Week 18: Invention, Intellectual Property and Income

Individual Assignment: 1) Develop a plan for dissemination of your final project, 2) Complete your final project, tracking your progress

Important Concepts

Invention can be generally understood as an innovative and novel solution to a problem. Apart from being something new, it must also have applicability - that is, beyond a mere idea, and so is often technical in nature. Invention is a type of Intellectual Property.

Intellectual Property covers a broader range of creations like inventions and artistic works, as well as confidential information and trade secrets. It encompasses things that an individual might claim a right to maintain control of their distribution or publication.

Income obviously refers to money, and although Fab Academy has an ethos of sharing via public documentation, income and trademarks should be considered in the context of the final projects just because these projects are creative inventions and may well carry commercial viability. It is also appropriate to consider proper licensing and assign the desired methods of sharing and distribution.

Licensing

There are a variety of licenses used to protect intellectual property, including 3 of the most famous: GNU, MIT, and Creative Commons. GNU or GNU General Public License (GPL) was created in 1983 and considered a "copyleft" type of license since it mandates that all use of the IP remains open source. By contrast, the MIT license allows derivative products and modifications to be closed-source and therefore amenable to commercial use. Both GNU and MIT licenses are focused on software.

Creative Commons licenses also apply to non-software like images, music, text and projects like that of ours and the Fab Academy. The Fab Academy uses Creative Common licenses as they generally allow free use and sharing which fits their ethos and educational goals. Hence we will consider this license in further depth.

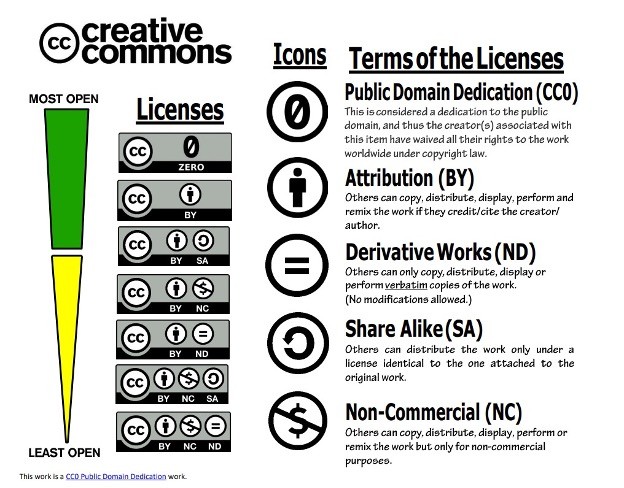

Creative Commons licenses are free and easy to use, clearly delineating the rights of the creator and specifying the fair use of the creative product / idea. There are a total of 6 types to chose from. The following table lists them in a scale of most to least open. Image credit.

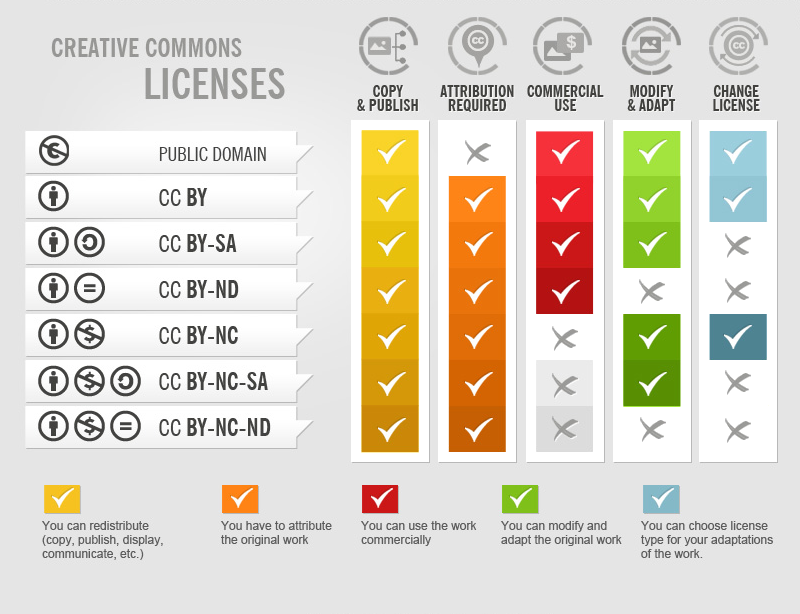

This is slightly overwhelming at first glance, but the following table makes it clear by clearly labeling the different rights associated with each license. Image credit.

Licensing Our Project

As I am not particularly concerned about someone using my project in a commercially viable manner, I have chosen not to add that restriction, and chose the "BY SA" license. This license allows others to modify and commerically use what we have developed as long as they give attribution.

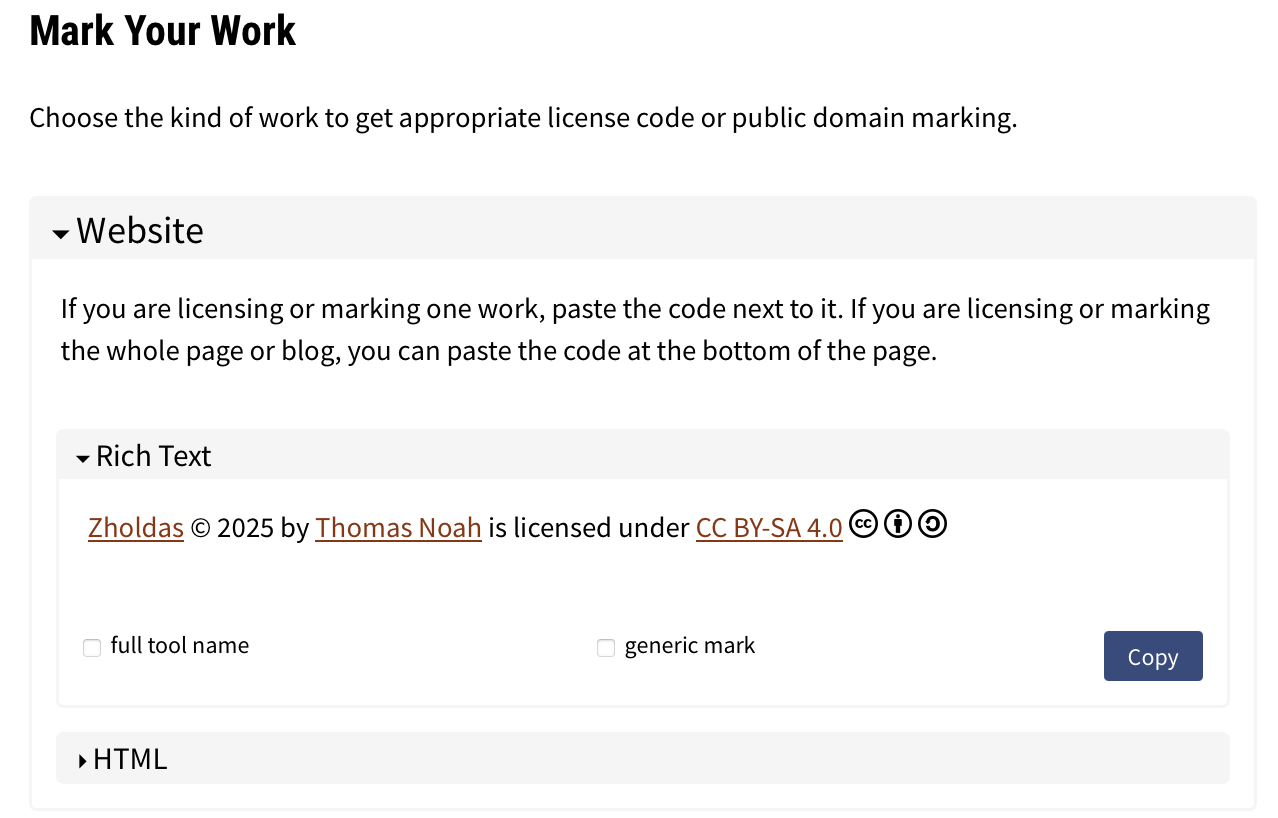

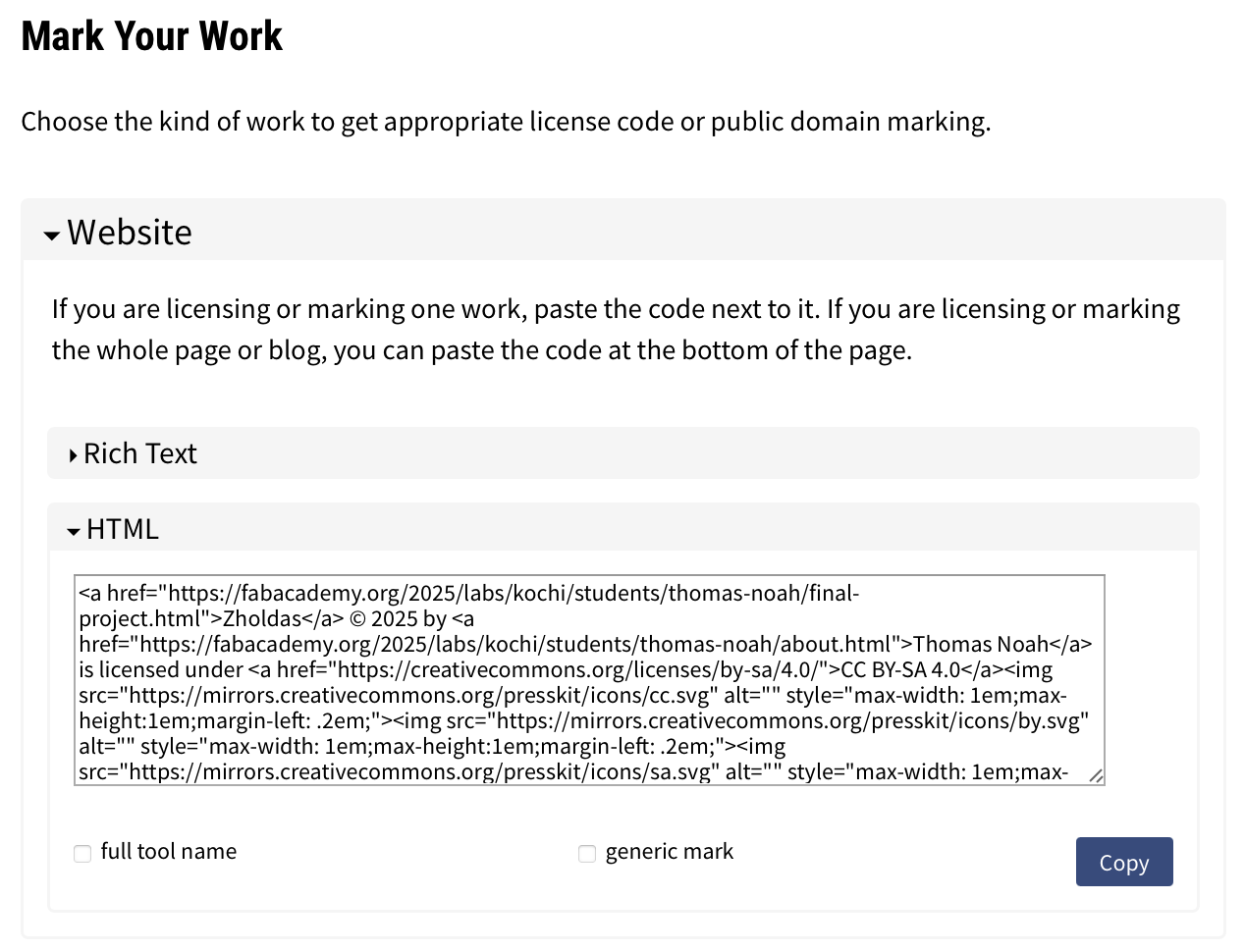

After we choose the license type, we may go ahead to actually officially license it through the creative commons website.

Here we must enter all the appropriate information:

And we may subsequently appropriately mark our work in Rich text...

...or html. As we will do at the bottom of the project page.

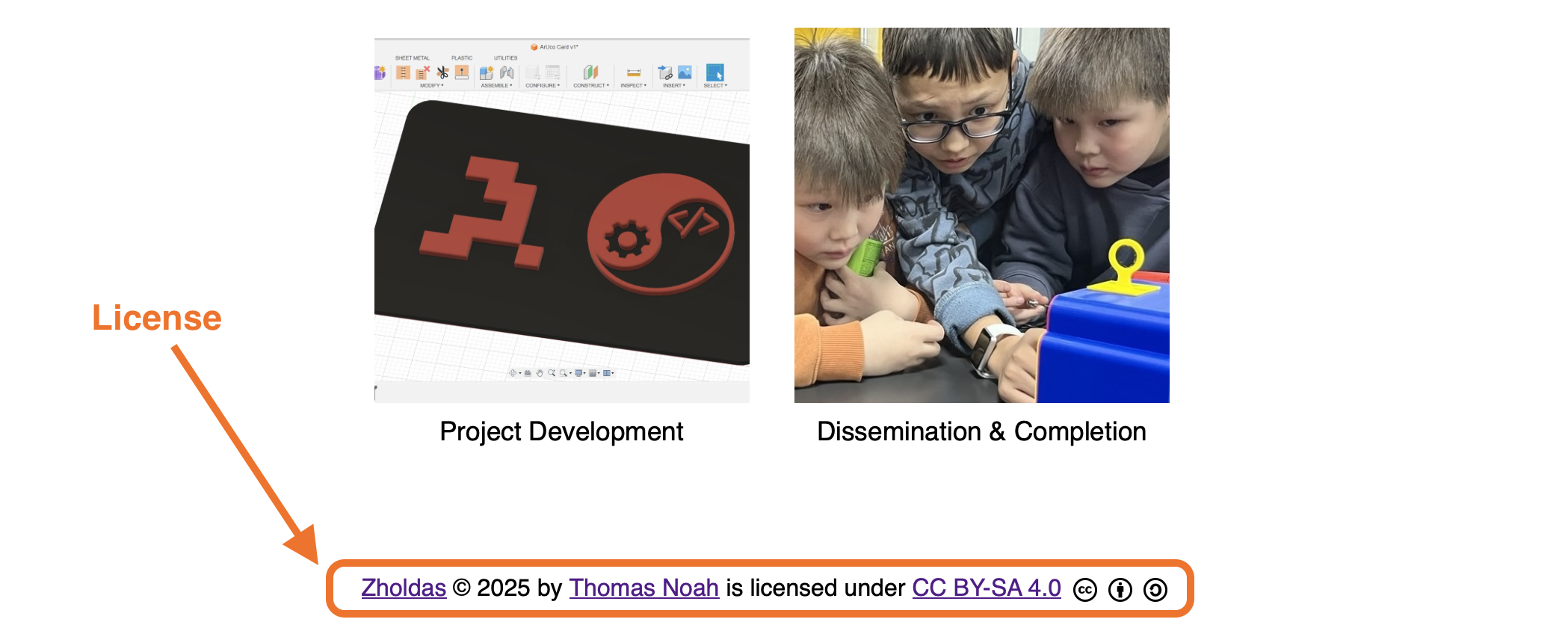

As promised, here is the license on our project page, proving ownership:

Project Dissemination

Dissemination relates to the sharing of the project. As I see there are two things that may be shared:

- idea & process development

- the physical product

As concerns the project idea and how it was produced - well, all of that is shared on this webpage. As concerns the physical product, this product has a minimal cost of about $20, so it may easily be produced and shared with others. This chocolate-dispensing friendly Robot face has already proven a hit at the Robotics Academy in Kazakhstan. Boys just use their bus card to take chocolate.

The plan now is to bring this project on a road trip for continued testing and durability. Subsequently after any final revisions, we will produce at least a half dozen to be given as gifts to dear and special people.

The initial prototype has actually proven surprisingly durable and professional-looking. The snap fit connections between the different parts give a very professional look and finishing touch, but at the same time can easily be taken apart for maintenance. However very little maintenance has been needed! One of the bigger concerns is that the chocolate would be jammed, but our method of restocking the robot with chocolates has proven reliable, and so has the mechanism. Therefore it can sit on the front desk and used:

This final project is actually relatively simple, but it therefore has the huge advantage that it can be maintained with ease, and others can be taught about the proper way to maintain it. Another advantage to its simplicity is that the initial iteration can be used as a basis for continued (spiral) development, adding additional features without being afraid that the core functionality will prove unreliable.