Week 10 & 11: Machine Design & Mechanical Design

Summary

The week 10, as a group, we had to design a machine that includes mechanism+actuation+automation+application. Then, in week 11 we had to actuate and automate the machine.

Process

What we manufactured was a pyrography machine that is used to mark wooden or plastic cutlery. It works by performing two parts at the same time: first with a Z axis going up and down in height and simultaneously rotating a drum holding several cutlery at the same time. The recorder will be fixed on the Z axis and it will mark the cutlery every time it goes down.

My contribution to the manufacture of this machine was to propose ideas for the design of the parts and operation.

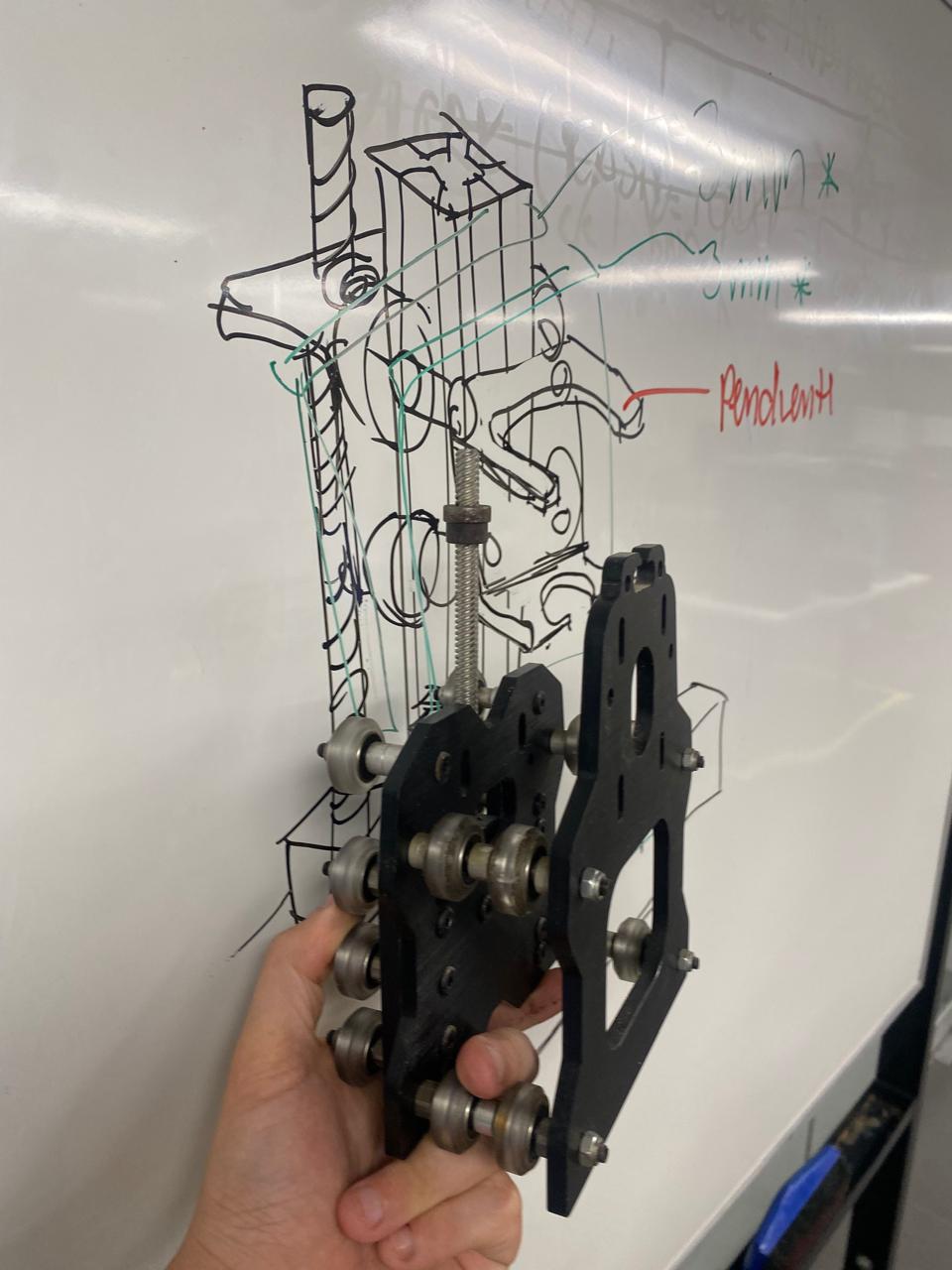

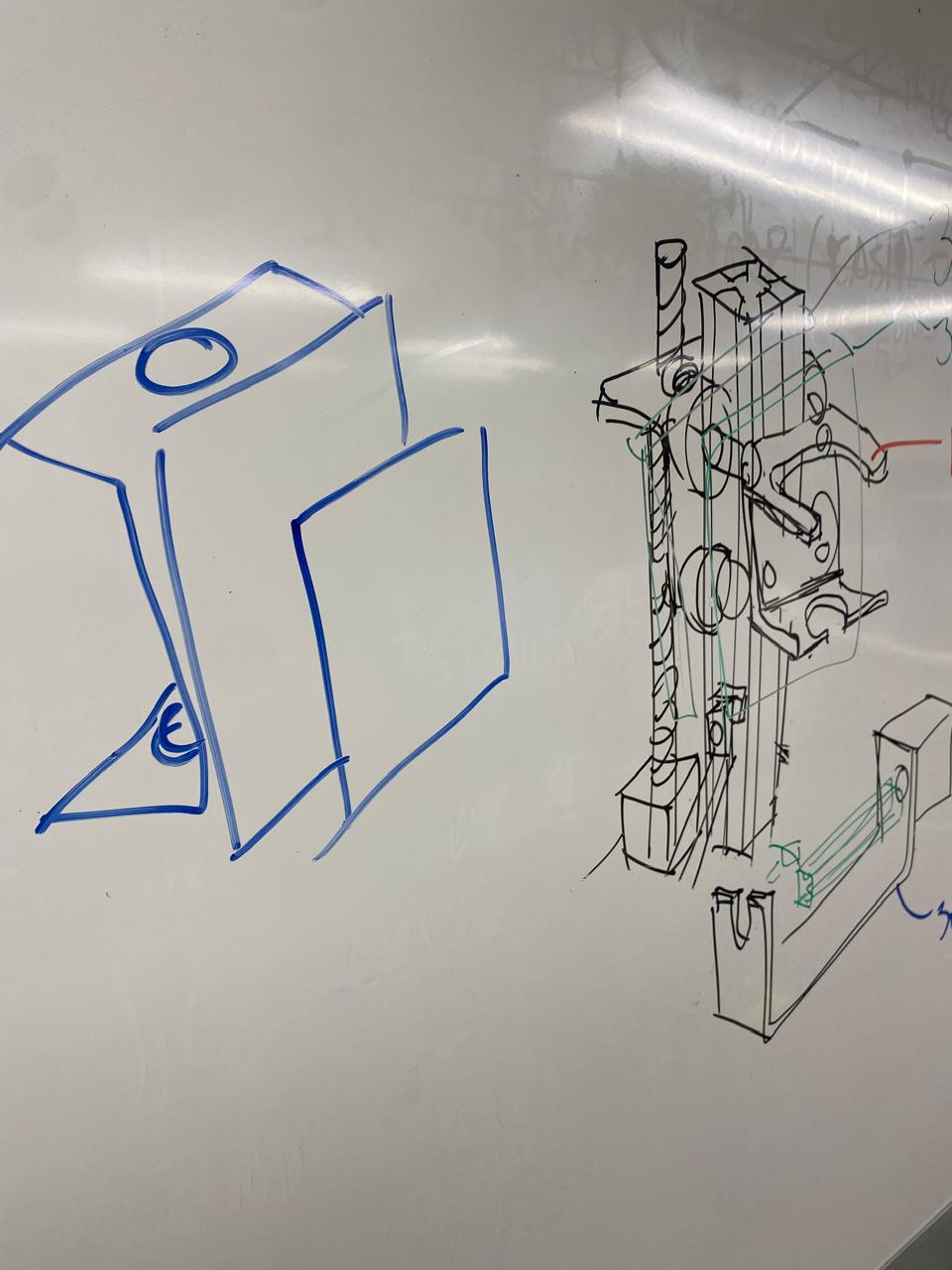

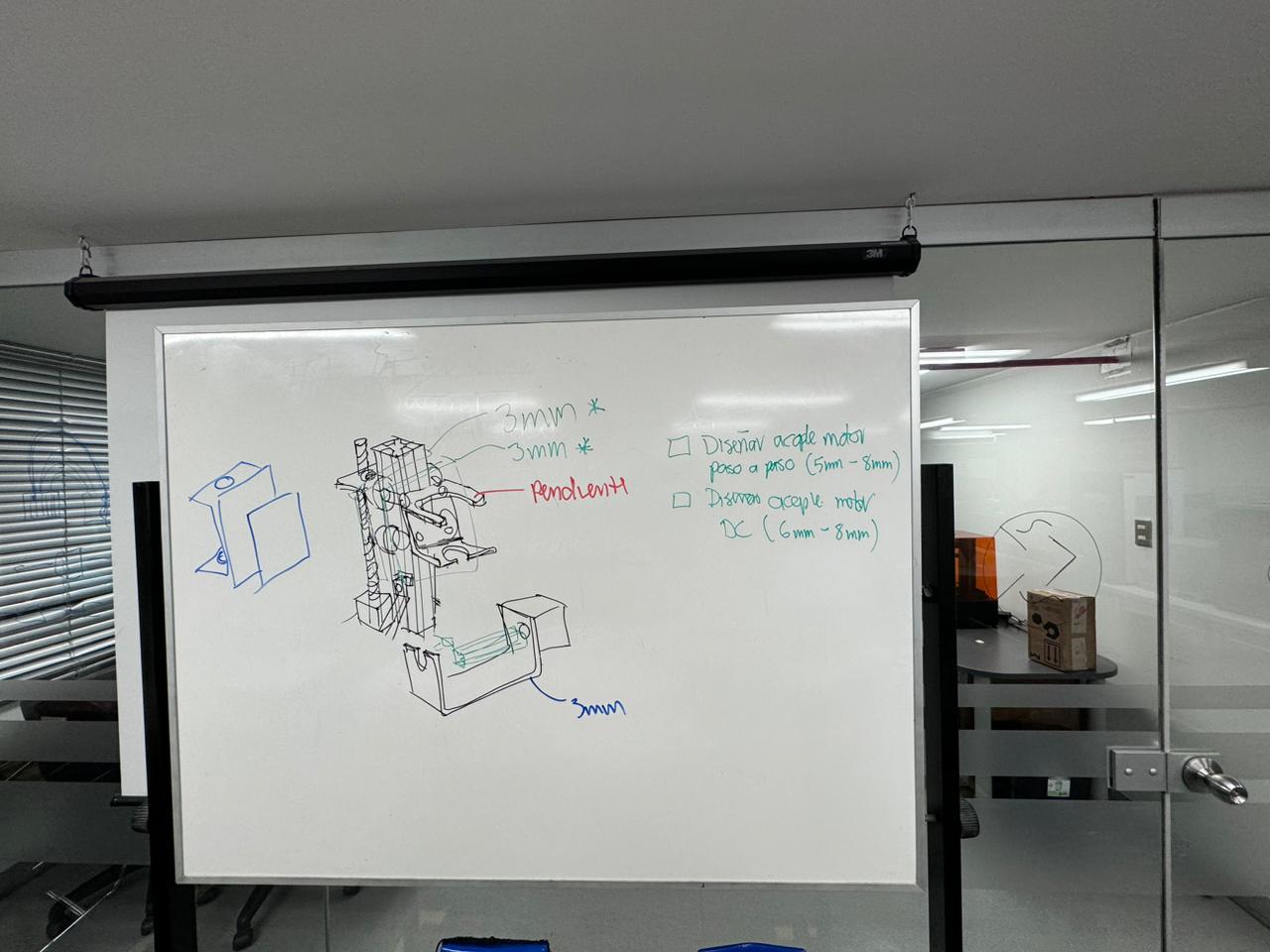

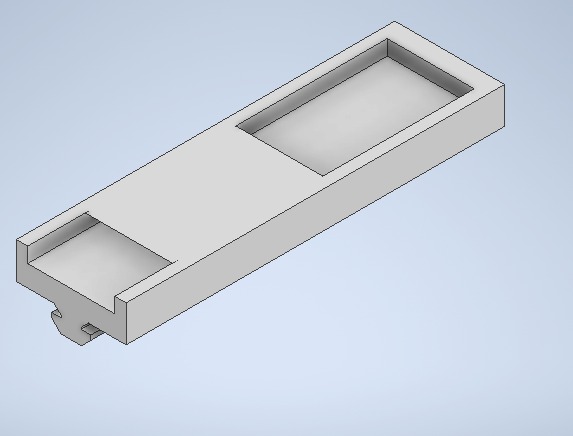

I made an initial design that helped us collect ideas and propose others, which helped us imagine how the Z axis would be working in height.

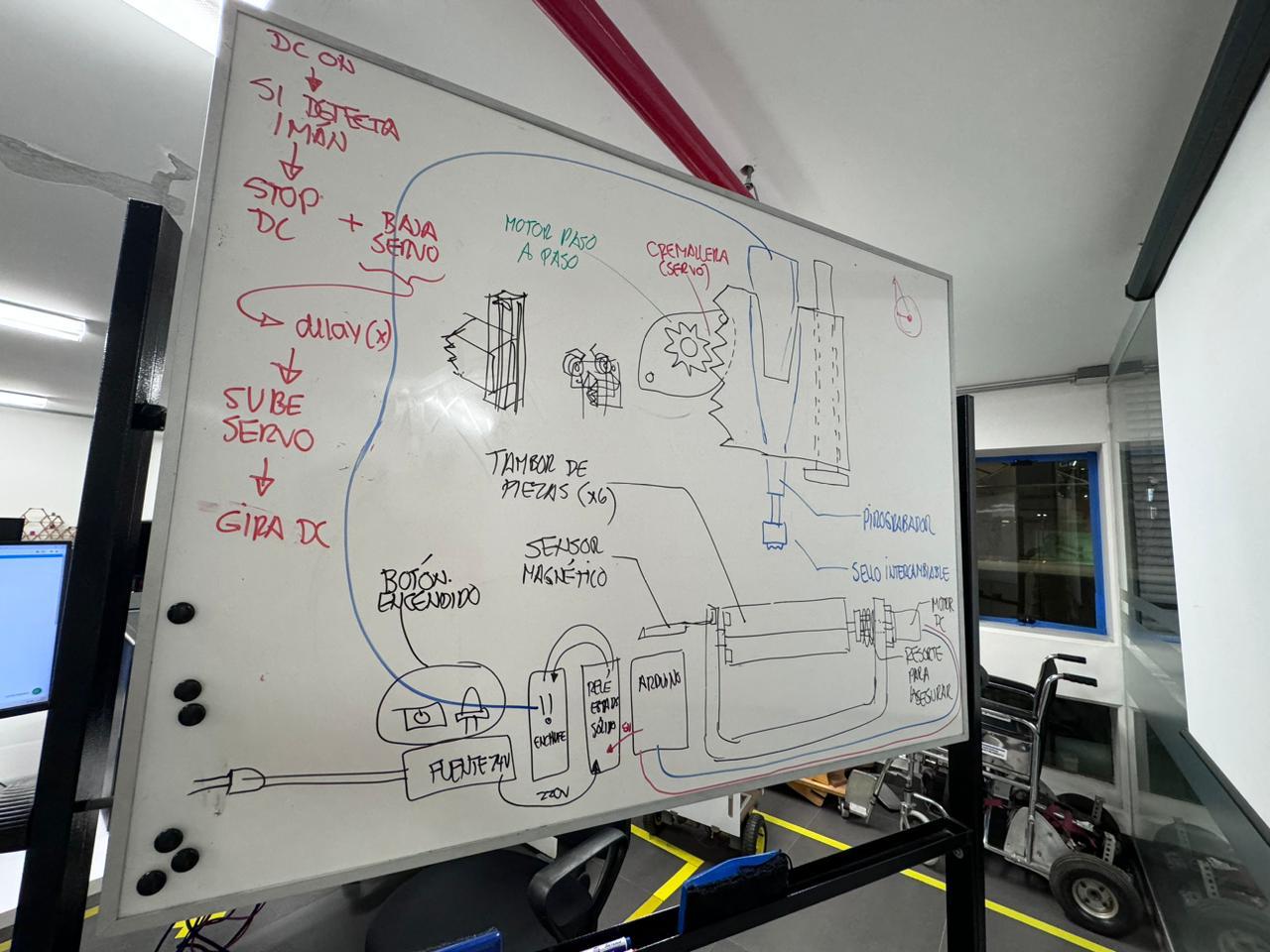

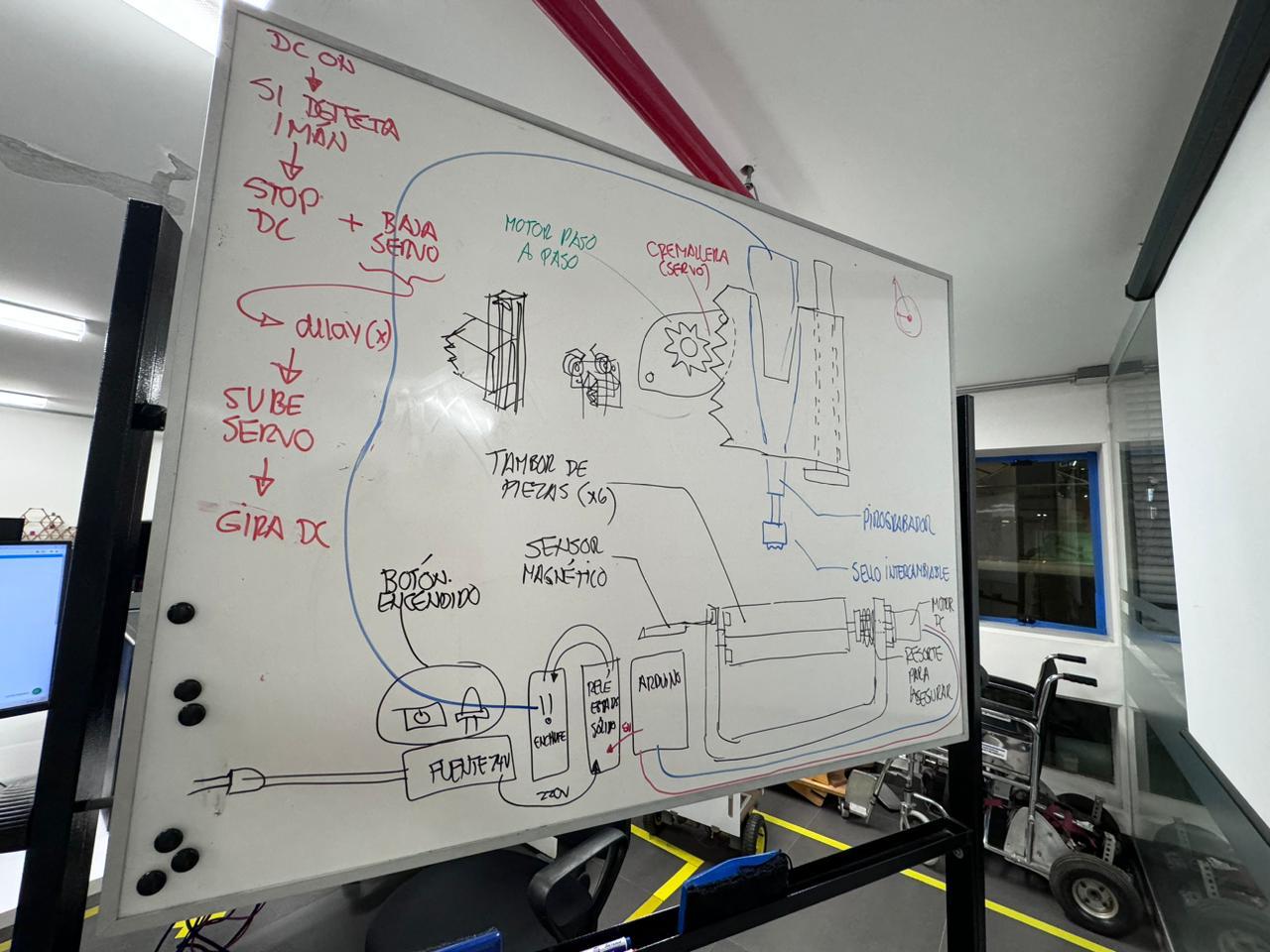

Next, with the proposals it was possible to arrive at a general diagram of the machine which helped us a lot to guide us as to what and how we were going to manufacture it.

Since this was an initial sketch, we had not yet decided how to manufacture the other part of the machine, which would be the rotating drum.

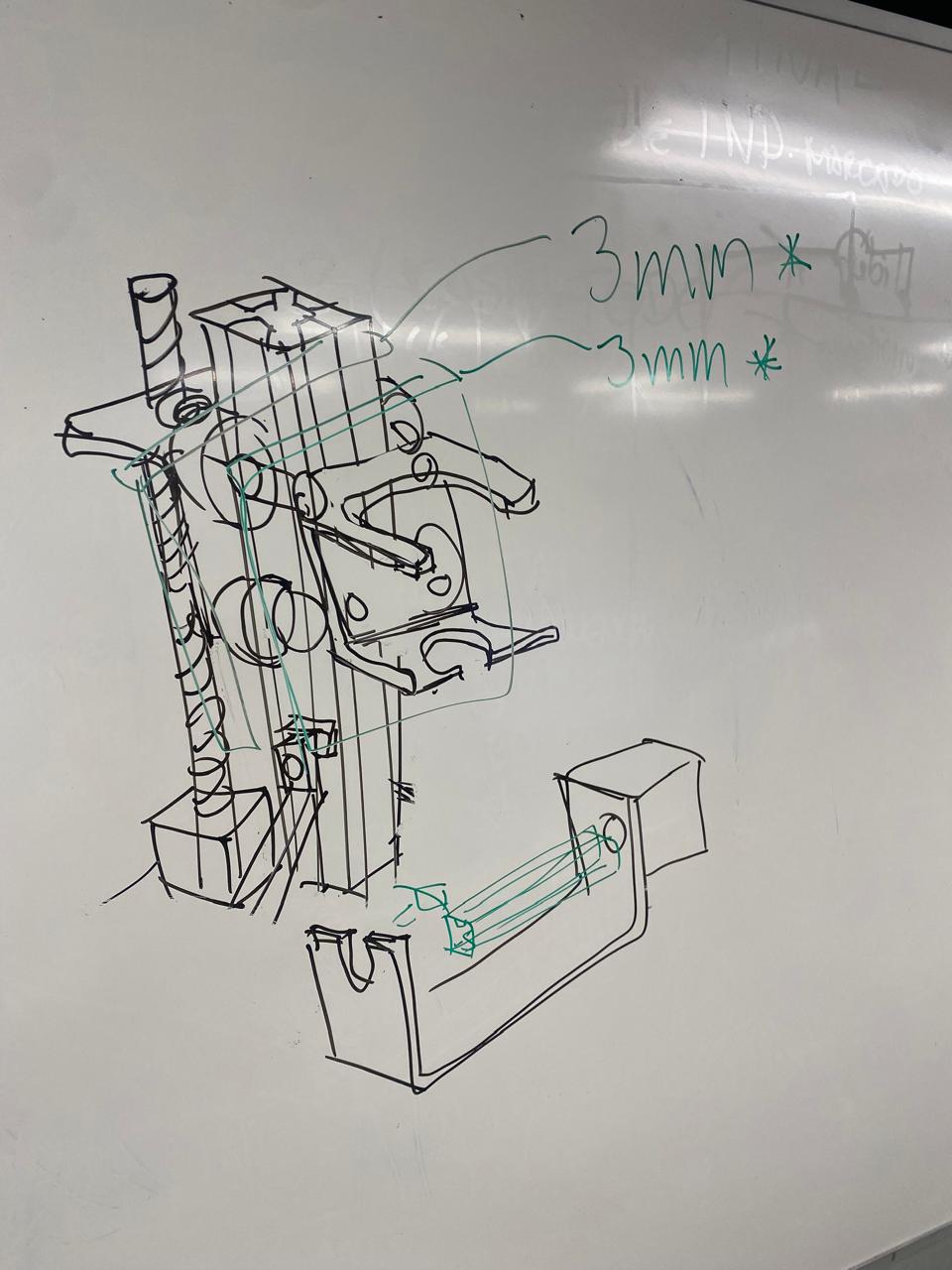

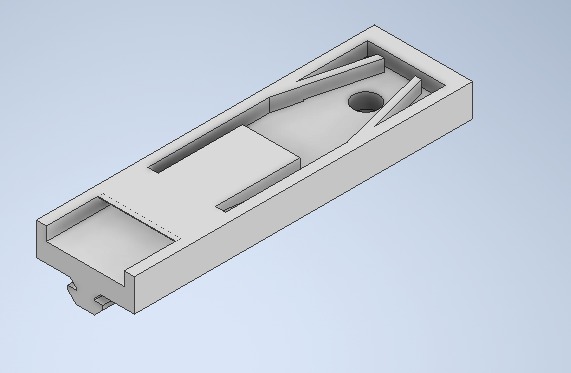

This is another idea that I proposed for the design of this drum, in a section view:

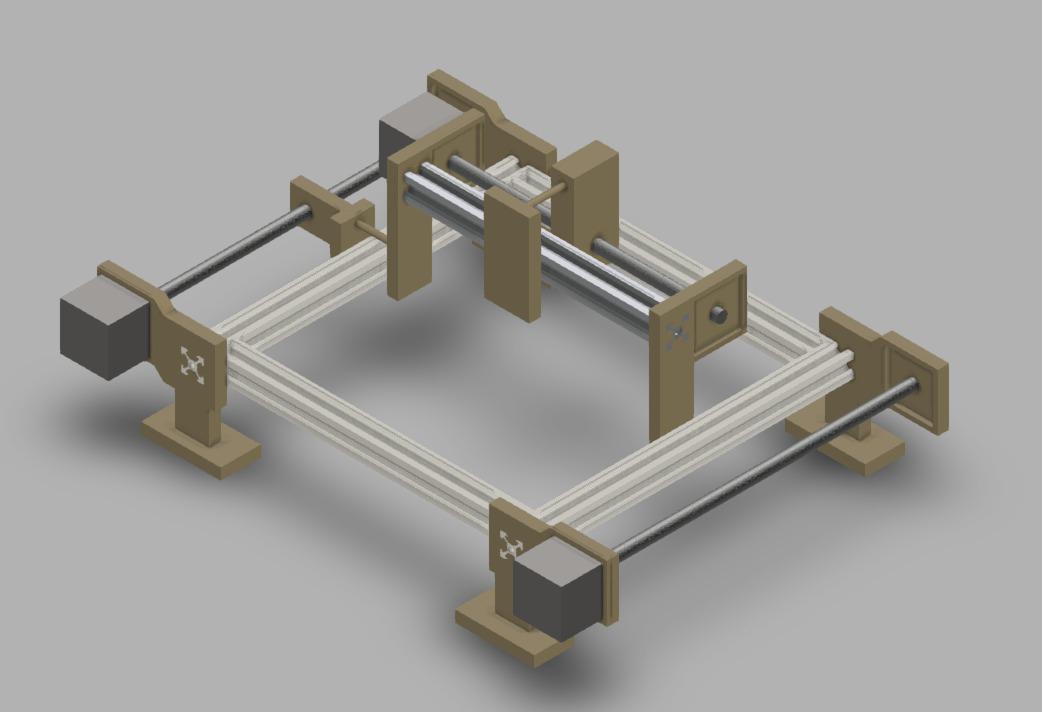

Finally, and after several changes and discussions, we managed to generate a total computer design based on the initial sketches.

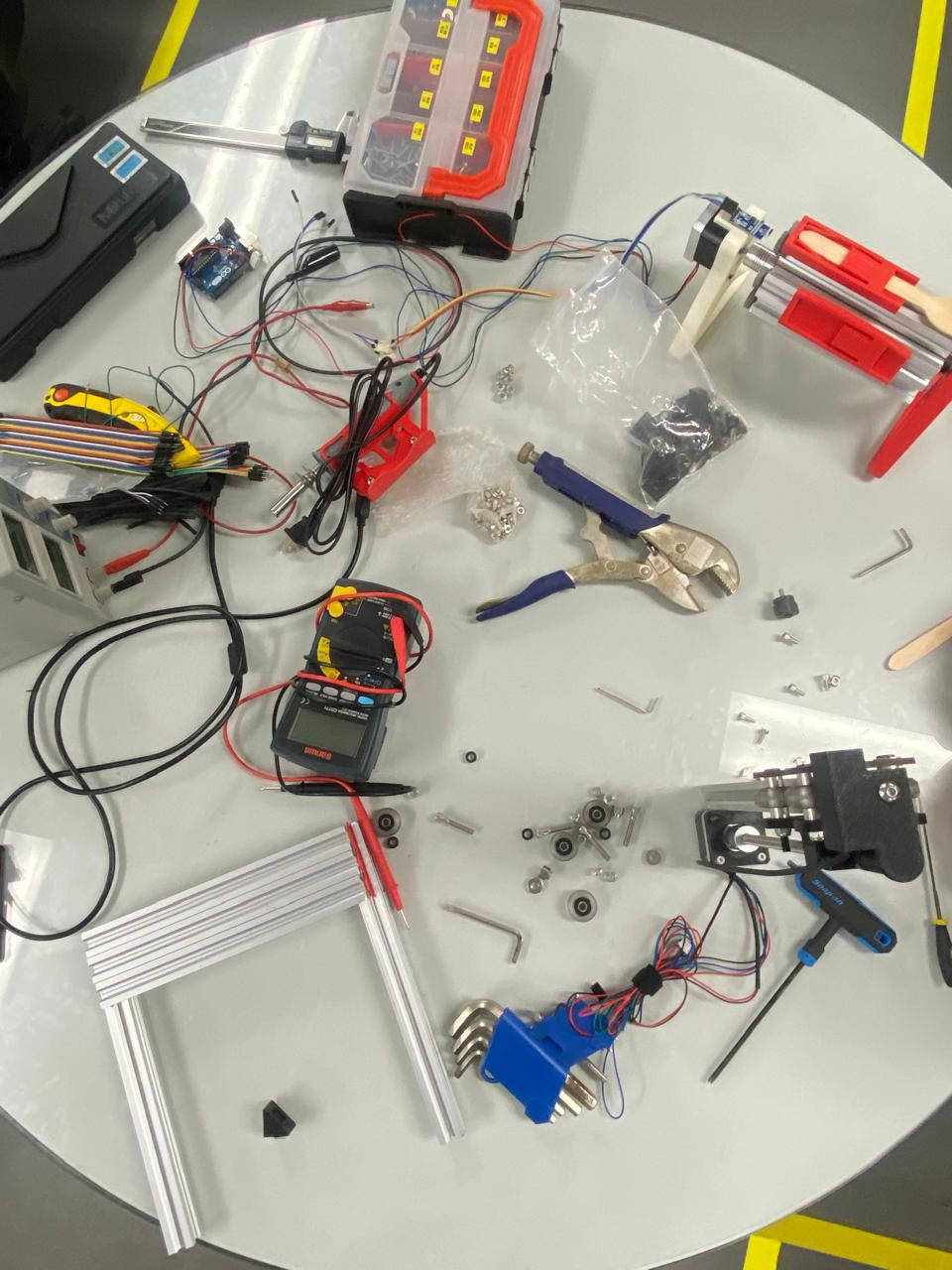

Another contribution I made to the manufacturing of the machine was assembling and connecting the electronic components.

Additionally, I designed and printed the system that would hold the cutlery. This was a bit challenging, since this design had to contemplate the quick change of the cutlery as well as the necessary support so that they did not fall while the drum rotated.

In some tests, the holder did not hold the cutlery as well and they fell off the drum.

Therefore, the design had to consider holding a range of thicknesses and also holding them not so tightly so that they can be easily removed manually, and not so soft so that they do not come off during rotation.

So, after testing, I designed a system in which we could hold commercial ranges of thicknesses of cutlery, whether made of wood or plastic. It consists of having an inclined slope where the cutlery is inserted. The further the cutlery is inserted, the more subject it will be (solving the thickness problem) and since it is an inclined slope, it will only adjust a force given by its geometry.

Also incorporate a guide at the end after all the cutlery has been inserted, since the pyrography only lowers on an established axis.

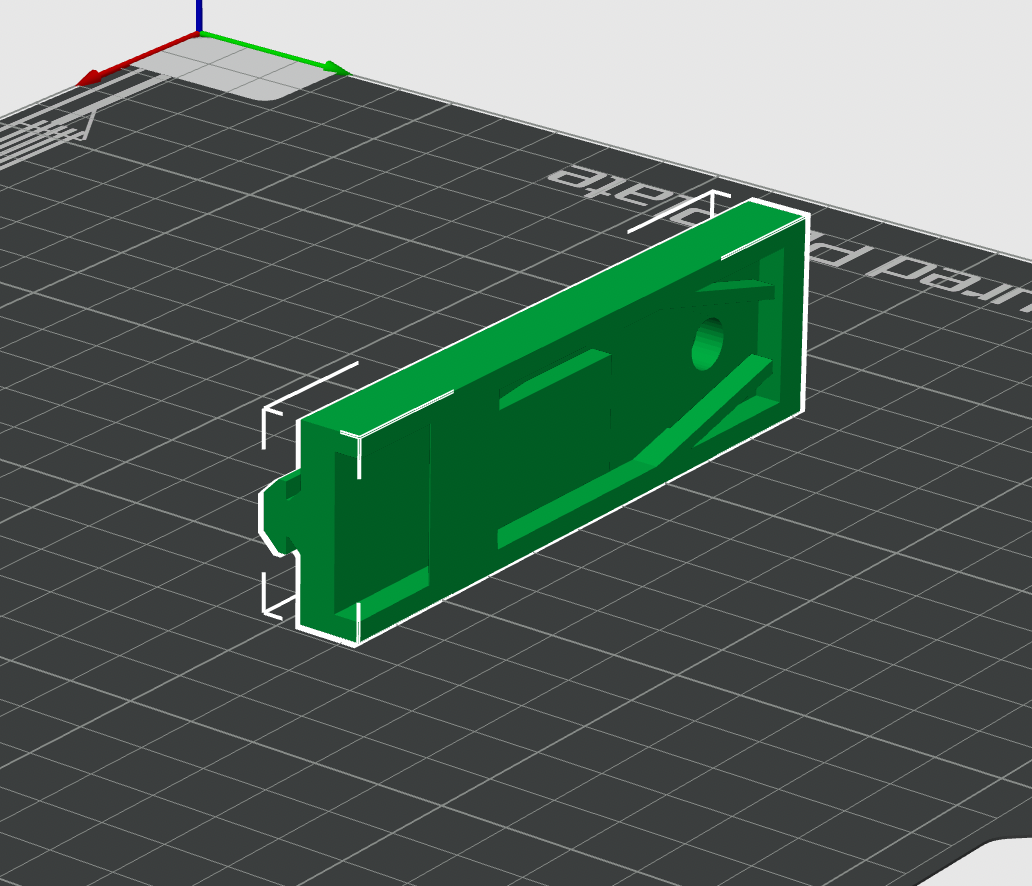

Finally, I printed several designs on the bambulab carbon printer, considering that the support would be a bit difficult to remove and could damage some parts.

Group assignment

What I learned these 2 weeks was how to work on a complete design as a group. While my colleagues advanced one part of the design and I another, we had to agree on measurements. In addition, to integrate the entire machine and use heat-shrinkable coatings for joining cables, after having soldered them. Finally, to share the progress, challenges, and solutions with the group.

Here is the link to the group assignments: