Week 15 — System Integration: Bandbox

Reflection

While designing Bandbox, I found that system integration is more than just connecting components — it's about creating a seamless experience. Balancing aesthetics, electronic functionality, and interactivity required a holistic approach. Simple decisions like servo placement had big effects on usability and structure.

Full System Description

Bandbox is an interactive music toy where pressing one of four buttons triggers a character’s LED, movement, and unique melody. Inspired by Incredibox, the device allows simultaneous button presses to build up a musical layer.

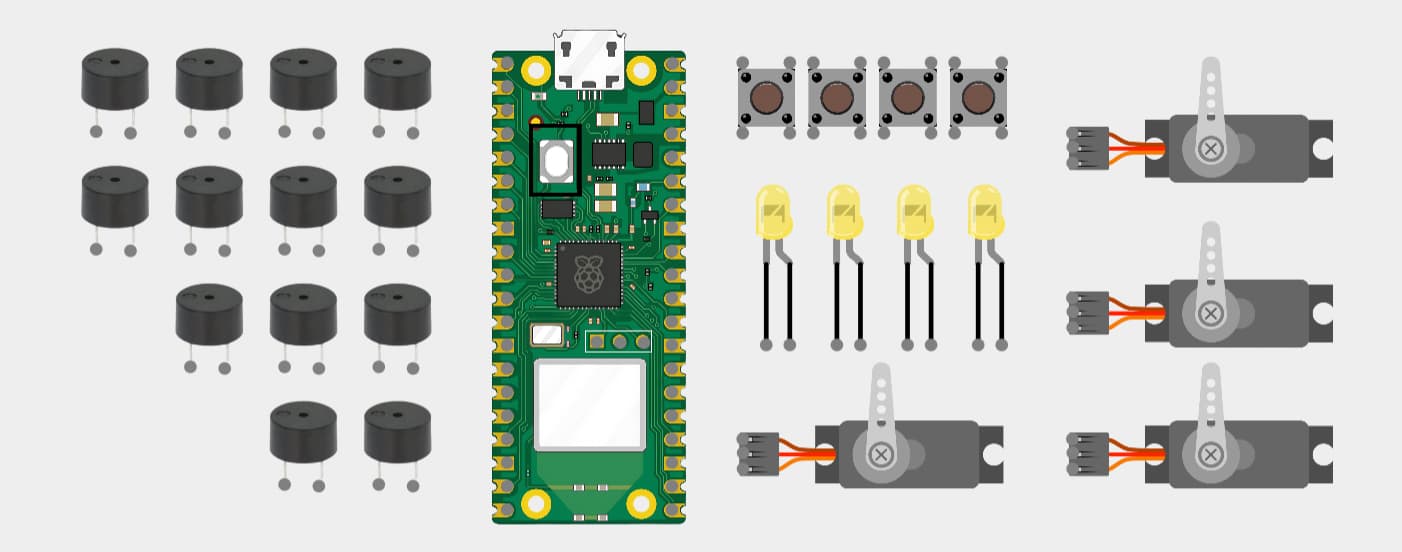

- 1x Raspberry Pi Pico W 2

- 4x Push Buttons (momentary)

- 4x LEDs (digital ON/OFF)

- 4x Servo motors (externally powered, 5V)

- 13x Passive buzzers (direct GPIO)

- Custom PCB with headers, no regulators or extra components

Each button controls 1 LED, 1 servo, and specific buzzers to play a sound or melody.

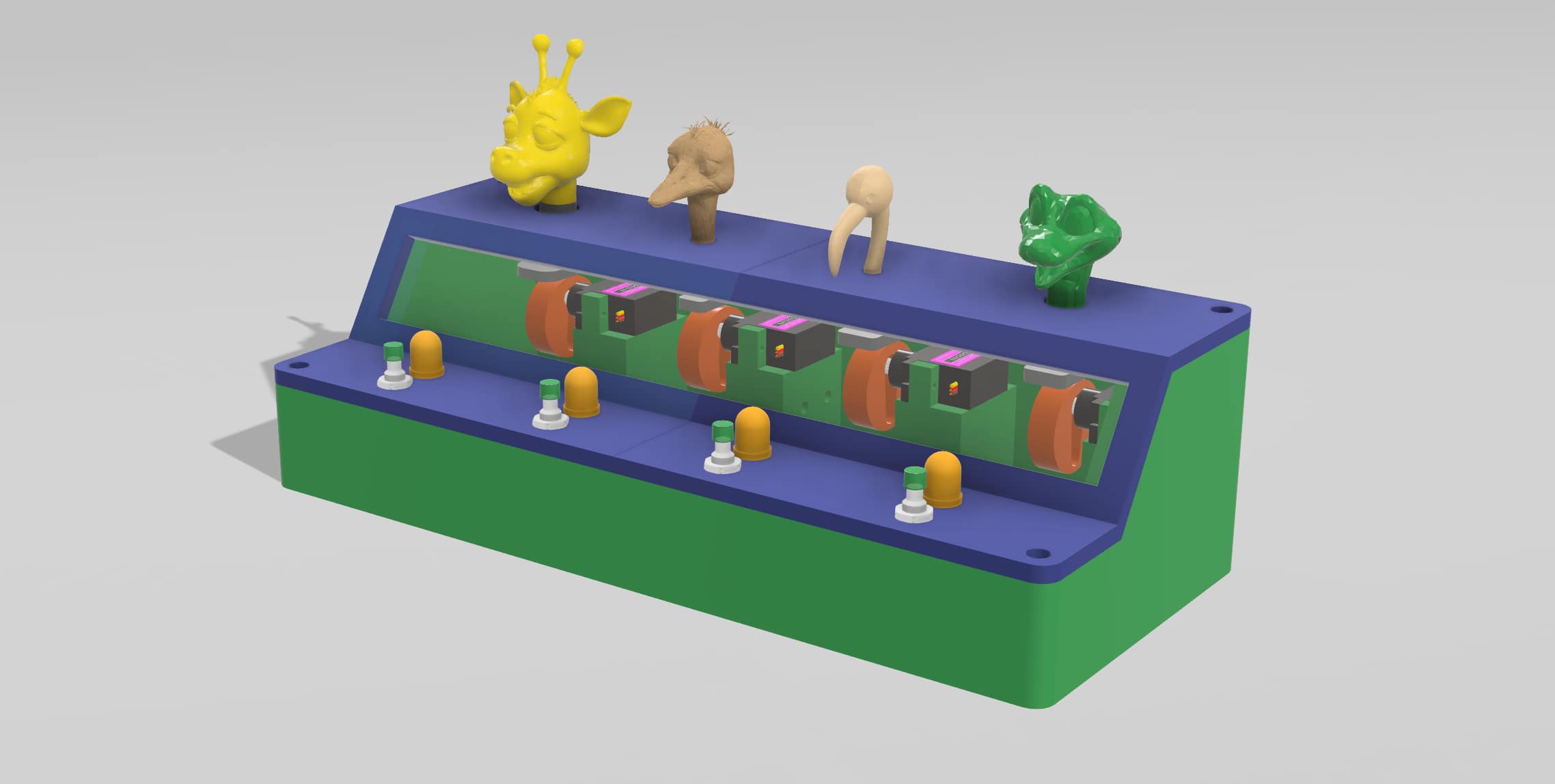

Rendered View

Below is a rendered image of the Bandbox system:

Integration Summary

- Direct GPIO connection for all components

- Servos powered externally via wall adapter

- Buzzers driven using MicroPython PWM

- Melodies coded manually with tone-duration pairs

User Interaction

- Buttons work on press-and-hold basis

- Multiple buttons can be pressed at once (polyphony)

- LEDs are ON/OFF only (no PWM)

- Servo motion loops while button is held

Physical Design & Fabrication

- PLA 3D printed body (4 parts combined into base and lid)

- 5mm clear acrylic panel (laser cut, glued to body)

- Assembly with M3 screws and brass inserts

- No sanding or painting applied

Packaging & Presentation

The system is designed to be visually self-contained and presentable. The transparent acrylic allows visibility into the electronics and mechanics without needing to open the device. One external cable supplies power; there are no loose wires or prototyping boards.

Documentation & Presentation Plan

- A short video will be created to show interaction and features

- Live demo during final presentation — user interaction enabled

Project Schedule

| Date Range | Focus & Tasks |

|---|---|

| May 10–17 | Initial CAD modeling, 3D printing tests, servo setup |

| May 18–24 | PCB design and production, wiring buttons, LEDs, servos |

| May 25–31 | Buzzer wiring, melody programming, multiple button logic |

| June 1–7 | Final assembly, acrylic mounting, full testing, photos/videos |

| June 8–10 | Buffer time, documentation finalization, video edit, prep |