DAY-06

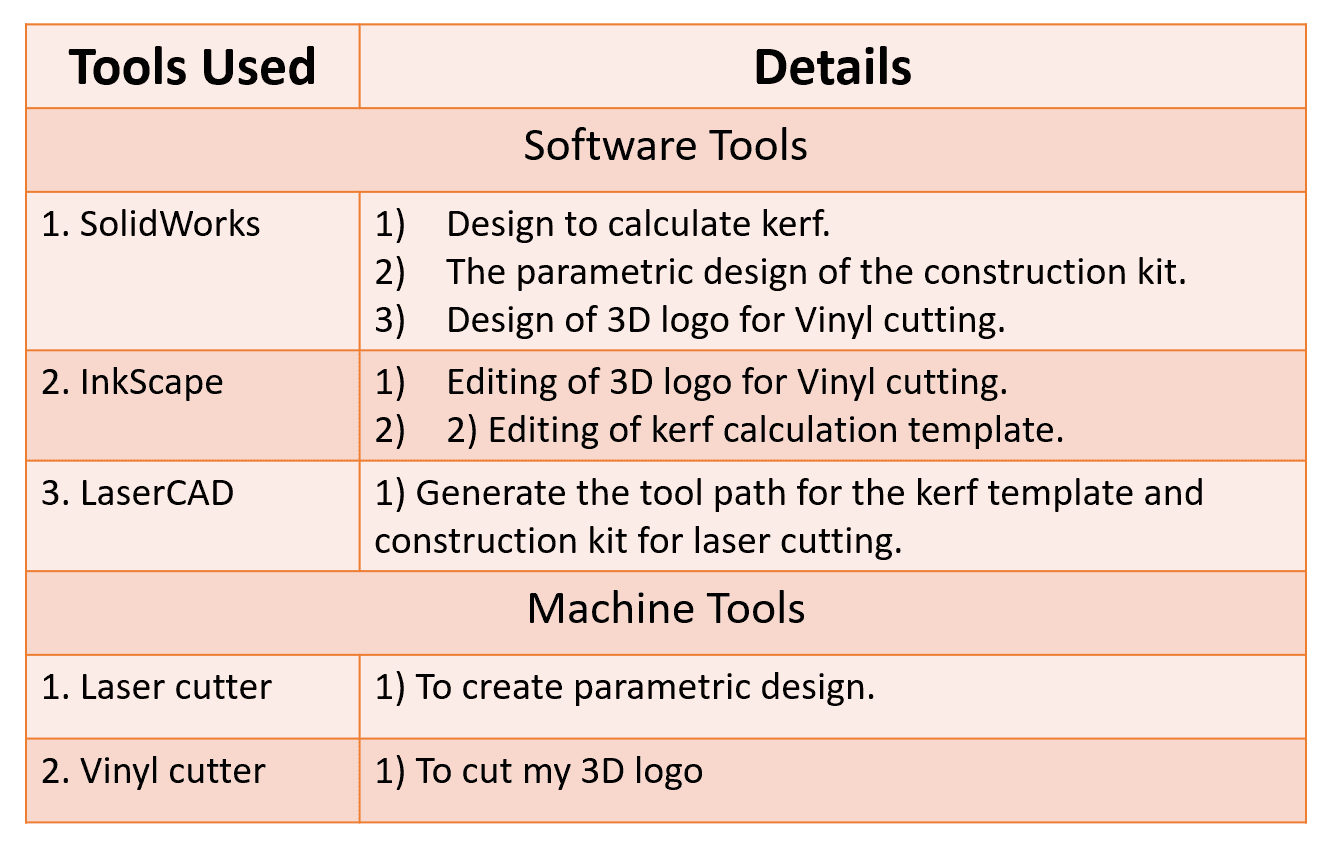

On the 6th day I started working on my assignments. Here is the list of Software and machine tools which I have used during my assignment.

1. Laser Cutting

Starting with laser cutting, the Sanjivani Fab Lab owns 100-watt CO2 Laser Cutting and Engraving Machine by India's first laser machine manufacturing company SIL-Suresh Indu Lasers Pvt. Ltd.

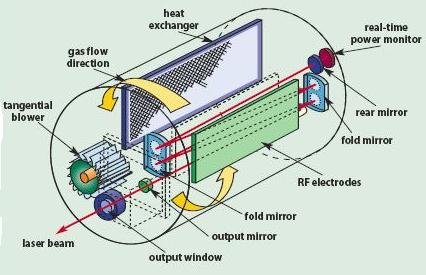

What is CO2 Laser Cutting?The word "CO2 Laser" stands for carbon dioxide laser. The machines uses CO2 to generate a laser beam that can cut and engrave a wide range of materials, known as a "CO2 Laser Cutter."

It is one of the most popular types of lasers because of its fast-cut speed, accuracy and superior cutting power.

What are its applications? The highly precise CO2 laser cutter are generally used for manufacturing processes in small as well as in large industry. Also, it can be used for educational purpose in schools and colleges. And hobbyists who want fast and flawless results on their projects and production lines.

How do CO2 lasers work?

Basically, it uses a stream of energised carbon dioxide to generate an intense beam of light that will cut, mark or engrave different materials. A CO2 laser machine has high pressure, gas filled tube with mirrors at each end and these mirros reflect the light generated by the energised CO2, forward na d backward direction which helps to amplify the beam of light. When the light reaches the desired intensity level, you can easily cut or engrave your chosen material.

Software used for CO2 laser:-

Here, I have used "LaserCAD" software to import my ".dxf" file into Laser cutter. First of all, I have design my 2D deawing in SolidWorks

and convert it into ".dxf" file.

What mterials can a CO2 laser cut?The CO2 laser is a very powerful and precise laser. It efficiently cut and engrave different material including MDF, Cork, Fibreglass, Rubber, Wood, Plastic, Acrylics, Cotton, Polyester, Other types of cloth materials, Cardboard, Paper, etc.

Based on the type of material, you have to set Power and Speed of laser which we have characterised in our group assignment.Click here to see more about Group Assignment.

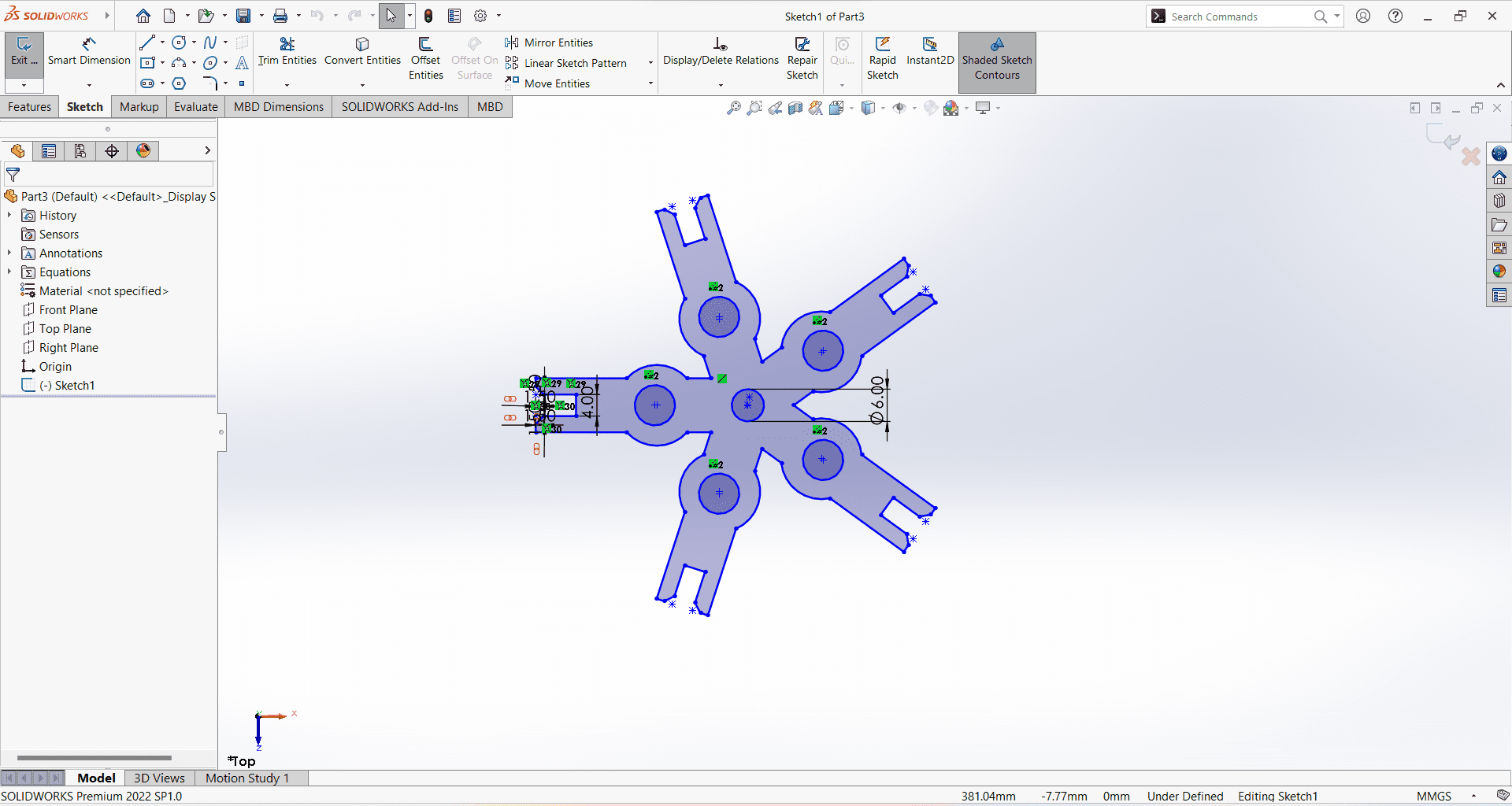

Now, I started designing my idea. So, I have designed a parametric drawing of five hand artistic design part with proper dimensions are as follows.

Here, I have drawn this design using SolidWorks software. I used "rectangle", "circle", "line" feature to draw simple geometry of my part. Also, I used "Circular pattern sketch" feature to draw the existing geometry into five circular pattern. I used "trim" feature to delete unwanted geometry from sketch. And "dimension" feature to give exact dimension with units to my sketch.

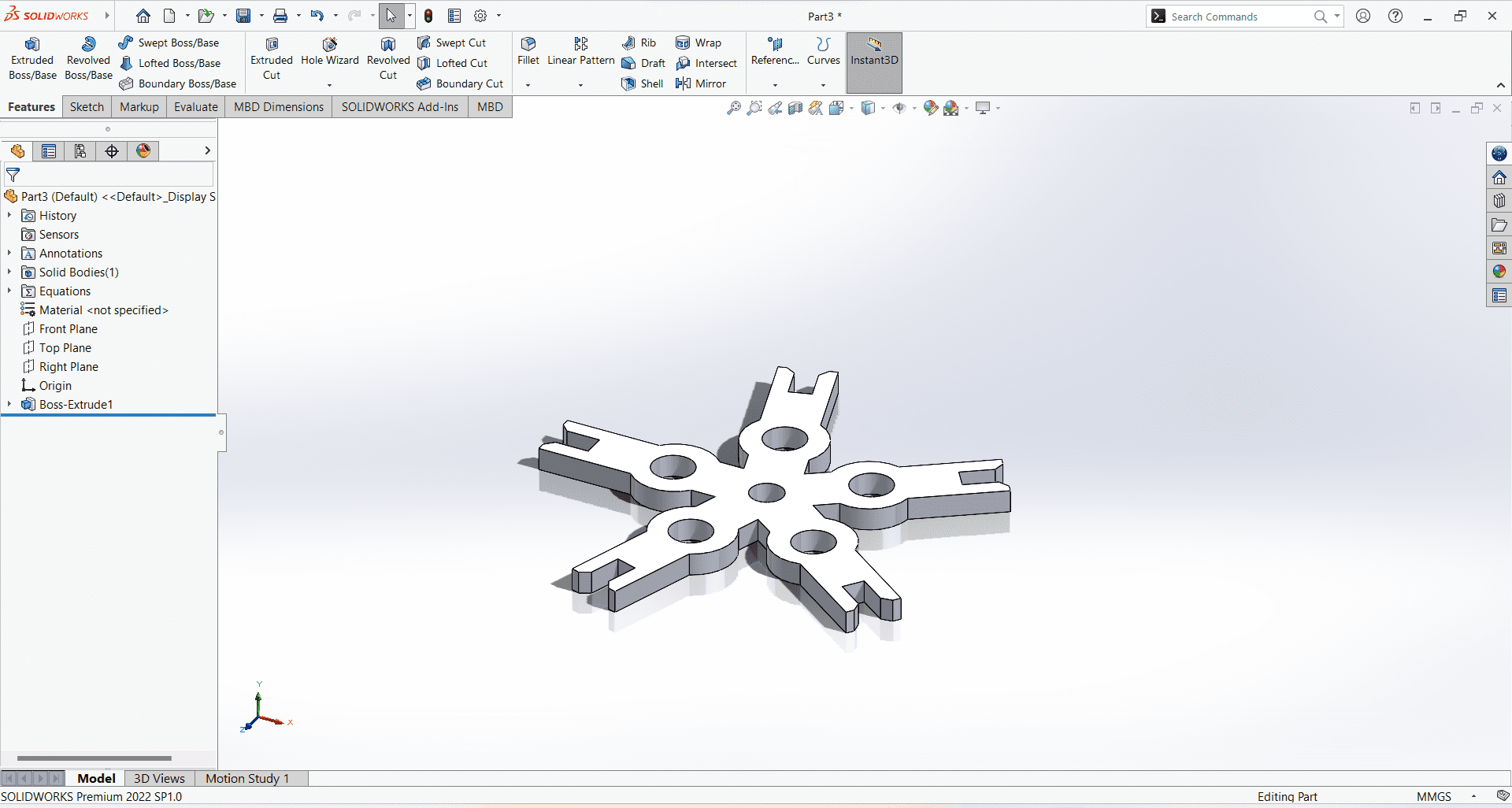

Above is the 3D model of my part using "extrude" feature which I have extruded it with 6mm.

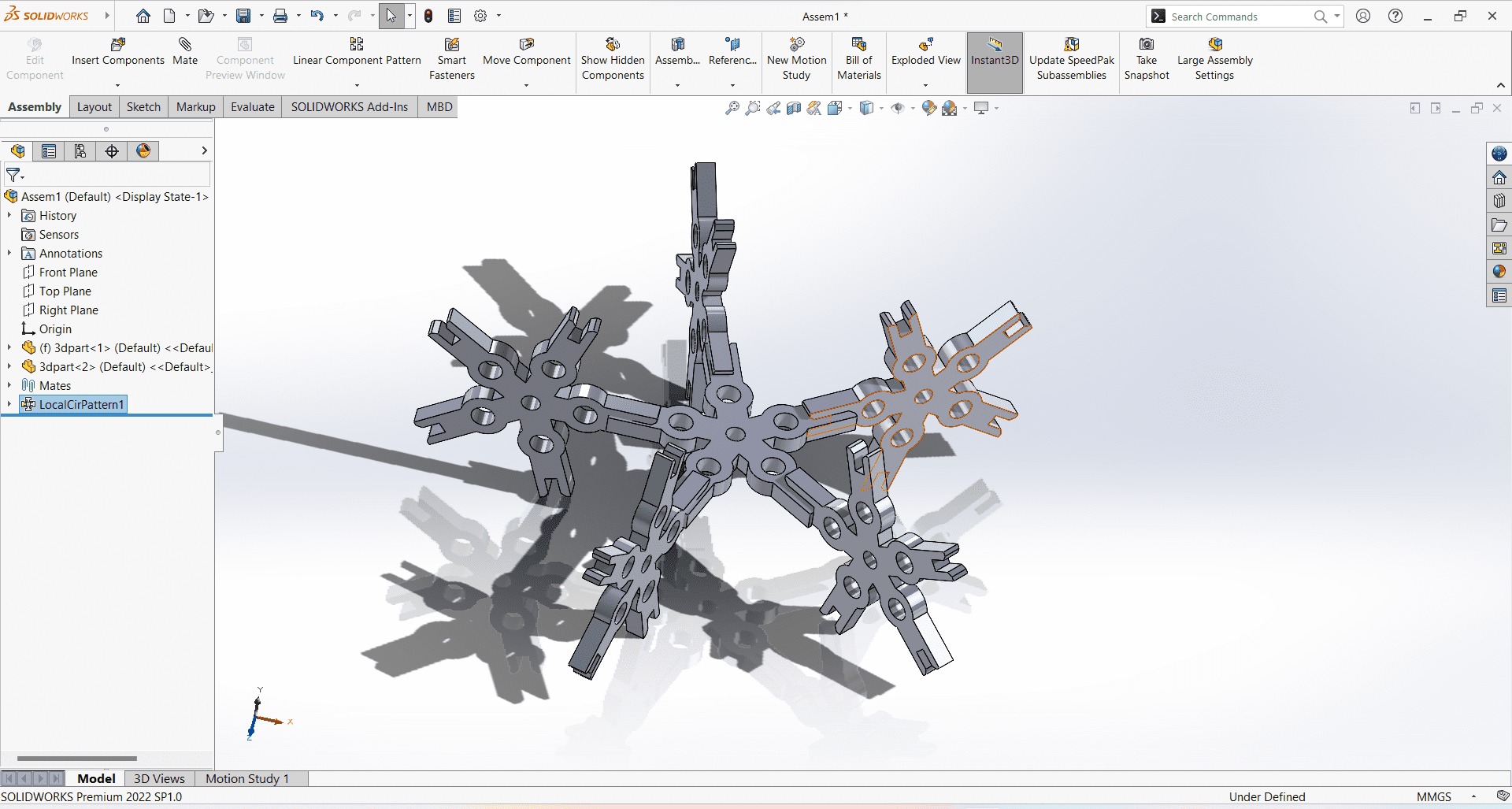

Here is the assembly of my design in SolidWorks.

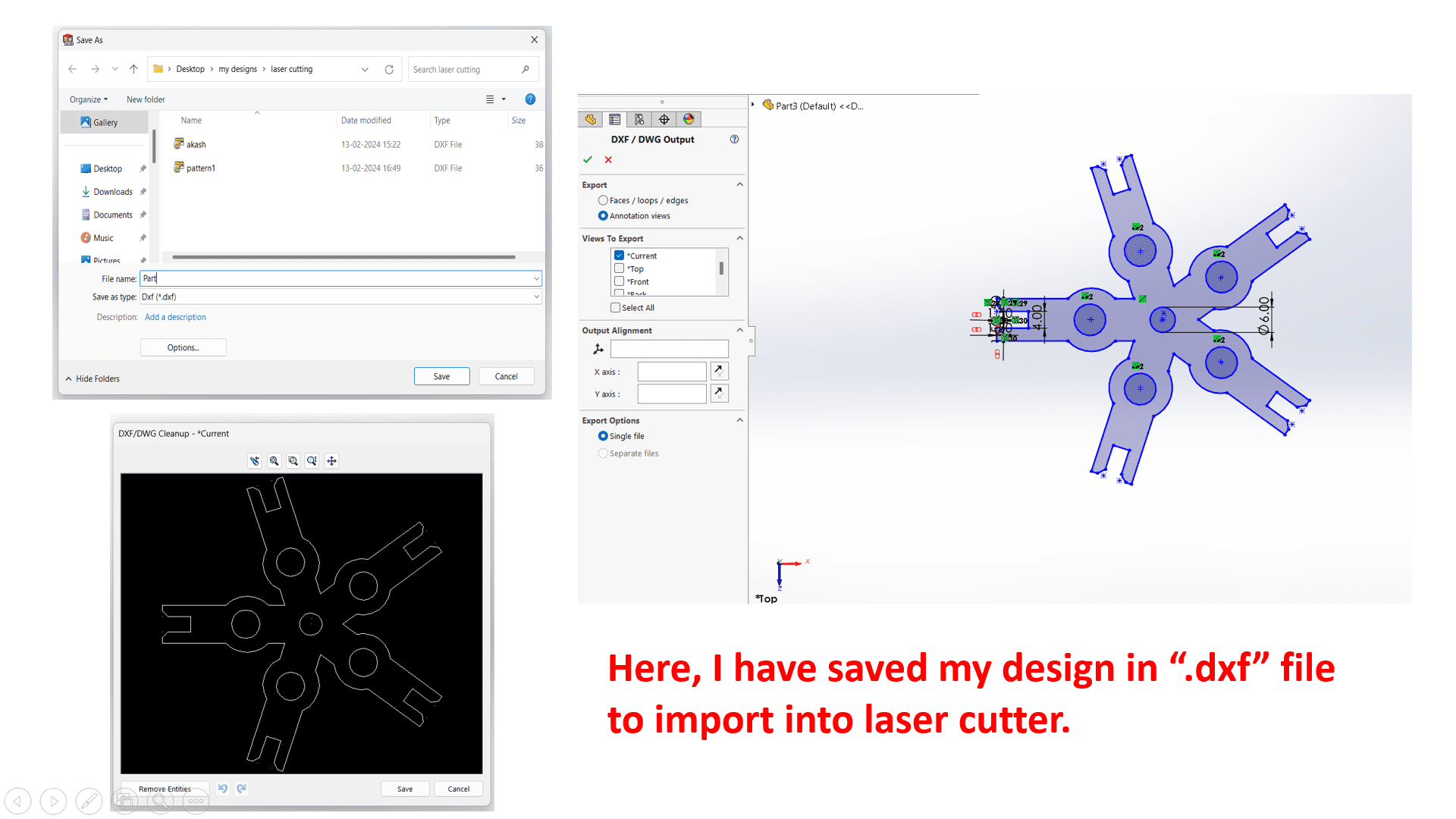

Now, I started laser cutting of my design. Firstly I saved my design in ".dxf" file from SolidWorks to import this file in laser cutter.

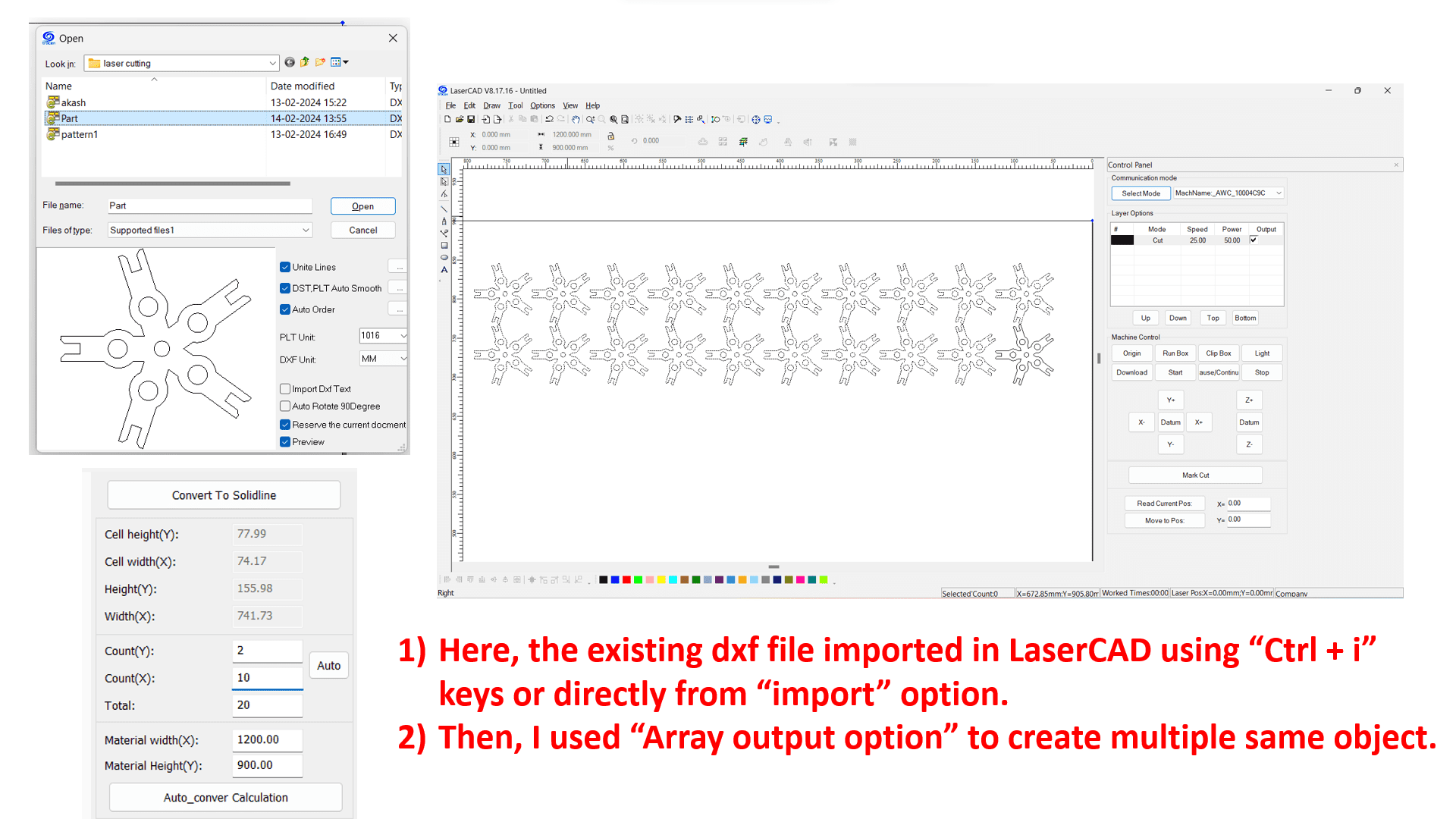

Here, I have imported the existing dxf file into LaserCAD to import into laser cutter using "Ctrl + i" keys or "import" option. Also. I have set the laser cutting parameters as 30mm/s speed and 38% power.

Before, cutting I have adjusted laser nozzle in Z-plane at a distance of 6mm from surface of material using "Display" of laser cutter according to Do's and Don'ts given by SIL Pvt.Ltd.

Here, is the video of cutting operation of my parts using laser cutter by taking all the precautions.

Here, you can see the real model of my design and the joining method of two parts.

Here are some glimpse during assembling all the parts to create parametric designs. It is very easy and enjoyable assembly which create numbers of different designs.

Finally, I have created some different parametric designs from similar type of parts using laser cutter. I have also calculated kerf of the material I have used i.e Cardboard. The original thickness of Cardboard is 4mm and after cutting it becomes 3.85mm. So, here I got kerf of 0.15mm for my part.

For this assignment, I focused on creating five unique artworks shaped like hands. Parametric design involves using math-based rules to adjust shapes easily, like changing their size or details. This allowed me to play around with different dimensions and styles for each hand design while keeping them all connected by a common theme.

After finalizing these designs on SolidWorks, I used a laser cutter to carefully cut them out from cardboard. The laser cutter is really precise, ensuring the edges are clean and each hand shape looks exactly how I planned. What's cool about parametric design is that it lets artists like me explore lots of variations of the same idea, tweaking details to create different looks while staying true to the original concept.

This assignment showed me how parametric design combines creativity with systematic control. By adjusting parameters like size or shape, I could create diverse artworks that all stemmed from the same initial idea of hand shapes. It's a method that not only enhances artistic expression but also demonstrates how technology can make art-making more precise and adaptable. Each hand artwork I made tells its own story, reflecting the versatility and creative possibilities of parametric design in modern art.

2. Vinyl Cutting

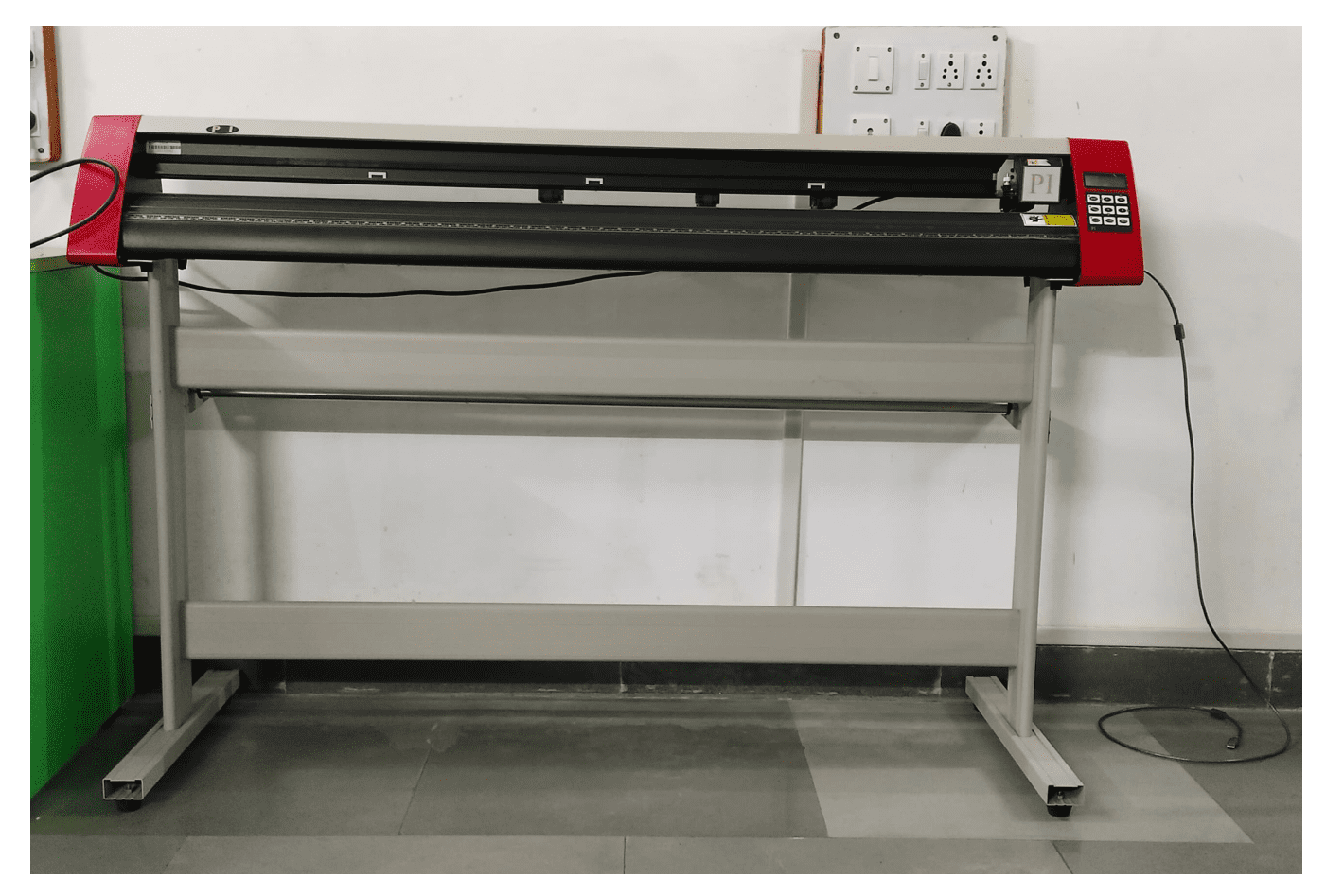

Now, moving towards next technology of cutting known as Vinyl Cutting. Sanjivani Fab Lab owns Vinyl cutter that operates within the voltage range of 85V to 264V and requires a current of 1Amp to cut any shape from vinyl material.

What is vinyl cutter? Vinyl cutting machines are computer controlled devices that use a sharp blade to cut designs and shapes from vinyl sheets or other materials. They are commonly used for creating some designs, logos, name plates,etc.

How it works? As we know, Vinyl cutter is a type of computer controlled machine tool. The computer controls the movement of sharp blade of nozzle to cut out shapes and letters from sheets of thin adhesive vinyl.

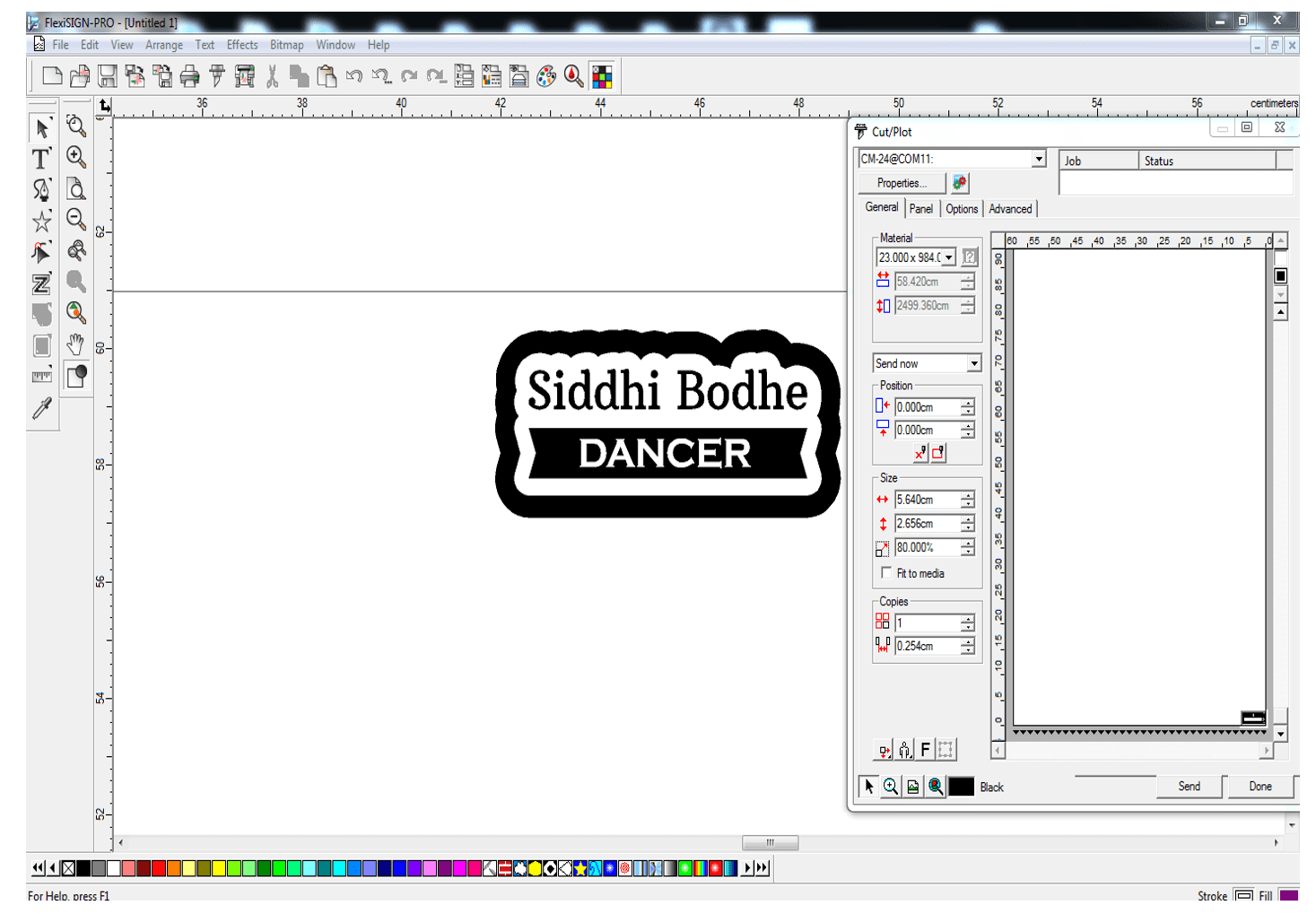

Now, I started for completing my assignment on Vinyl Cutter.I wanted to make my name logo to pasted on my laptop. Before cutting this design, I designed my logo into "CorelDRAW" software as shown in above picture.

Here, I have inserted my design which I have saved as ".eps" file into "FlexSIGN-PRO" software which is basically used to import file into vinyl cutter. Also, I set all the required parameters including size.

Here is the video of how vinyl cutter cuts any design.

Finally, I got my logo in proper cutting phase. While pasting this logo on my laptop, I was struggling to cut text portion but it was a fun activity. so, here are some glimpse of mine while pasting my logo.