Week 18: Aplications and Implications

Week 17: Aplications and Implications

What will it do?

The Coquiduino Braille Printer is designed to be a gateway to knowledge for blind children living in challenging conditions. Its purpose is to provide affordable access to Braille, making educational resources more accessible to visually impaired students. This printer will autonomously print Braille characters onto a A4 paper, helping to bridge the educational gap and empower these children with the tools they need for learning and development.

Who's done what beforehand?

Affordable Braille Printers Available to the Public:

- Braigo: Invented by Shubham Banerjee, Braigo is a low-cost Braille printer made using LEGO pieces and low-cost electronics. It significantly reduces the cost compared to traditional Braille printers, making it more accessible.

- Mountbatten Brailler: While not as affordable as Braigo, the Mountbatten Brailler is a well-known electronic Braille writer that offers both Braille writing and embossing functions. It is designed for educational purposes but is generally more expensive than newer affordable projects.

- Perkins Smart Brailler: This device combines the traditional Perkins Brailler with modern technology to provide audio feedback and a digital display. It is an educational tool designed to help both students and teachers, but it comes at a higher price point.

Fab Academy Projects:

- Braille Printer (Fab Lab Trivandrum): I found in the repositories a Group Project that they made a Braille printer with a low cost implementation.

- Braille Printer (Marwa Baalouche's Final Project): I found in the repositories a Final Project with a very nice implementation and system integration.

These existing projects and products highlight the ongoing efforts to make Braille printing more accessible and affordable. However, there remains a need for cost-effective, easy-to-use Braille printers tailored to educational purposes, particularly in under-resourced areas. The Coquiduino Braille Printer aims to address this gap by providing a low-cost, accessible solution for blind children in challenging conditions.

What will you design?

I am designing a compact and affordable Braille printer with a sleek, wire-free design that is user-friendly and safe for children to use. The goal is to create a machine that children can easily handle.

Electronics Design:

The electronics will be designed to drive 2 stepper motors and a MOSFET to power the solenoid. Additionally, it will include extra ports for LED status lights if needed. The board will feature a 3-pin header to connect the IR sensor. For this project, I will use the Seeeduino XIAO, which has the SAMD21 microcontroller running the logic at 3.3V.

Mechanical Design:

The assembly of components will prioritize compactness, with the motion axes and solenoid positioned internally to prevent accidents. A feeder mechanism with spring-loaded rollers will ensure a secure grip on the paper sheet.

In the mechanical assembly, the solenoid will be positioned with the punching part facing up. An acrylic sheet with milled Braille holes will be used, and a 3D-printed rib will hold the embossing surface securely in place.

To facilitate smooth operation, a feeder helper will be integrated to align the paper before it is caught by the rollers.

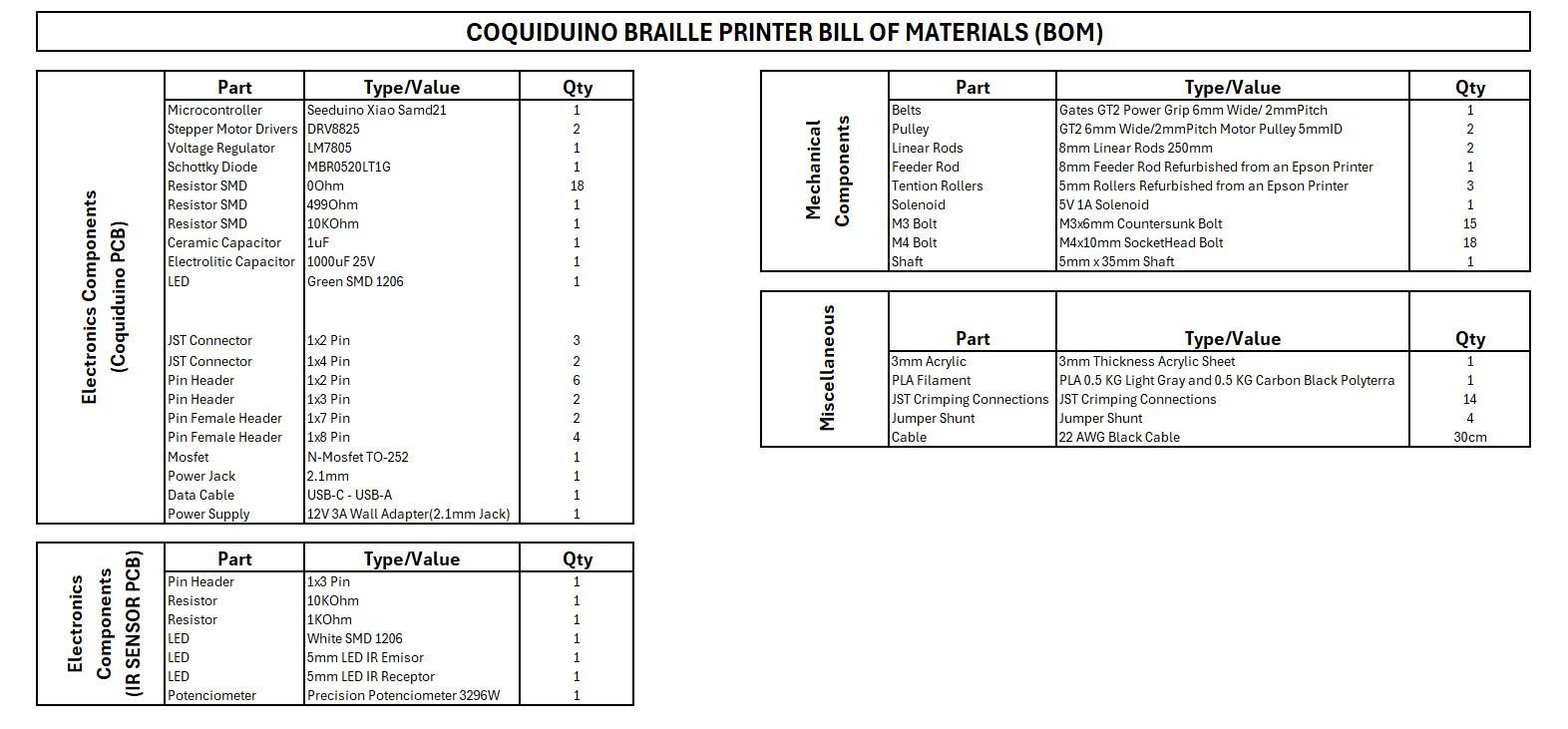

What materials and components will be used?

Bill of Materials

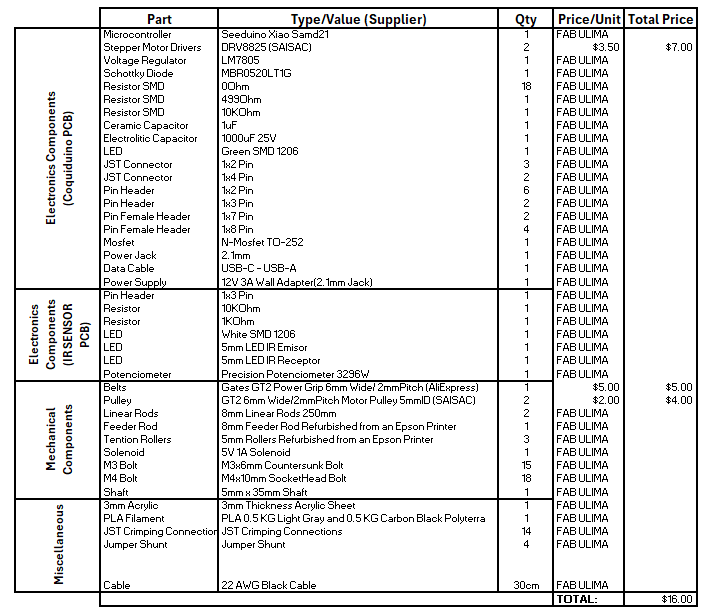

How much will they cost?

Budget Overview:

What parts and systems will be made?

Parts and Systems to be Made

- Punching Mechanism

- Responsible for embossing Braille dots onto the paper.

- Designed to be precise and reliable to ensure accurate Braille output.

- Feeder Mechanism

- Feeds paper into the printer and positions it correctly for the punching mechanism.

- Ensures smooth and consistent movement of paper to prevent jams or misalignment.

- Motherboard

- Seeduino Xiao: Microcontroller managing overall printer operations.

- DRV8825 Stepper Drivers: Control the stepper motors for the punching and feeder mechanisms.

- N-MOSFET: Controls power output to high-power components .

- IR Sensor

- Detects paper presence.

- Punching Mechanism's Endstop.

What processes will be used?

- Computer Controlled Cutting:

- I will use the Epilog CO2 Laser to cut the 3mm thick back panel of the machine and the punching platform. This laser cutter will ensure precise and clean cuts necessary for the accuracy of the Braille printer components.

- Computer Controlled Machining:

- The 3mm thick punching platform will initially be cut using the laser cutter. Following this, it will be placed on the Roland Modela CNC Mill, where a ball mill will be used to carve semispherical molds. These semispheres are crucial as they serve as molds for forming the Braille dots, ensuring they are perfectly shaped and properly aligned.

- 3D Printing:

- Various custom parts required for the assembly of the Braille printer will be designed and produced using 3D printing technology. This will include:

- Motor Mounts for Punching Mechanism and Feeder, and IR Sensor Mount: This piece holds the two stepper motors and the IR sensor. It also serves as a structural component, providing necessary support and alignment.

- Spring-Loaded Rollers: These rollers increase the friction between the feeder rod and the paper, ensuring smooth and consistent feeding.

- Punching Carriage: Responsible for traveling along the X-axis and holding the solenoid for the punching process, this component ensures precise movement and positioning.

- Feeder Alignment Guide: Mounted at the front of the machine, this guide ensures the paper is properly aligned to prevent paper jams and ensure smooth operation.

- Electronic production:

- MotherBoard: The main control board will be designed and produced, featuring the Seeduino Xiao microcontroller, DRV8825 stepper drivers, and N-MOSFETs. This motherboard will manage all the printer’s electronic functions.

- IR Sensor:Sensors will be developed to detect paper presence and act as a limit switch for the punching carriage. These sensors will ensure the punching and feeder mechanisms operate at the correct locations in the coordinate system, maintaining the accuracy of the Braille printing process.

- Embedded Programming:

- The Seeduino Xiao microcontroller will be programmed to control all aspects of the Braille printer. This will include:

- CNC Control via G-code: The microcontroller will interpret G-code commands to precisely control the two axes of the printer through a terminal interface.

- Homing Procedures: Implementing homing procedures to accurately position the punching mechanism at a known starting point, ensuring precise and repeatable movements.

- Feeding Procedure: Developing a reliable feeding procedure to load paper sheets correctly, ensuring smooth and consistent paper handling.

- Safety Features:

- Setting axis maximum limits to prevent the mechanisms from moving beyond their intended range, thereby avoiding potential crashes and mechanical failures.This will ensure the protection of both the machine and the operator.

- Detecting and handling unavailable commands to prevent the execution of invalid instructions, ensuring the system remains stable and secure.

- Ensuring seamless integration of all components to produce accurate and reliable Braille output. The programming will coordinate the punching and feeder mechanisms, along with the IR sensors, to maintain the printer's precision and efficiency.

What questions need to be answered?

- How can the programming of the Braille Printer be optimized to accept characters from a Python program running on a PC?

- Would it be more effective to utilize a 2x3 matrix for character representation, or should the program send G-code sequentially to the machine?

- What measures can be taken to ensure the stability and strength of the printer using PLA 3D printed parts?

- Is it advisable to use a single sensor for both axes, considering the operational requirements and potential drawbacks?

How will it be evaluated?

The Braille printer will be evaluated based on its functionality and usability. It must emboss characters cleanly and clearly, ensuring correct spacing. Printed output on paper should be easily readable and precise when fed into the machine.