WEEK 5 - 3D Scanning and Printing

Checklist

3D Scanning

- 3D scan an object (and optionally print it).

3D Printing

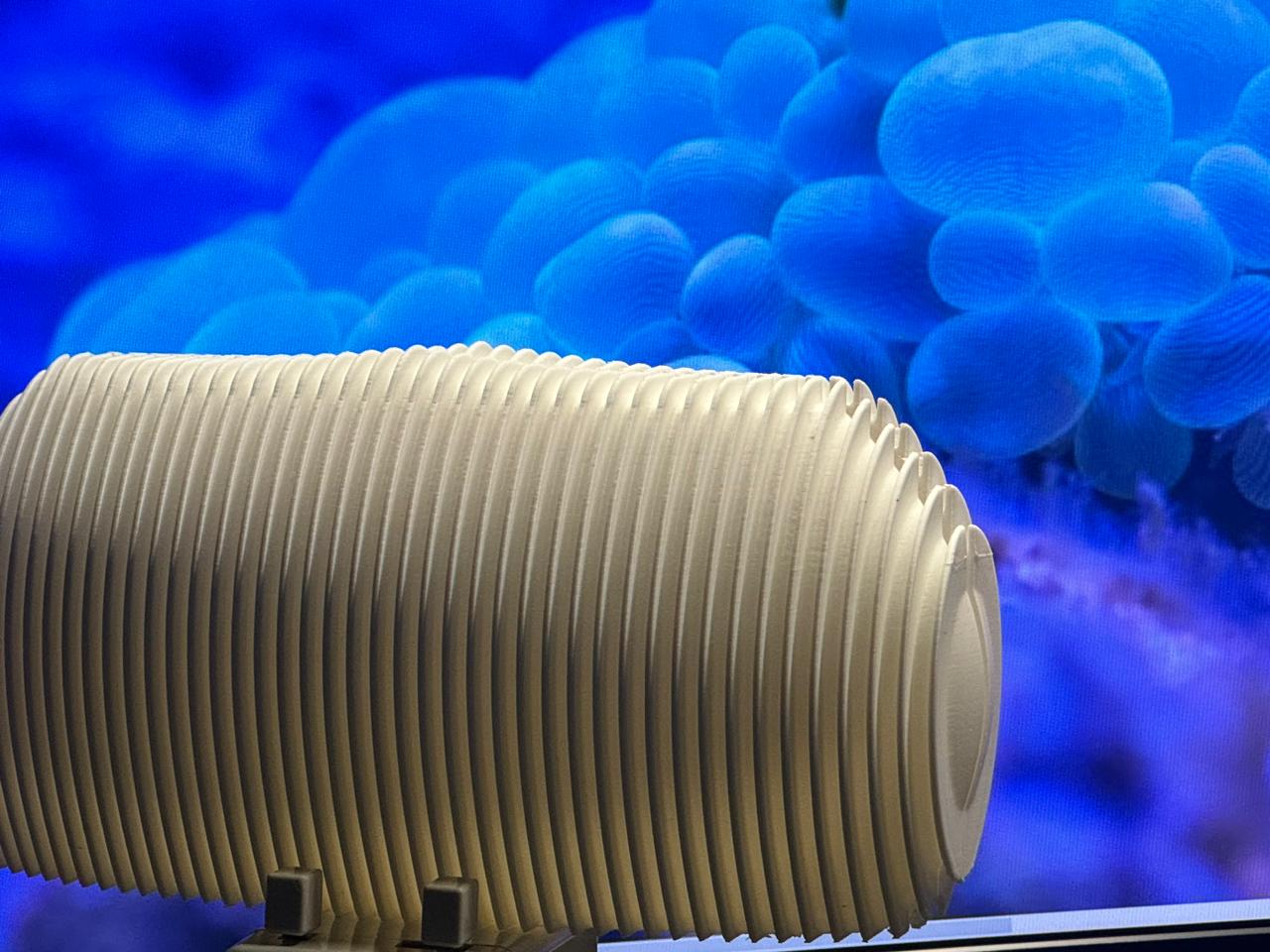

- Design and 3D print an object (small, few cm3, limited by printer time) that could not be easily made subtractively.

3D Scanning

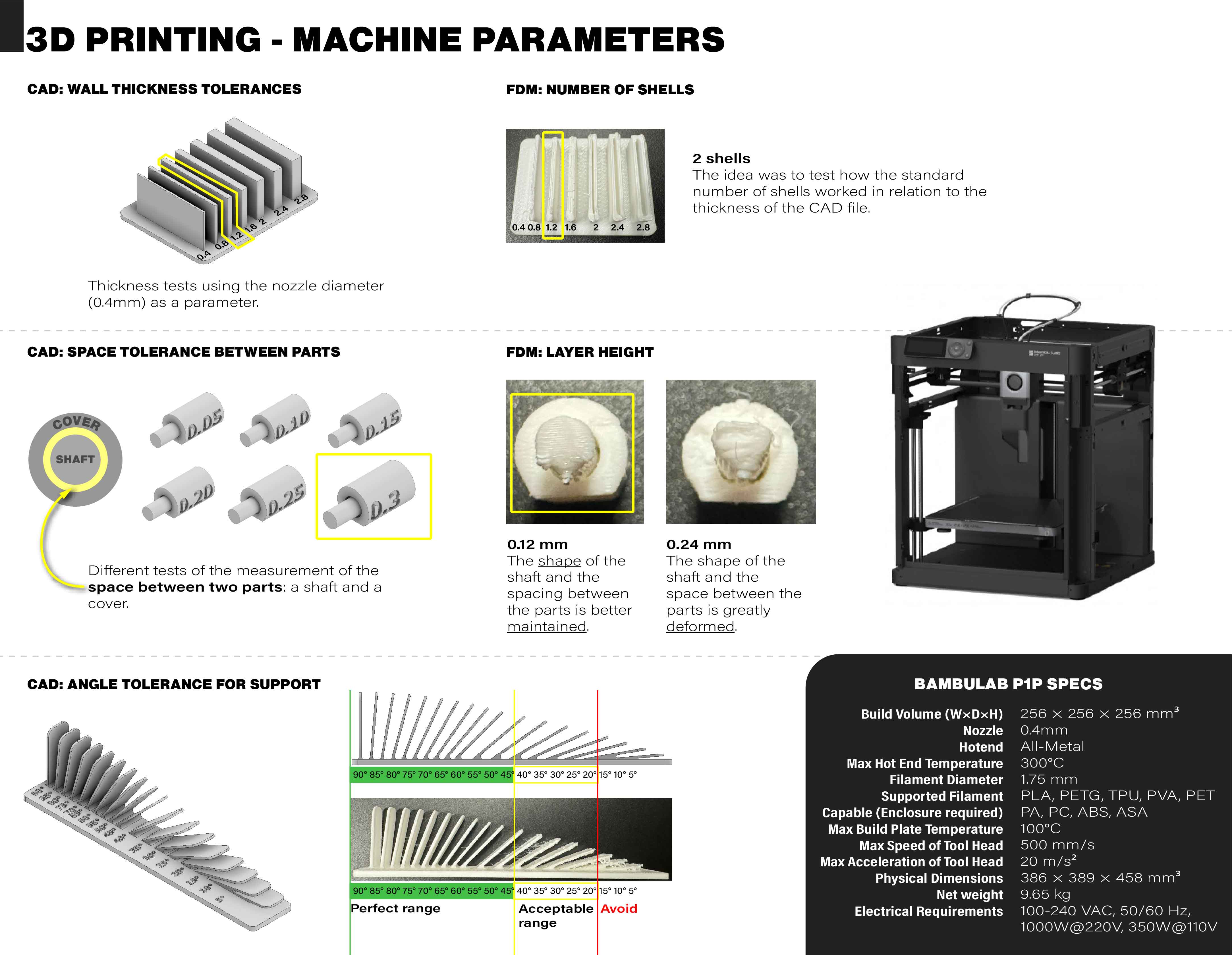

Machine parameters

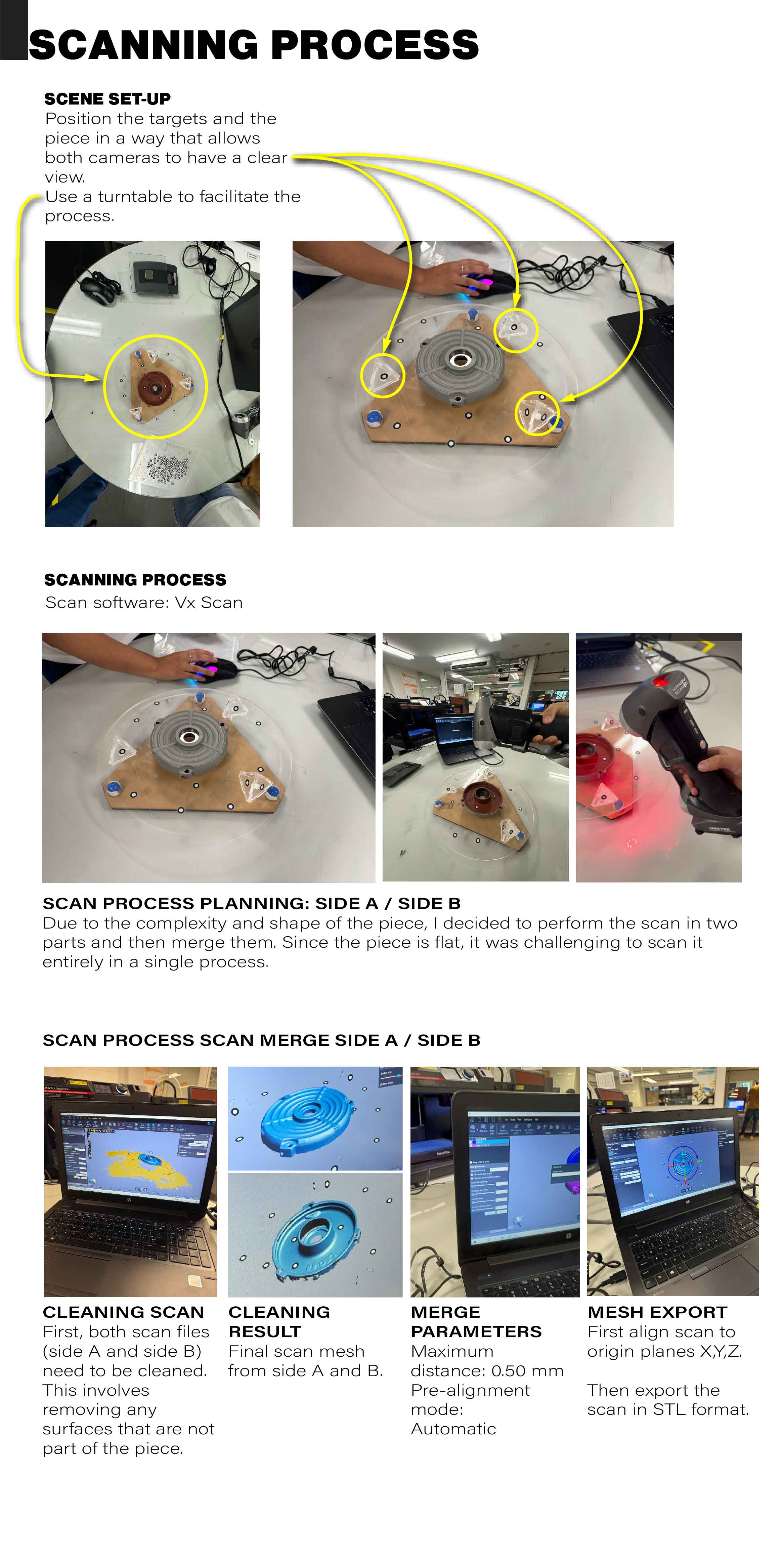

Scanning process

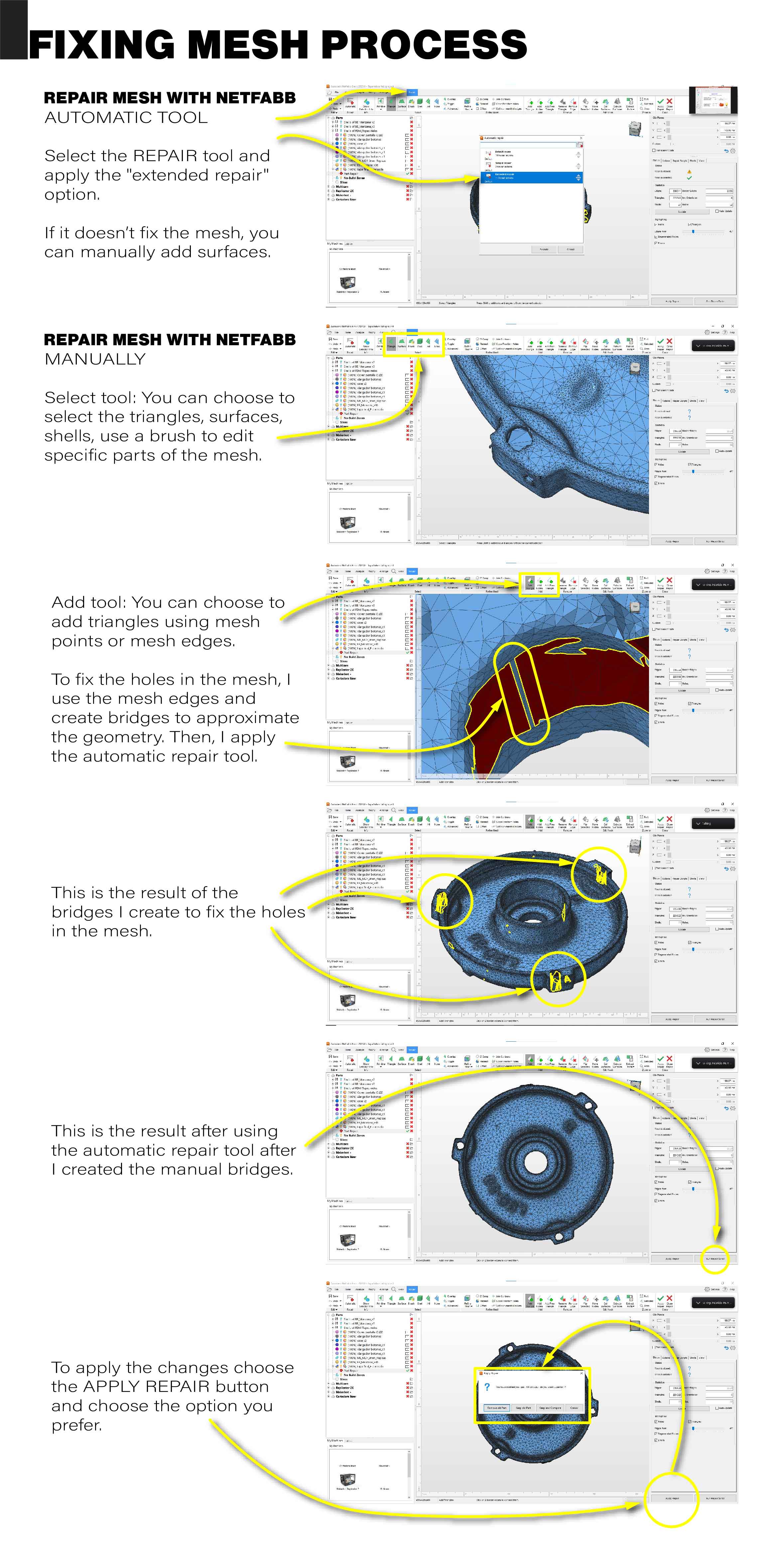

Preparing mesh for 3D printing

Reverse engineering

During the 3D scanning process, I took the opportunity to scan a part that I needed for the development of a project in the laboratory. The idea is to reverse engineer a Siemens motor in order to propose improvements. To achieve this, I used one of the covers and the Handy Scan 700 scanner to scan the part.

3D Printing

Group assignment

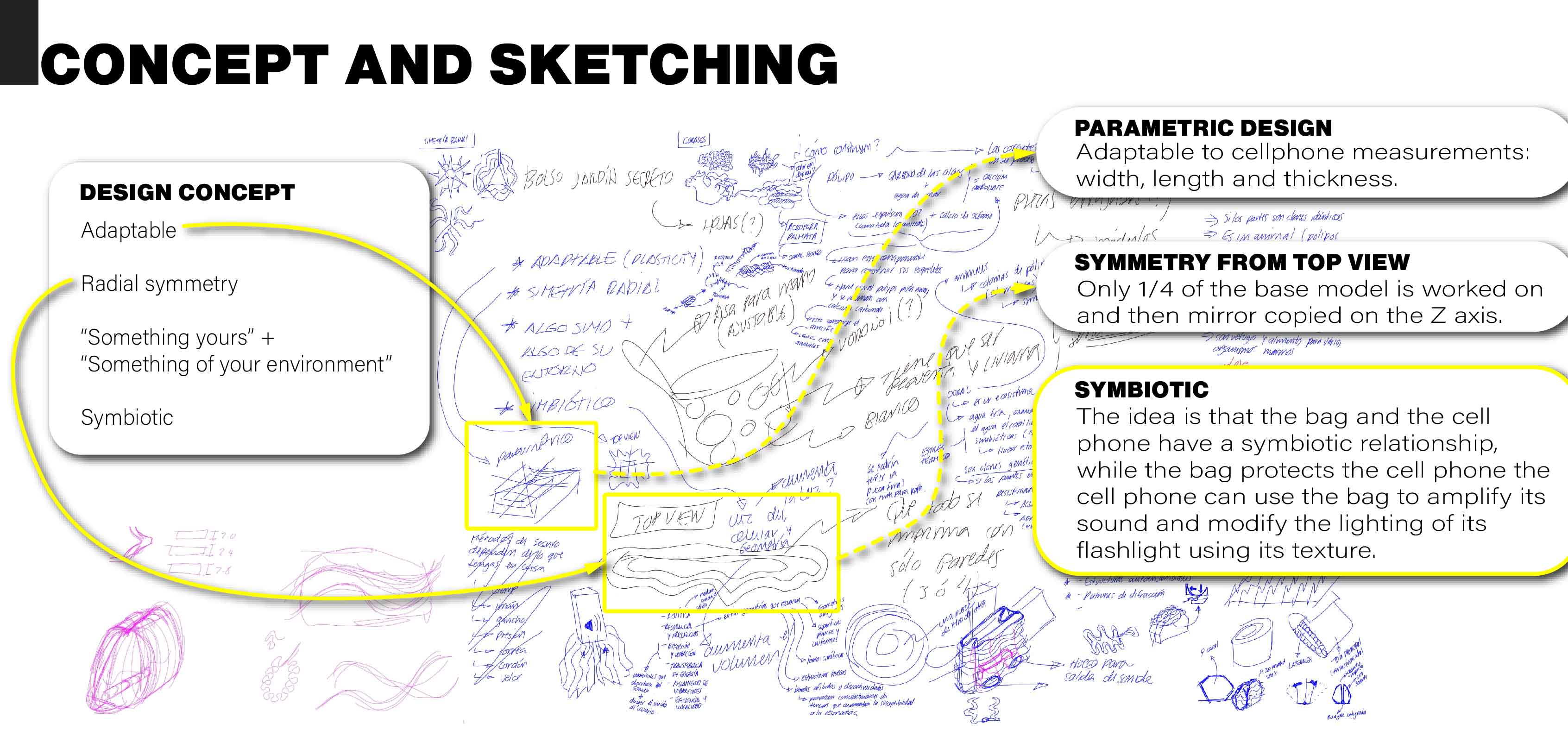

Design process

Using 3D printing in this design allows me to print the parts as a single unit, unlike other manufacturing processes where this isn't feasible or would significantly increase the final cost. The geometry of the walls also adds complexity, making it difficult to fabricate with CNC machining, especially in delicate areas like hinge joints and the latch.