Week 16: Applications and implications & Project development

Some questions and answers about my final project

What will it do?

- Attract and Kill Mosquitoes: Use UV and blue lights to attract mosquitoes and a fan to suck them into a container, effectively reducing mosquito populations without using chemicals.

- Monitor Air Quality: Continuously measure air quality by detecting harmful gases like NH3, NO2, CO2, Humidity and Temperature, providing real-time data on environmental conditions.

- Enhance Public Health: Reduce malaria transmission and monitor air pollution, contributing to overall community health and well-being.

- Operate Sustainably: Utilize solar power for eco-friendly operation, functioning during the day and storing energy in a battery for nighttime use.

- Provide Data for Decision-Making: Supply valuable data to authorities and communities for informed decisions on public health and environmental interventions.

Who Did It Before?

- Various Researchers: Studies have been conducted on using UV and blue lights to attract and kill mosquitoes. For example, research on transmitted light as an attractant for mosquito traps in urban Bangkok, Thailand.

- Commercial Manufacturers: Companies have developed solar-powered mosquito killers and air quality monitoring devices separately, but the integration of both functions into a single device is relatively new.

- Public Health Initiatives: Some public health programs in malaria-endemic regions have experimented with environmentally friendly mosquito control methods, though primarily focusing on standalone mosquito traps or nets rather than combined systems.

- Operate Sustainably: Utilize solar power for eco-friendly operation, functioning during the day and storing energy in a battery for nighttime use.

- Environmental Monitoring Projects: Numerous projects worldwide have implemented air quality monitoring systems using sensors like the MQ135 to track pollution levels and inform policy-making.

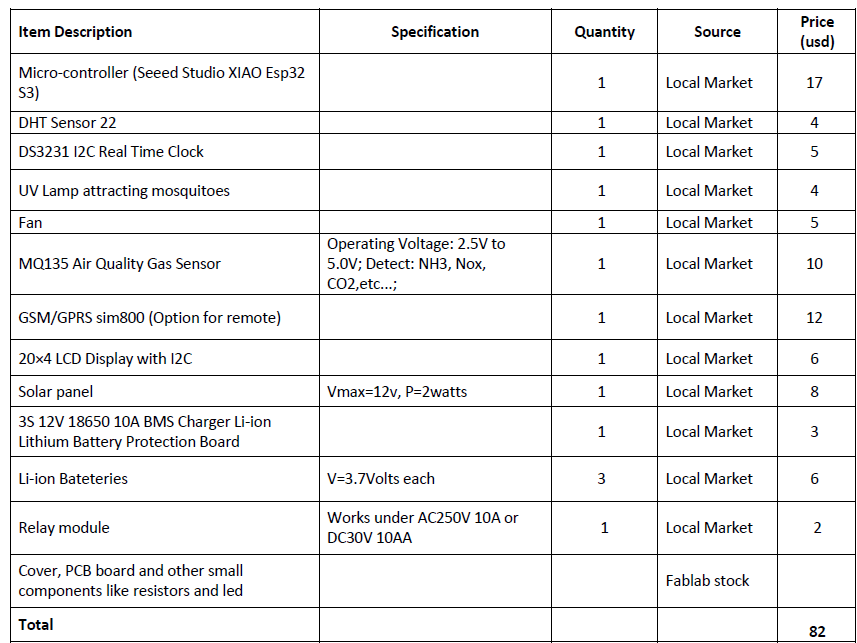

What materials and components will be required?

Some materials are available in Fablab Rwanda Stock and the reamaing raw materials will be found locally in the available shops of elecronics and the web dashboard I will use open source tools.

How much will it cost?

What parts and system will be made?

The smart solar-powered mosquito killer will comprise several integrated parts and systems. The mosquito attraction system will include UV and blue light lamps designed to attract mosquitoes and a fan mechanism to suck the mosquitoes into a container. The power system will consist of solar panels to harness solar energy during the day, rechargeable Li-ion batteries to store energy for nighttime operation, and a Battery Management System (BMS) to protect and manage the charging and discharging of the batteries.

The control system will feature a Seeed Studio XIAO ESP32 S3 micro-controller to oversee the operation of lights, fans, and sensors, alongside a single-channel relay module to switch the lights and fan on and off based on the time of day and sensor inputs. The air quality monitoring system will include an MQ135 air quality gas sensor to detect and measure levels of harmful gases such as NH3, NOx, and CO2, as well as a DHT22 sensor for monitoring temperature and humidity.

To ensure accurate timing for automated operations, a DS3231 I2C real-time clock (RTC) will be used. For data display and communication, a 20×4 LCD display with I2C will show real-time data on air quality, temperature, humidity, and device status, while a GSM/GPRS SIM800 module will facilitate remote data transmission and communication, enabling monitoring and control via a mobile network.

All these components will be housed in a protective enclosure to shield them from environmental factors, and appropriate mounting hardware will be used to secure the solar panels, sensors, and other components. This integration of parts and systems will result in a functional and efficient smart solar-powered mosquito killer with an air quality monitoring facility, offering a sustainable solution to reduce mosquito-borne diseases and monitor environmental conditions.

What parts and system will be made?

The procedures for developing and deploying the smart solar-powered mosquito killer with an air quality monitoring facility begin with comprehensive design and planning. This involves defining project requirements and creating detailed schematics. Component procurement follows, ensuring the purchase of compatible and high-quality parts such as the micro-controller, sensors, UV and blue light lamps, fan, solar panels, batteries, BMS, relay module, LCD display, RTC, and GSM/GPRS module.

The assembly phase involves building the power system by connecting the solar panels, batteries, and BMS. Next, the mosquito attraction system is assembled with UV lights and a fan, followed by integrating the control system with the micro-controller, lights, fan, sensors, and relay module. The air quality monitoring system, including the MQ135 gas sensor and DHT22 sensor, is then set up, along with the RTC and LCD display for timekeeping and data visualization. The GSM/GPRS module is added for remote communication.

Programming entails developing and uploading code to the micro-controller to automate functions such as controlling lights and fan, reading sensor data, managing power usage, and transmitting data remotely. Testing and calibration are crucial to ensure proper functionality. This involves individual component tests, sensor calibration, and integrated system tests, followed by necessary adjustments based on results.

The device is then enclosed in a weatherproof housing, with solar panels mounted for optimal sunlight exposure, and securely positioned within the enclosure for deployment. Once deployed, the device is monitored regularly to collect data on mosquito capture rates and air quality, with adjustments made to enhance efficiency and reliability.

What is the schedule?

Project Timeline

| Activity | Dates | Description |

|---|---|---|

| Concept Development and Planning | 08/01/2024 - 12/01/2024 | Develop project concept, define scope, and initial planning. |

| Research and Requirements Gathering | 13/01/2024 - 15/02/2024 | Conduct research, gather requirements, and analyze feasibility. |

| Design and Prototyping | 16/02/2024 - 15/03/2024 | Design project components, create prototypes, and develop core functionalities. |

| Testing and Debugging | 01/04/2024 - 30/04/2024 | Perform testing, debug issues, and ensure functionality meets requirements. |

| Integration of Modules | 01/05/2024 - 15/05/2024 | Integrate all project modules, ensure compatibility, and conduct system testing. |

| Testing | 16/05/2024 - 25/05/2024 | Conduct Testing, gather feedback, and make necessary refinements. |

| Documentation and Finalization | 26/05/2024 - 04/06/2024 | Prepare project documentation, user manuals, and finalize deliverables. |

| Presentation and Deployment | 05/06/2024 - 12/06/2024 | Prepare for final presentation, showcase project outcomes, and deploy if applicable. |

Starting from midterm

The project schedule for developing and deploying the smart solar-powered mosquito killer with an air quality monitoring facility is organized into eight weeks. In the first week, the focus is on design and planning, including defining project requirements, creating detailed schematics, and developing a power management plan. The second week is dedicated to component procurement, where all required components are sourced, purchased, and verified for compatibility and quality. During the third week, the assembly phase begins, involving the construction of the power system with solar panels, batteries, and BMS, the assembly of the mosquito attraction system with UV lights and a fan, the integration of the control system with the micro-controller, sensors, and relay module, the setup of the air quality monitoring system with MQ135 and DHT22 sensors, the connection of the RTC and LCD display, and the installation of the GSM/GPRS module.

In the fourth week, programming is undertaken, developing and uploading code to the micro-controller to automate the device's functions. The fifth week is dedicated to testing and calibration, including testing individual components, calibrating sensors, conducting integrated system tests, and making necessary adjustments to the code and hardware. The sixth week involves designing and constructing a protective enclosure, mounting the solar panels, positioning the device components within the enclosure, and installing the device at the deployment location.

The seventh week focuses on deployment and monitoring, where the device is deployed in a field setting, and its performance is monitored with data collection. Finally, in the eighth week, Documentation and presentation. This schedule ensures a systematic approach to the project's development, testing, deployment, and evaluation stages.

How will it be evaluated?

- The evaluation of the smart solar-powered mosquito killer with an air quality monitoring facility will be comprehensive and multifaceted, ensuring that all specified requirements and skills are demonstrated effectively.

- Firstly, 2D and 3D design will be assessed through the creation of detailed schematics and 3D models of the device. These designs will illustrate the layout and integration of all components, including the enclosure, mounting system, and internal arrangement. The use of CAD software to produce these designs will be a key evaluation criterion.

- Additive and subtractive fabrication processes will be evaluated by examining the methods used to create the physical parts of the project. Additive fabrication will involve 3D printing certain components, such as the protective enclosure, while subtractive fabrication will involve cutting, drilling, or machining parts as needed. The ability to effectively utilize both types of fabrication processes to produce high-quality, functional parts will be critical.

- Electronics design and production will focus on the development and assembly of the electronic circuits required for the project. This includes designing custom PCB layouts, soldering components, and ensuring proper connectivity and functionality of all electronic parts. The evaluation will consider both the design quality and the practical execution of the electronics.

- Embedded microcontroller design, interfacing, and programming will be assessed by reviewing the code developed for the micro-controller. This will include the implementation of automation features, sensor data collection, and remote communication capabilities. The ability to interface effectively with various components, such as sensors, relays, and the communicaiton module, and to program these interfaces for reliable operation, will be key factors in the evaluation.

- System integration and packaging will be evaluated based on how well the different subsystems are combined into a cohesive, operable device. This includes ensuring that all components work together seamlessly and that the device is packaged in a way that is both functional and aesthetically pleasing. The durability and weatherproofing of the packaging will also be considered.

Flow of work for the final project:

- Design and Planning

- Component Procurement

- Additive and Subtractive Fabrication

- Electronics Design and Production

- Embedded Microcontroller Design, Interfacing, and Programming

- System Integration

- Packaging

- Testing and Calibration

- Deployment and Monitoring

- Documentation and Presentation

PROGRESS OF MY PROJECT

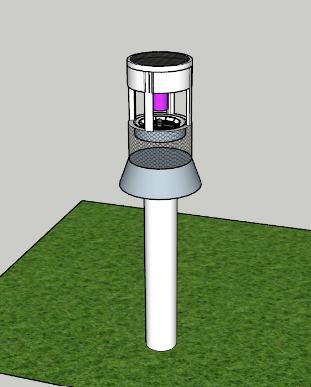

Computer design of planed project

2D Design in Autocad, details in computer-aided assignment

3D Design in sketchup, details in computer-aided assignment

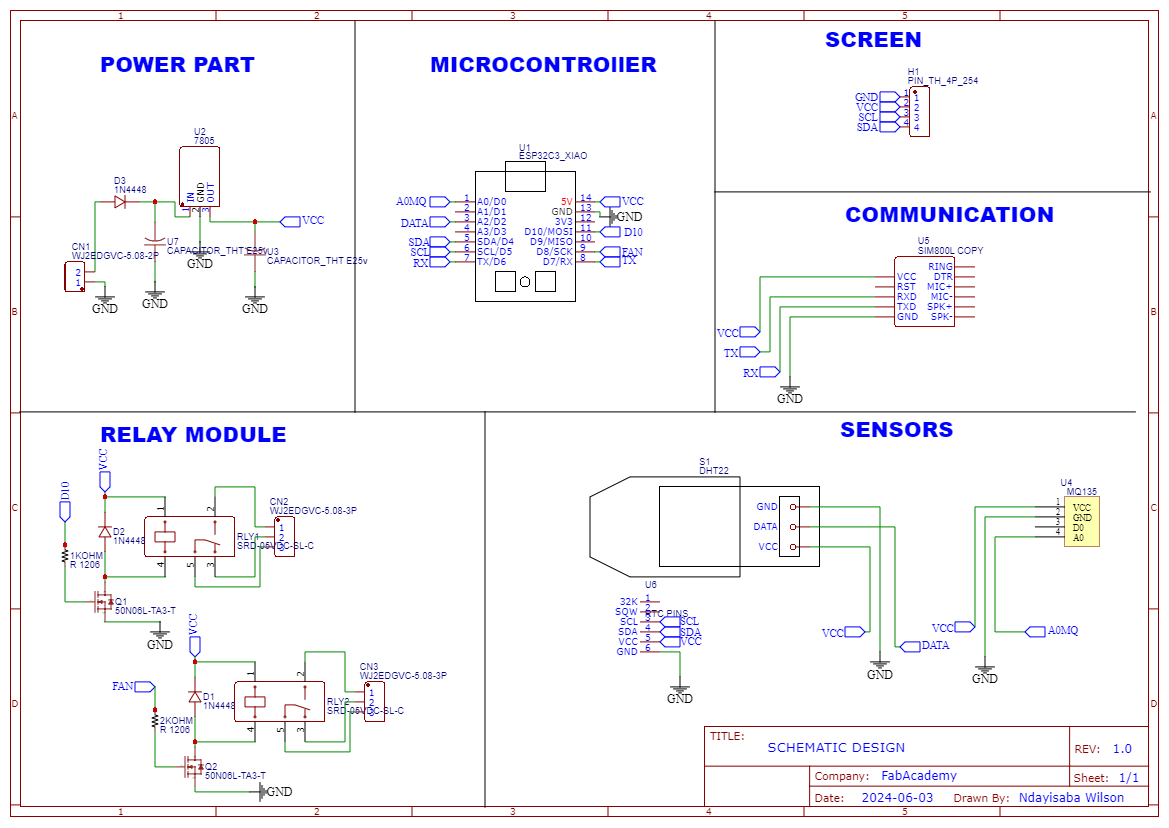

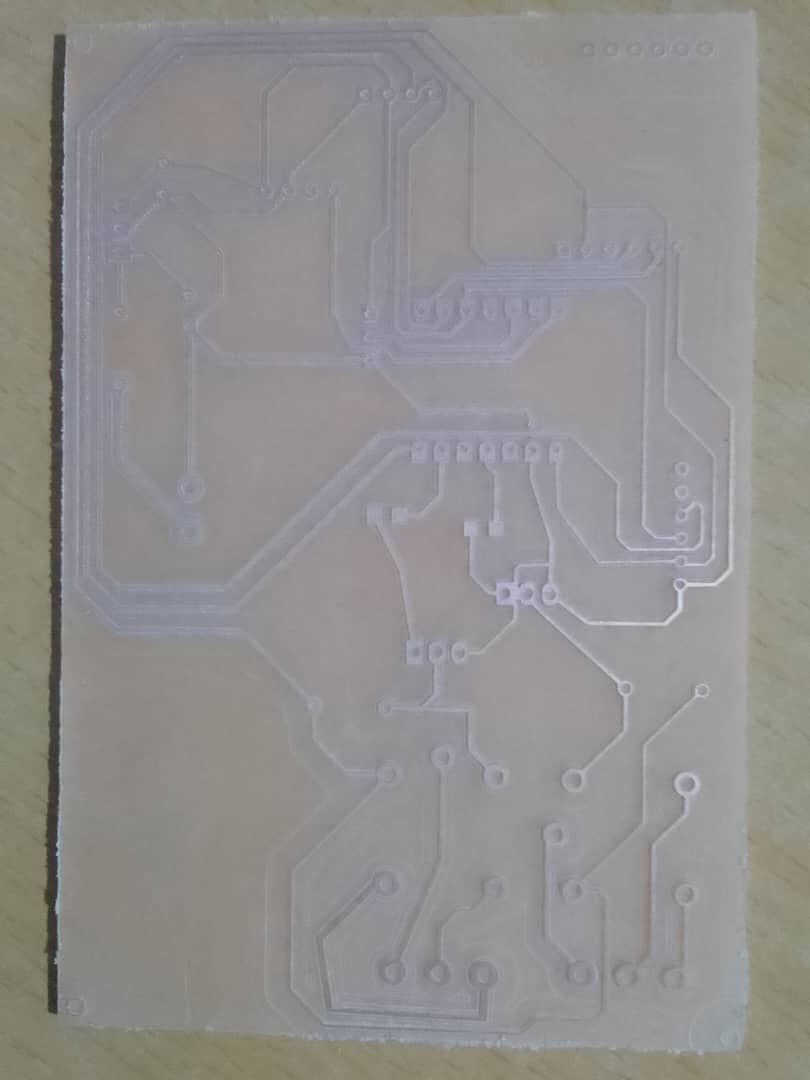

Schematic and PCB designed

Schematic Design

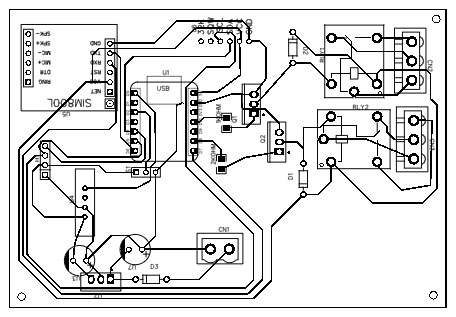

PCB Design

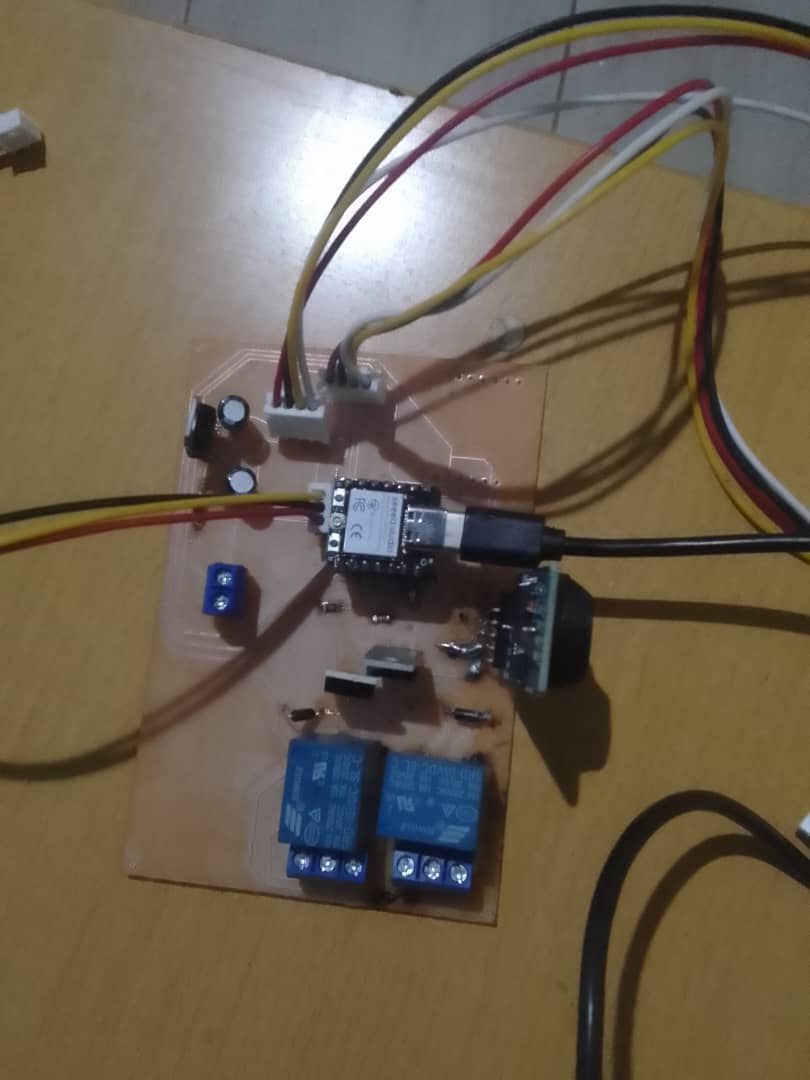

Printed PCB Board and the finishied board

PCB board

Soldered components and tested

The image above shows how the device is sending data in the cloud with the code shown

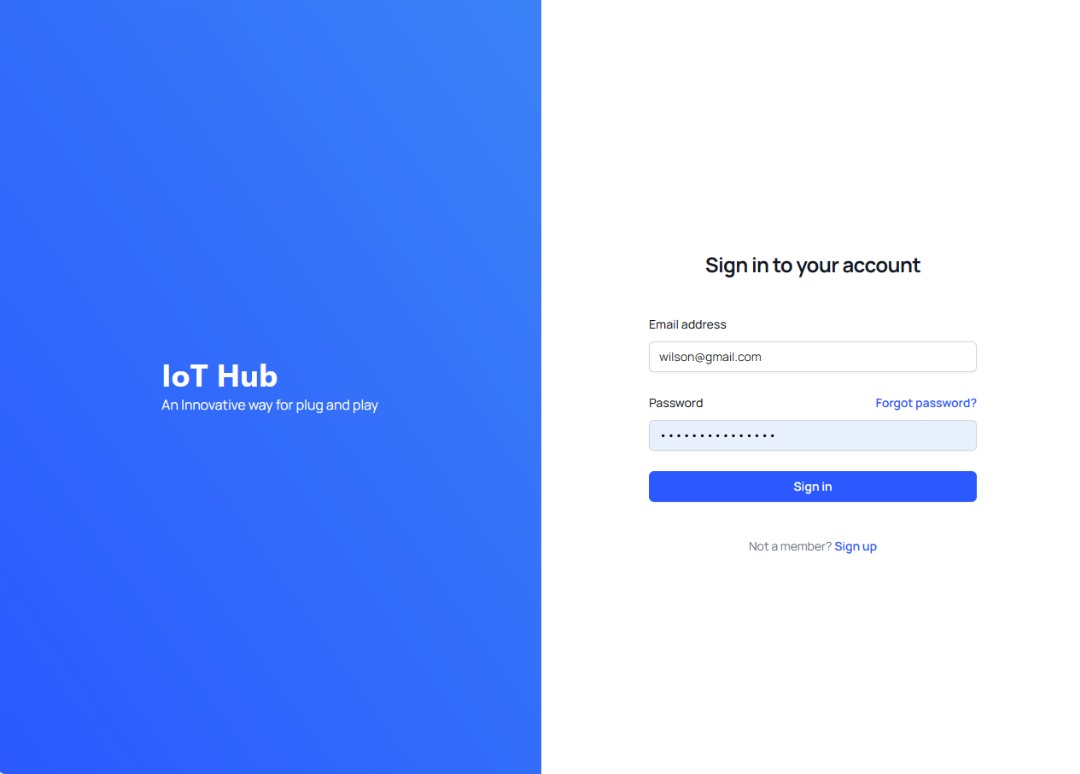

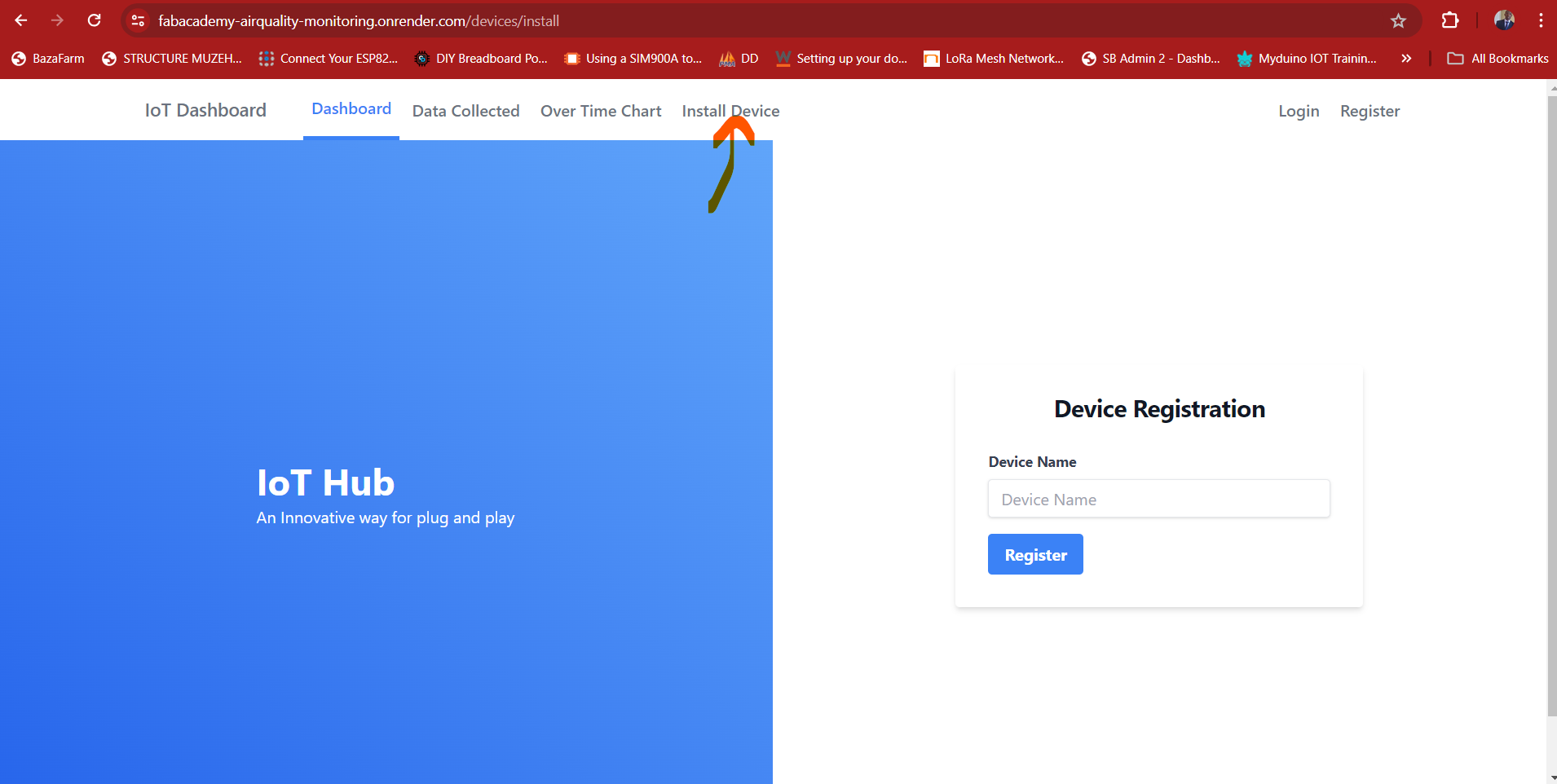

Screenshots of login page and registration of a device

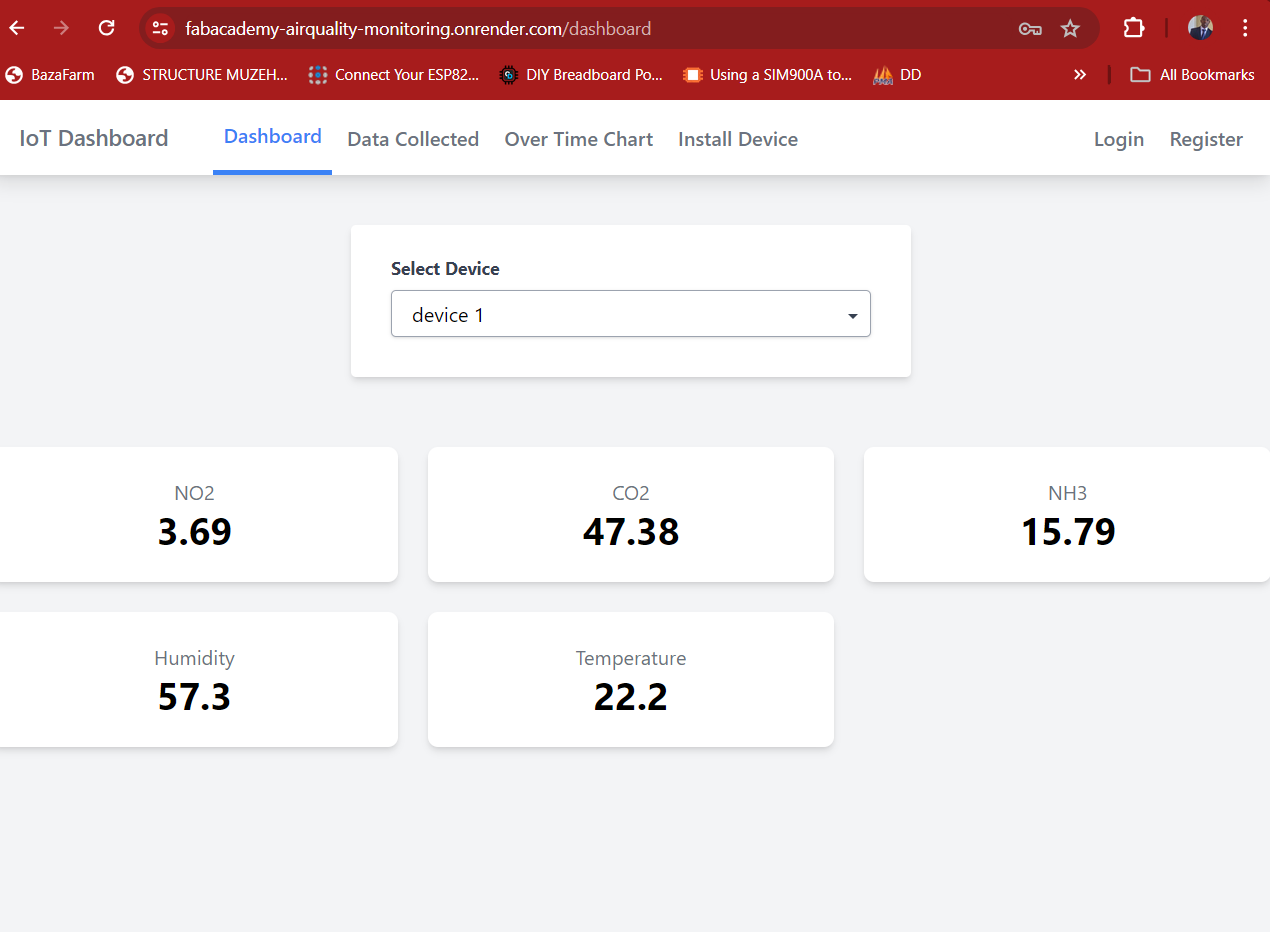

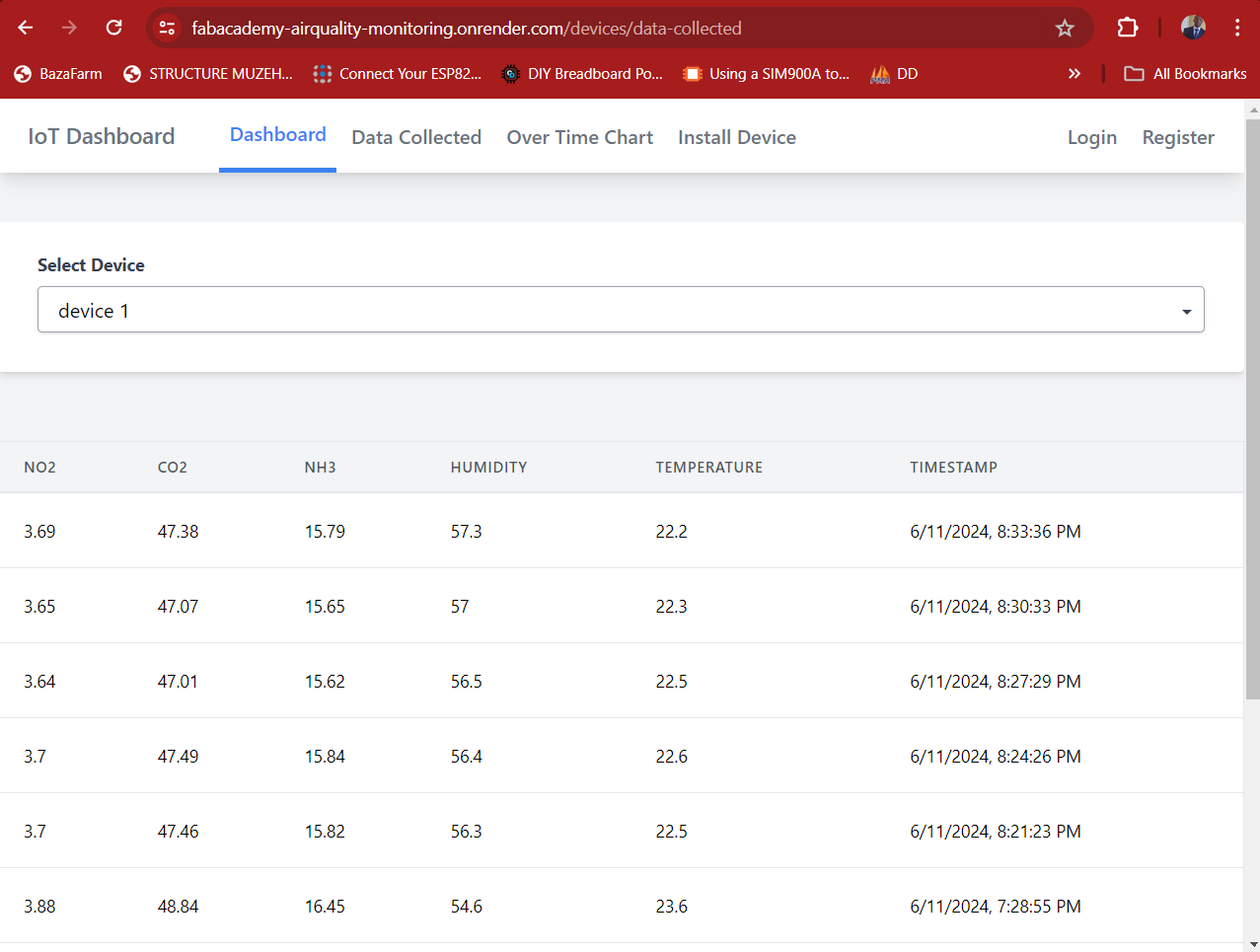

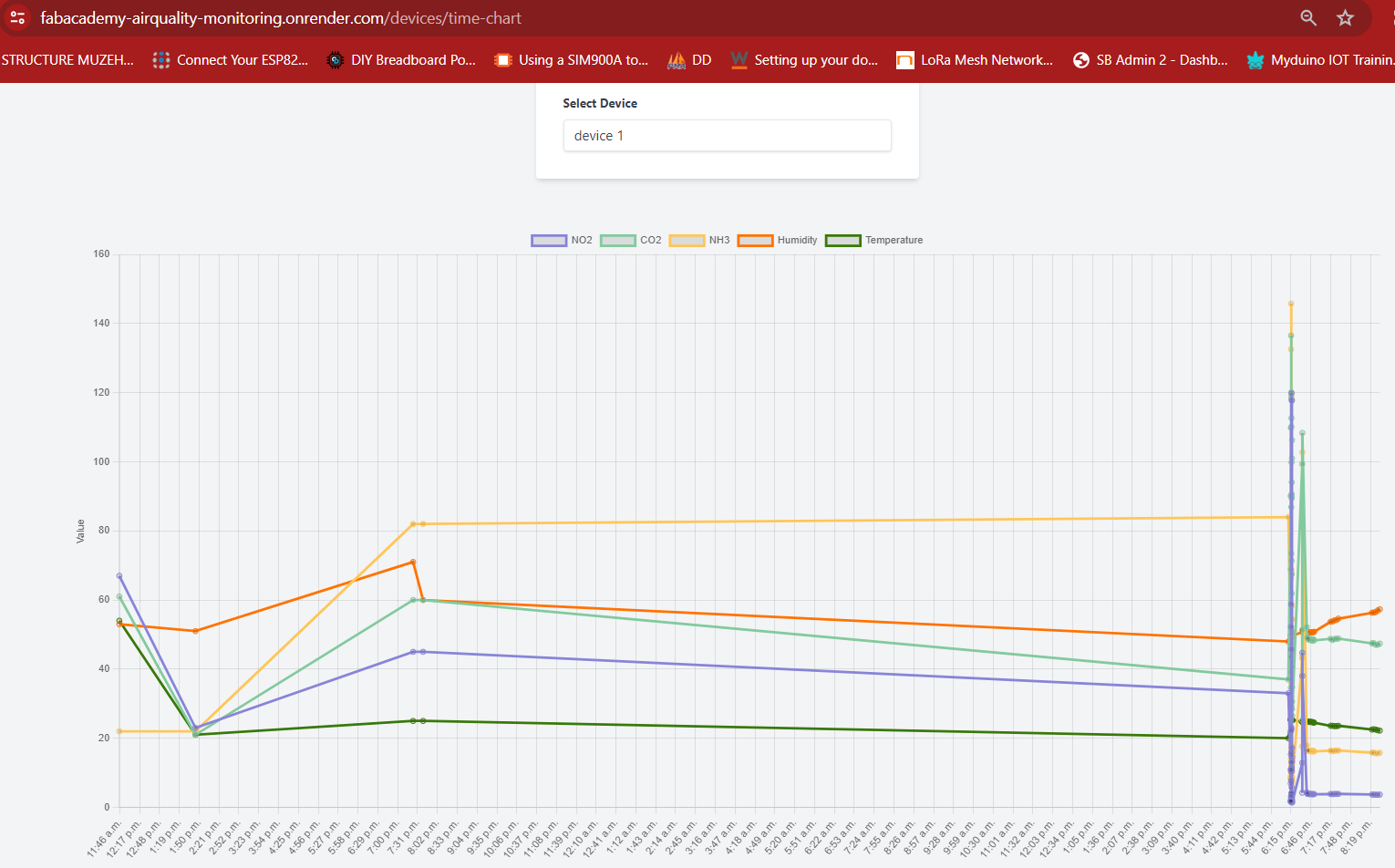

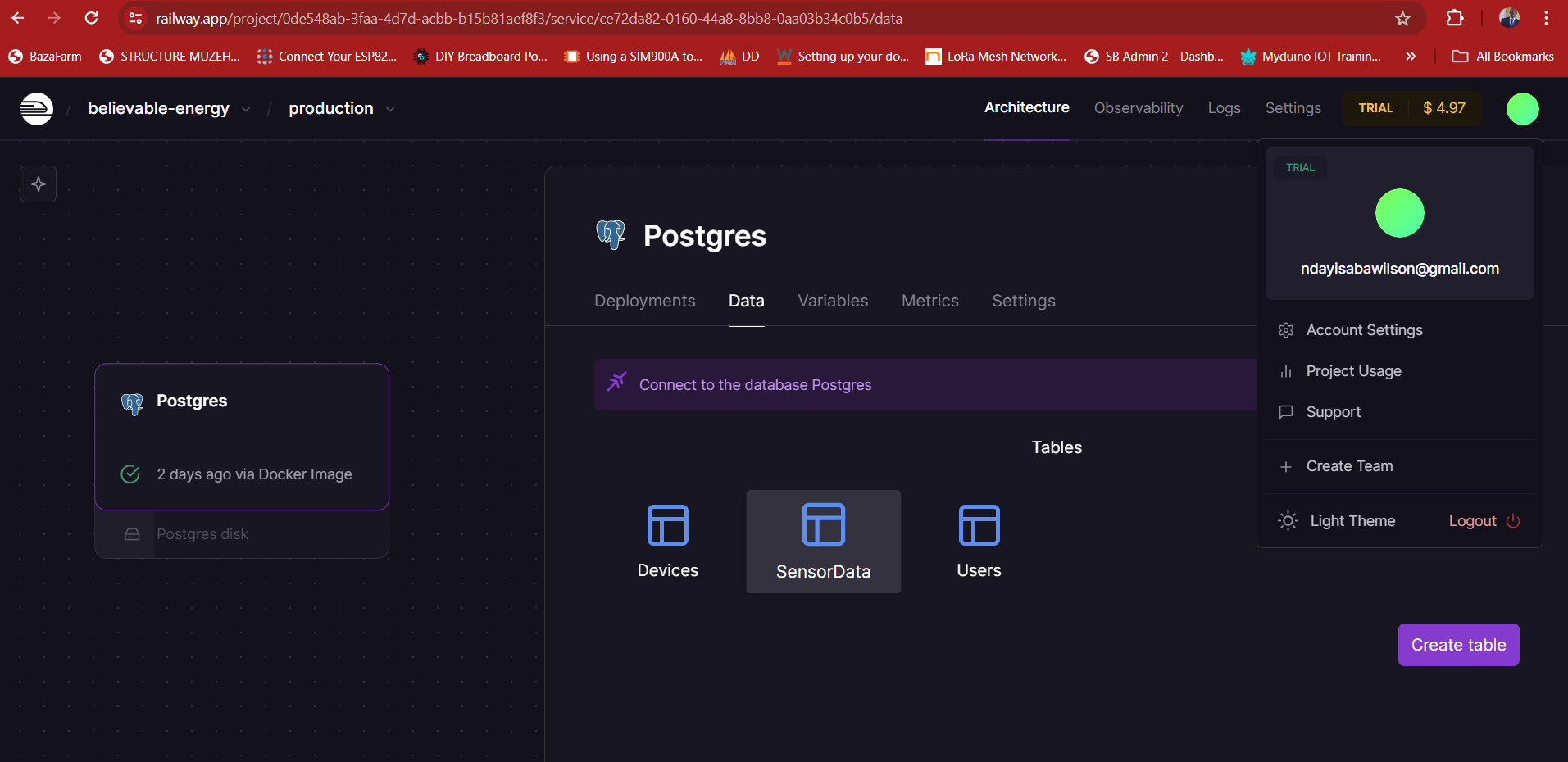

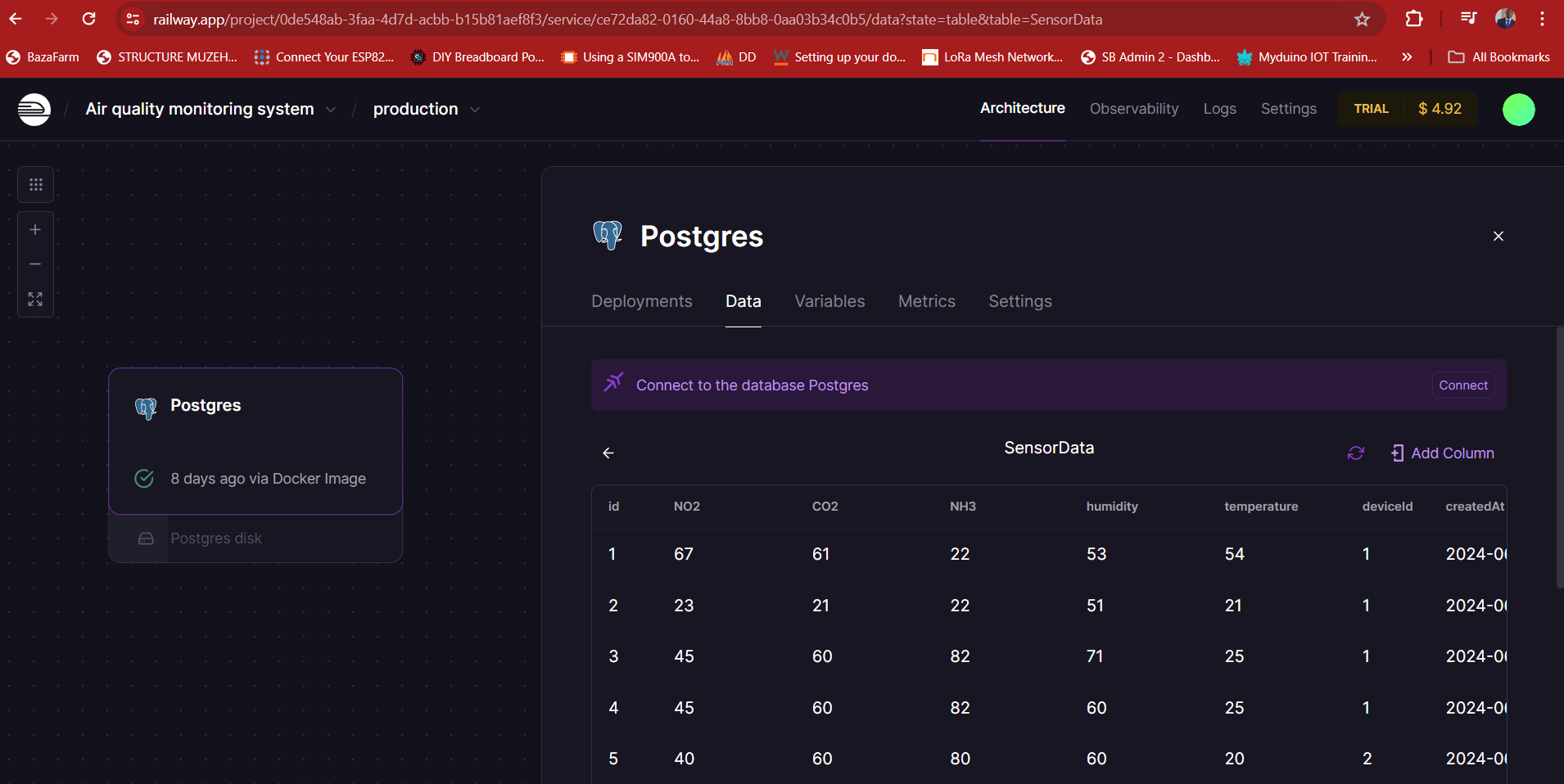

Data collected dashboard pages developed

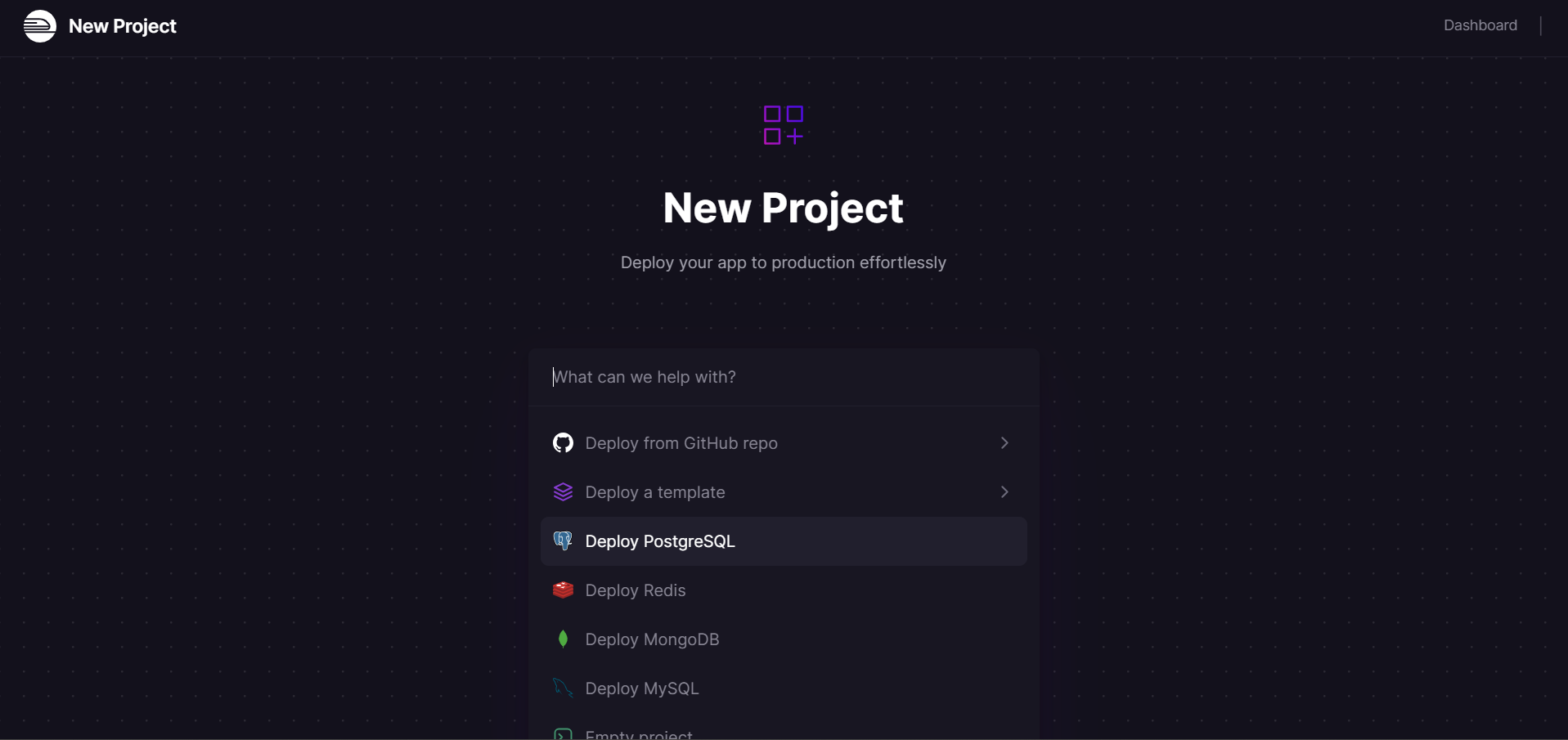

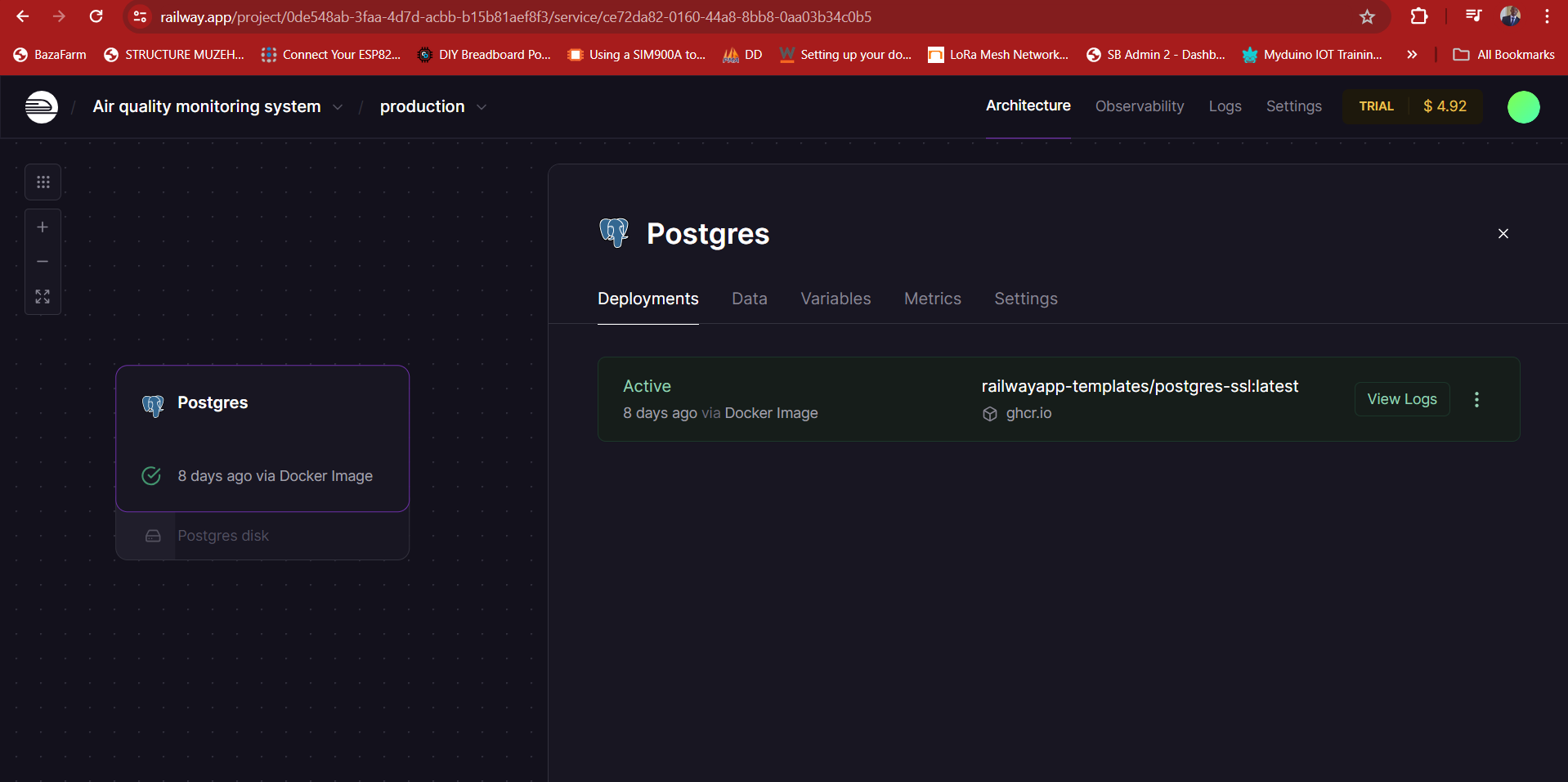

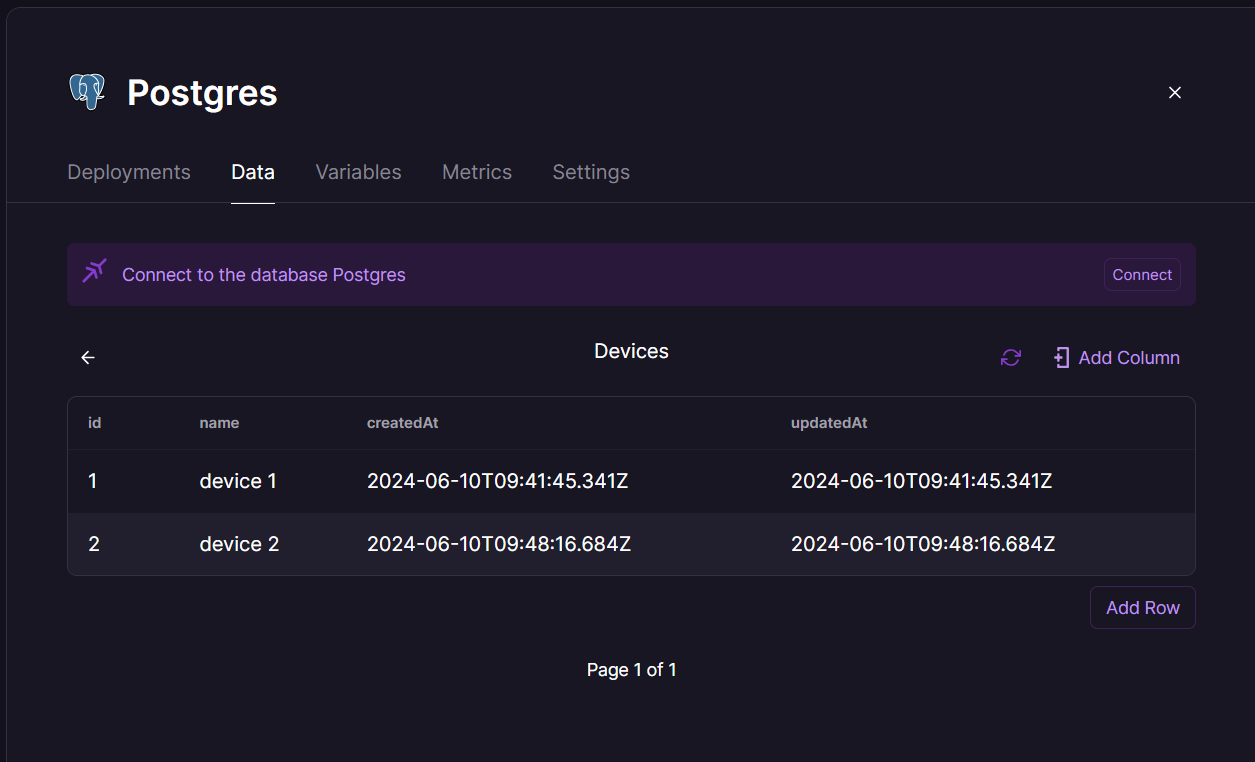

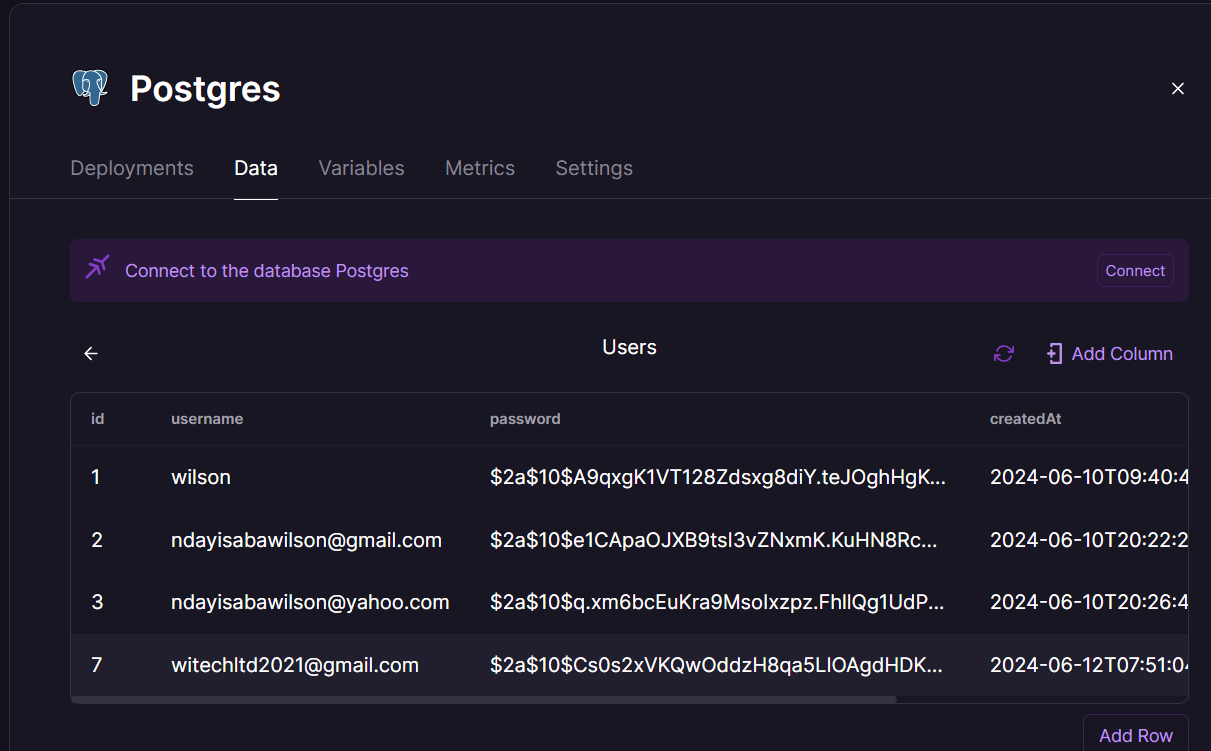

Database hosted on railway.app

You can access the dashboard where it is hosted here: https://fabacademy-airquality-monitoring.onrender.com

How to access the dashboard?

To access the dashboard, it requires login. You can create an account to access the dashboard or use the already created account here: Email Address: ndayisabawilson@gmail.com , password: wilson

Source code directory

All the code can be found on my github here: https://github.com/Wilsonndayisaba/fabacademy-airquality-monitoring