Week 6: Electronics Design

Goal of the Week

This week’s assignment was to design a pcb(printed circuit board). and perform all necessary checks for fabrication. I decided use the Seeed Studio XIAO ESP32-C3 and design a custom board that includes:

- 2 mini LEDs

- 1 normal LED

- 1 button

- 1 buzzer

- 1 DC motor

- 1 servo motor

Group Assignment

Click to access the group assignment

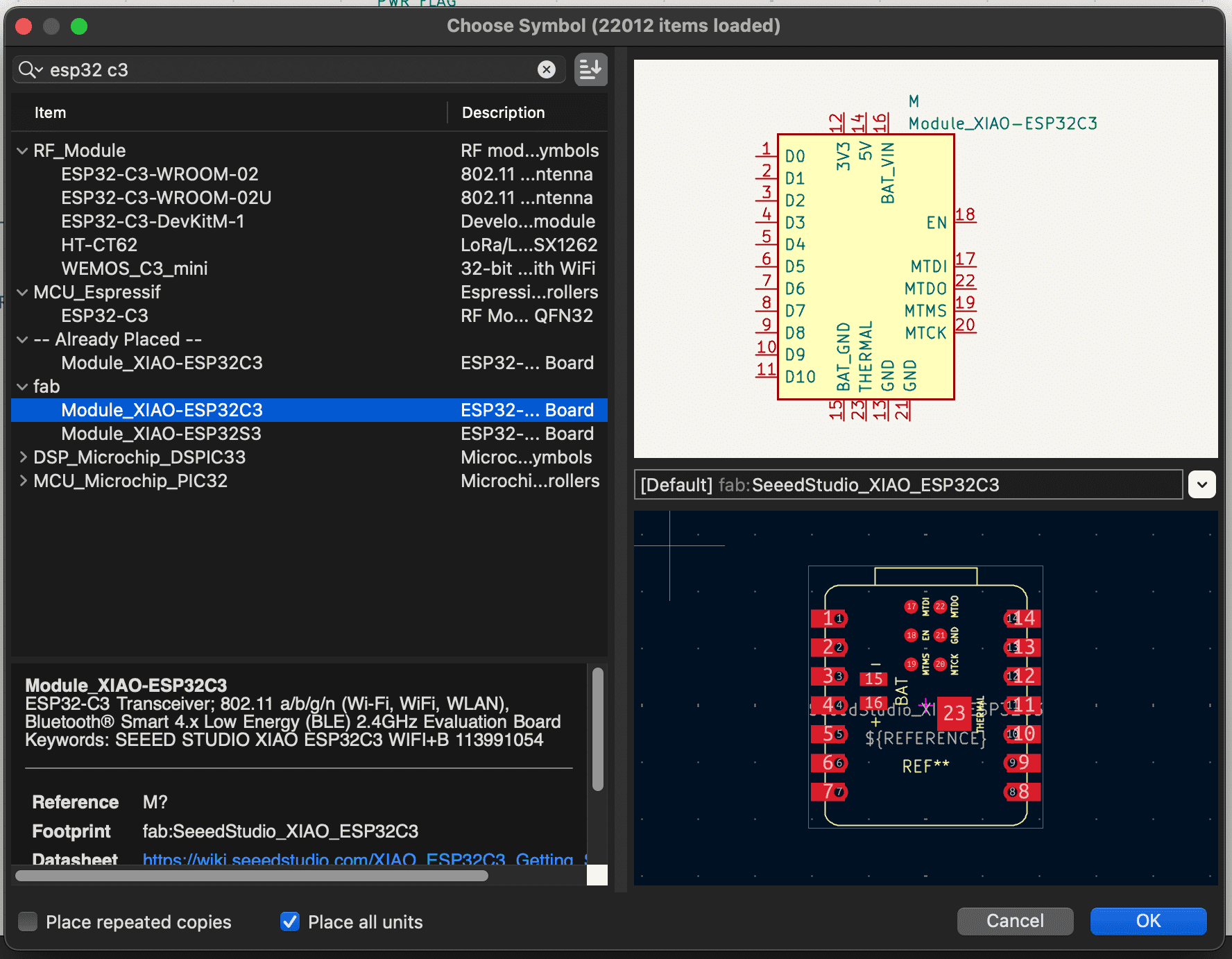

Step 1: Selecting the ESP32-C3 Symbol

I selected the correct microcontroller symbol from the KiCad libraries. I chose Module_XIAO-ESP32C3 from the fab library, which matches the Seeed Studio XIAO ESP32-C3 module.

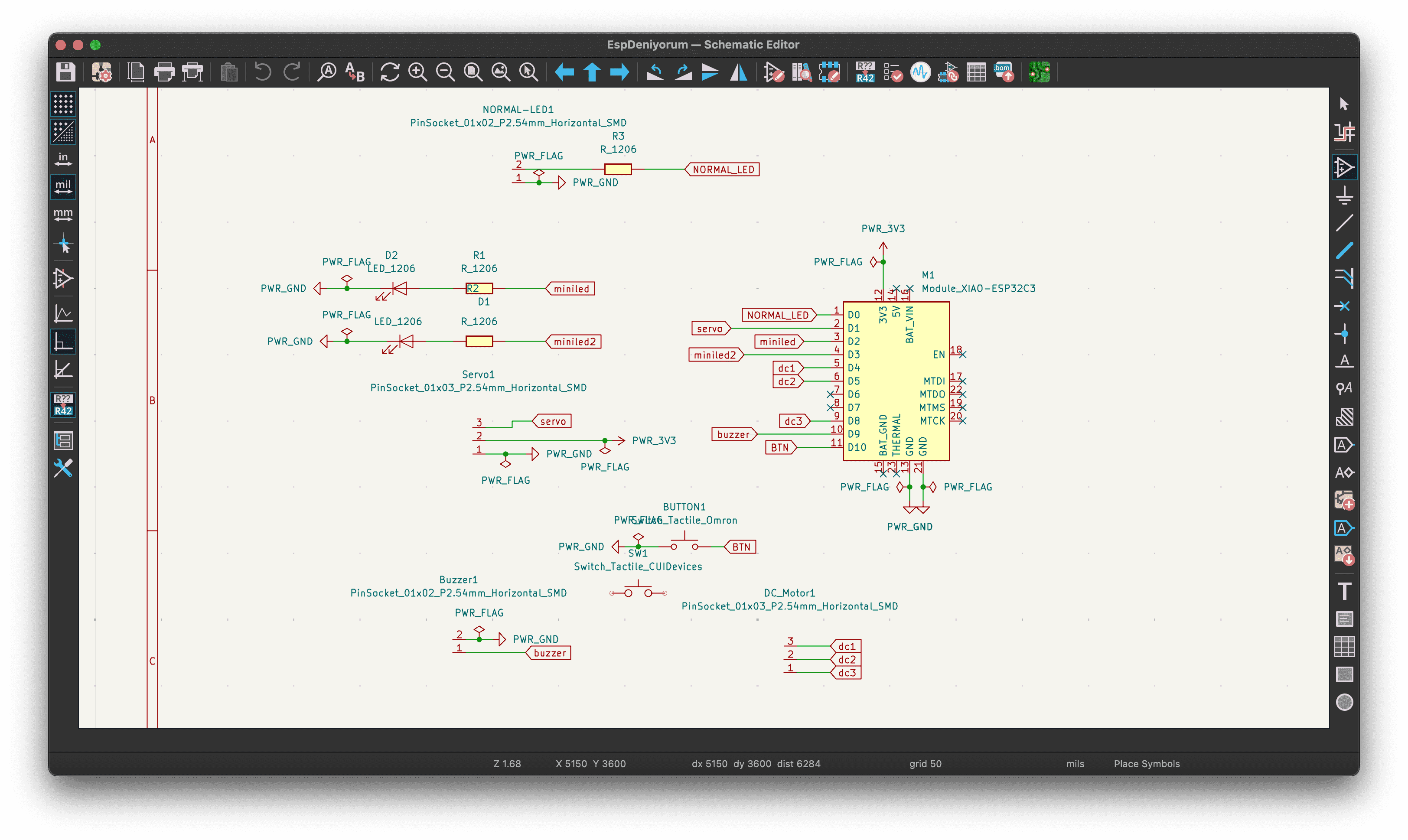

Step 2: Schematic Design

I designed the schematic using the KiCad Schematic Editor. I began by placing the ESP32-C3 module from the fab library and added the supporting components: two mini LEDs, one normal LED, one tactile button, a buzzer, a servo motor header, and a DC motor header.

Each component was connected to an appropriate GPIO pin of the ESP32-C3. I used PWR_FLAG symbols on both the 3.3V and GND lines to avoid power connection errors during ERC.

All non-polarized components were labeled, and I kept wiring clean by using Label (L) and Net (N) tools to avoid tangled wires.

Useful Shortcuts in Schematic Editor:

A– Add a new componentW– Draw a wire (connect pins)L– Add a labelR– Rotate selected itemCtrl + E– Edit component propertiesShift + Click– Highlight connected netAlt + G– Group select multiple elements

Step 3: Electrical Rules Check (ERC)

- ⚠️ Initial warnings about unconnected power pins were resolved by adding power flags.

- ✅ Final result: No remaining warnings or errors.

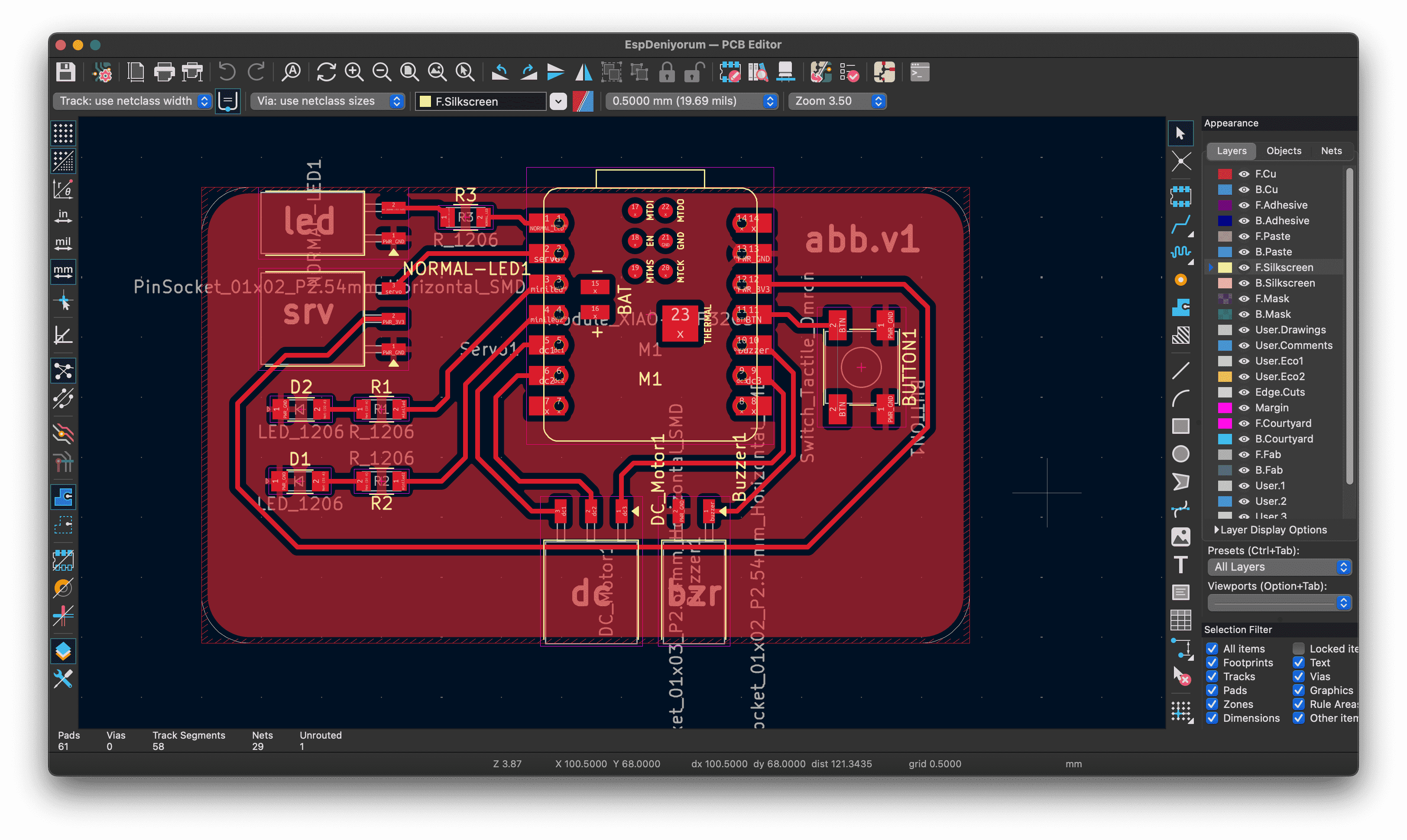

Step 4: PCB Layout

Once the schematic was complete and error-free, I assigned footprints and switched to the PCB Editor. I started by arranging the components logically — placing the ESP32-C3 in the center and distributing headers, LEDs, and resistors around the board edges for easy access and neat routing.

I used a 0.4 mm track width for signals and added a ground fill zone on the front copper layer (F.Cu) using the zone tool (Shift + Z). All signal traces were routed manually for better control using the interactive router.

I also added labels for clarity and testability. Components are spaced to avoid soldering issues, and I used the DRC tool frequently during layout to make sure all clearances and trace widths were correct.

Useful Shortcuts in PCB Editor:

Ctrl + Shift + R– Update PCB from schematicAlt + 3– 3D View of PCBX/Y– Start a horizontal/vertical trackM– Move selected componentR– Rotate componentShift + Z– Add filled zone (for ground planes)Ctrl + H– Highlight netDelete– Remove track or zone

Step 5: Design Rules Check (DRC)

- ✅ All tracks met clearance and width requirements.

- ✅ Ground zone filled properly.

- ✅ Result: 0 errors, 0 warnings.

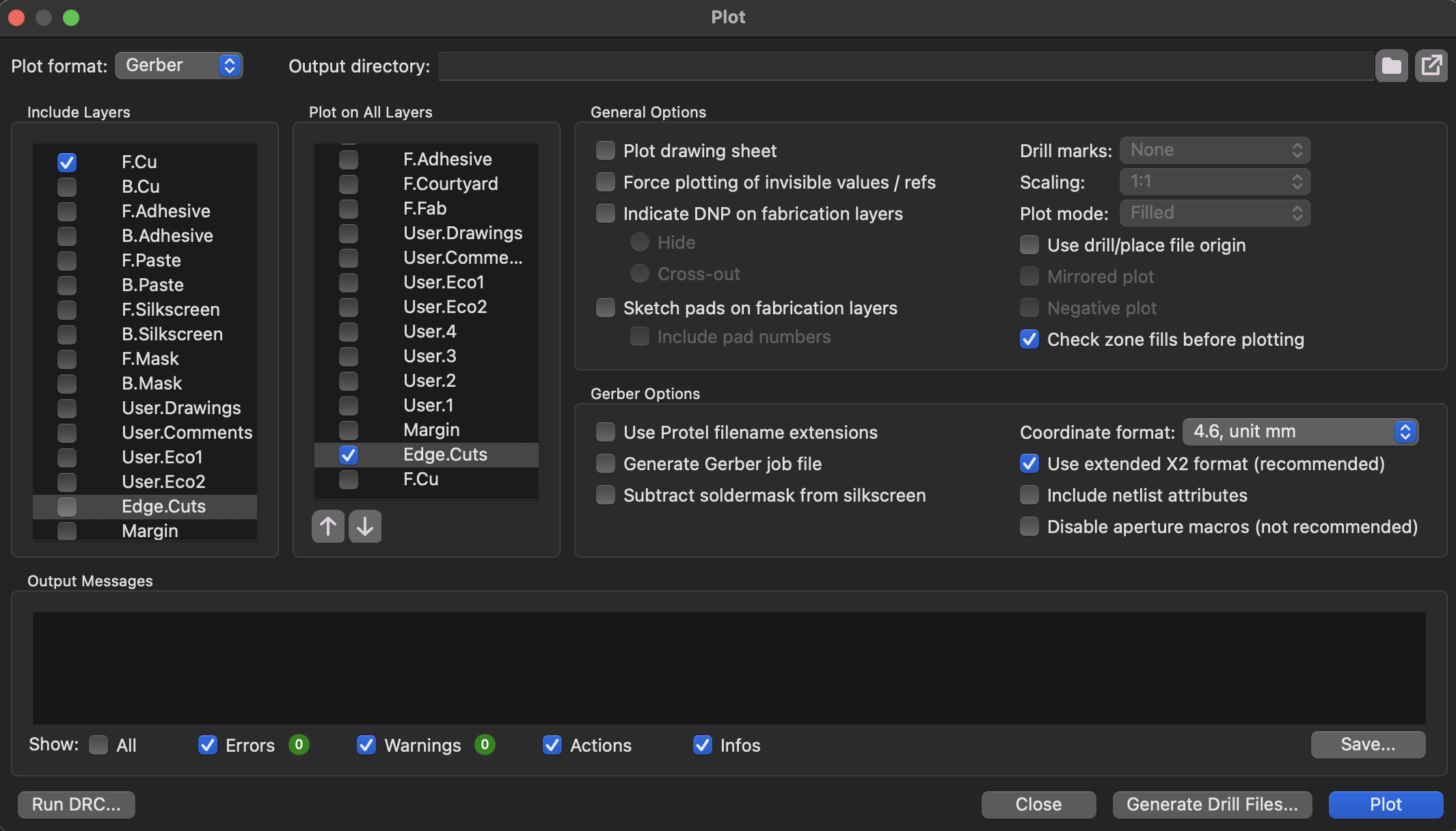

Step 6: Generating Gerber Files

Using the Plot window, I exported the Gerber files needed for PCB manufacturing. I enabled:

- F.Cu, Edge.Cuts

- "Check zone fills before plotting"

- X2 coordinate format

Final Pin Mapping Table

| Component | ESP32-C3 Pin | Board Label |

|---|---|---|

| LED1 (Mini) | GPIO4 | D2 |

| LED2 (Mini) | GPIO5 | D3 |

| Normal LED | GPIO2 | D0 |

| Button | GPIO10 | D10 |

| Servo Motor (PWM) | GPIO3 | D1 |

| Buzzer (PWM) | GPIO9 | D9 |

| DC Motor Speed (PWM) | GPIO6 | D4 |

| DC Motor Direction 1 | GPIO7 | D5 |

| DC Motor Direction 2 | GPIO8 | D8 |

Download Design Files

Here is the Edge_Cuts

Here is the F_Cu

What I Learned

This week taught me:

- How to use custom microcontroller modules in KiCad

- How to assign pins with a balance of hardware constraints and software usability

- How to route multi-component boards cleanly

- How to validate a design through ERC, DRC, and generate professional-grade Gerber files