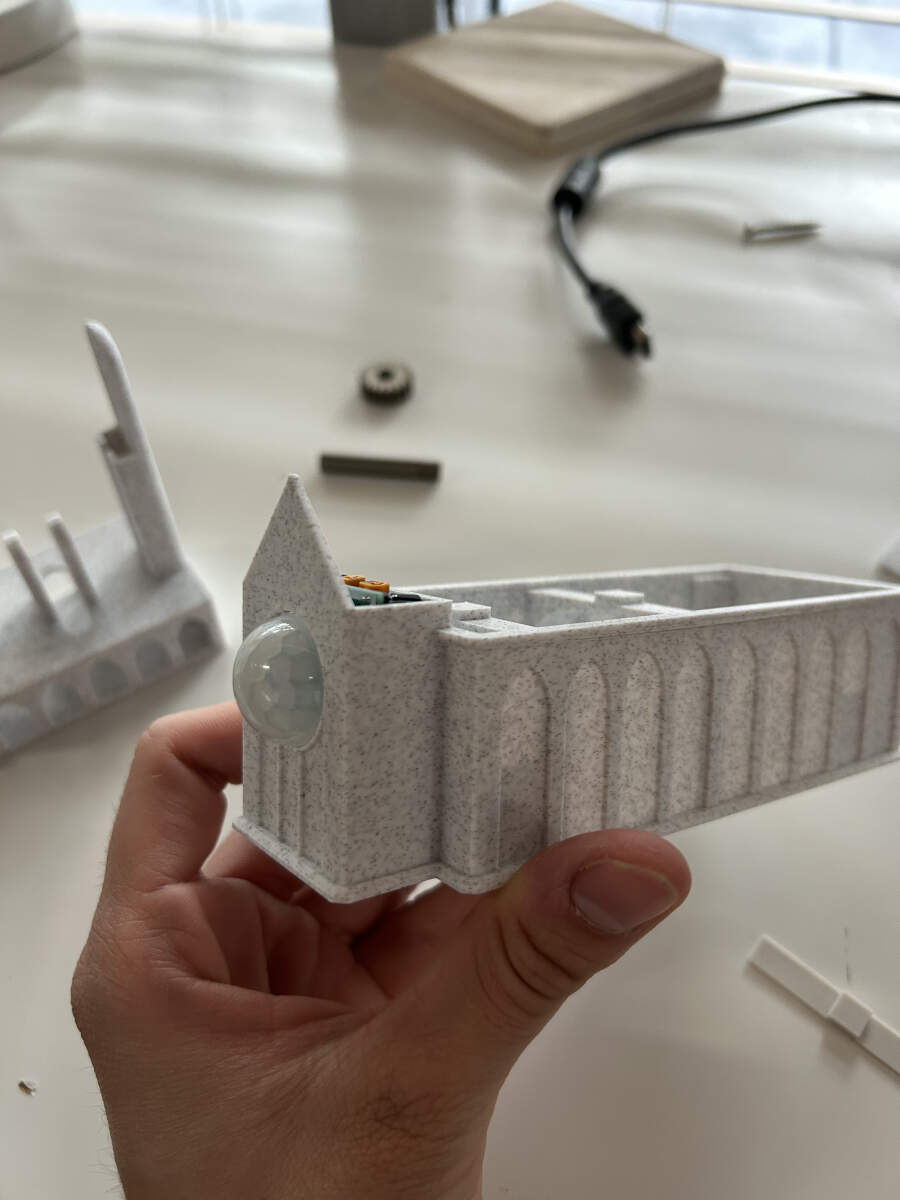

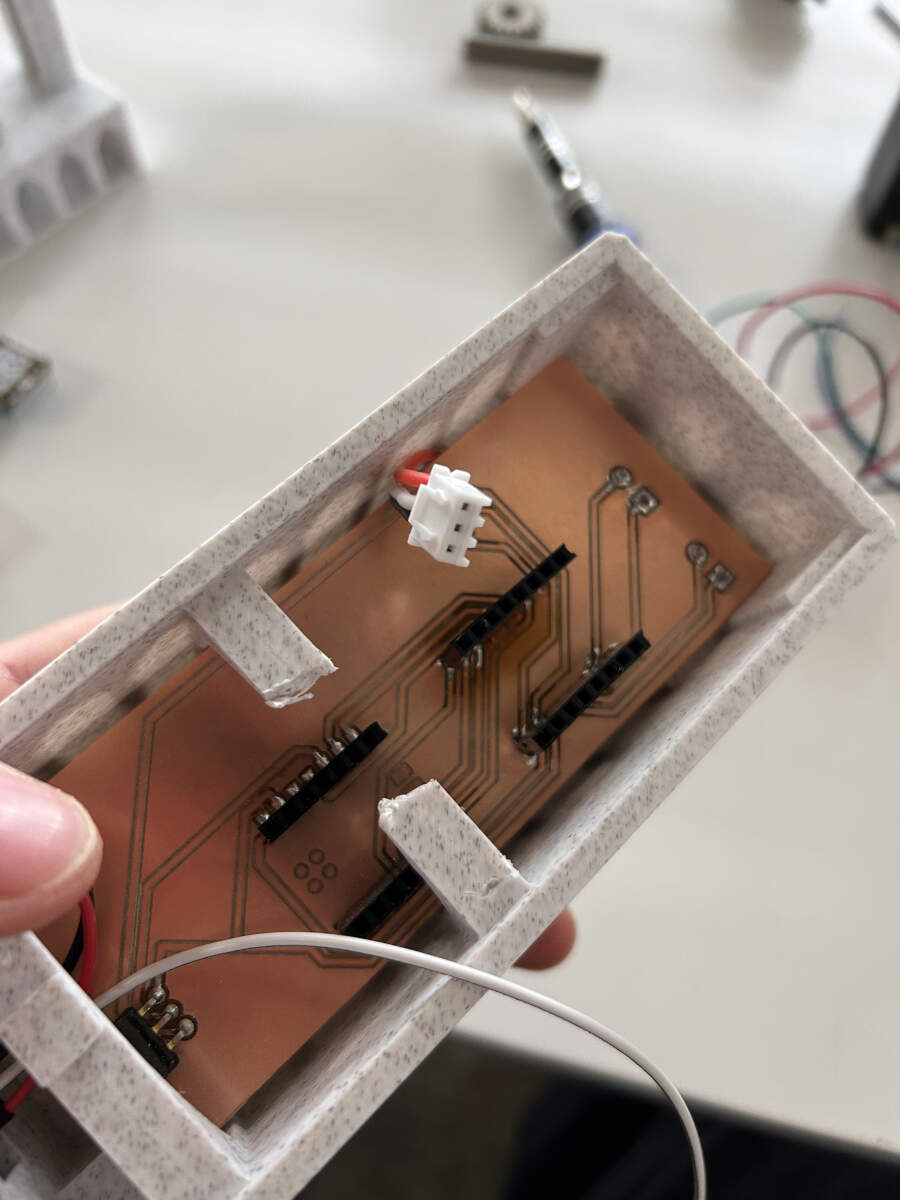

An enclosure was made for the custom electronics board. There is a makeshift rose window that will house the PIR sensor. The arches have an extrusion that will slot into a further modified base. The arches will also allow the board to slide through.

Tolerance tests were created to ensure that the slots worked perfectly before printing the full model. These tolerances were also used to modify the base so that it fit onto the electronics enclosure as well.

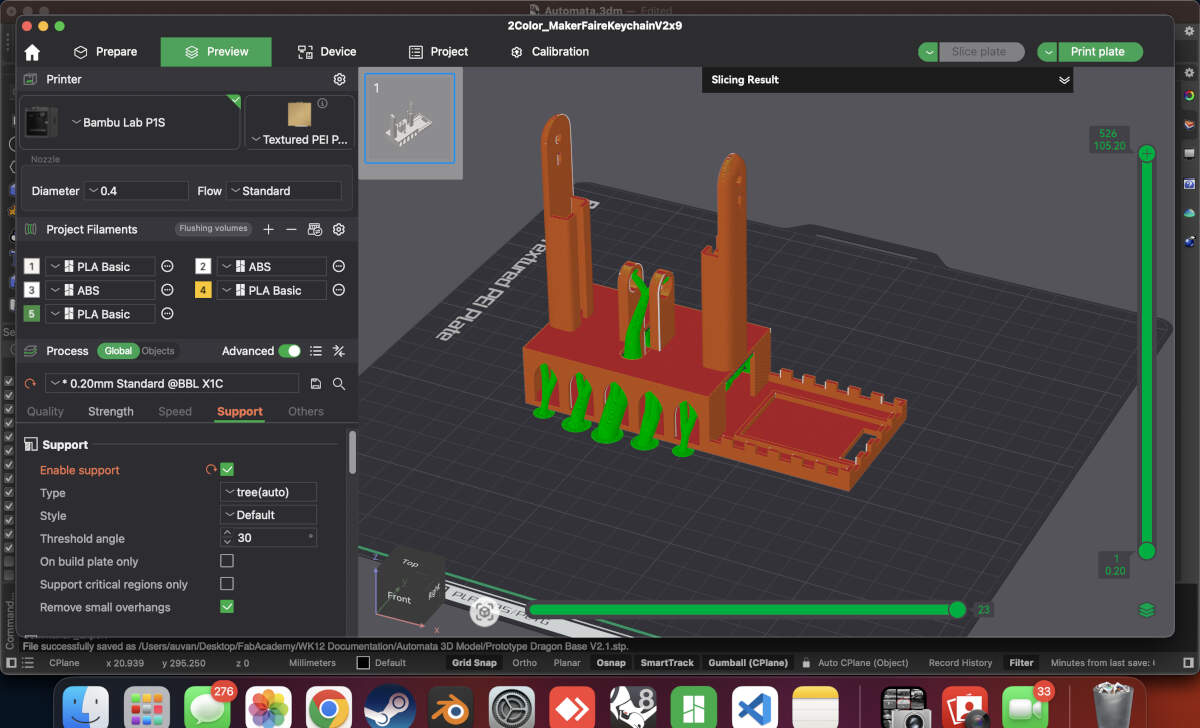

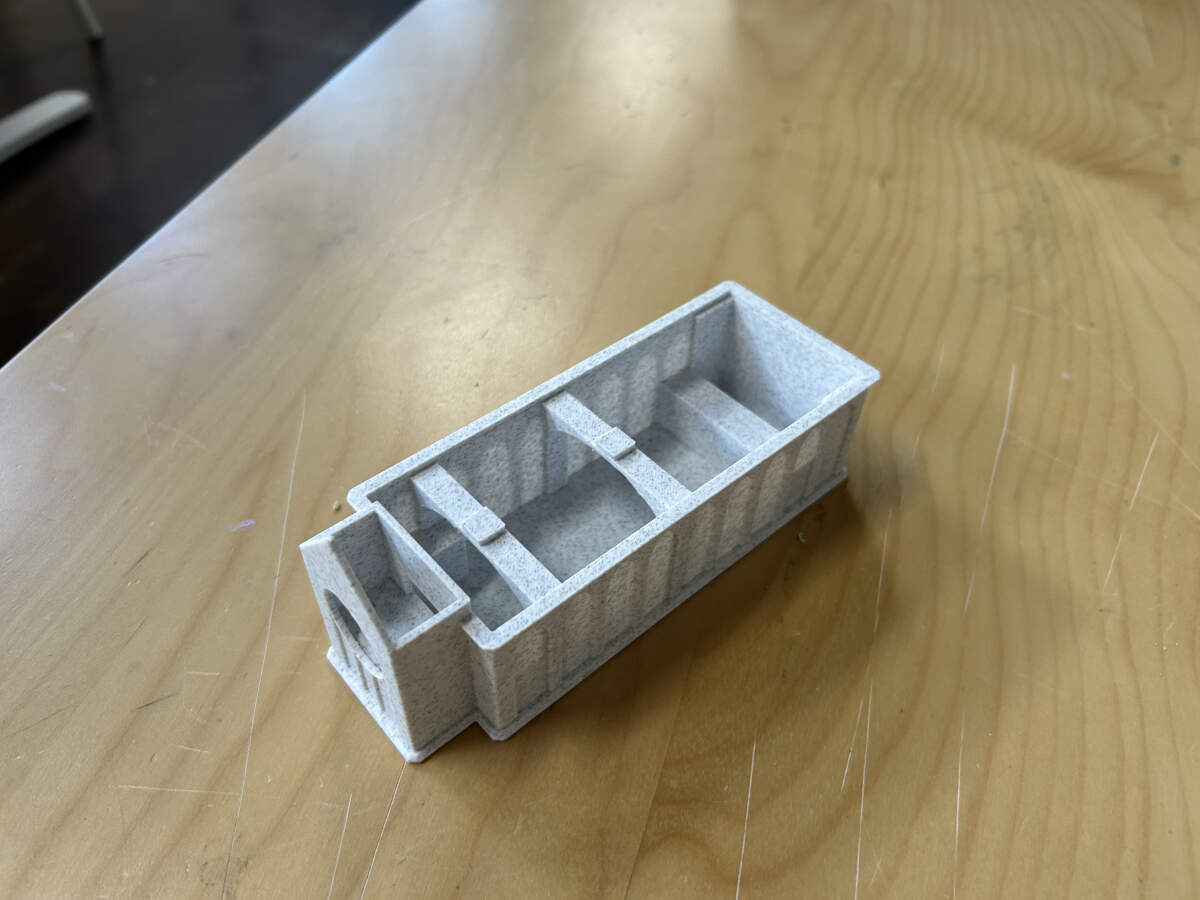

When both models were ready, they were sent to print.

Base and enclosure print successful. Only required some post processing to remove supports.

Both prints slot into one another just fine.

The PIR Sensor fits into place.

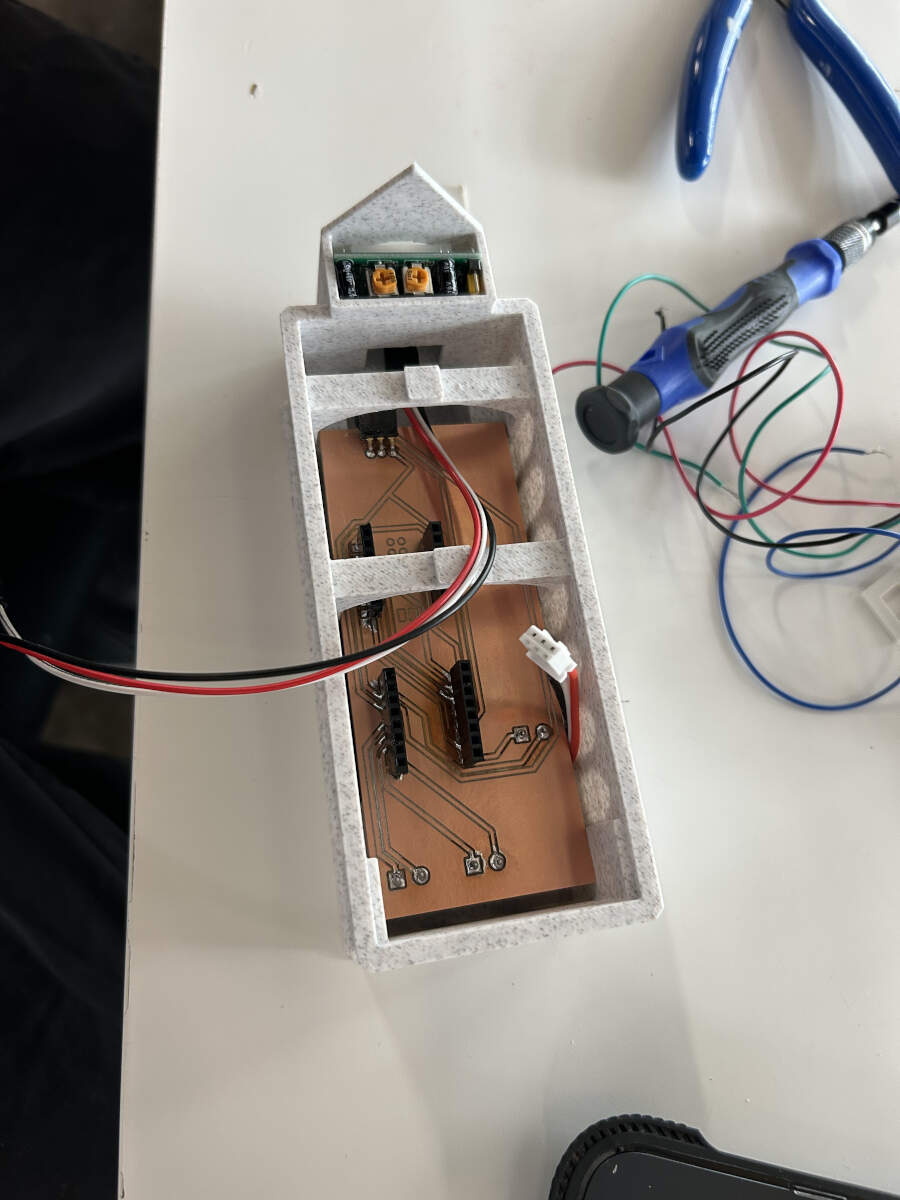

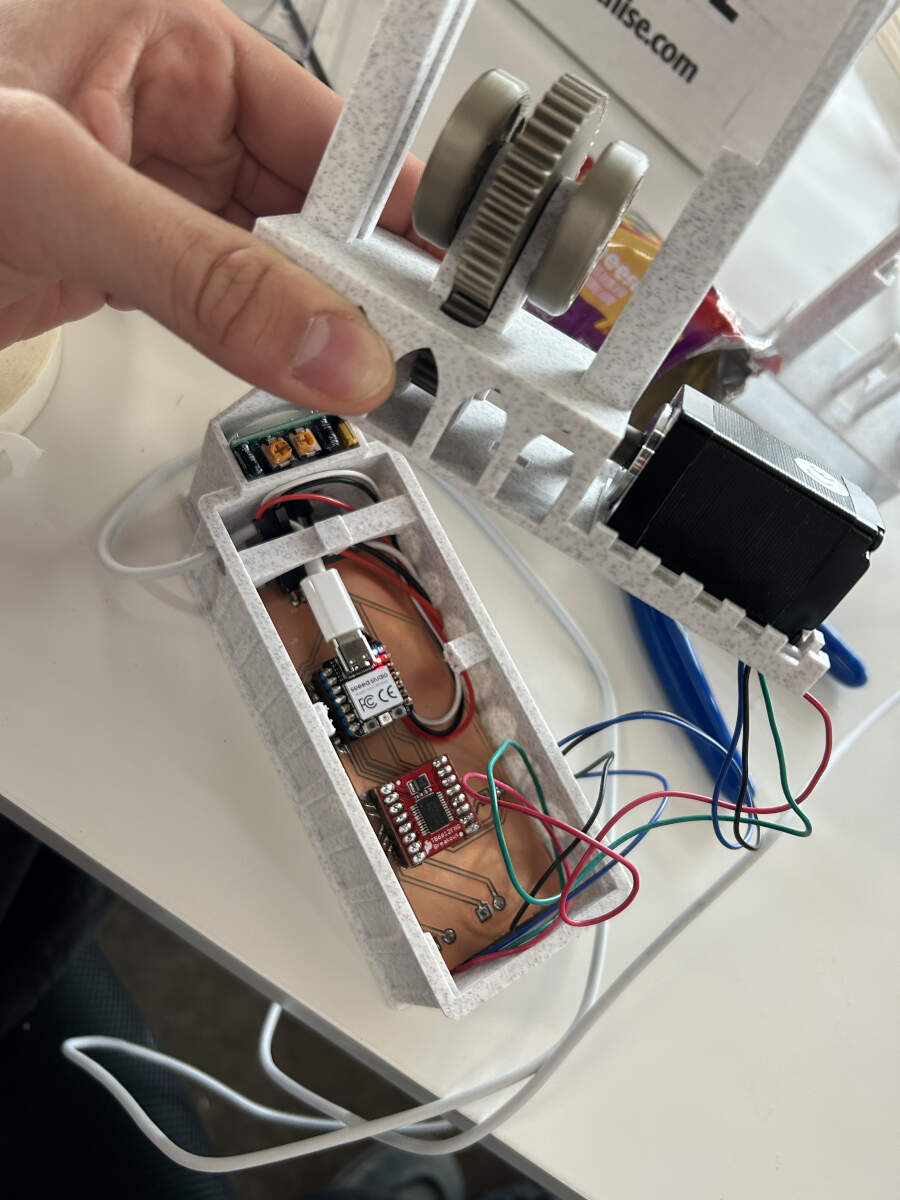

Board put together. There was an attempt to place it inside the enclosure but it was far too large. Even though the board was milled to fit inside the enclosure, Augusto forgot to account for the arches that were put in place so he had to sand them down using a belt sander in the shop.

There were a few other hiccups encountered when trying to put the build together. While the board now fit inside the enclosure, there was a realization that the microcontroller would not fit inside because the arch was blocking it from entering its stands. This was a design flaw that was overlooked by Augusto so to quickly resolve the problem and submit the assignment on time, he used a pair of flush cutters to remove that arch allowing for clear entry. Additionally, it was realized that the microcontroller would require power of its own. This was another design flaw overlooked when designing the 3D model so Augusto drilled a hole in the side of the model all for the sake of testing the prototype.

Augusto was able to put all the necessary components and cables in place, especially after the last minute alterations.

The build was completed albeit with a few hiccups here and there. With it working and in order all that was missing now was to transfer the dragon wings and clips from the earliest print to the newer model in addition to adding the dragon body to the top of the model. All of these later additions can be seen in the final video below or in our group assignment page.

Copyright 2025 Augusto Vanegas - Creative Commons Attribution Non Commercial Source code hosted at gitlab.fabcloud.org