W3 | Computer-Controlled Cutting

INDIVIDUAL ASSIGNMENT

- Design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways.

- Cut something on the vinyl cutter.

- Vinyl Cutting

Roland GX-24 CAMM-1Servo

During Week 3, I worked with the Roland GX-24 CAMM-1 Servo, a desktop vinyl cutter that allows precise

cutting of shapes and designs from adhesive materials. Using it, I was able to cut adhesive vinyl paper

and create custom stickers. I also discovered that this machine can be used for another interesting

application — preparing vinyl masks for a sandblasting process, which makes it possible to engrave designs

onto glass surfaces.

During Week 3, I worked with the Roland GX-24 CAMM-1 Servo, a desktop vinyl cutter that allows precise

cutting of shapes and designs from adhesive materials. Using it, I was able to cut adhesive vinyl paper

and create custom stickers. I also discovered that this machine can be used for another interesting

application — preparing vinyl masks for a sandblasting process, which makes it possible to engrave designs

onto glass surfaces.

DESIGN

Before starting the vinyl cutting, I first needed to prepare the design. I wanted to try something different this week

— a small sandblasting experiment on a glass coaster. So, I measured the coaster carefully to know exactly where the vinyl

sticker would go. While designing, I had to keep in mind that the parts not covered by the vinyl would be the ones exposed

and engraved by the sandblasting process.

Before starting the vinyl cutting, I first needed to prepare the design. I wanted to try something different this week

— a small sandblasting experiment on a glass coaster. So, I measured the coaster carefully to know exactly where the vinyl

sticker would go. While designing, I had to keep in mind that the parts not covered by the vinyl would be the ones exposed

and engraved by the sandblasting process.

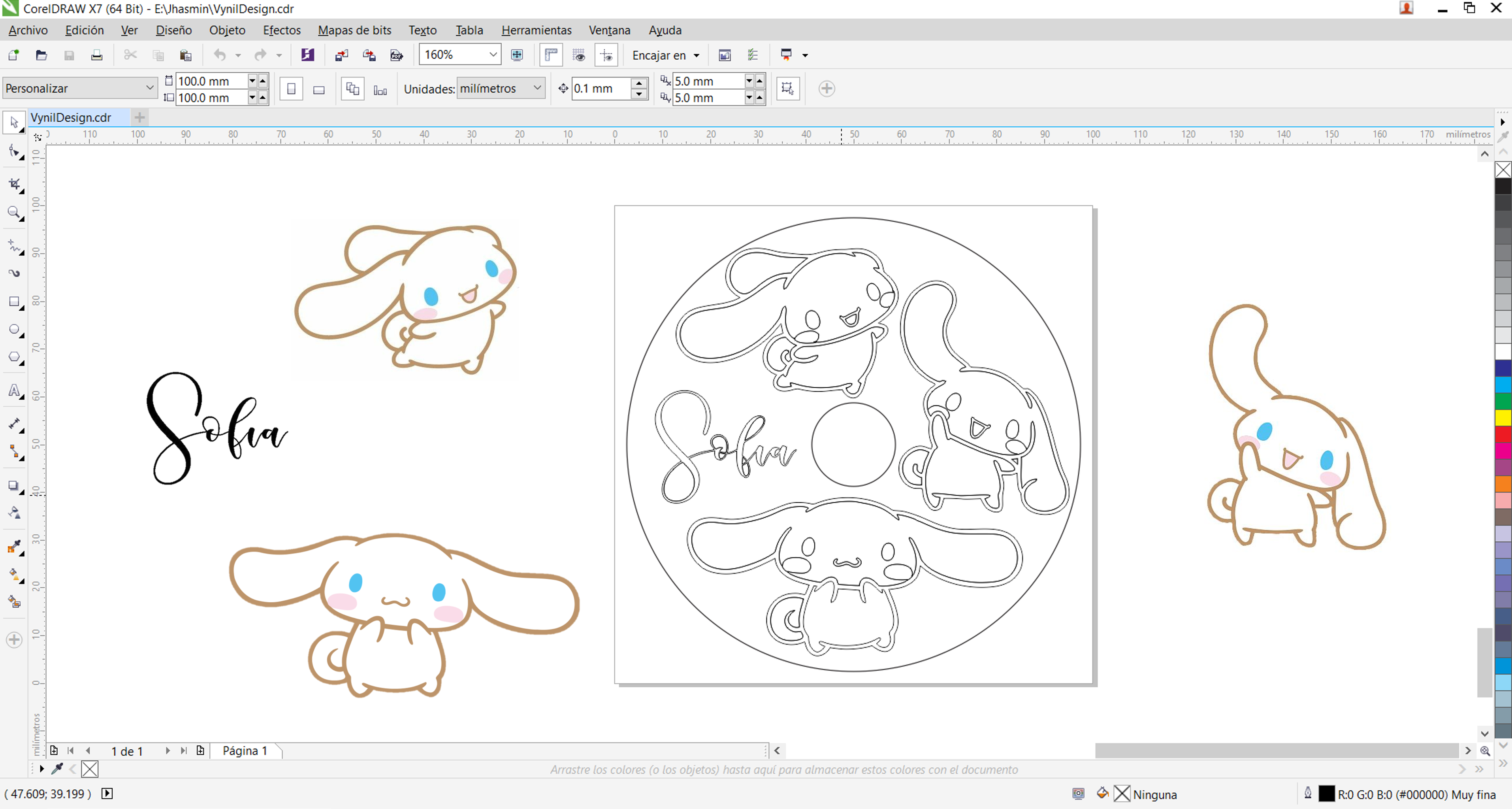

With those considerations in mind, I began designing. For this project, I chose one of my sister's favorite characters

— Cinnamoroll, one of Hello Kitty's friends — and decided to personalize the coaster for her. I arranged several Cinnamoroll

figures around the border of the coaster and added her name.

For the design process, I used CorelDRAW, a 2D software that made it quick and easy to vectorize an image from the internet,

clean up what I didn't need, and keep the shapes ready for cutting. I really enjoyed seeing how the design came together —

this was the final result. Then, I exported the design in SVG format.

CorelDRAWX7 - Final Design

SETTING UP THE VINYL CUTTER SOFTWARE

-

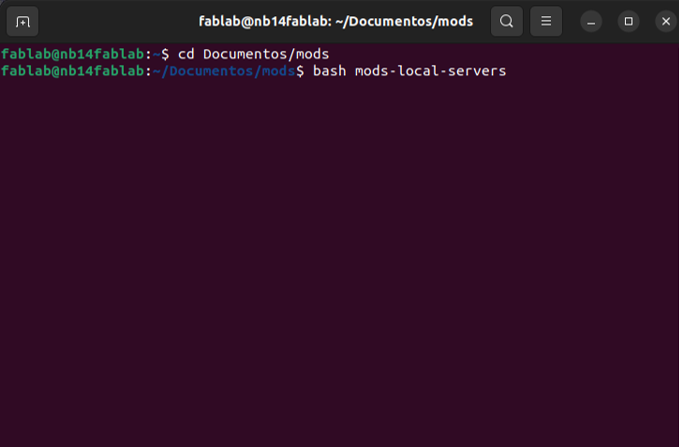

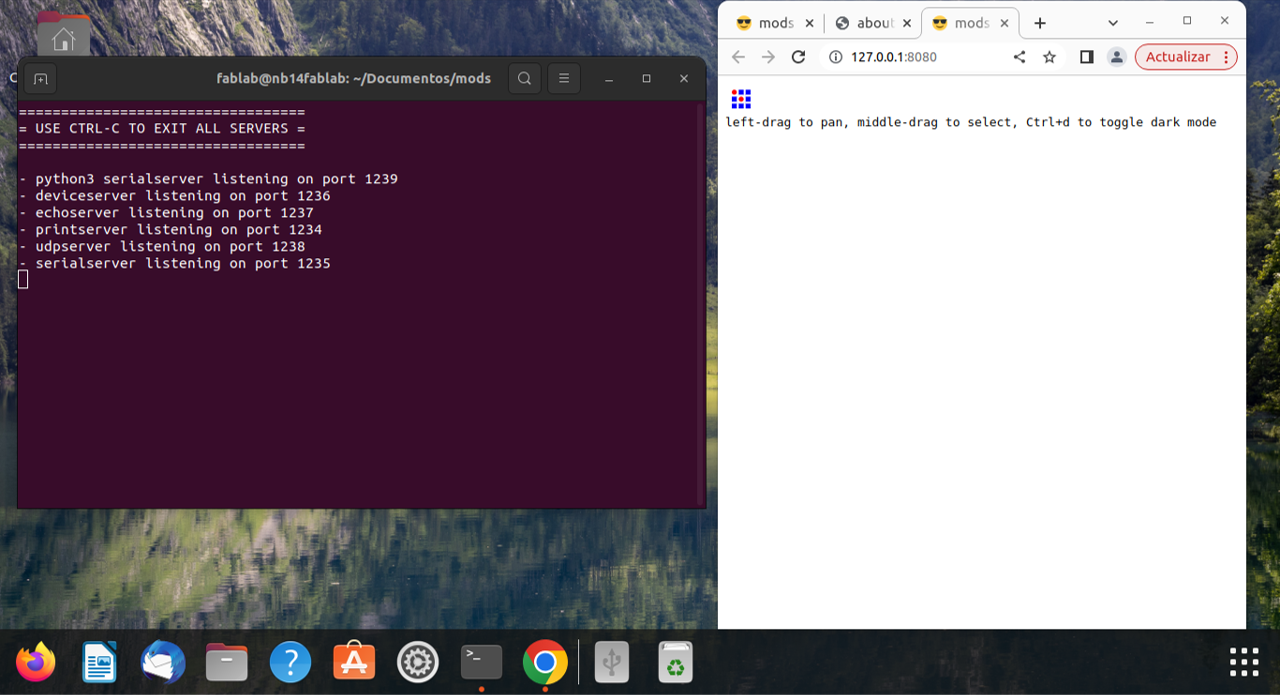

To set up the vinyl cutter, I first connected the Roland GX-24 to the laptop using the serial cable. The laptop has the driver and controller software that allows communication with the machine. Once everything was connected, I opened the terminal to launch ModsProject, the program that generates the toolpaths — the cutting paths the machine will follow. Then, in the terminal, I typed the following commands:

$ cd Documentos/mods $ bash mods-local-server

After pressing Enter, the ModsProject interface opened automatically in my browser, ready to configure the cutting settings and load the SVG file.

- Here are the examples:

-

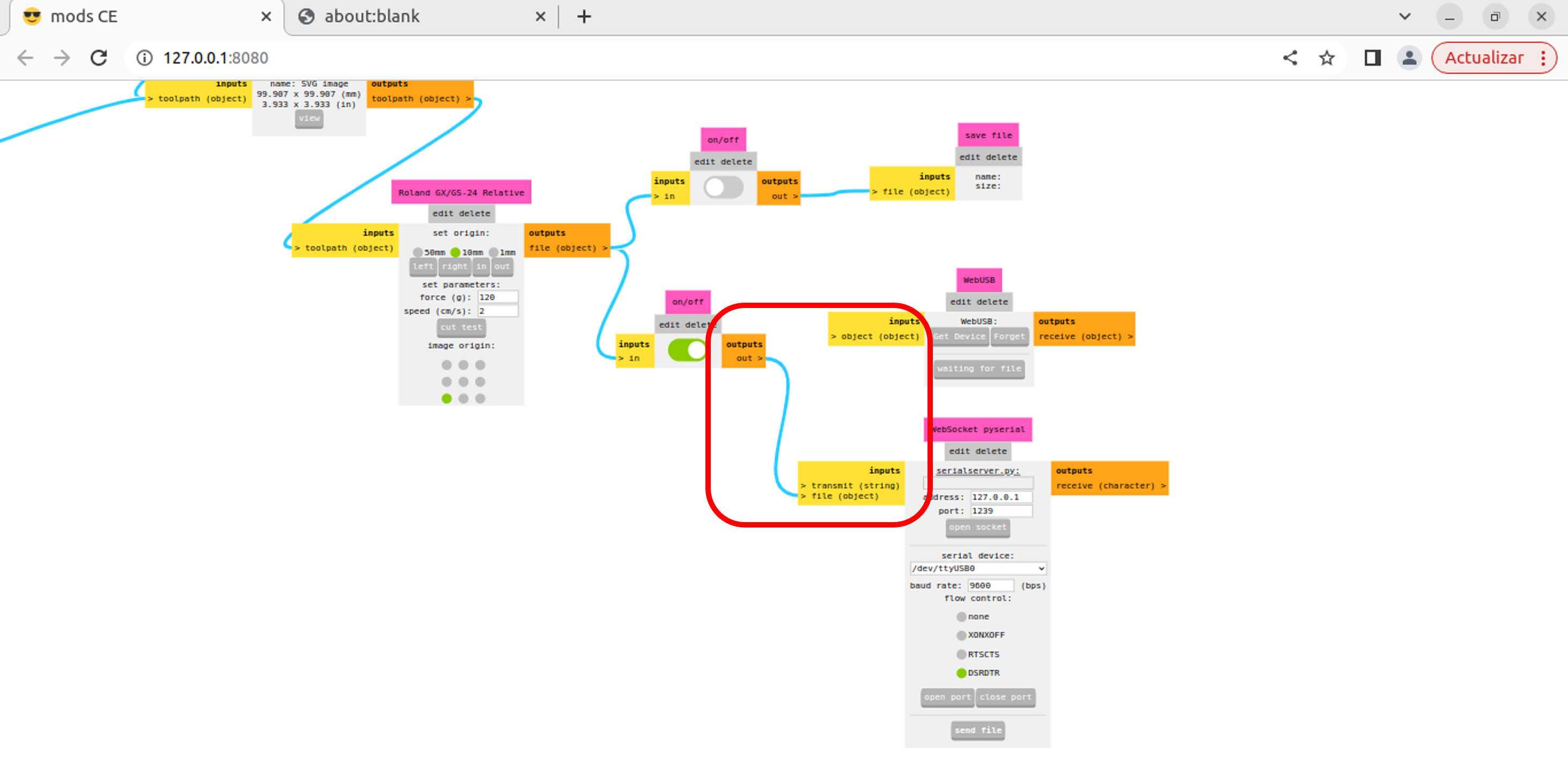

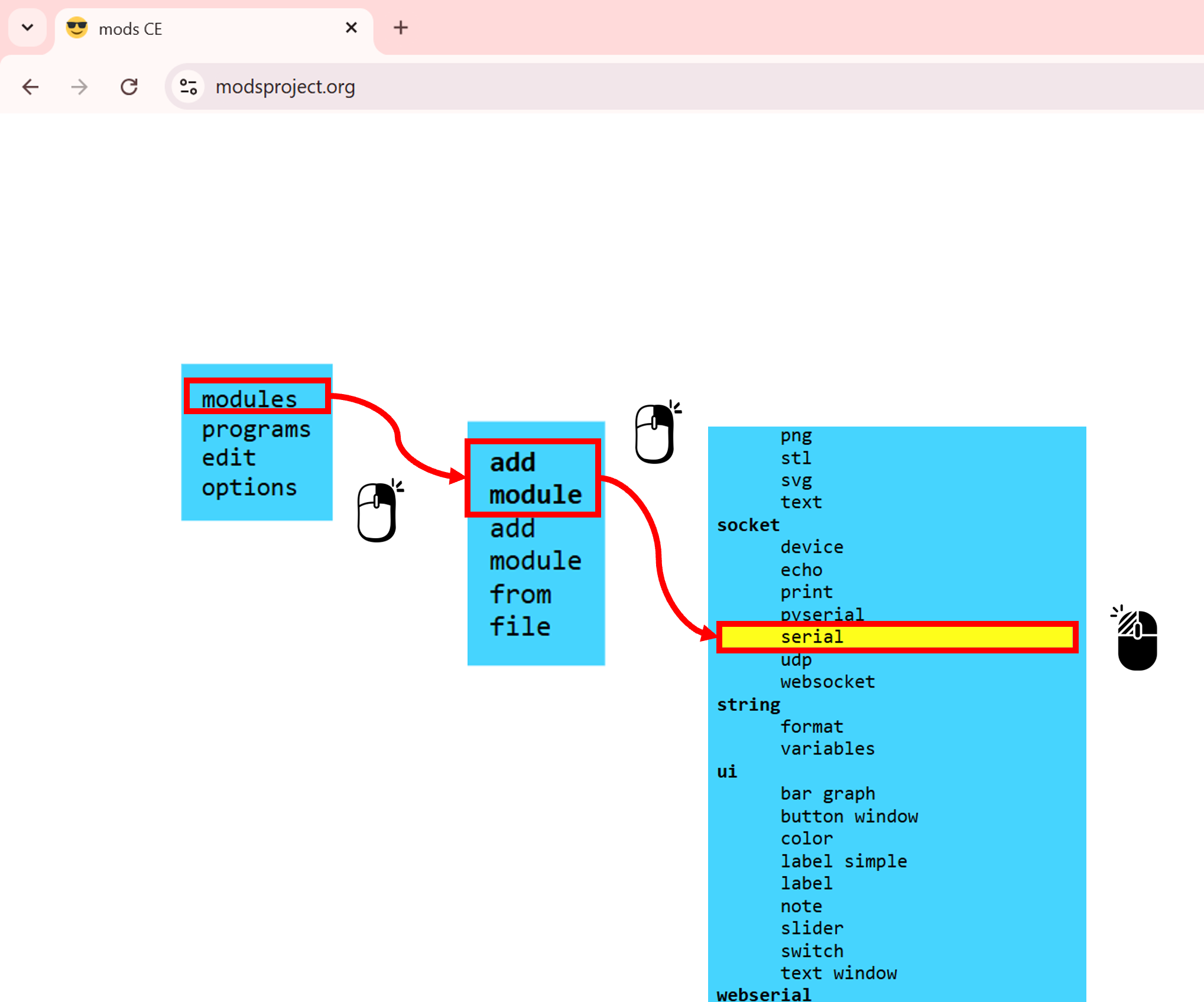

In ModsProject, the first step is to select the correct machine. In this case, I searched for the vinyl cutter module, as shown in the image below. This module allows the program to recognize the Roland GX-24 and generate the proper toolpaths for cutting. The workflow is shown in the next image (2)

-

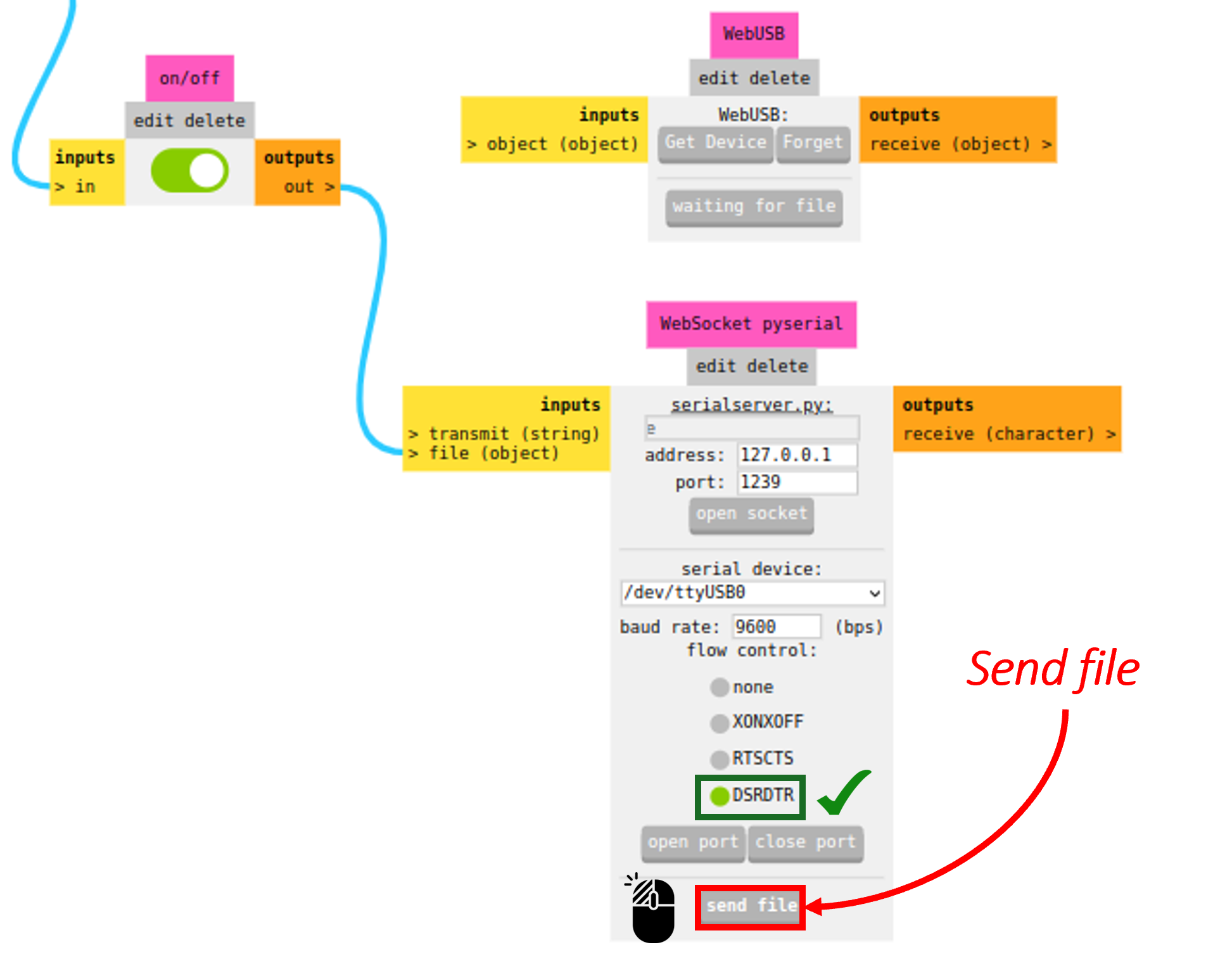

Once the machine is selected, the next step is to add the module that connects the vinyl cutter through the serial port. This connection allows the machine to communicate with the computer so that, once the file is loaded, the cutting job can be sent directly to the Roland. The complete workflow can be seen in image (3).

-

This module must be linked to the existing workflow generated when the machine is selected.

- Here is the example:

-

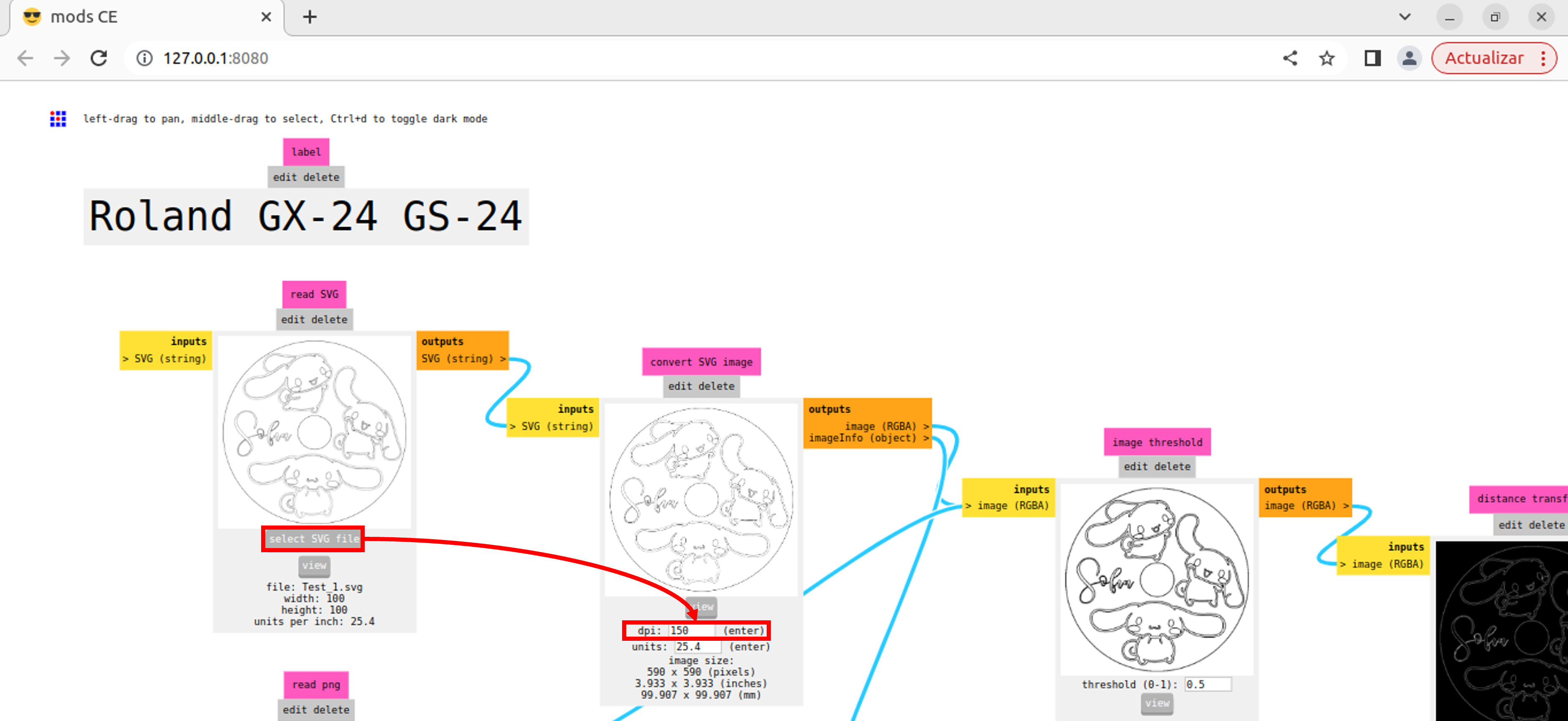

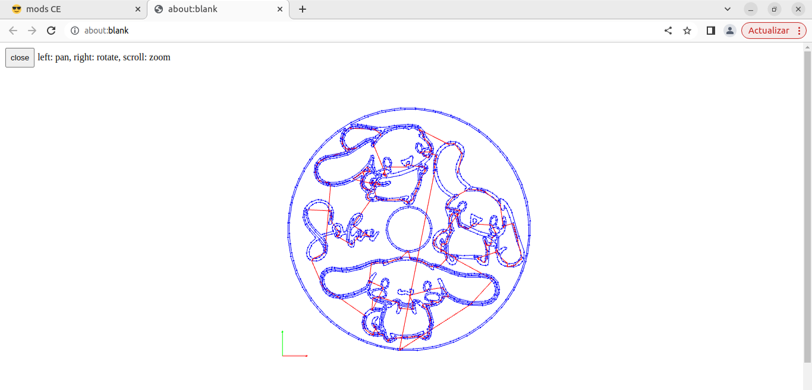

Then, I loaded the SVG file into the workflow and checked both the size and the DPI settings. The size is automatically detected once the image is uploaded, but the DPI must be adjusted manually until all the cutting paths appear correctly in the preview. This step is important to make sure every line of the design is recognized and ready to be cut.

📝Note: For this example, I used 150 DPI. When I tried other DPI values, the preview didn't show the complete toolpaths. I believe this is related to the size of the design, meaning that the DPI setting must be adjusted according to the dimensions of the file. It's something I'll need to explore further in future tests. 👀 - Here are the examples:

-

Once I confirmed that all the toolpaths were correct and the machine was properly connected to the new module, I sent the

file to the vynil cutter.

- Here is the example:

Select the machine (2)

Add the module (3)

SETTING UP THE VINYL CUTTER MACHINE

-

First, I placed the material. I was going to work with — blue vinyl.. The material is loaded from the back of the cutter, where there is a tray that supports it. It must be inserted from the back toward the front (a), leaving it at a specific height as shown in the image. Then, the material is secured using the lever located on the left side of the machine (b).

📝Note:

- The machine has white alignment marks, and the vinyl must be positioned between those marks to avoid any issues during the cutting process.(c)

- Once the material was properly fixed, I turned on the machine. When you press the power button again after turning it on, the cutter automatically measures the length of the material to detect its available area. This step ensures the machine knows the limits of the vinyl before starting the cut.

- Here are the examples:

a. Inserting the vinyl into the machine

b. Adjusting and securing the material

c. Verifying the vinyl position

-

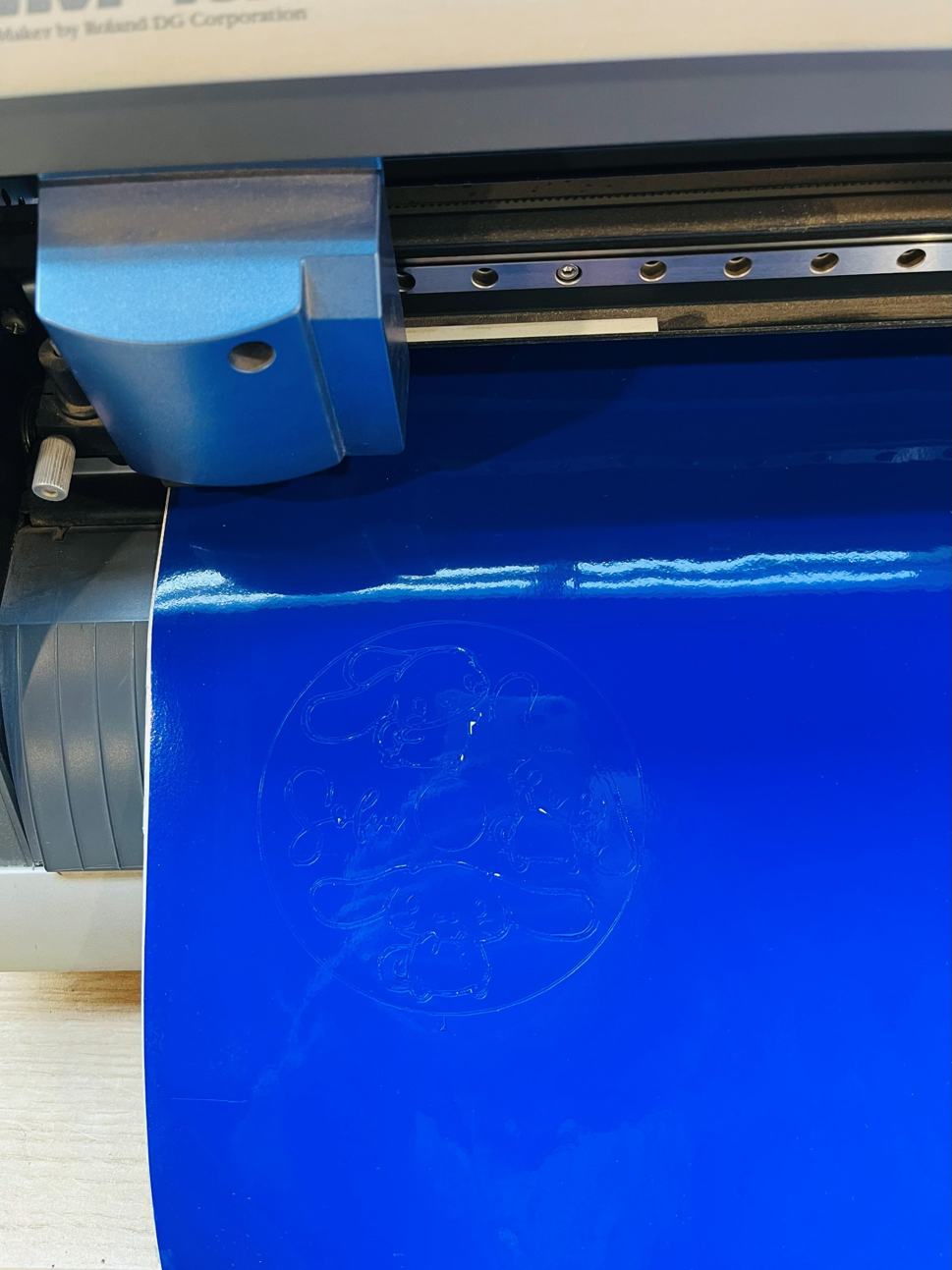

After that, I followed the steps mentioned in the previous section, Setting Up the Vinyl Cutter Software.. Once the file was sent, the machine began cutting. In the following videos, you can see how the Roland GX-24 performs the cutting process.

- Watch the video:

📝Note:

- You can notice that in some areas, the vinyl started to slightly lift off the surface during cutting. I think this could be related to the design itself — perhaps due to broken vector lines or the DPI and size settings used earlier. 🤔

- Watch the video:

-

After finishing the cut, I needed to remove the material from the machine. For this, I used a cutter knife to trim it off. The vinyl cutter has a small built-in cutting section that makes this step easier, as shown in the image. And with that, the cutting process was complete — the design was ready for the next steps!

- Here are the examples:

Removing the cut-out area

APPLYING THE VINYL TRANSFER

-

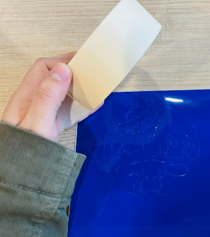

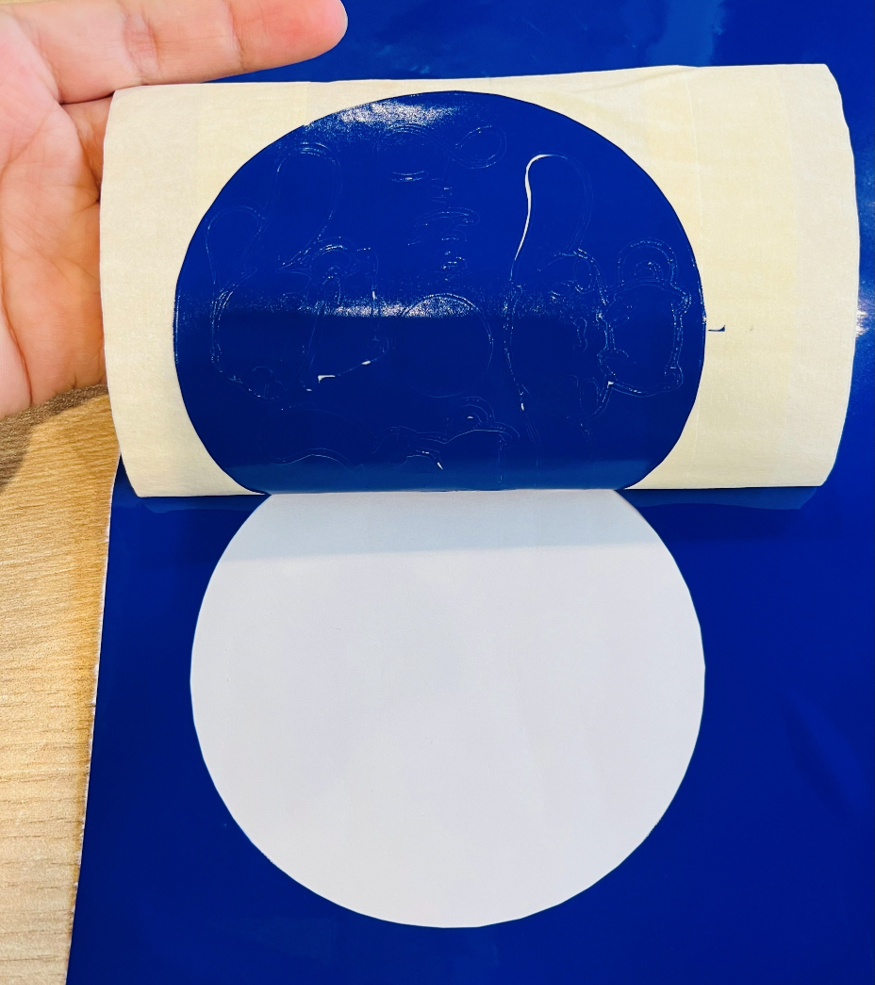

Once I had the piece of vinyl that was already cut, I placed a transfer sheet (also called transfer sticker) on top of it. This layer helps lift the entire design from the vinyl backing and makes it easier to position it on the desired surface.

- Here are the examples:

Process of applying the transfer paper

- After applying the transfer sheet, I carefully placed the vinyl onto the glass surface, pressing it firmly to make sure it adhered well. Then, I started removing the areas that would be sandblasted, leaving only the parts covered with vinyl to protect them during the process.

- Here are the examples:

- If the design is intended to be used only as a sticker and not for sandblasting, the same transfer process applies — you can place it on any smooth surface and simply remove the vinyl parts you don't need.

- For this step, I used a pair of tweezers to help peel off the small pieces of vinyl. It took a bit more time because of the complexity of the design, but the result came out just as planned.

- Here is the result:

Process of removing the transfer paper

📝Note:

Removing the parts that will be sandblasted

Vinyl mask ready for sandblasting

SANDBLASTING PROCESS

This part was one of the most exciting steps! I worked on it together with Jorge, my local instructor, who helped me connect and operate the machine. The air pressure is quite strong, and the cabinet is a bit high for me, so teamwork definitely helped. 😄

Before starting, we made sure to connect everything carefully because the machines use different voltages, which means a transformer is needed. Once everything was ready and we had our safety equipment on, We used the sandblasting gun — a handheld tool that blows fine sand at high pressure to engrave the exposed areas of the glass.

As we moved the gun slowly and evenly across the surface, the design began to appear.

- Watch the video:

Using the sandblasting gun to engrave the glass surface

Once the sandblasting was finished, we put everything back in its place and turned off the machines. It was time to clean the exposed surface and remove the remaining vinyl sticker. After wiping away the dust and checking the engraved areas, the design was finally complete — and this was the result

Final result: personalized Cinnamoroll glass coaster

Final Thought 💭

During the vinyl cutting process, I noticed that some areas started to lift or peel off. In my next tests,

I'll try adjusting the parameters, but I suspect the issue might come from the vectorization step 🤔 —

some of the design lines weren't clean and looked slightly cut or broken. There were also small parts that didn't cut properly,

which might be due to the tiny details of the design or even the DPI configuration. In the sandblasting process, a few sections

of the vinyl mask also lifted due to the air pressure, so next time I'll make sure

to press and secure the mask more firmly before starting.

These small issues are all part of learning, and they'll definitely help

me improve the next trials! The result wasn't perfect, but I'm really happy with this first test and the overall result.😄