Introduction

This week, I had the opportunity to experiment with the Raspberry Pi Pico. The most significant aspects of this experience were reading Datasheets and understanding how a microcontroller works: what are it's pins used for, what type of pins are there. I also contributed to the group assingment by documenting how to download Thonny, Arduino, and VS Code. I also blinked the LED on Pico and documented it.

This is the link to our group project

Simulation

This week to simulate embedded programming I used the Wokwi simulation environment to control a Raspberry Pi Pico to get the hang working with some of the electronic components. Wokwi is a web based embedded programming environment. Steps to open Wokwi:

- search wokwi pico, micropython in your browser of choice

- click the first link that pops up

- the Wokwi micropython simulation environment appears!

Here, I decided the create a circuit which involved some fundamental electronics components.

Electronics

Bill of Materials (BOM)

| Component | Quantity | Description |

|---|---|---|

| Raspberry Pi Pico | 1 | Microcontroller |

| Red LED | 1 | Visual indicator |

| Yellow LED | 1 | Visual indicator |

| Green LED | 1 | Visual indicator |

| Push Button | 1 | User input trigger |

| Servo Motor (SG90 or similar) | 1 | Servo |

| Jumper Wires | Various | Connections |

| Breadboard | 1 | Circuit assembly |

Wiring

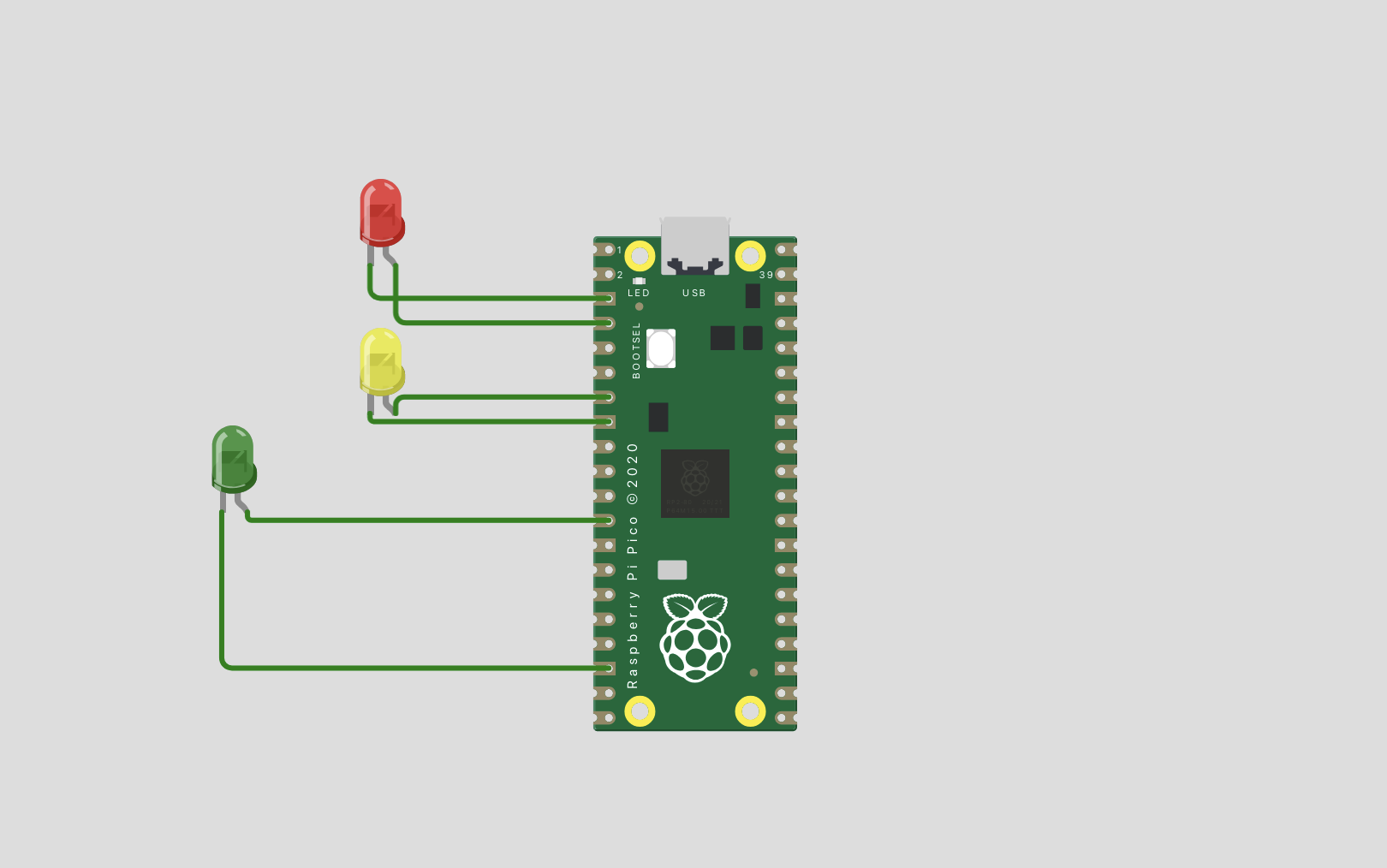

In the environment I firstly decided to wire the LED's and tried to create a system similar to traffic lights. I wired red, yellow, green LED's to GP (general purpose) pins 2,5 and 9 respectively. !

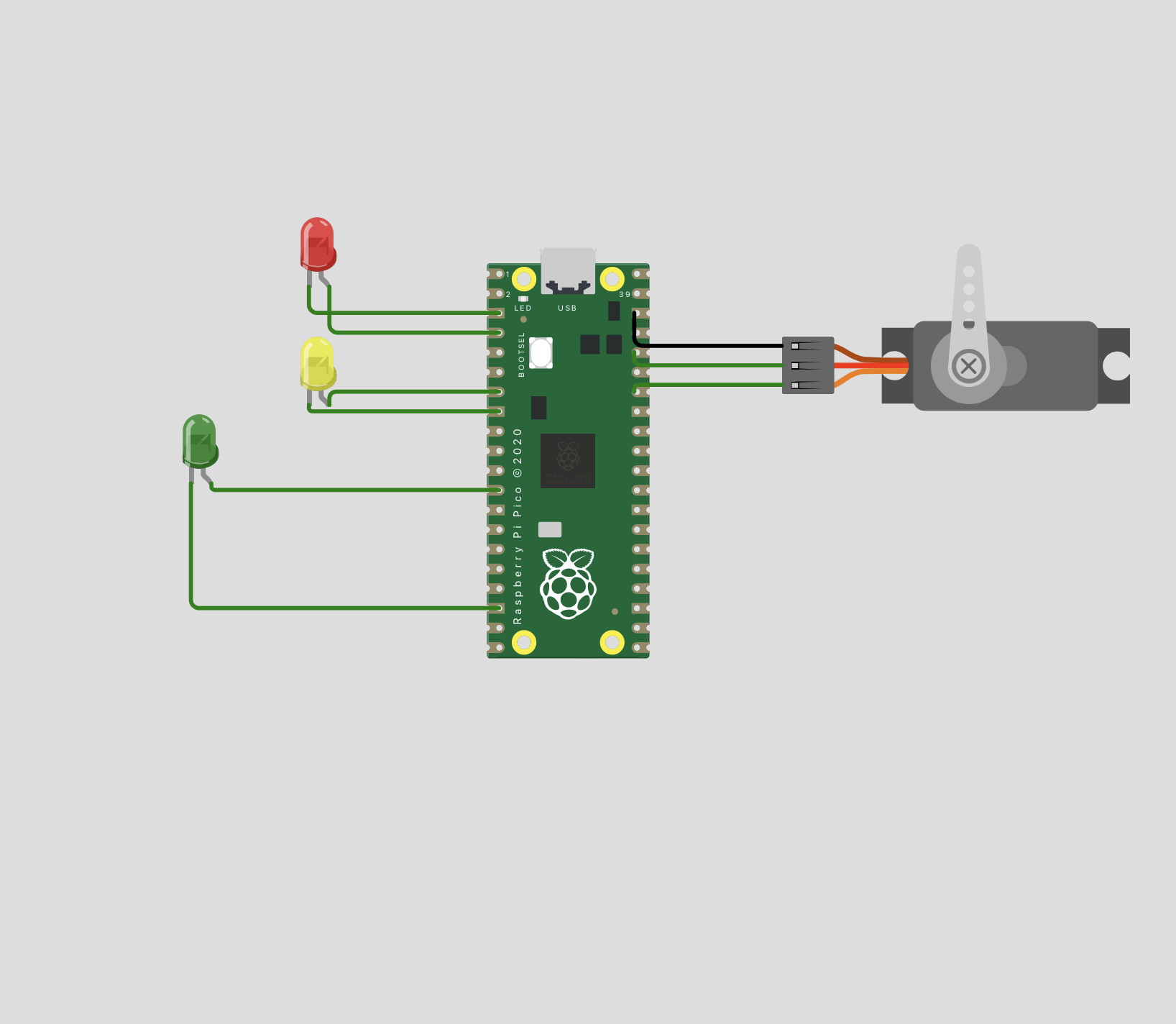

After getting this system to work, I added a Servo into the mix which would rotate from 0-160 and 160-0 in a continuous loop. I connected the servo to GP 28 on the opposite side of the board and LED's!

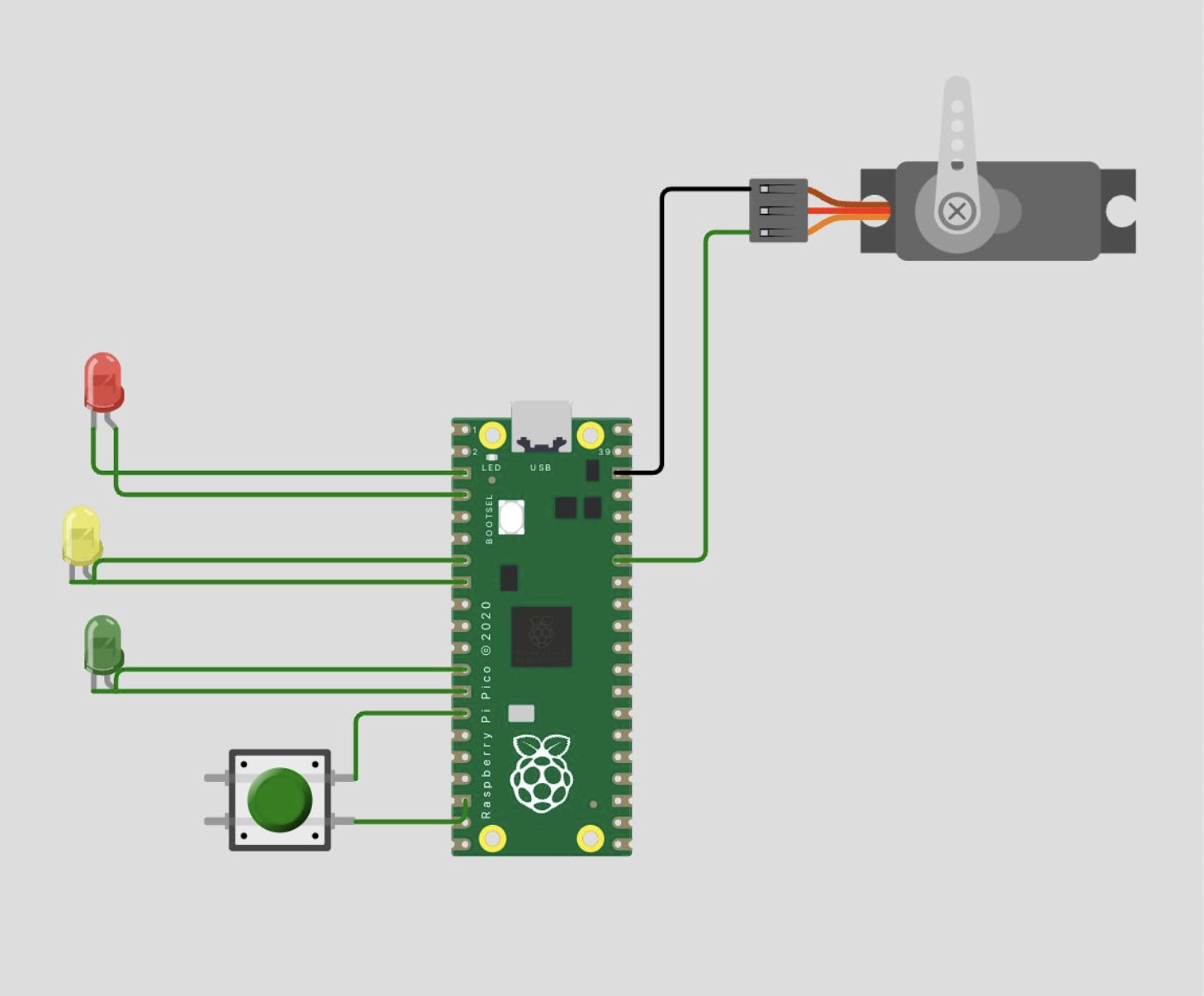

Lastly, I added a push button in order for it to serve as a initiator to the program so that it wouldn't run at the start every time.

Programming

Code Overivew

from machine import Pin, PWM

import time

# Pin definitions for hardware connections

RED_LED_PIN = 2 # Red LED connected to GPIO 2

YELLOW_LED_PIN = 5 # Yellow LED connected to GPIO 5

GREEN_LED_PIN = 9 # Green LED connected to GPIO 9

SERVO_PIN = 28 # Servo motor signal connected to GPIO 28

BUTTON_PIN = 10 # Push button connected to GPIO 10

# Initialize LED pins as digital outputs

red_led = Pin(RED_LED_PIN, Pin.OUT)

yellow_led = Pin(YELLOW_LED_PIN, Pin.OUT)

green_led = Pin(GREEN_LED_PIN, Pin.OUT)

# Initialize servo with PWM at 50Hz (standard servo frequency)

servo = PWM(Pin(SERVO_PIN))

servo.freq(50)

# Initialize button with internal pull-up resistor

# When button is pressed, it will read LOW (0)

button = Pin(BUTTON_PIN, Pin.IN, Pin.PULL_UP)

def turn_on_led(led_pin):

"""

Turn on specified LED and ensure others are off

Args:

led_pin: GPIO pin number of LED to turn on

"""

red_led.value(led_pin == RED_LED_PIN)

yellow_led.value(led_pin == YELLOW_LED_PIN)

green_led.value(led_pin == GREEN_LED_PIN)

def servo_movement(angle):

"""

Move servo to specified angle

Args:

angle: Desired angle between 0 and 180 degrees

"""

# PWM duty cycle values for 0° and 180°

# These values may need adjustment based on your specific servo

min_duty = 1638 # Duty cycle for 0 degrees (1/20 * 65535)

max_duty = 8192 # Duty cycle for 180 degrees (5/20 * 65535)

# Ensure angle is within valid range

angle = max(0, min(180, angle))

# Calculate duty cycle for desired angle

duty = int(min_duty + (angle / 180) * (max_duty - min_duty))

servo.duty_u16(duty)

# Define movement sequence

# Moves from 0° to 160° and back in 20° increments

ANGLE_SEQUENCE = [0, 20, 40, 60, 80, 100, 120, 140, 160,

160, 140, 120, 100, 80, 60, 40, 20, 0]

# Create LED sequence that cycles through all three LEDs

# Length matches ANGLE_SEQUENCE by repeating pattern

LED_SEQUENCE = [RED_LED_PIN, YELLOW_LED_PIN, GREEN_LED_PIN] * (len(ANGLE_SEQUENCE) // 3)

try:

while True:

# Wait for button press

if button.value() == 0:

time.sleep(0.05) # Debounce delay

# Wait for button release

while button.value() == 0:

pass

# Execute movement sequence

for i in range(len(ANGLE_SEQUENCE)):

turn_on_led(LED_SEQUENCE[i]) # Update LED

servo_movement(ANGLE_SEQUENCE[i]) # Move servo

time.sleep(1) # Wait 1 second

except KeyboardInterrupt:

# Clean up on program exit

servo.duty_u16(0) # Stop servo

red_led.value(0) # Turn off all LEDs

yellow_led.value(0)

green_led.value(0)

Mistakes and What I Learned

MicroPython Code Breakdown: LED and Servo Control System

1. Imports and Pin Definitions

from machine import Pin, PWM import time RED_LED_PIN = 2 YELLOW_LED_PIN = 5 GREEN_LED_PIN = 9 SERVO_PIN = 28 BUTTON_PIN = 10

This section imports necessary modules and defines constants for GPIO pin assignments. The machine module provides hardware control capabilities, while time is used for delays.

2. Hardware Initialization

red_led = Pin(RED_LED_PIN, Pin.OUT) yellow_led = Pin(YELLOW_LED_PIN, Pin.OUT) green_led = Pin(GREEN_LED_PIN, Pin.OUT) servo = PWM(Pin(SERVO_PIN)) servo.freq(50) button = Pin(BUTTON_PIN, Pin.IN, Pin.PULL_UP)

This block initializes the hardware:

- LEDs are set up as digital outputs

- Servo is configured with PWM at 50Hz (standard servo frequency)

- Button is set up with an internal pull-up resistor (reads 1 when not pressed, 0 when pressed)

3. LED Control Function

def turn_on_led(led_pin):

"""

Turn on specified LED and ensure others are off

Args:

led_pin: GPIO pin number of LED to turn on

red_led.value(led_pin == RED_LED_PIN)

yellow_led.value(led_pin == YELLOW_LED_PIN)

green_led.value(led_pin == GREEN_LED_PIN)

"""

This function implements mutually exclusive LED control:

- Takes a pin number as input

- Uses boolean comparisons to ensure only one LED is on at a time

- Elegant implementation avoiding multiple if-statements

4. Servo Control Function

def servo_movement(angle):

"""

Move servo to specified angle

Args:

angle: Desired angle between 0 and 180 degrees

"""

min_duty = 1638 # Duty cycle for 0 degrees (1/20 * 65535)

max_duty = 8192 # Duty cycle for 180 degrees (5/20 * 65535)

angle = max(0, min(180, angle))

duty = int(min_duty + (angle / 180) * (max_duty - min_duty))

servo.duty_u16(duty)

The servo control function:

- Converts angles (0-180°) to appropriate PWM duty cycles

- Includes bounds checking for safety

- Uses linear interpolation to calculate duty cycle

- Works with 16-bit PWM resolution (0-65535)

5. Movement Sequences

ANGLE_SEQUENCE = [0, 20, 40, 60, 80, 100, 120, 140, 160, 160, 140, 120, 100, 80, 60, 40, 20, 0] LED_SEQUENCE = [RED_LED_PIN, YELLOW_LED_PIN, GREEN_LED_PIN] * (len(ANGLE_SEQUENCE) // 3)

Defines the movement patterns:

- ANGLE_SEQUENCE creates a sweep pattern (0° → 160° → 0°)

- LED_SEQUENCE cycles through the LEDs in sync with servo movement

- Multiplication operator creates a pattern matching ANGLE_SEQUENCE length

6. Main Control Loop

while True:

if button.value() == 0:

time.sleep(0.05) # Debounce delay

while button.value() == 0:

pass

for i in range(len(ANGLE_SEQUENCE)):

turn_on_led(LED_SEQUENCE[i])

servo_movement(ANGLE_SEQUENCE[i])

time.sleep(1)

except KeyboardInterrupt:

servo.duty_u16(0)

red_led.value(0)

yellow_led.value(0)

green_led.value(0)

The main program loop:

- Waits for button press with debouncing

- Executes the movement sequence when triggered

- Includes cleanup code for graceful shutdown

- Uses try-except to handle program termination

Technical Details

PWM Calculations

- The servo uses a 50Hz signal (20ms period)

- Duty cycle range: 1638 (2.5%) to 8192 (12.5%)

- These values correspond to typical servo pulse widths:

- 0° position: 0.5ms pulse (2.5% duty)

- 180° position: 2.5ms pulse (12.5% duty)

Button Debouncing

- 50ms delay after button press detection

- Waits for button release before continuing

- Prevents multiple triggers from a single press

Extra Credit: Working with a Development Board

After completing the main assignment of this week I had a chance to experiment with a Raspberry Pi Pico in real life. I decided to try to light the LED on the Pico's board, I used the picozero libraries pico_led class for this below is the code implementations and result:

from picozero import pico_led from time import sleep pico_led.on() sleep(10) pico_led.off()