WEEK 13 - Moulding and Casting

The idea for this task was to work on modules that could be part of a system for creating wall textures in existing walls or for the creation of new ones, which will serve as guides for people with low vision to navigate within a building or space.

In this case, I worked on two options: one for assembling in two dimensions and another in three dimensions. The idea is to work on modules that, when joined together, can generate a texture that allows the identification of an area and can also indicate the direction of circulation.

The two-dimensional modules can be applied to existing walls, while the three-dimensional modules are used to build new divisions in specific spaces. The idea of the 3D modules is that, in addition to having a texture, they can generate different light levels to also serve as a guide for people with low vision or complete blindness, as 95% of them maintain light detection cells.

Checklist

- Design a mold around the process you'll be using, produce it with a smooth surface finish, and use it to cast parts.

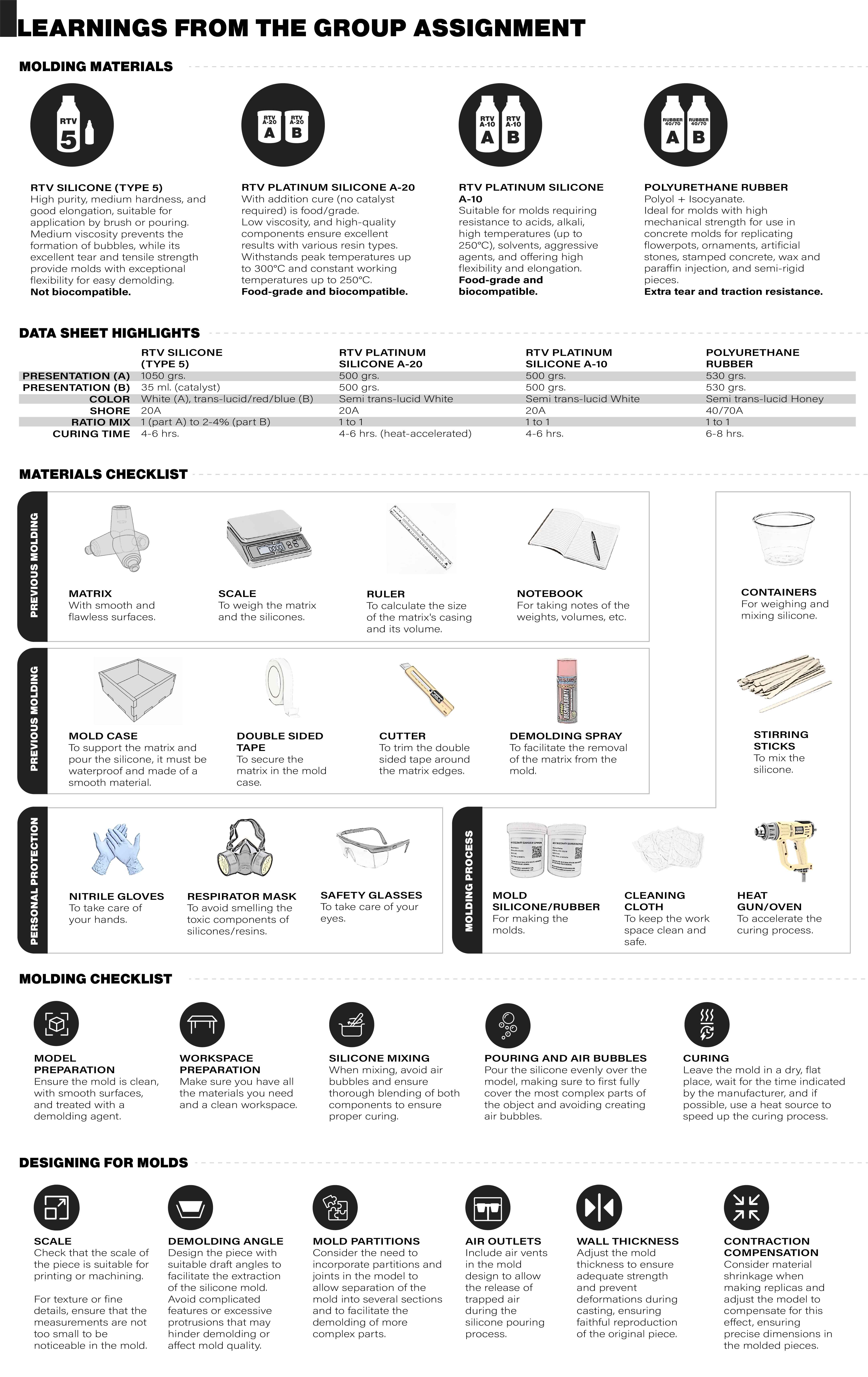

Learnings from the group assignment

My contribution to the group work was to review the datasheets of the materials and extract the most important points.

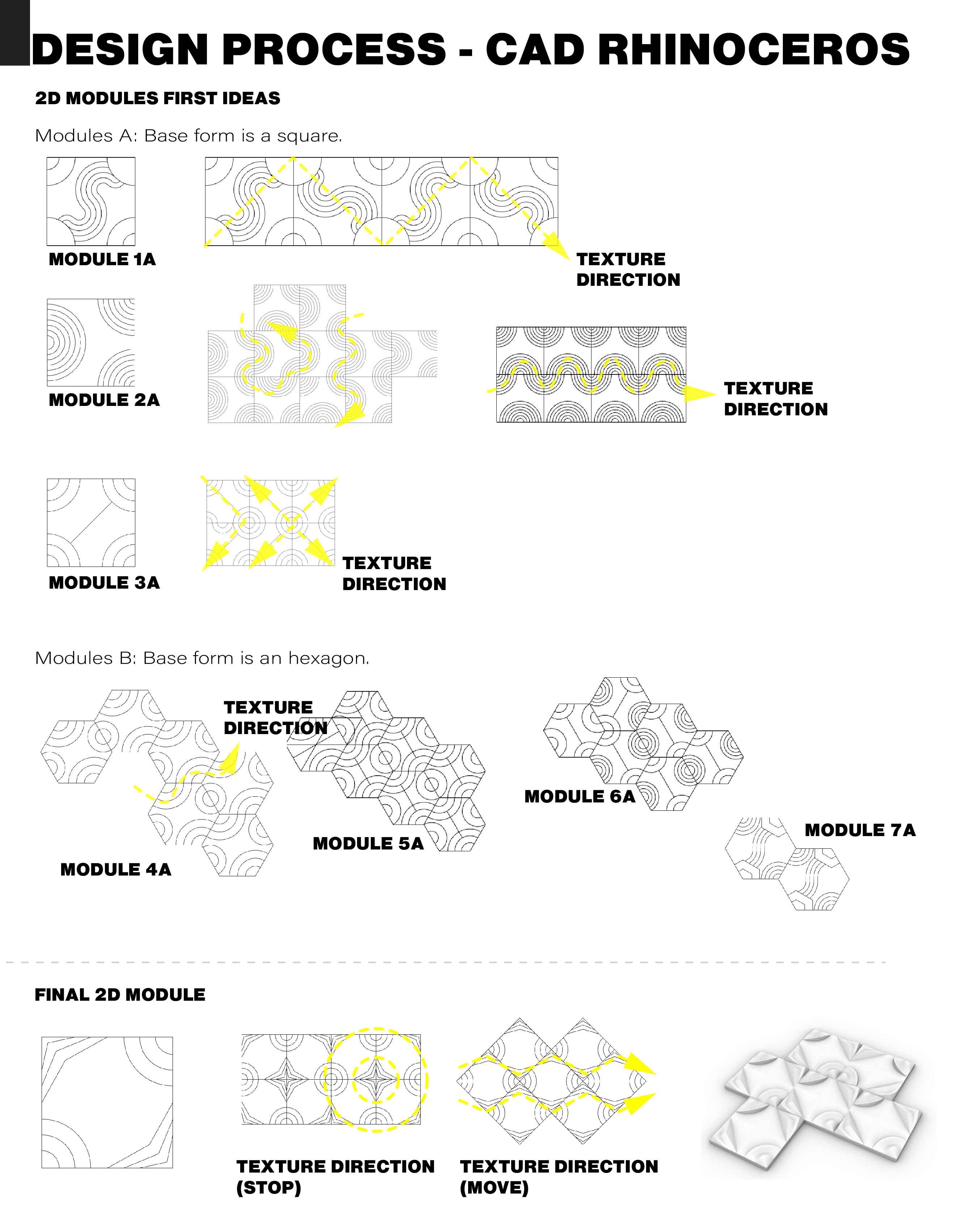

Design process

Design concept

The concept originates from designing an object for a fictional world where the majority of people are blind or have difficulties seeing. Therefore, I designed modules (2D and 3D tiles) that could be part of a system for creating wall textures in existing walls or for the creation of new ones, which will serve as guides for people with low vision to navigate within a building or space.

Design process

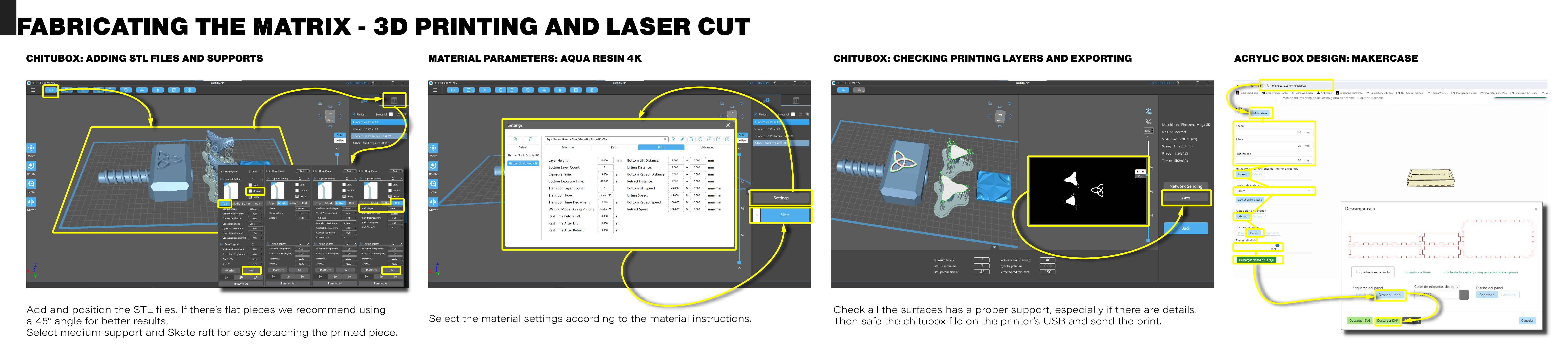

Fabrication

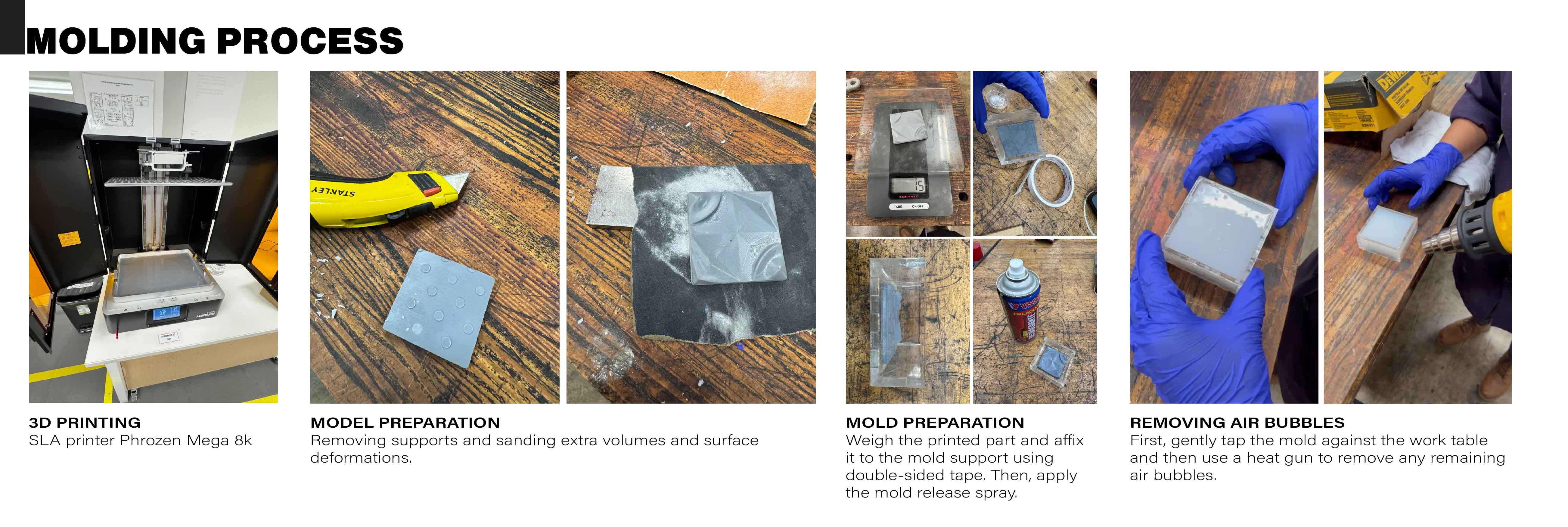

Process

Process 3D pattern mold

Mold joints detail

The joints, however, worked perfectly.

Results

Cement casting

Learnings

- Avoid using high temperatures when using a heat gun.

- Check the expiration date of the silicones; if expired, allow them to cure for longer.

- If you plan to cast cement, it's better to use the polyurethane mold to ensure more perfect copies.

- When sending for SLA printing, avoid printing large resin blocks as they may detach due to weight.

Errors and solutions

Group apport

- Review of silicone data sheets.

Download resources

CAD: Rhinoceros 7

- Patterns design process

- File with all the patterns tried during the design process.

- Final 2D pattern STEP

- 2D tile module CAD file.

CAD: Autodesk Inventor

- Final 3D pattern IPT

- 3D module CAD file.

- Extra 3D pattern IPT

- 3D module CAD textured sphere file for the ends of the 3d construction system.

- 3D pattern mold design

- CAD file with all the pieces for the 4 parts mold.

CAD: STEP files

- Final 3D pattern STEP

- 3D module STEP file.

- Final 3D sphere pattern STEP

- 3D module (sphere) STEP file.

STL files

- Final 3D pattern STL

- 3D modules STL files.