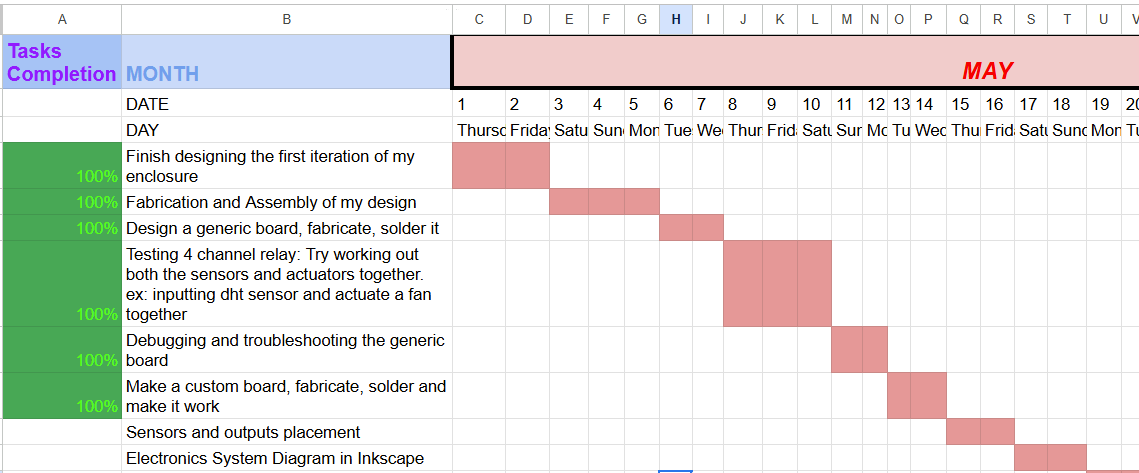

GANTT Chart

I started off this week by creating a Gantt chart for my final project which is a project management tool that visually represents a project's schedule using horizontal bars. Each bar corresponds to a task, showing its start and end dates, duration, and dependencies.

You can access my GANTT Chart here

Final Project Task Breakdown

- 📟 Electronics

- ✅ Finalize electronics architecture (sensors, actuators, power, microcontroller)

- ✅ Design custom PCB(s)

- Generate toolpath for milling (Roland or other mill)

- Mill PCB

- Stuff and solder components

- Test continuity and basic functionality

- Debug PCB (if needed)

- Integrate power supply system

- ✅ Connect sensor and actuator wiring (neat and modular)

- ✅ Finalize electronics system diagram (what components, what connections, what power requirements, what supporting electronics...regulators, resistors, filtering capacitors, protection diodes)

- ✅ Breadboard all subsystems and test with MCU and code to ensure proper, predictable functionality

- ✅ Connect sensor and actuator wiring (neat and modular)

- ✅ Finalize electronics system diagram

- ✅ Breadboard all subsystems

- 💻 Programming

- ✅ Write microcontroller firmware (Arduino/C code)

- ✅ Interface with sensors (temperature, humidity, light, soil moisture)

- ✅ Control actuators (fans, water pump, LED light, etc.)

- ✅ Implement automation logic (thresholds, timers, etc.)

- ✅ Test sensor readings and actuator outputs

- Calibrate sensors and tune responses

- ✅ Write a list of functionality you want your code to perform...ex:

- Turn on LED when Phototransistor reading > 500.

- Turn off LED when Phototransistor reading ≤ 500.

- Turn on Water Pump for 10 seconds when Soil Moisture Sensor reading < 200.

- Turn on Fan when Temperature Sensor reads > 35°C or when Humidity > 80%.

- Write (sub) programs to control the functionality of each device connected to the microcontroller

- Test each program with the electronic subsystem that it should control

- 🛠️ Fabrication (3D Printing, Laser Cutting, CNC)

- ✅ Design 2D/3D parts in Fusion 360 or similar

- ✅ Laser cut enclosure walls and the head of the pig(1st and 2nd module)

- 3D print small parts (sensor holders, motor couplers, joints)

- Assemble all fabricated parts

- Integrate electronics into the structure securely

- ✅ Determine the enclosure size and shape required to contain and protect your electronic system

- Design an enclosure

- 📝 Documentation & Presentation

- ✅ Document each process step (photos, videos, sketches)

- ✅ Write weekly updates (include learnings and challenges)

- ✅ Create a dedicated Final Project Page

- Record final project video (showing demo & features)

- Compress files and prepare for final project upload (CAD, code, etc.)

- ✅ Ensure site is clean, accessible, and meets Fab Academy standards

- ⚙️ Mechanism Design

- Design water distribution system (pipes, pump, valves)

- Design ventilation system (fan placement, airflow direction)

- ✅ Mount sensors in optimal positions for accurate readings

- ✅ Ensure modularity and maintenance access

- Create holders and guides for moving parts (if any)

- Include adjustability (light position, irrigation level, etc.)