Wildcard Week: Metal Coin Embossing with xTool F1 Ultra

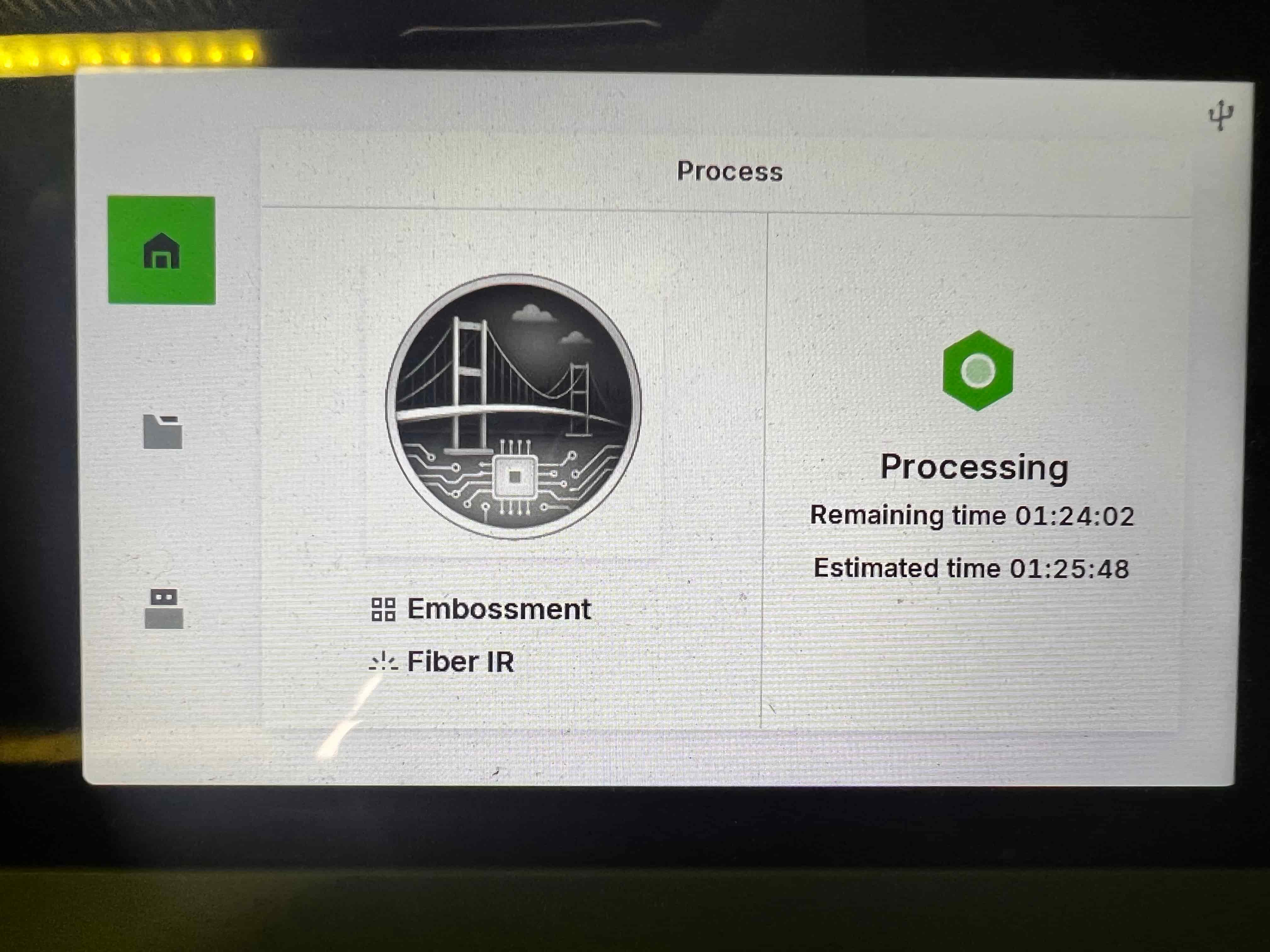

Project Summary: This week, I experimented with an unconventional subtractive process — embossing a custom-designed pattern onto a small 925 silver coin using the xTool F1 Ultra fiber laser machine.

Assignment Checklist:

- ✔️ Documented the workflow(s) and process(es) used

- ✔️ Explained how your process is not covered on other assignments

- ✔️ Described problems encountered and how you fixed them

- ✔️ Included original design files and source code

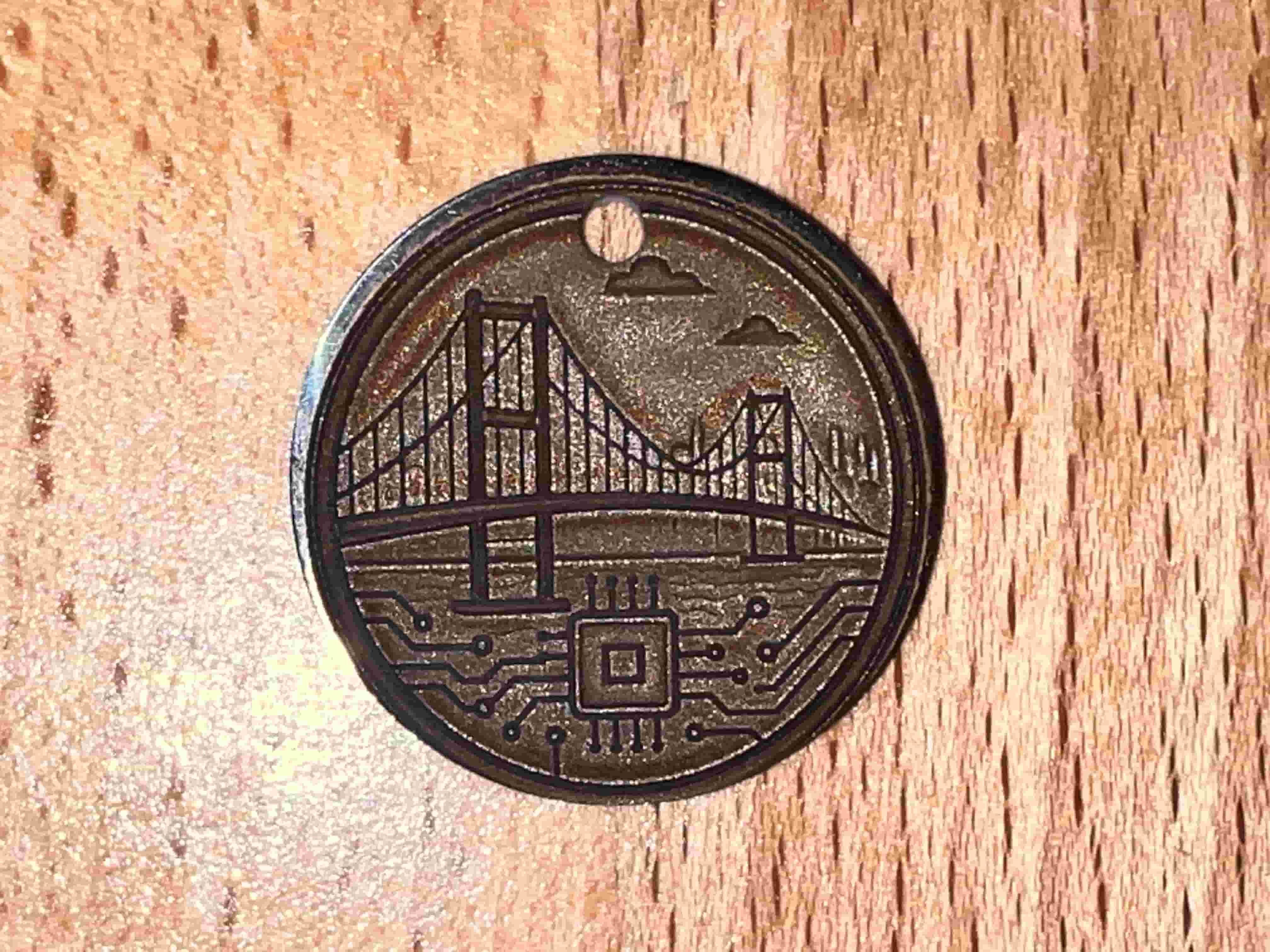

- ✔️ Included ‘hero shot’ of the result

Step 1: Design Generation using GPT

I prompted GPT to create a medallion design that represents the fusion of technology and structure. The result was a circuit-integrated bridge medallion.

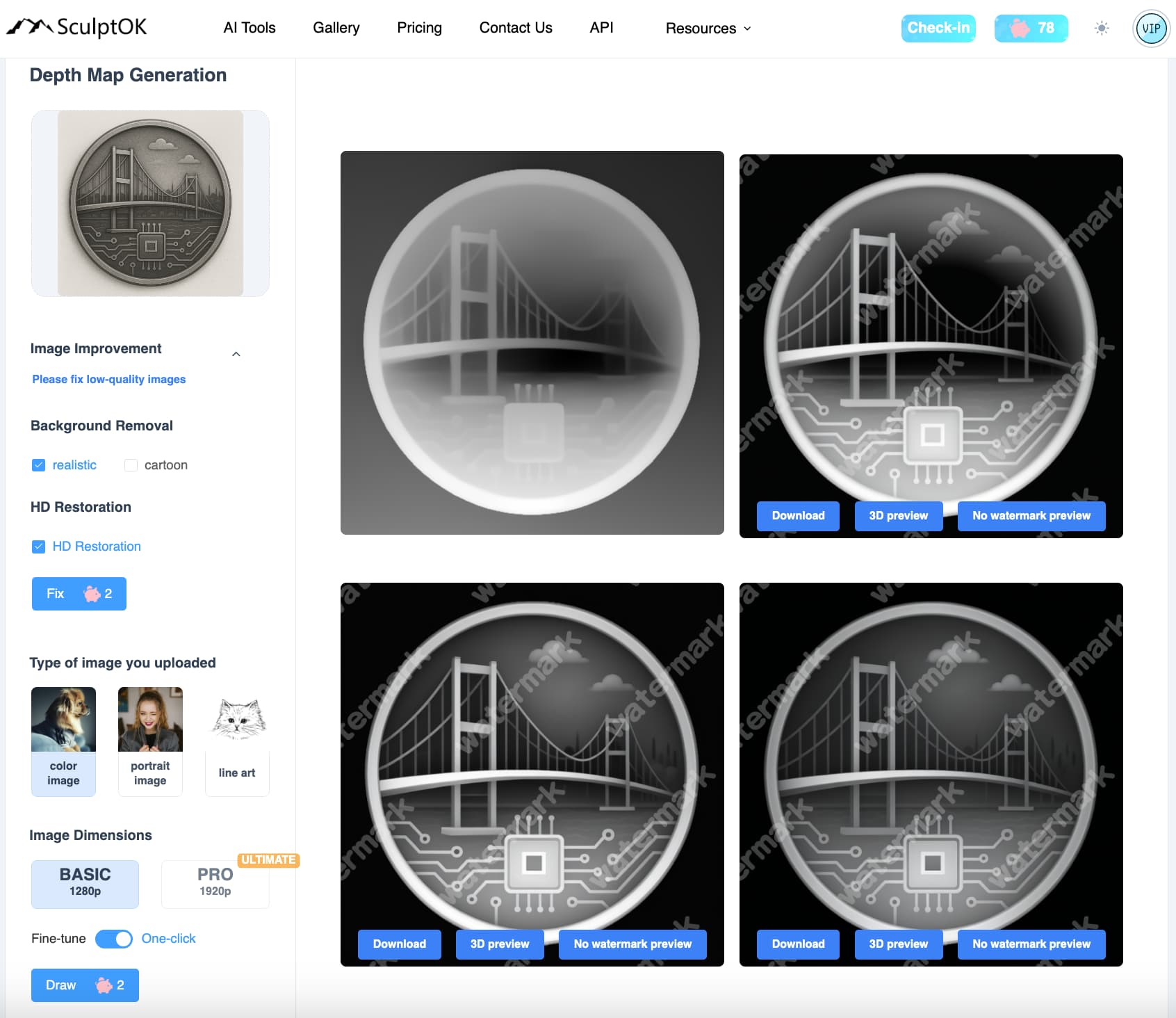

Step 2: Creating a Depth Map

I used SculptOK to convert the generated image into a depth map suitable for 3D embossing. Settings used included HD Restoration and background removal.

You can also view your design in 3d if you click 3d view.

Step 3: Machine Preparation

Always start by turning on the ventilation. Click the big button to do that.

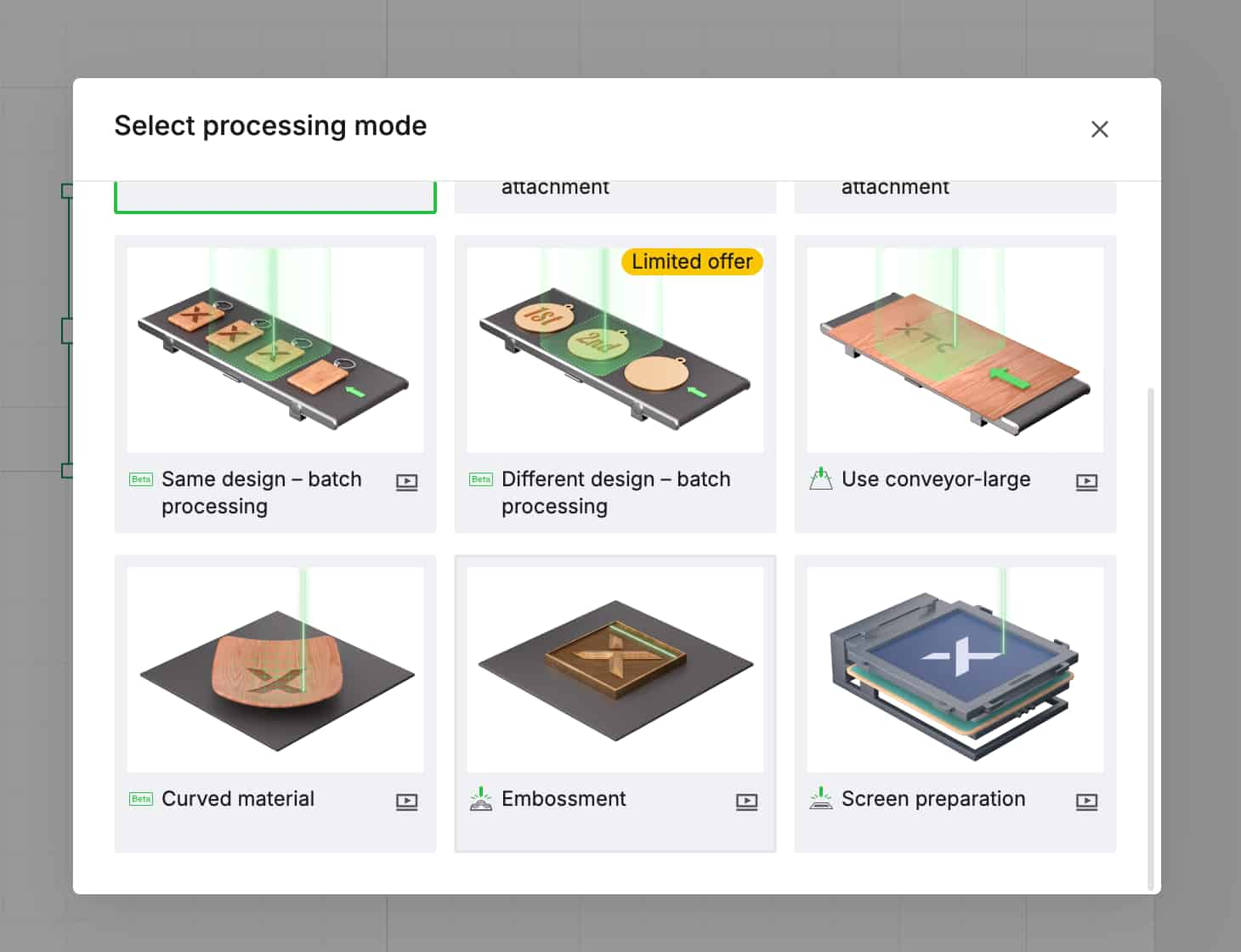

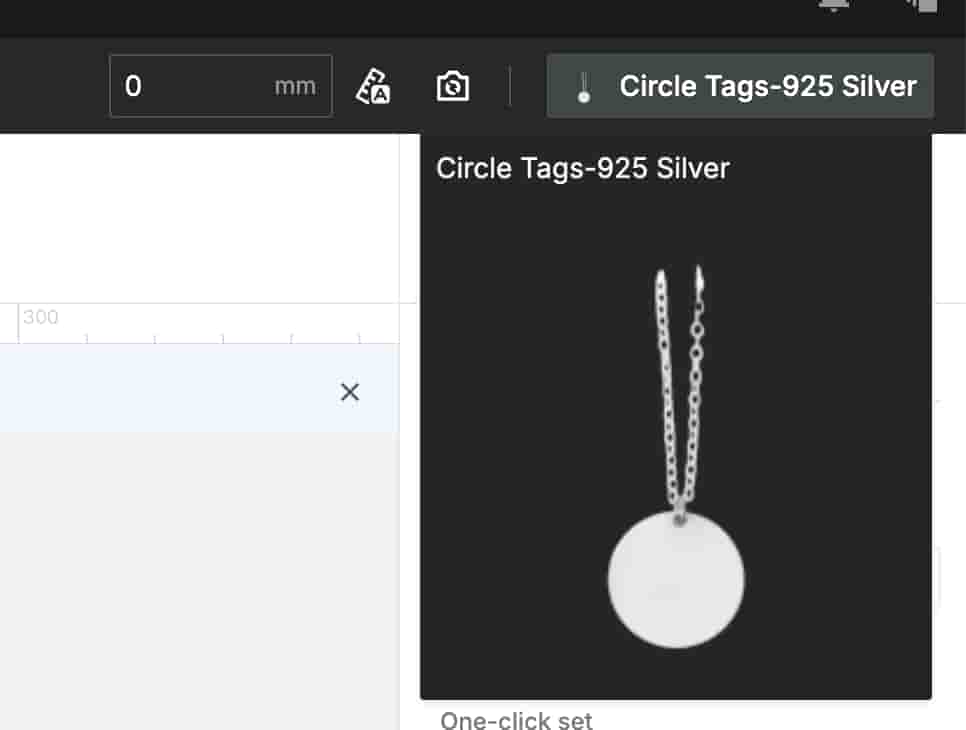

I used the xTool F1 Ultra to perform the embossing. The material was a silver coin (Circle Tags - 925 Silver). I placed the coin on the laser bed and selected the “Embossment” mode.

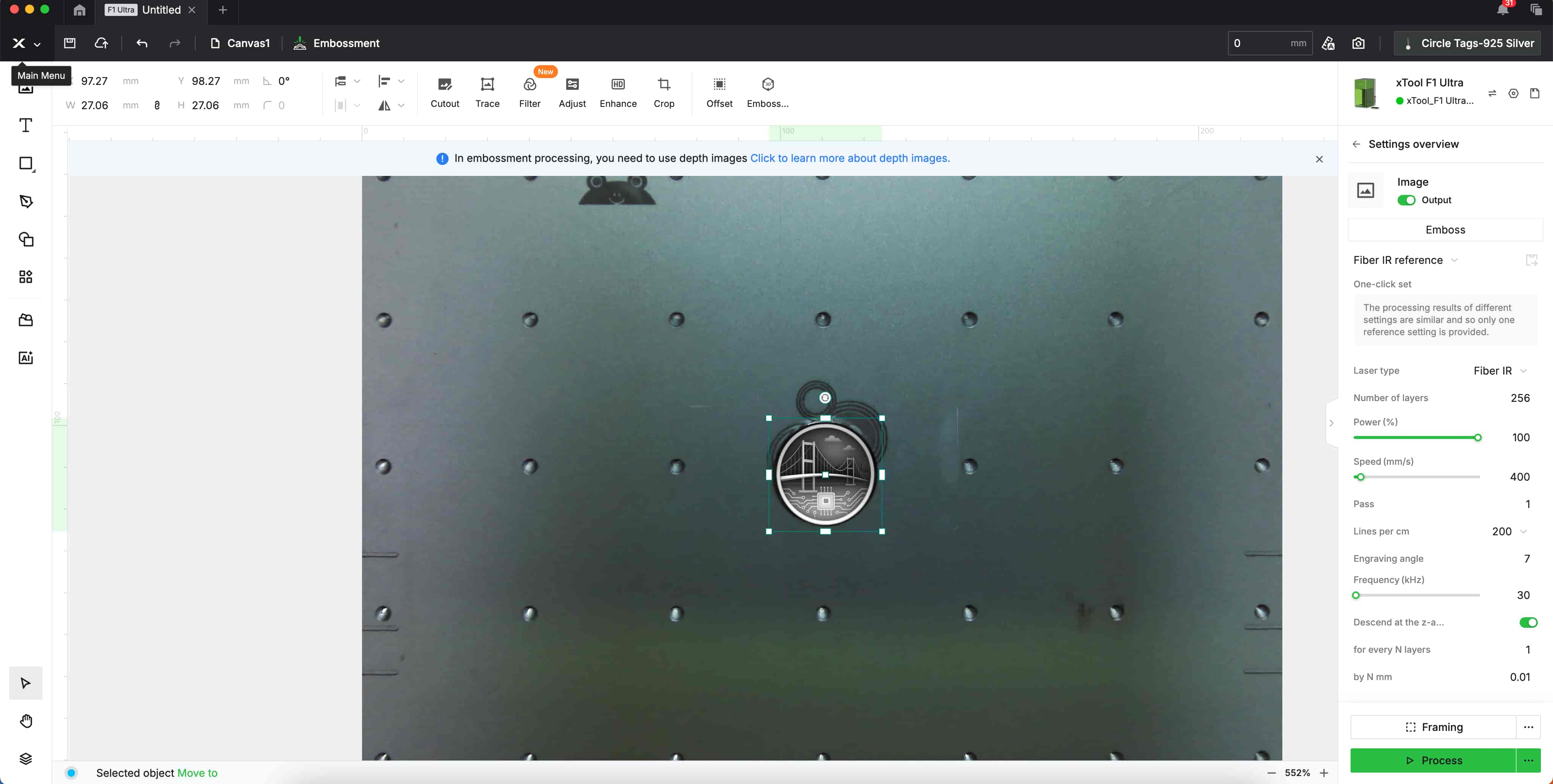

Step 4: Software Setup and Laser Parameters

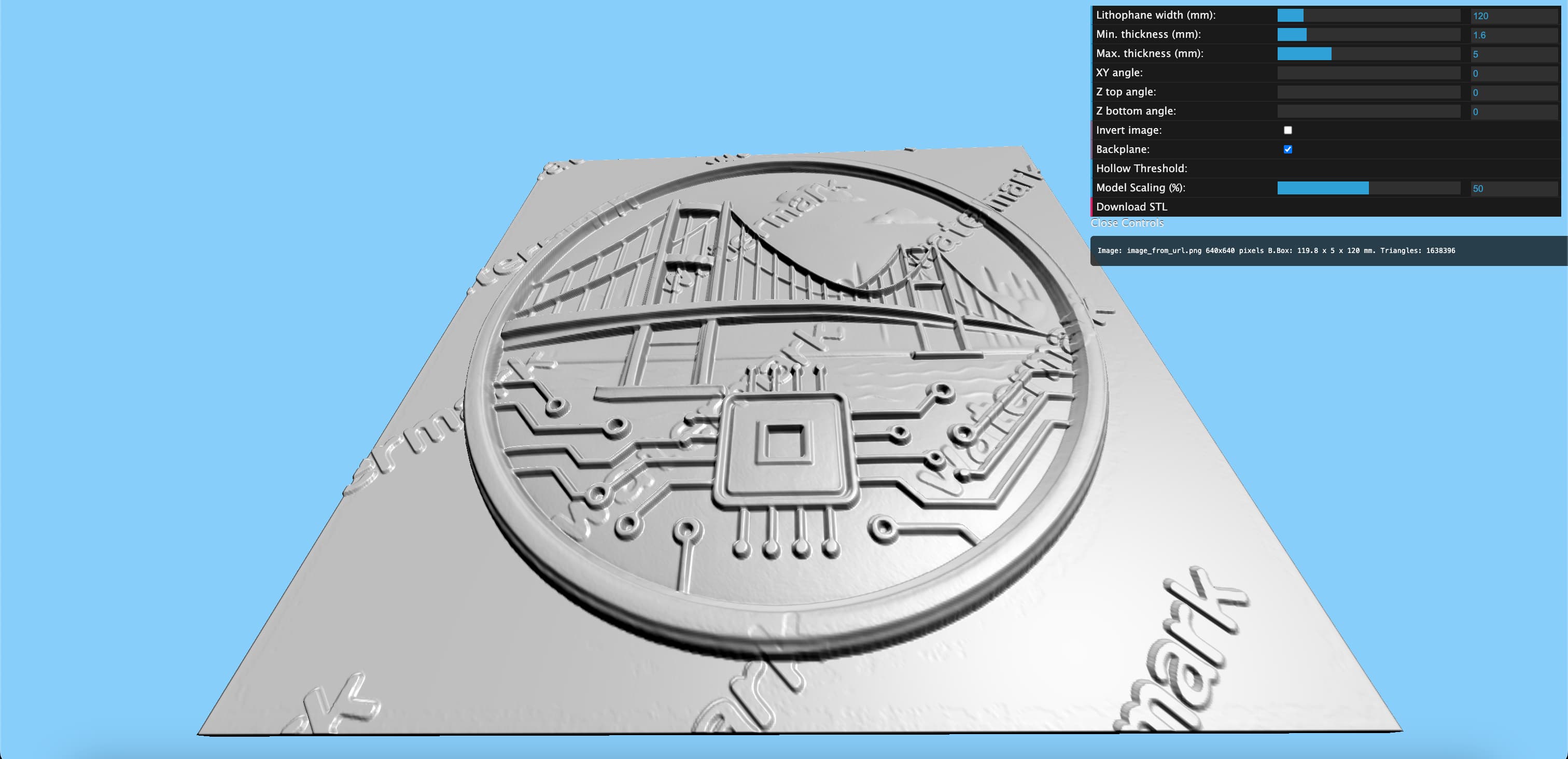

I uploaded the STL model and adjusted the settings as follows:

- Laser Type: Fiber IR

- Power: 100%

- Speed: 400 mm/s

- Lines per cm: 200

- Frequency: 30 kHz

- Pass: 1

- Z-axis descend: 0.01 mm every 1 layer (256 layers total)

Step 5: Problems and Fixes

I didn't encounter any problems. This process was really really easy.

Why This Belongs in Wildcard Week

This process was not used in any other assignment. While I worked with laser cutting before, this was the first time I:

- Used a fiber laser (instead of diode or CO2)

- Applied STL/depth map based 3D embossing

- Worked with precious metal (silver) as a material

Files and Resources

Hero Shot

The final engraved result on the silver coin: