Week_13 Assignments

- Group assignment

- Individual assignment

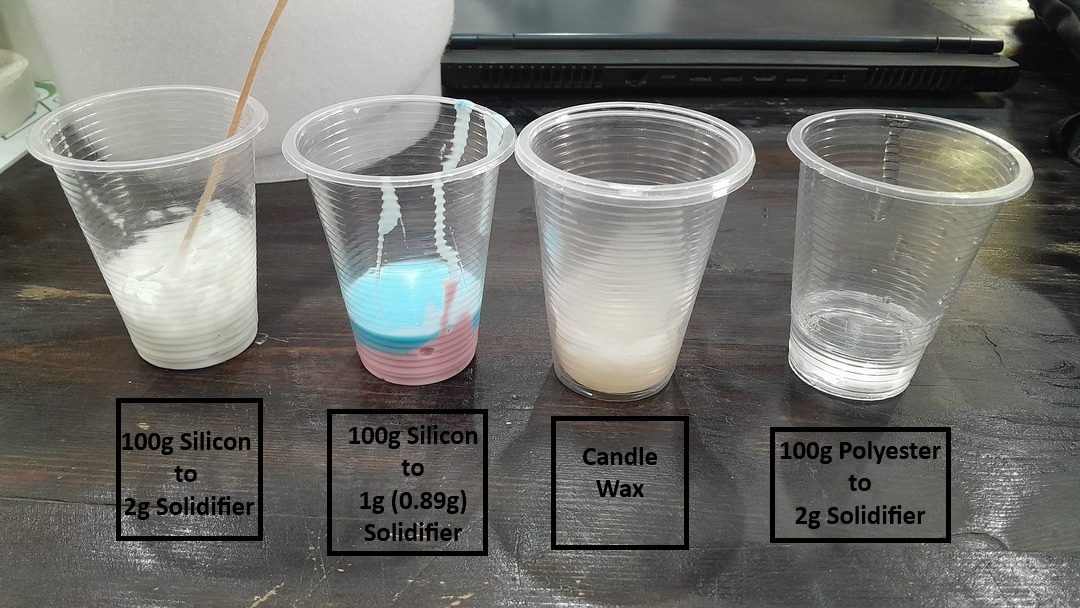

We needed to test multiple materials that can be used in molding to make the mold itself or make the object out of it.

I have to design and make a mold to make a 3d body that has a smooth finish.

Group assignment

Before testing materials we needed to follow safety guide using these chemicals like wearing gloves while preparing, working in a well-vintilated environment and be cautious of any spillage on out clothes and wear gear.

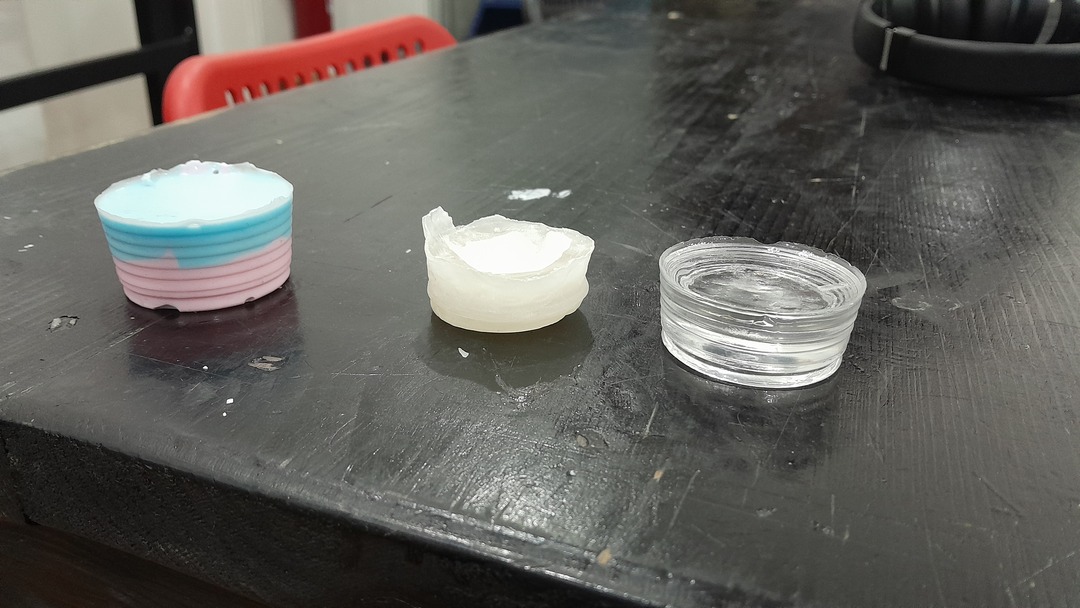

We tested Silicon rubber to make the mold and Polyester and wax (candle wax) to make the object. The Material we used was Generic material which has no recipe or instruction on it so we tried mixing ratios and what we found having great results for Silicon a ratio of 100g of silicon to 1g of Solidifier and for Polyester it was 100g to 2g.

A note don't hold the polyester solidifier mixture to long of after it mixed as it heats up and could reach a tempreture not comfortable or easy to hold.

These are the good results.

Individual assignment

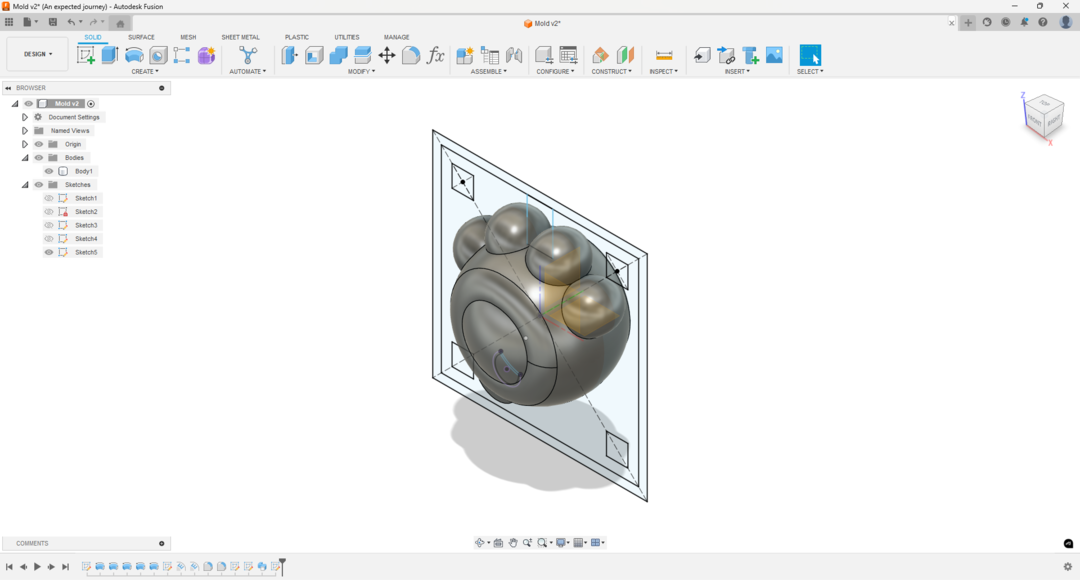

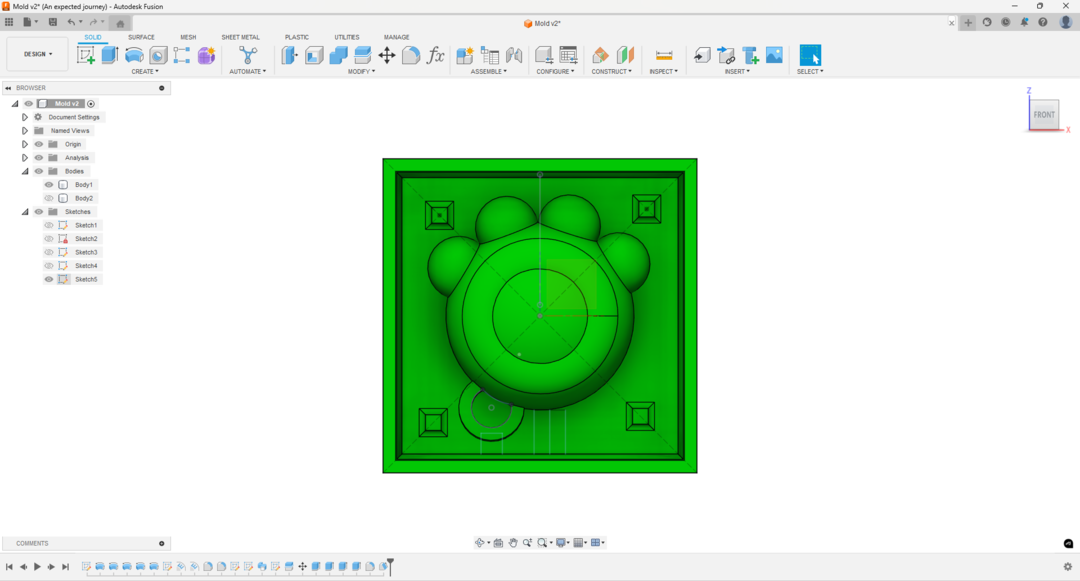

I started designing a simple shape in fusion and I made it symmetrical to make it easy to design and cut time.

Note: As you can see in the design I added extra cylinderically like shape connected to the body to add a way to pour the material and another way to make the air go through as when we pour something it takes the volume filled with air so the air should have a way to escape a ventilation way.

Note: You can see that I designed four holes facing four pins that they will considered registration pins to help align the two halves of my mold.

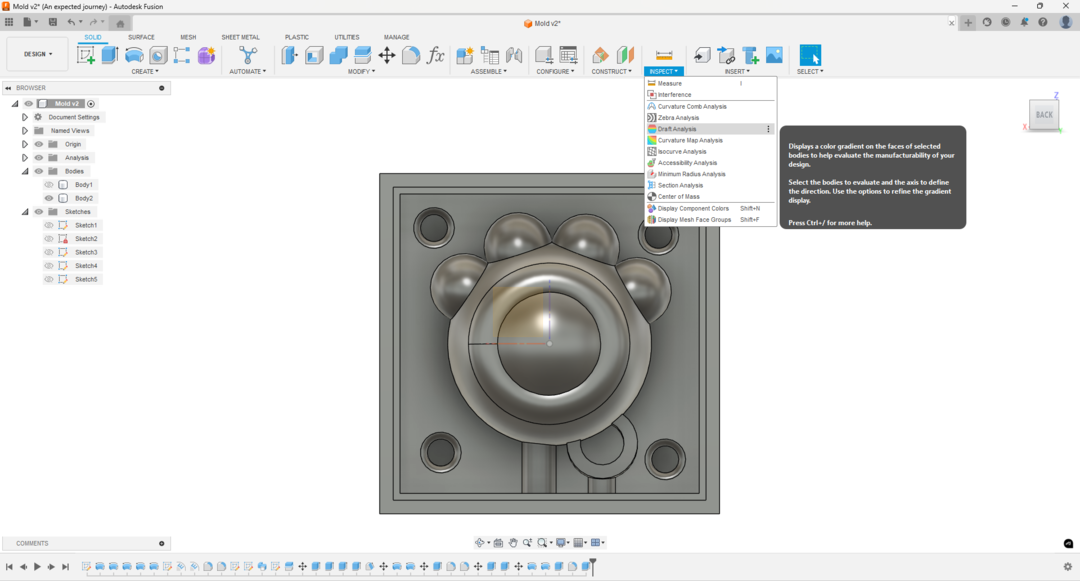

I used draft analysis to see the surfaces where the mold could stick to and make and edite the draft angle according to this.

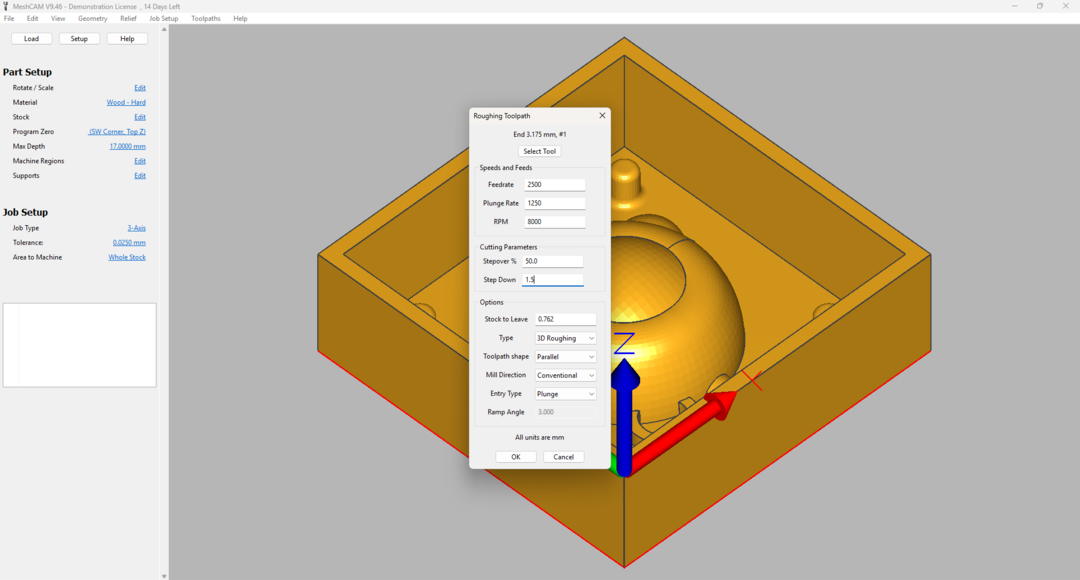

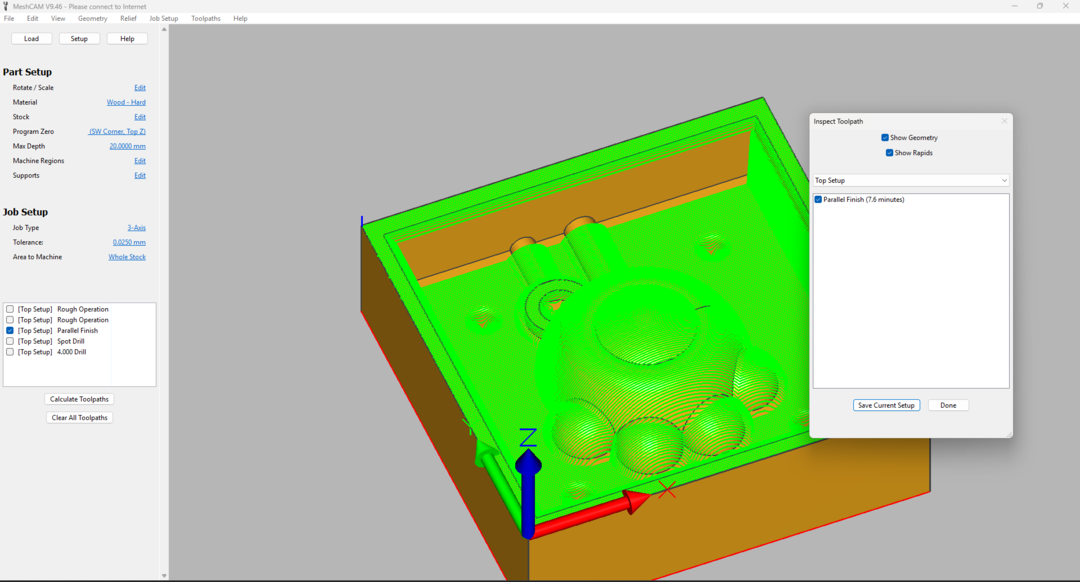

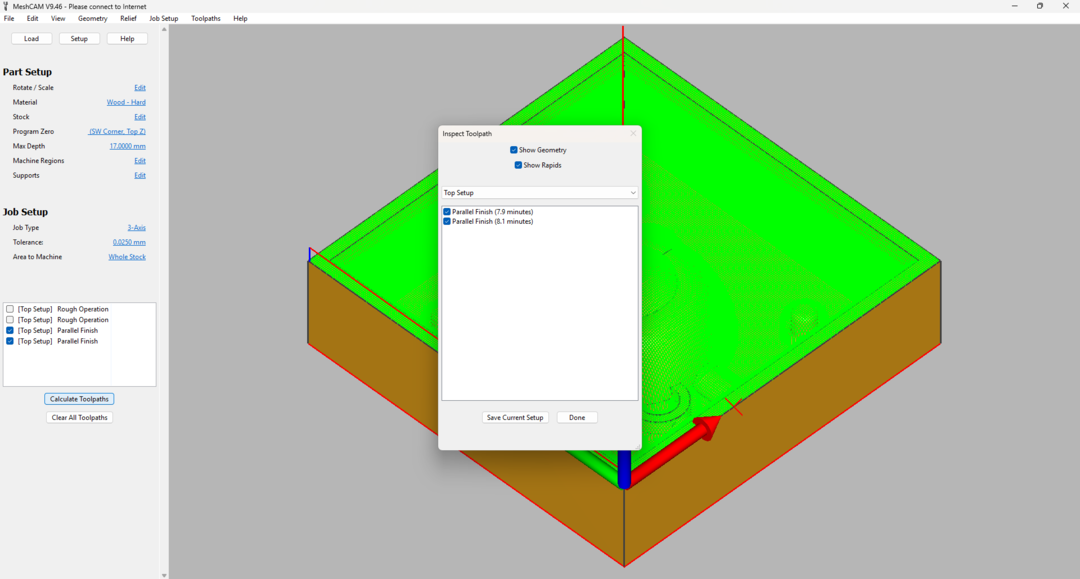

I used Meshcam to get the gcode files and make the toolpathes for the roughing process (I used a 3.175mm flat endmill) and the finishing processes (I used a 3.175mm ball nose endmill).

.png)

Parallel finishing in one axis.

Parallel finishing in two axes for more smoothness at the cost of time.

I started fabrication on the China router to make the mold.

.jpg)

.jpg)

After the fabrication I poured the silicon inside the mold, then waited till it solidified.

.jpg)

I used two ways to hold the two pieces of the mold together I used clear tape and used rubber bands.

.jpg)

.jpg)

After that I started mixing the polyester and then started pouring.

After that I waited for the polyester to finish curing and solidify.

I took liking for the molding and casting so I made many keychains for my friends in different colours.

This a clear one:

.jpg)

This a black one (I mixed here acrylic colours for experimenting) :

.jpg)

This a greenish one:

.jpg)

A photo for the journey:

.jpg)

Some problems I faced That the silicon first try took a loooooooong time to solidify but it still didn't solidify all the way. So I take it of washed the mold and tried to raise the percentage of the solidifier and started a gain this time it worked and added extra 0.5gram of the solidifier.