12. Group Assignment

This week's brief:

Group assignment:

GROUP ASSIGNMENT

You can view our group assignment here!

INDIVIDUAL ASSIGNMENT

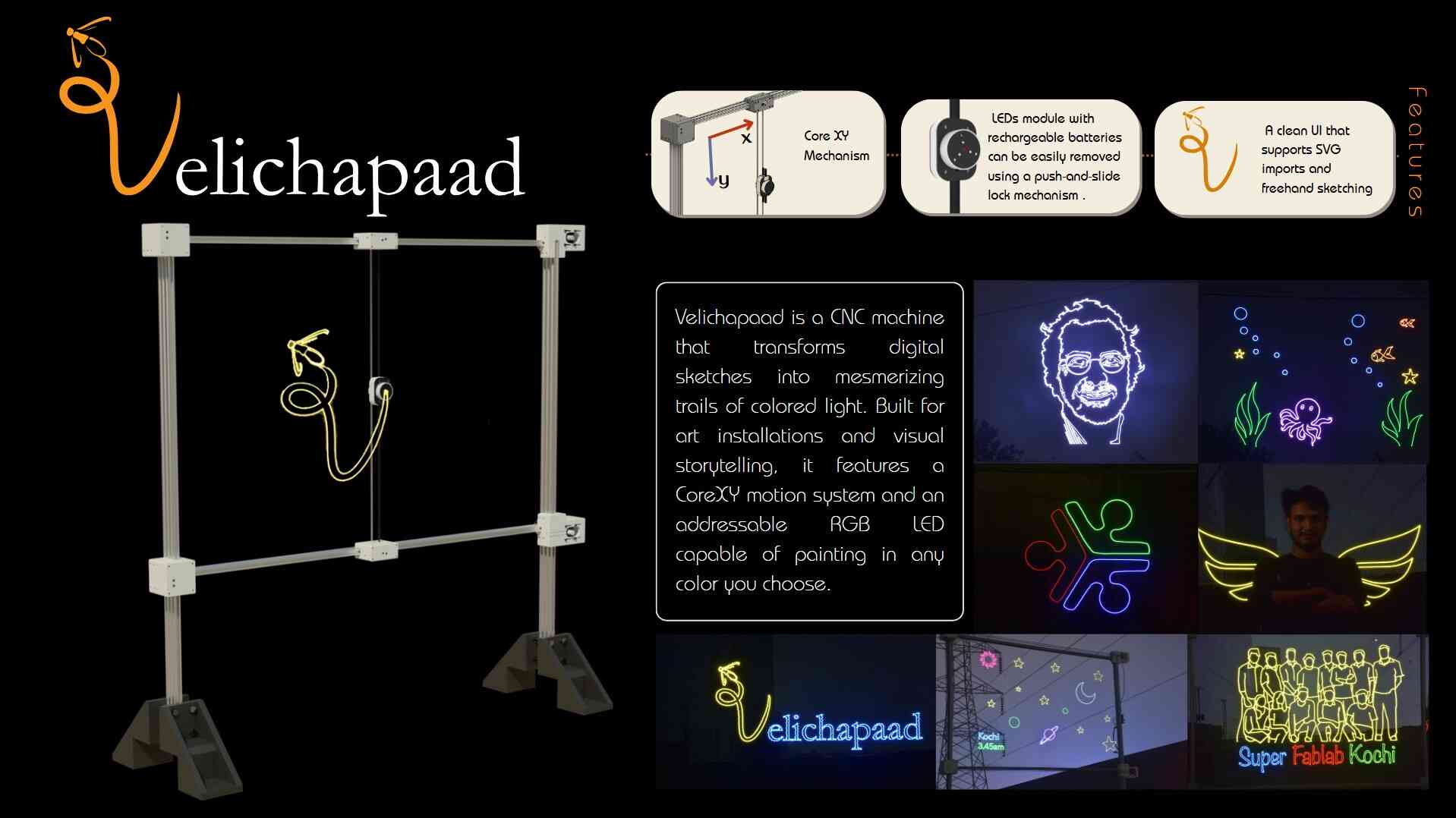

Brainstorming and Project planning

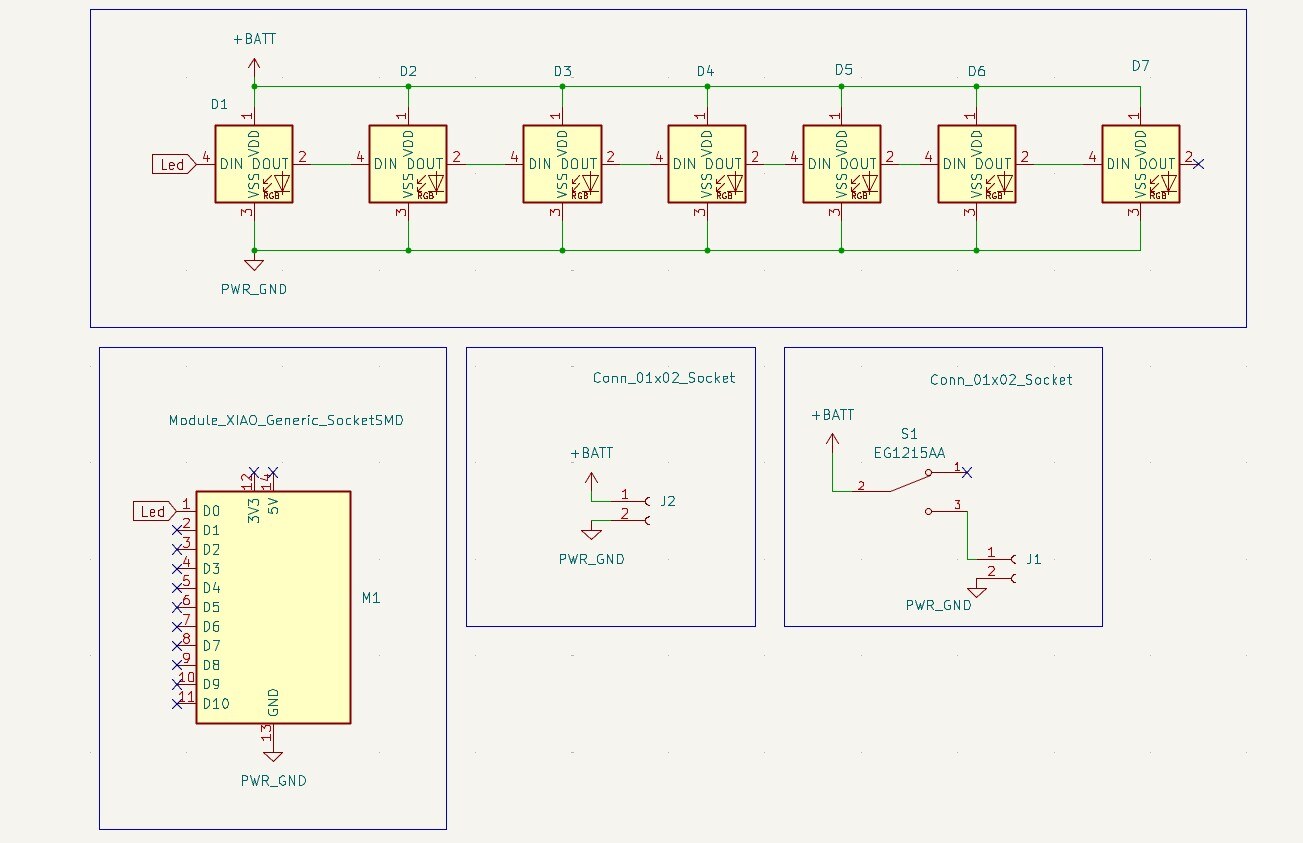

System Design

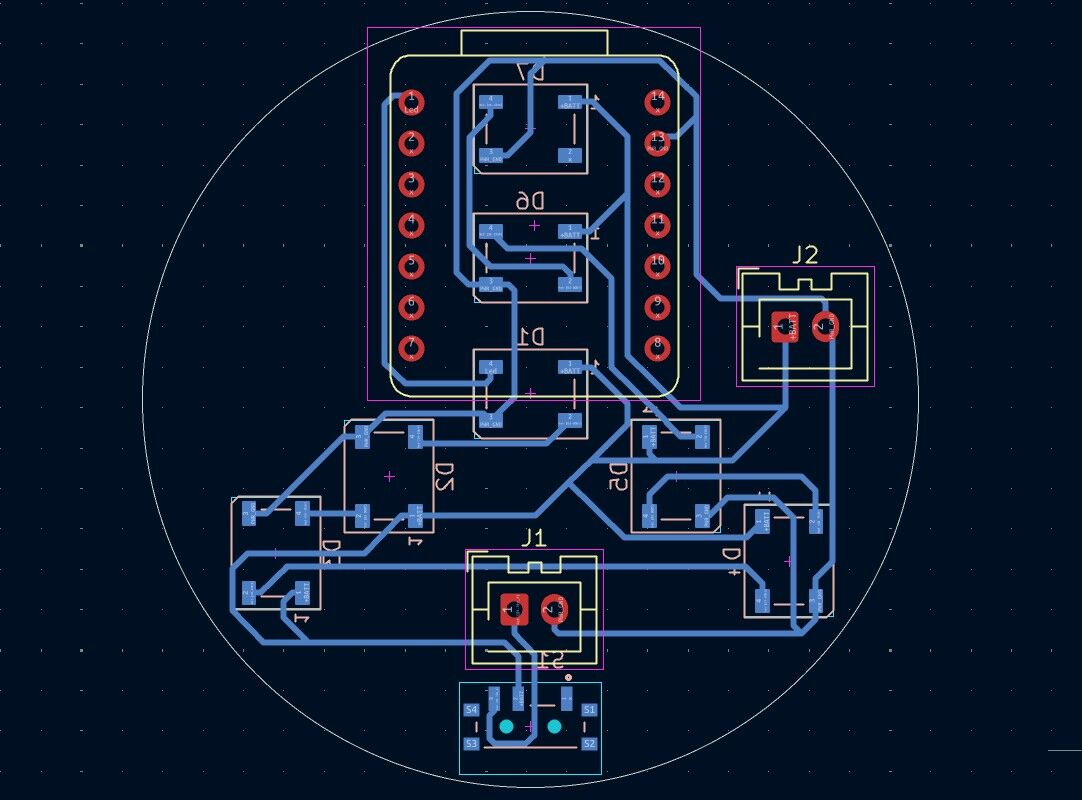

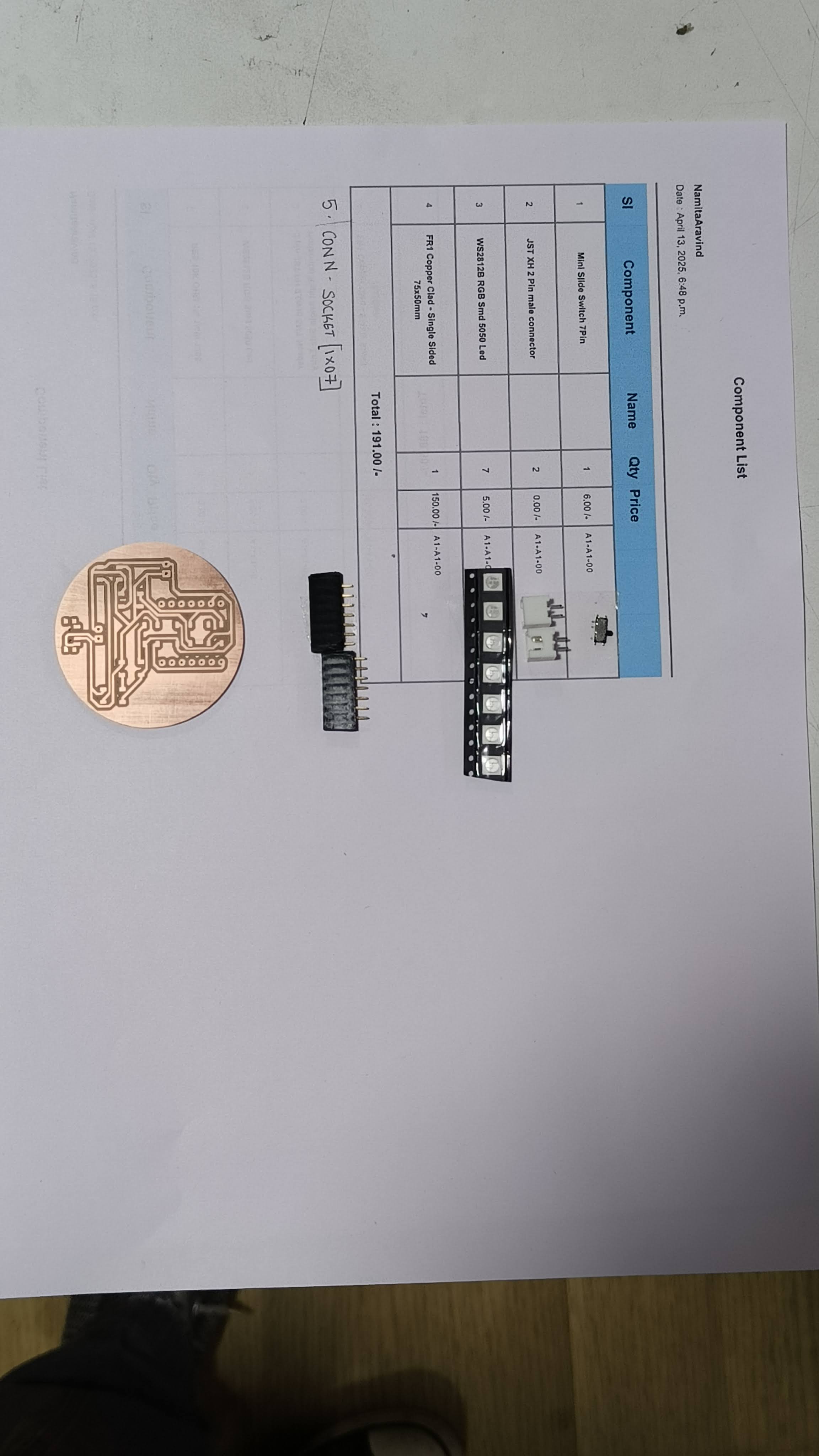

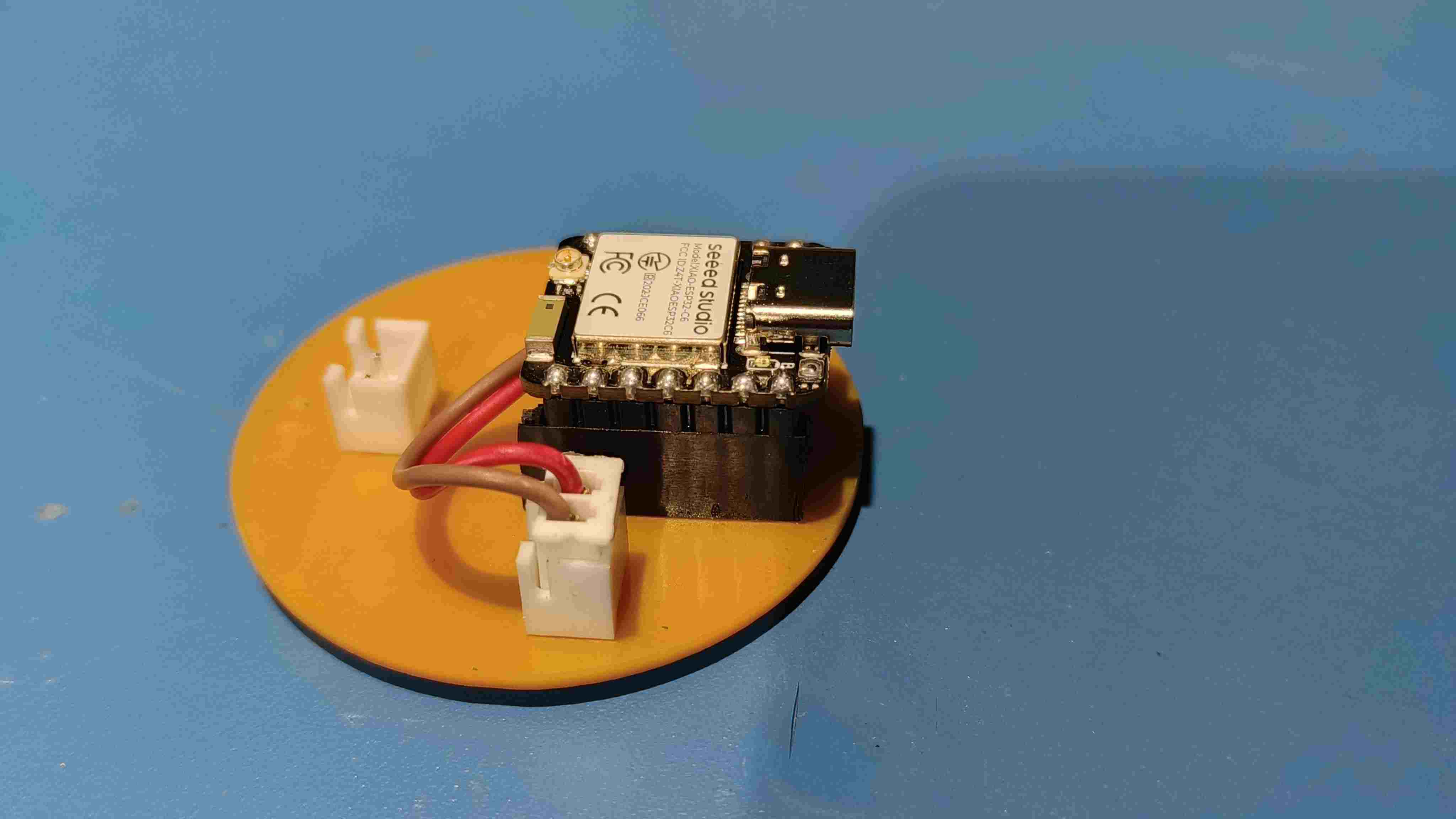

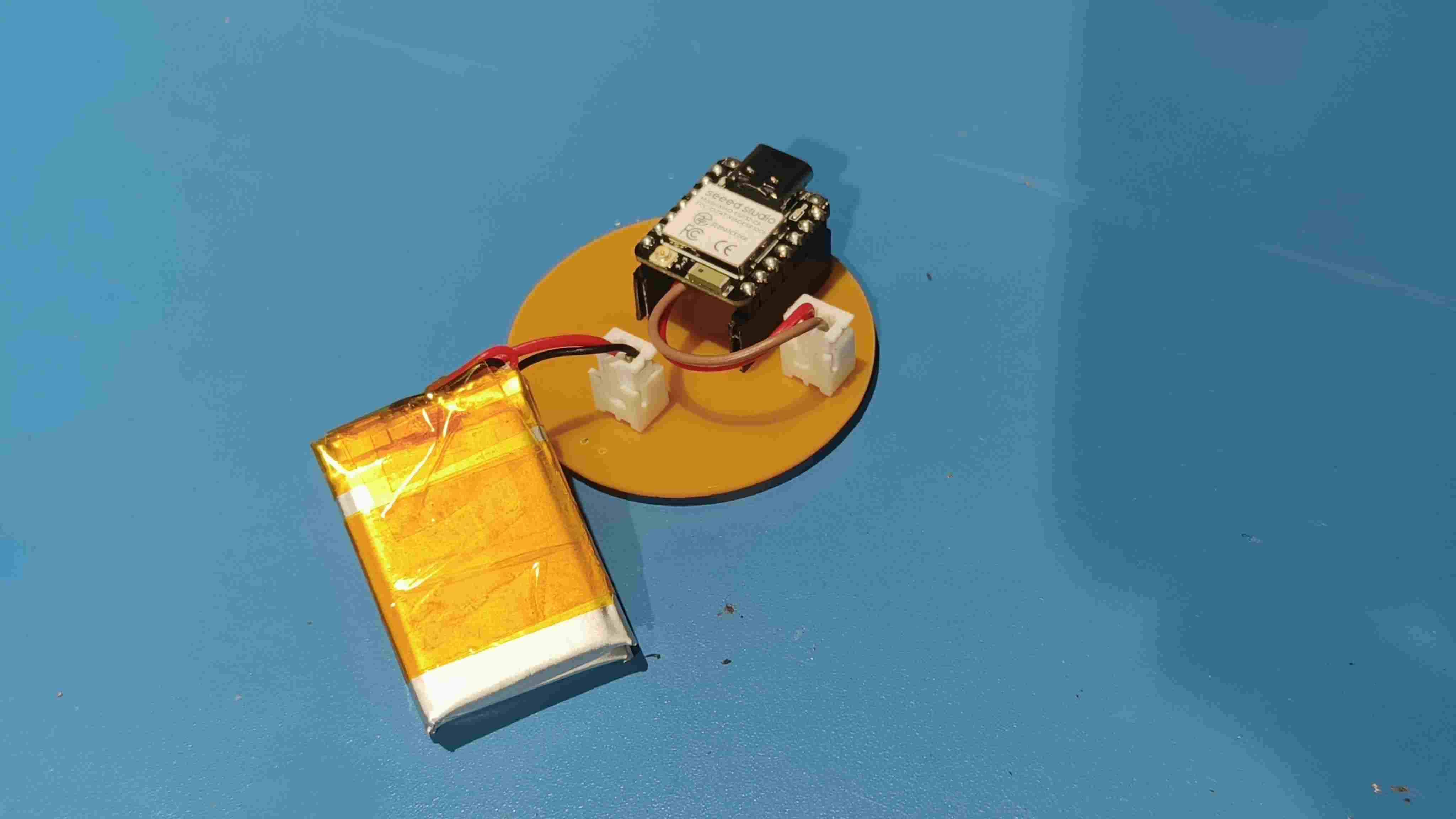

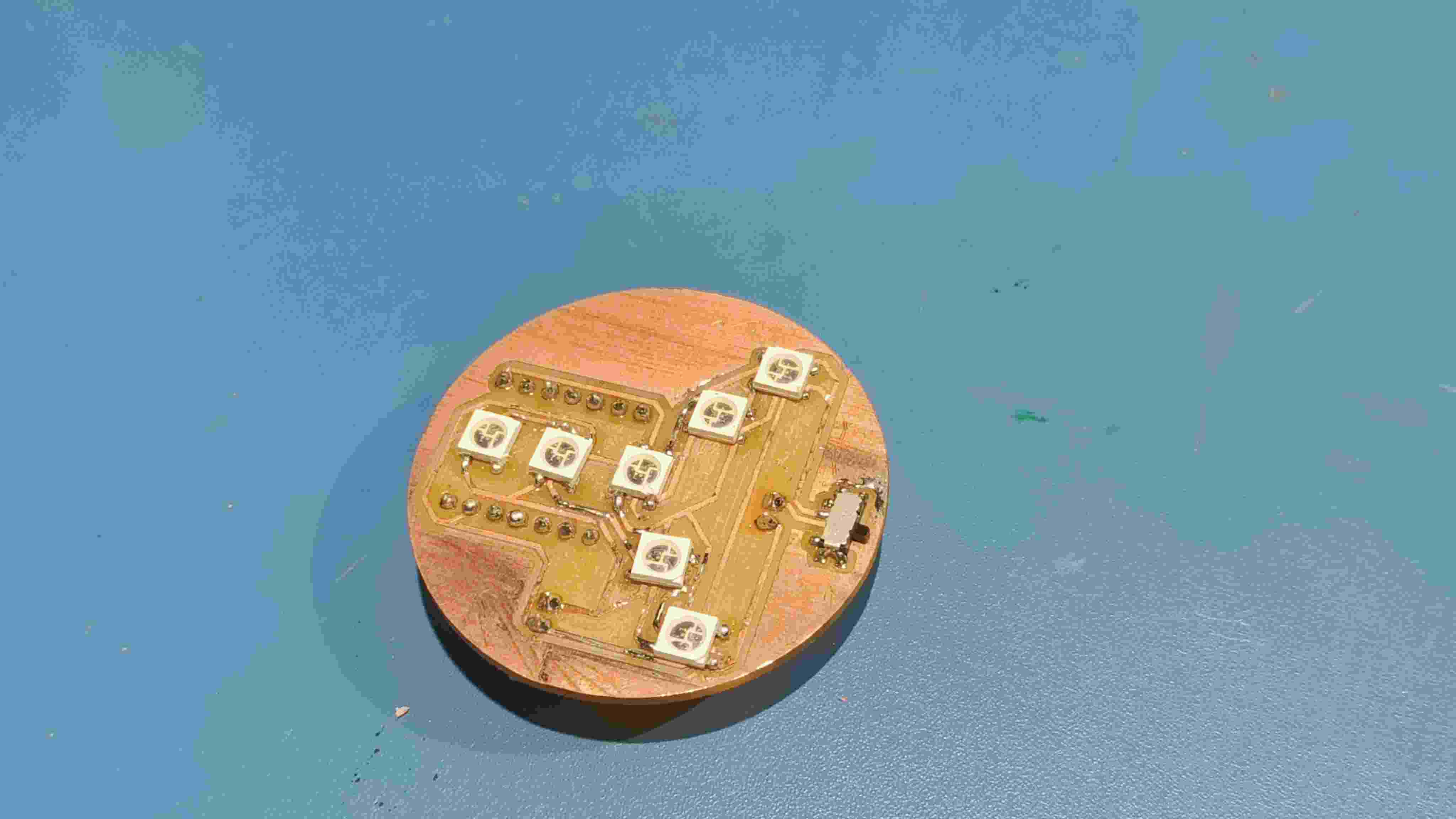

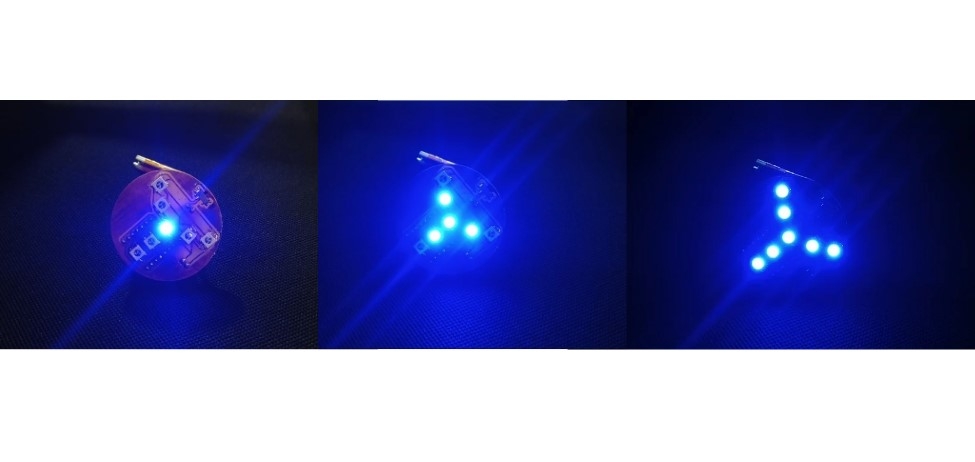

Making the PCB and mount of the LEDs

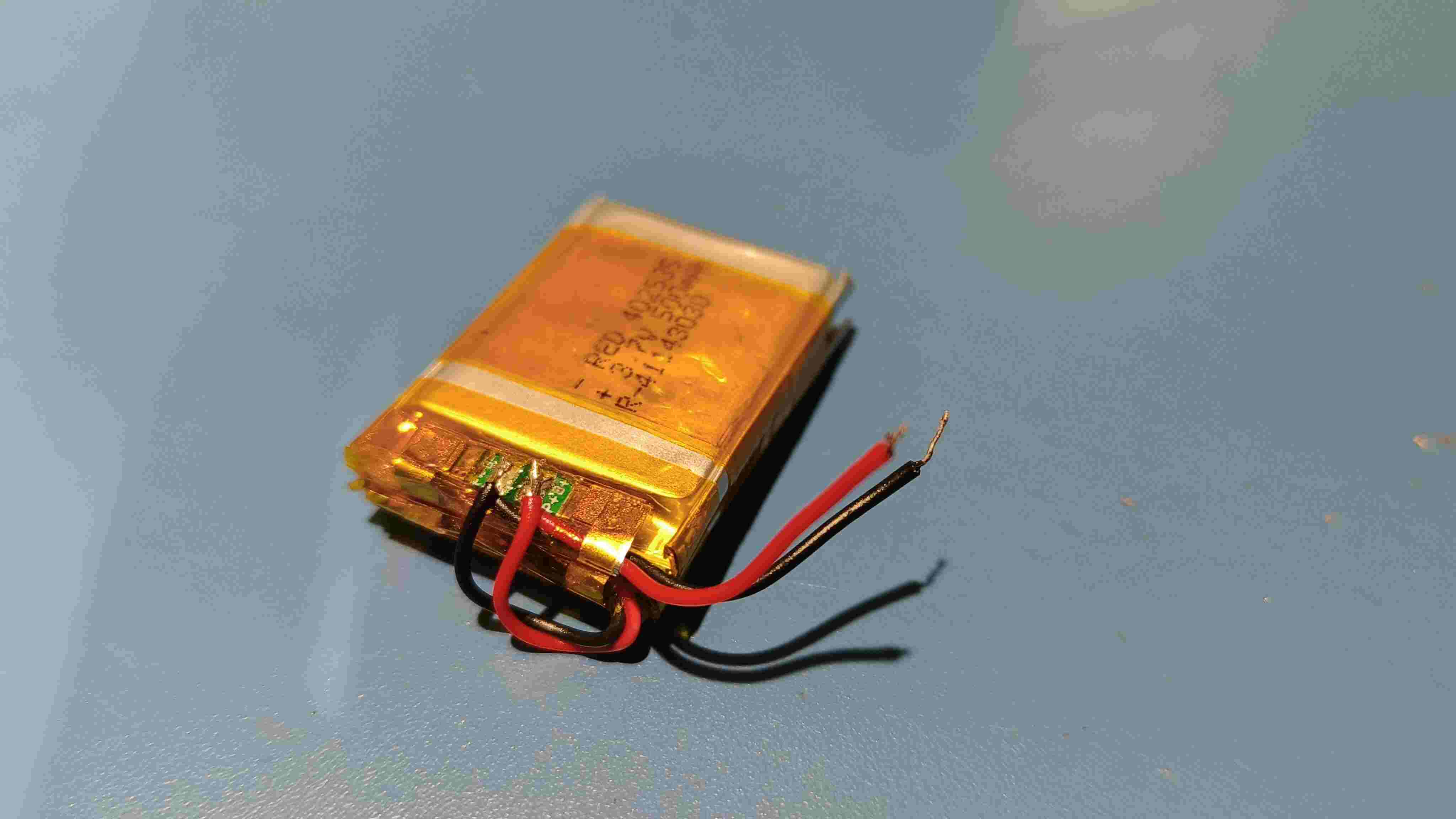

therefore 7 neopixels consumes : 7 x 60m A = 420mA

to find the battery consumption:

battery consumption =current x time it is left on

i.e. 420mA x 2 Hrs = 840mA

For the Battery

Branding and Logo

Presentation Slide

Graphics for Light Painting