Week 1: Web Design & Project Management

The first week we were introduced to version management, and best practices for doing projects under sharp time constraints. Our tasks included building a personal website for documentation.

Starting every wednesday, we had one week to find, plan, and finish a new project connected to the topic that was introduced to us in a weekly lecture. On this page, you see the documentation for each of these projects.

The first week we were introduced to version management, and best practices for doing projects under sharp time constraints. Our tasks included building a personal website for documentation.

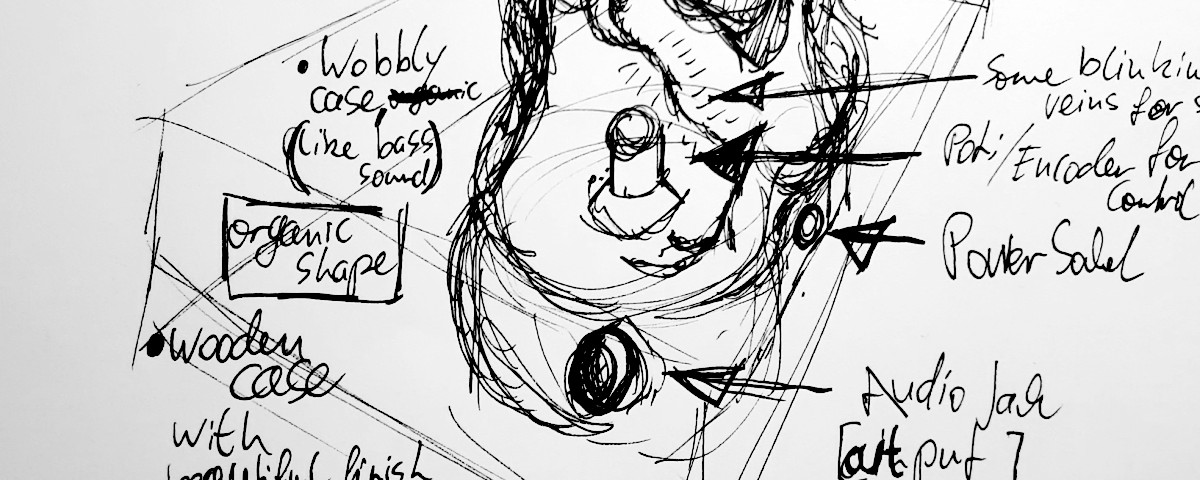

This page contains the first ideas for a the final project. If you want to see the final idea and the development process, check the final project page.

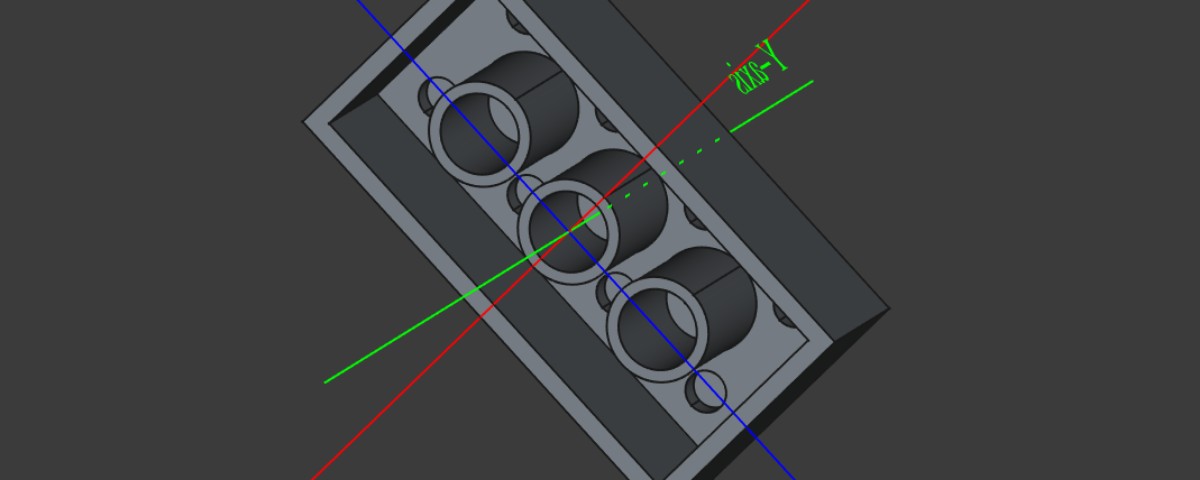

This week was about getting familiar with 2D and especially 3D design software. I refreshed my CAD skills using FreeCAD and introduced myself to Blender.

This week, we got introduced to vinyl and laser cutting including machine setup and the corresponding safety training. I designed and lasered a cardboard construction kit to assemble plant-like constructions with. As an introduction to vinyl cutting, a custom sticker was designed and fabricated.

This week was MOSTLY LITERATURE RESEARCH.

If you are INTERESTED IN MY PROGRAMMING WORK during the program, please refer to the networking week or the final project

This week, we got introduced to 3D scanning and printing. Our tasks were to characterize the available printers, scan and refine a real object, and learn how to design an object for 3D printing. In particular, I worked with Blender where among other things I learned how to perform physics simulations.

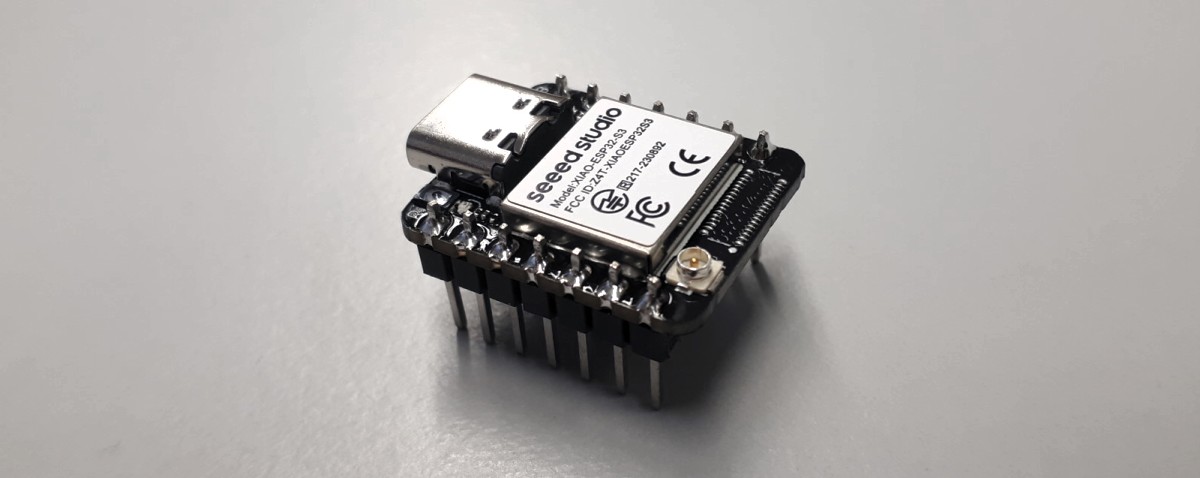

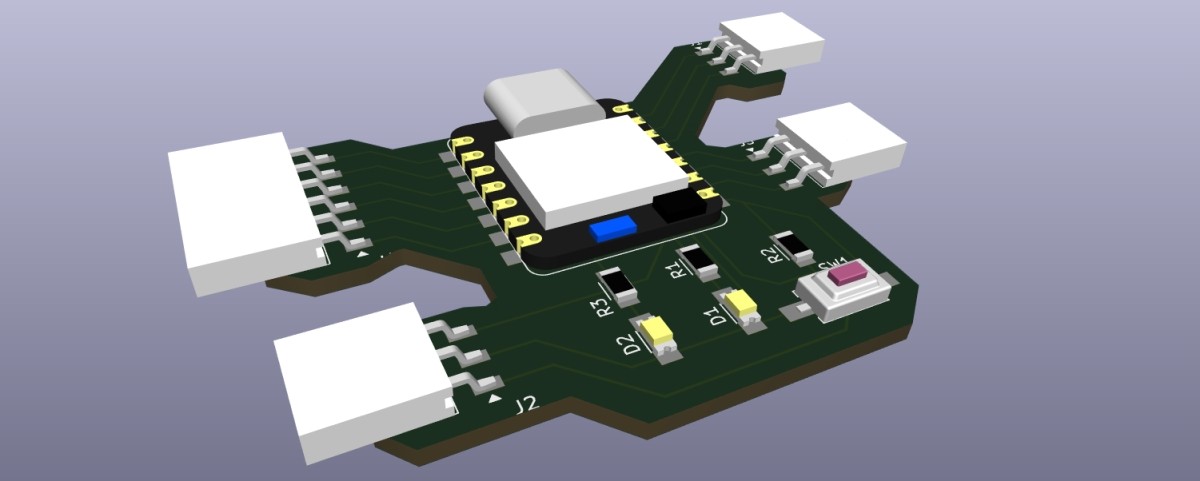

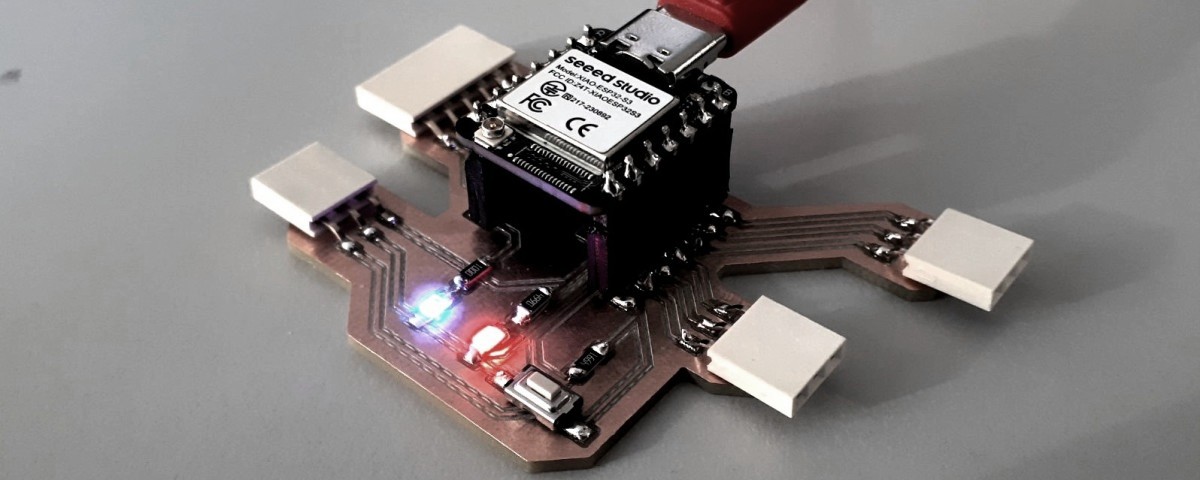

This week was about getting familiar with the design of printed circuit boards (PCBs) using electronic design automation (EDA) software. Our task was to design a development board for an MCU. Besides that, we introduced ourselves to electrical measurement devices in the lab.

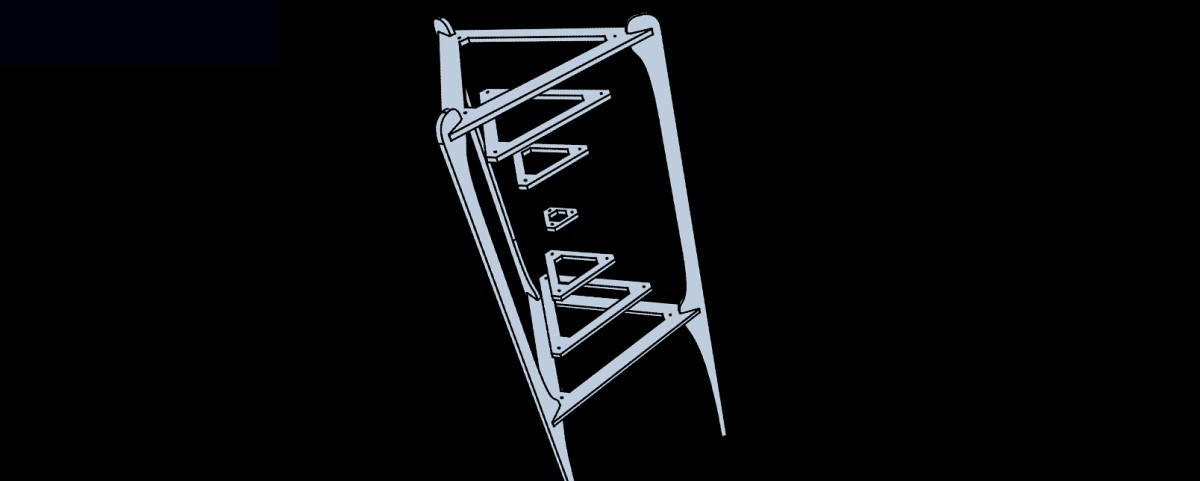

This week we got introduced to CNC milling. I designed and built a meter-scale wood installation containing floating triangles and a disco ball. It is mounted using press-fit joints and wire. The design is optimized for quick build up and build down. It was fabricated in meter-scale to be used as a decorative element e.g. on open-air music events.

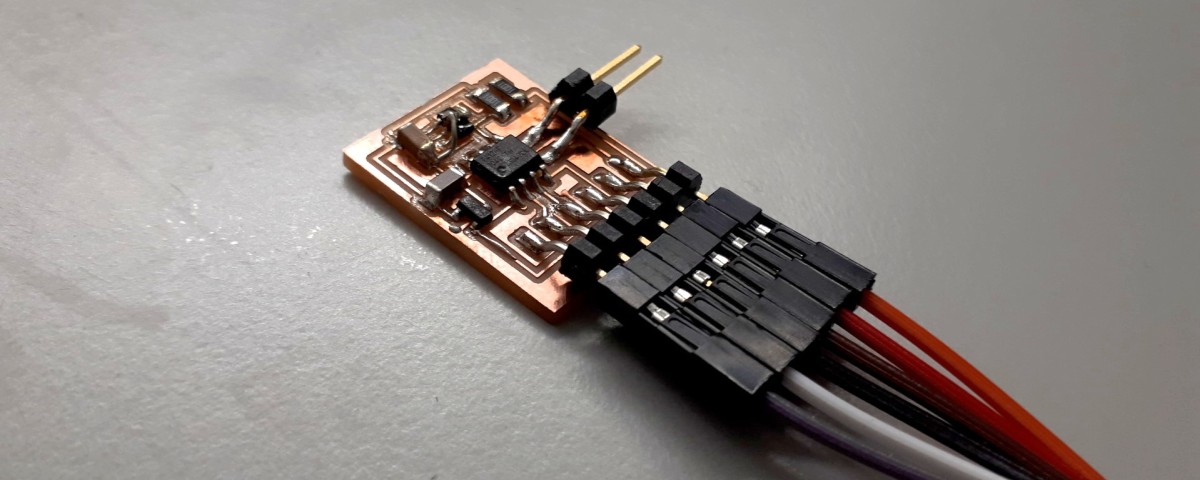

This week, we learned how to fabricate a PCB based on the design from week 8 using a milling machine. We did so by milling copper-foiled PCB stocks.

This week, we set up different sensors to send data to an MCU. In particular, I investigated an inertial measurement unit (IMU) as well as a vector magnetometer. Furthermore, I had more practice in SMD soldering.

This week, we were introduced to different output devices (such as various types of motors, addressable LEDs, etc.), and how to work with them. In my personal assignment, I designed and built small addressable LED matrix based on WS2812B LEDs and set it up to be controlled by the gyroscope I worked with in the input-devices week.

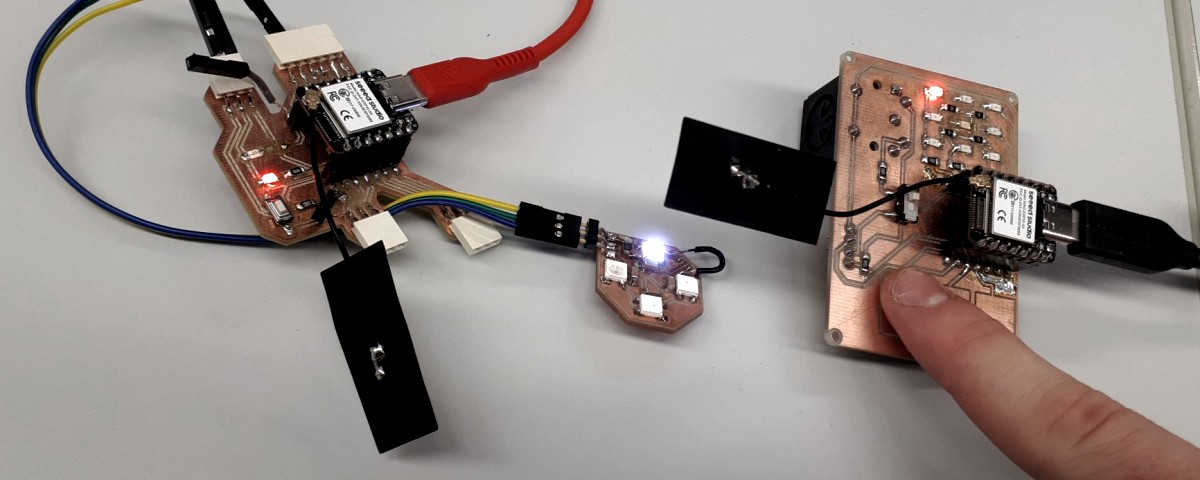

This week was about various methods to connect multiple units using network protocols. In the group assignment, we connected our boards wireless using the ESP-NOW protocol. In the individual assignment, I made my board to be a simple USB-MIDI controller, sending note-on and control-change messages to a DAW on my laptop.

This week, we built a two-axis drawing machine in a small group. Inspired by the projects UrumbotXY 2.0 and AxiDraw, we designed it to work with an H-bot motion system driven by a capstan drive. The whole documentation can be found on the group page while this page contains the work I have contributed to the project, which included parts of the CAD as well as the automation part. I worked together with Niclas and Matthias.

This week, we were introduced to basic molding and casting techniques. In my personal assignment, I created silicone molds from both printed and milled positives of an object. Those were used again for casting resin.

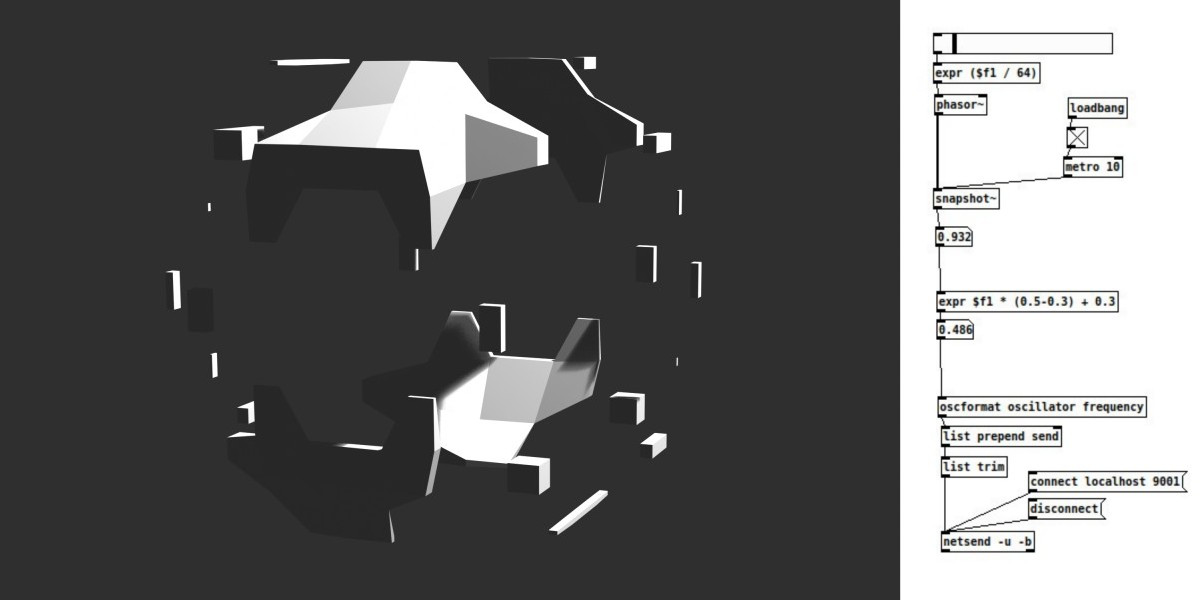

This week introduced user interfaces. The task was to write a graphical output or input for an a device we made earlier. I did not plan to use any GUI for my final project, so I used the week to try out some things. I set up an example visualization to display the output of a sensor I made using Tkinter. Additionally, I learned Pure Data and connected it with Blender via OSC using the plugin NodeOSC.

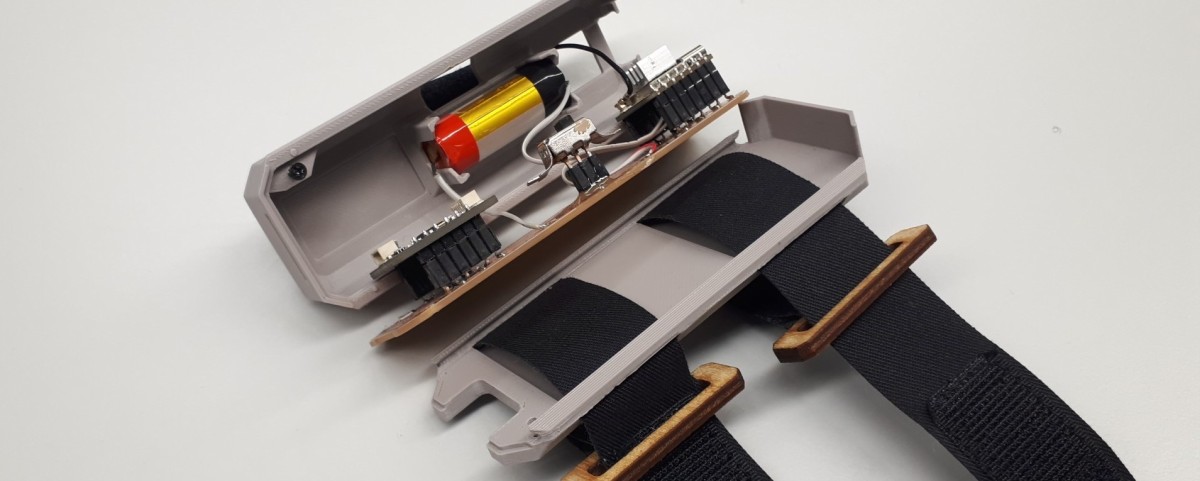

This week, the Task was to continue working on the final project, including programming, design, electronics, and assembly. In particular, it should be considered how to integrate all components of the system in a nice way.

This week, we were to choose our assignment ourselves. I designed patches with Inkscape with the Ink/Stitch extension and fabricated them using the brother PR-655 embroidery machine available at our university’s library.

This week, we were to officially propose our final project, develop an initial project plan and a bill of materials (BOM). The final project documentation together with the final BOM can be seen at the final project page.

This week, again, was meant to continue working on our final project. As a small assignment, we had to choose a license for our project and think about our future plans with it.