XY (almost) Z Plotter

What Machine to Choose?

This week's challenge was a big one—our group assignment asked us to go full maker mode and:

- Design a machine that includes mechanism + actuation + automation + application

- Build the mechanical parts and operate it manually

- Document the group project and our individual contributions

So, when we got the assignment, we were like: “Cool! Let's build a machine!”… and then reality hit: “Wait—what kind of machine?” Ideas flew everywhere, but the reality hit: we were on a deadline, with limited resources… and, oh yeah—it was our first time ever building something like this!

In the end, we decided to build a basic XY plotter. Why? Because it's an awesome way to understand how two-axis systems work, and it is an entry point into digital fabrication—combining mechanism, actuation, and automation in a way that's visual, hands-on, and super satisfying when it actually works. Plus, it's a solid foundation for more advanced machines in the future—like CNC routers, laser cutters, or even 3D printers.

We did a deep dive into other similar projects for inspiration, and got inspired by all the cool variations. We grabbed the best ideas, mixed them with our own, and little by little, our concept started to take shape.

Team Responsibilities 🤝

We both worked side by side throughout the project, from research and planning to building, testing, and documenting.

- Jhasmin Ayala:I did mechanical design of the machine. I modeled the structure and parts, making sure everything would fit and work together. I also participated in the fabrication, assembly, programming, documentation, and testing.

- Marita Chang:Focused on assembly, electronics, programming, documentation, and testing. Even though this was her first time building a machine like this, she was super hands-on and did an amazing job figuring things out along the way.

Is it perfect? Nope.

Is it functional? Yes!

Did we learn a lot? Absolutely. 🚀

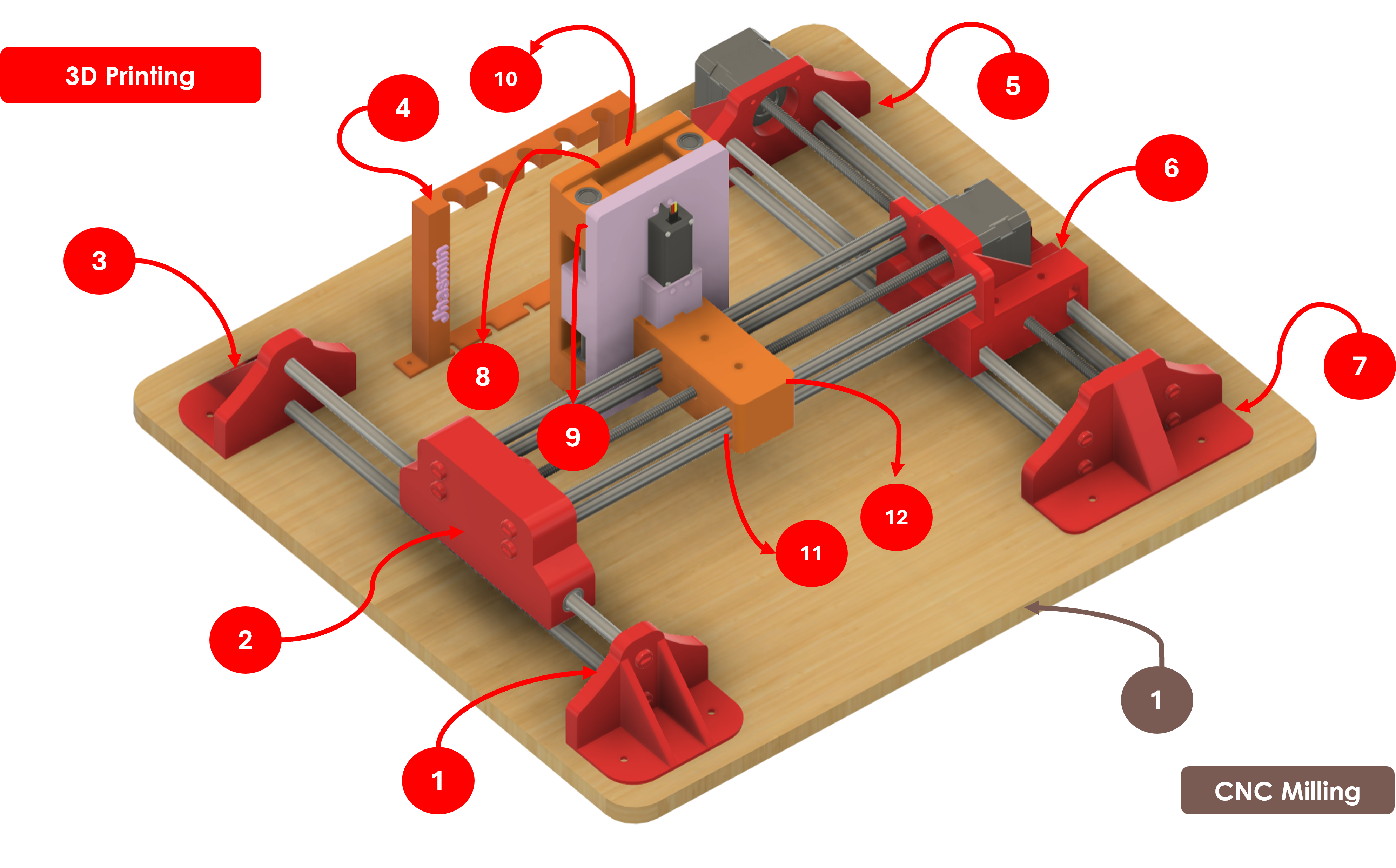

Design 3D 🧑💻

We originally planned to build a basic XY plotter, but then we found a video of a machine that could switch between colors while drawing—and

we were instantly hooked. To do that, we needed to add a Z-axis. which would control the up and down movement of the pen (or market).

Our simple plotter turned into a much more ambitious (and slightly more chaotic) project.

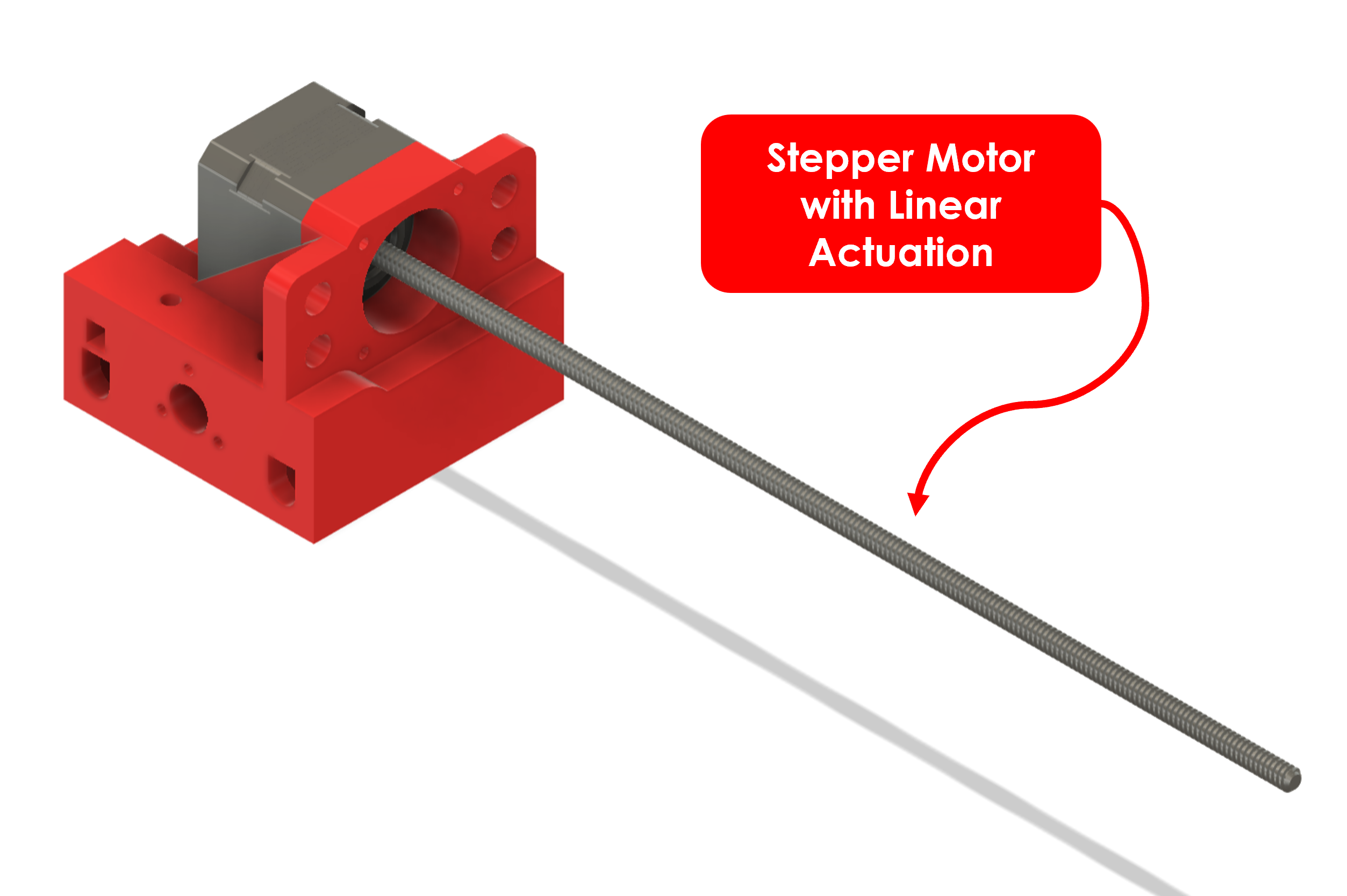

Before starting the design, we had to consider all the technical components that would define the machine's structure. Since we were working with stepper

motors for the X and Y axes, a servo motor for the Z-axis, and an extra servo to grab and release the marker, the design had to fit around those parts.

We also used an Arduino Uno with a CNC shield, and our software would run on GRBL. With all that in mind, the goal was to create a design that brought these elements together

smoothly—and actually worked in real life.

We used Fusion 360 to design the whole machine. To keep everything accurate, We imported models of the stepper motors from McMaster-Carr, and added STEP files

for the servos. That helped us design the custom parts around real dimensions.

Assembling the machine virtually allowed us to catch issues early and make quick adjustments. After a many tweaks, we had a solid design ready for fabrication!

Fabrication 🛠️

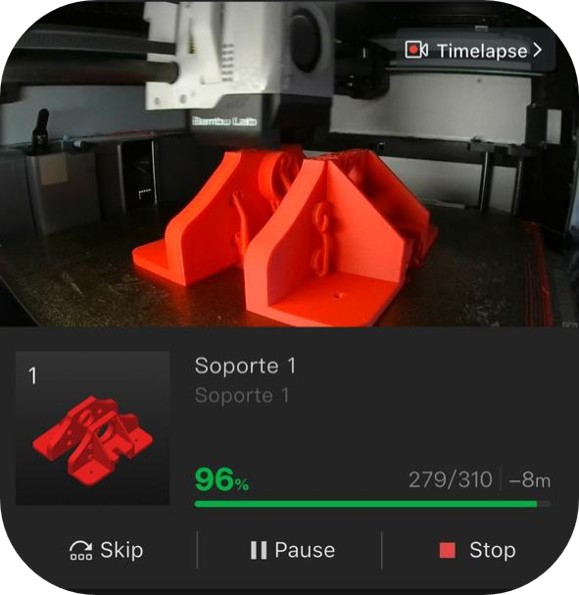

For the fabrication process, we used two main digital manufacturing technologies:

- 3D Printing: We printed a total of 12 custom parts for the plotter, including supports, mounts, and the pen mechanism. Each piece was designed to fit precisely with the components we selected.

- CNC Milling: We used the CNC to cut a solid MDF base, which serves as the platform where the entire plotter is mounted. This gave us a strong and stable foundation to work on.

3D printed parts and CNC milled base used in the plotter

Assembling 🔧

Before putting anything together, we made sure we had all the components ready to go. That included:

- The 12 3D printed parts and the CNC milled base.

- All mechanical components like bearings, metal rods, screws, and nuts.

- The electronic parts, including stepper motors, servo motors, the Arduino, and the CNC shield

| Item | Qty | Use |

|---|---|---|

| Linear bearings | 8 | Facilitate the movement of the component with the pen on the Y-axis |

| Circular bearings | 4 | Fix the steel rods to the 3D printed bases |

| Steel rods 8 mm (31.5 cm) | 8 | Provide stability to the base of the structure |

| Rods 8 mm (14.2 cm) | 2 | Used to place springs and assemble the part that supports and moves the pen |

| Arduino Uno | 1 | Microcontroller that connects the program with motors and servos to give functionality to the machine |

| DC motor shield | 1 | Regulates motor functionality |

| Servomotors | 1 | Controls movement on the Z-axis |

| Nema17 linear screw stepper motors | 3 | Controls movement on the X and Y axes |

| MDF cut (50x45 cm) | 1 | Base that supports the structure |

| Wires | - | Connect motors, power supply, and Arduino |

| Screws and nuts | - | Fix the parts of the machine |

| 12V Power supply | 1 | Provides power to the machine |

- Components ready to be assembling:

Components (mechanical, electronic, and some 3D printed parts)

- It's finally time to put everything together!:

- Alignment is Key: The rods, bearings, and 3D printed components needed to be perfectly aligned to ensure smooth operation when the motors started moving.

- Secure Everything: All parts had to be tightly fastened with screws and nuts—no loose or wobbly components allowed!

- Stability: The entire structure had to be securely attached to the CNC-milled base to ensure maximum stability.

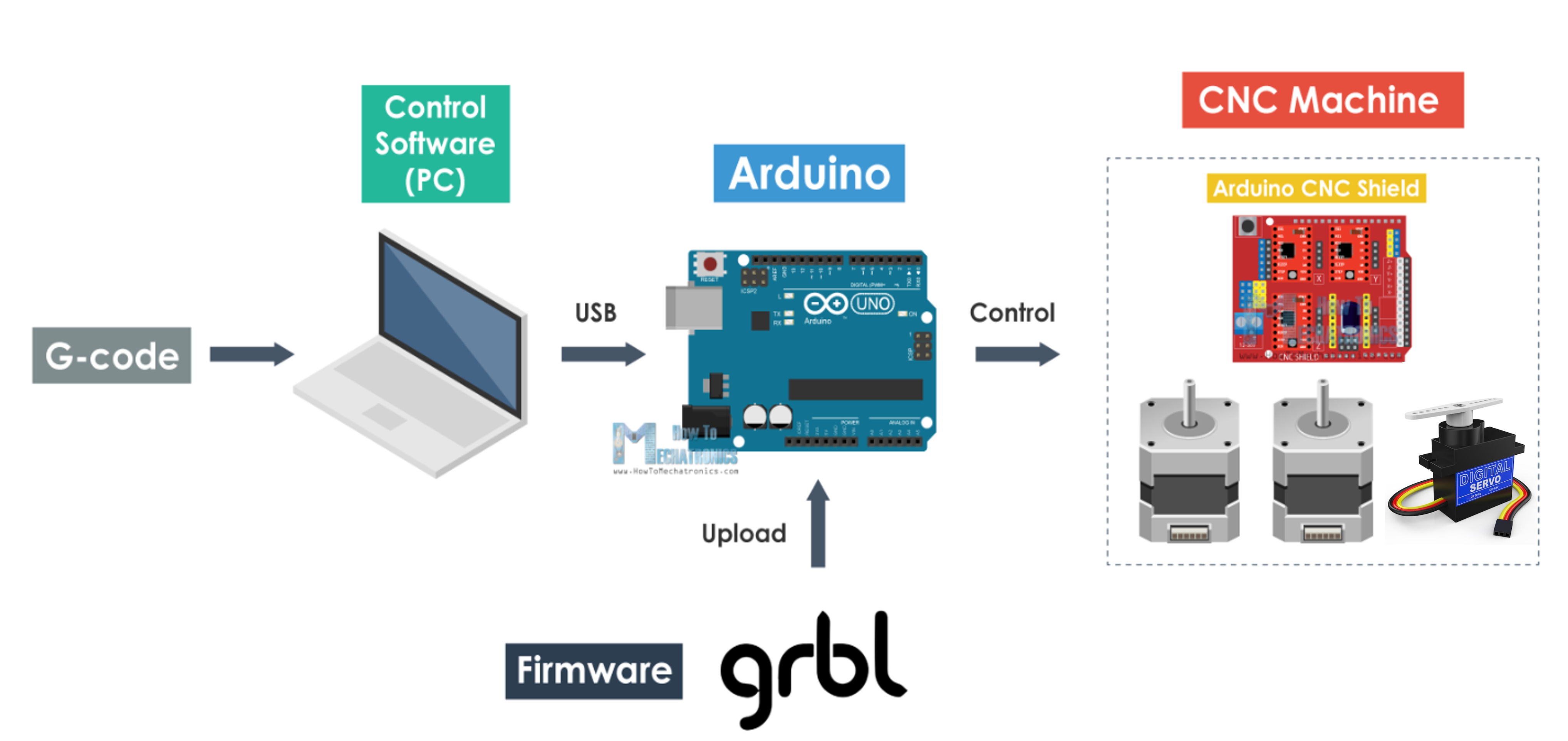

Programming and Software 💻

To bring our XY (almost Z) plotter to life and turn it into a real CNC machine, we needed two key things:

- Firmware installed on the Arduino to control the machine's motion.

- Control software to send G-code instructions and manage the plotting process.

For the control software, we used GRBLPlotter—specifically the servo version, since our design includes two servo motors. One servo is used to lift and lower the pen, effectively enabling movement along the Z-axis, while the second servo allows the plotter to grab and release the pen.

This setup is slightly different from the example we were following, which originally used a DC motor for the Z-axis. We decided to modify it by using a servo motor instead, giving us more precise and simpler control for the pen's vertical movement.

With everything connected and configured, GRBLPlotter allows us to send G-code to the Arduino, which in turn tells the stepper motors and servos exactly how to move—turning code into motion.

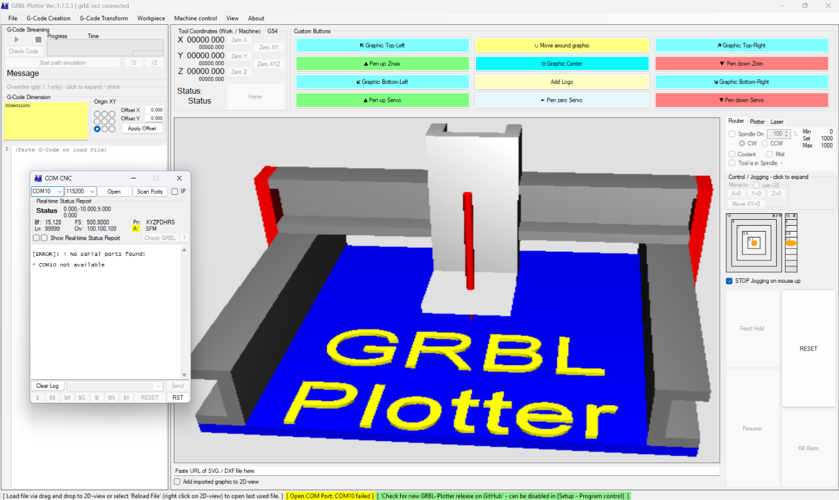

Control Software & GRBL Parameters ⚙️

For controlling our plotter, we used GRBL-Plotter, an open-source software specifically designed for plotters. It includes a built-in graphics converter that allows us to generate G-code from images or vector graphics, making it easier to send drawing instructions to our machine. You can find and download the software directly from GitHub.

Once the software was set up, the first critical step was to configure the GRBL parameters, especially the travel resolution (steps/mm). This value defines how many steps the stepper motor needs to take to move 1 mm and depends on factors such as the motor type, step resolution, and motion transmission system.

Challenges in Configuring the Controller Software 🔧

We encountered several challenges during this phase:- Limited documentation and tutorials: The GRBL-Plotter version we used didn't have many reference videos or guides, so understanding its full functionality required a lot of testing and exploration.

- Z-axis configuration issues: In the original example we followed, the Z-axis was driven by a stepper motor. However, in our case, we replaced it with a servo motor—one servo to lift/lower the pen, and another to grab/release it. Because of this change, we had to manually adapt the G-code commands for the Z-axis, which wasn't straightforward.

- Custom mechanical setup: The original design used rails for motion, but our setup used threaded rods (leadscrews) for movement. This meant we couldn't rely on the same step/mm values. We had no datasheets for our stepper motors, so we had to determine the movement per revolution manually through trial and error.

- Color change feature: Our goal was to enable automatic pen color changes using the servo. The GRBL-Plotter software technically supports this feature (as shown in demo videos), but we couldn't fully integrate the Z-axis with the controller software. While we did confirm that the servo moved as intended, we couldn't configure it within the controller's interface to perform coordinated Z-axis operations during plotting.

Eventually, after many tests, we managed to determine the correct steps/mm values for the X and Y axes, making the plotter fully functional in those two dimensions. That's why we named our project “XY (almost Z)”—we're nearly there, and we'll keep working to complete the full 3-axis functionality!