Week 16

Application & Implications

This week's assignment is about detailing what the projects is about through different point that will be stated below.

What the projects will do

The project Digital Measuring Tool is about making a digital measuring tool to overcome a few things such as Minimum measurement length by the usual tape measure; Digital display, measurement is shown on a digital screen hence making it easy to read. Multiple Units Of Measurements; you can usually switch between different units of measurement, Memory Function; the ability to store the data taken, Accuracy; this tool will be providing measurements by the device that aligns with the actual length or distance being measured. Portability; they are compact and easy to carry around, unlike traditional measuring tapes.

WHAT'S BEEN DONE BEFORE

Digital measuring tools have undergone significant evolution since their introduction. Here are some of the notable models and milestones in the development of digital measuring tapes over the years:

- we have Leica DISTO Series comprised of

Leica DISTO Classic; One of the earliest models, introduced in the mid-1990s, featured basic distance measurement capabilities.

-

Leica DISTO D3; introduced in the early 2000s, this model included features like an integrated digital level and Pythagorean functions for indirect measurements.

Leica DISTO D510: Known for its advanced capabilities, including Bluetooth connectivity, a digital viewfinder, and high precision over long distances.

-

Leica DISTO D510 ; known for its advanced capabilities, including Bluetooth connectivity, a digital viewfinder, and high precision over long distances.

-

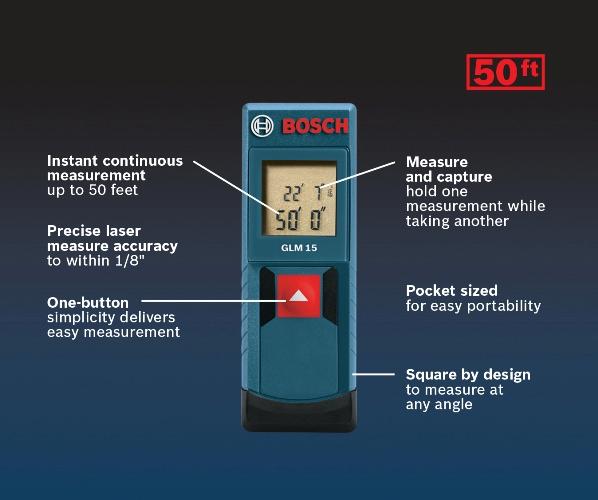

We also have Bosch GLM Series that introduced more advanced features like extended range, high precision, and extensive data storage capabilities, bluetooth connectivity, a color display, multiple measurement modes including area, volume, and indirect measurement.

These models represent key advancements in the development of digital measuring tapes, each bringing new features and capabilities to the market. As technology has advanced, newer models have continued to build on these foundations, offering greater precision, connectivity, and user-friendly interfaces.

DESIGN & MATERIALS USED

THE desing i will do has a few pricipal things simplicity, accuracy and the ability to be light or portable anywhere, so i will use PLA as an enclosure due to PLA being known for its print quality. It has the best detail reproduction of the common 3D printing filaments, making it ideal for models where aesthetics are important and also given the fact that where i reside PLA is the most accessible and affordable on our market.

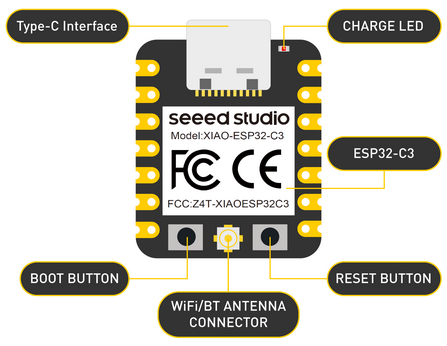

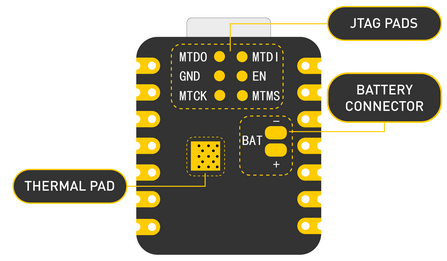

Seeed Studio XIAO ESP32C3 is an IoT mini development board based on the Espressif ESP32-C3 WiFi/Bluetooth dual-mode chip. ESP32-C3 is a 32-bit RISC-V CPU, which includes an FPU (Floating Point Unit) for 32-bit single-precision arithmetic with powerful computing power. It has excellent radio frequency performance, supporting IEEE 802.11 b/g/n WiFi, and Bluetooth 5 (LE) protocols. This board comes included with an external antenna to increase the signal strength for your wireless applications. It also has a small and exquisite form-factor combined with a single-sided surface-mountable design. It is equipped with rich interfaces and has 11 digital I/O that can be used as PWM pins and 3 analog I/O that can be used as ADC pins. It supports four serial interfaces such as UART, I2C and SPI. There is also a small reset button and a bootloader mode button on the board.

A rotary encoder is an electromechanical device used to measure the position or motion of a rotating object. They are commonly used in applications requiring precise rotational positioning and speed measurement, such as in robotics, industrial machinery, and automotive systems.

For this project i used an incremental encoder type that consist of a disk with evenly spaced lines and an optical or magnetic sensor that detects these lines as the disk rotates. The sensor generates pulses, which are counted to determine the relative position.

Copper Clad Laminate (CCL) is the base material of PCB. Bonding a layer of copper foil to a non-conductive substrate, such as fiberglass, plastic, or paper-phenolic made this laminate. The copper layer serves as the conductor for the electrical signals in the PCB, while the substrate provides mechanical support.

Copper-clad combines copper plating with a second metal (core material). Furthermore, they have almost the same properties as copper but aren't 100% copper. Thus, the fusion consists of copper and steel and copper and aluminum. CCL has many applications, from simple circuits to large, complex multi-layer boards.

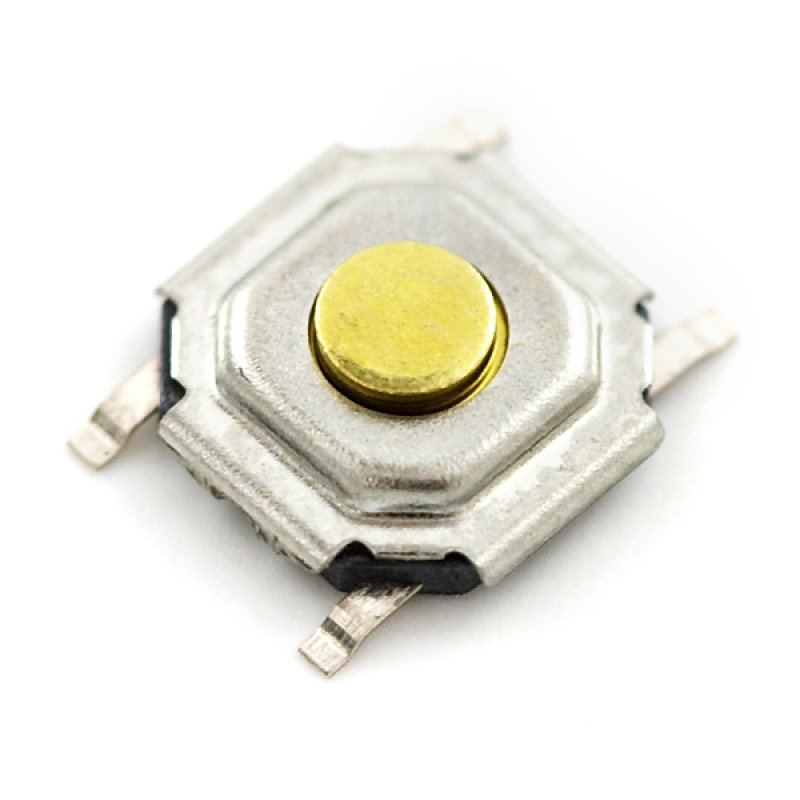

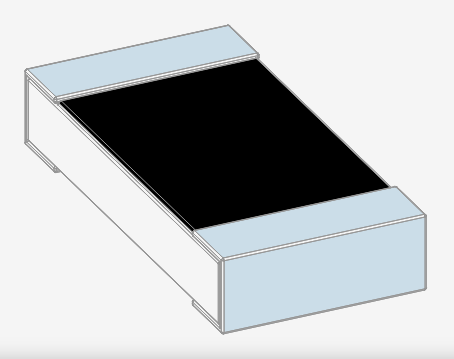

Miniature push button switches with a low height of 4,55 - 4,95 mm for surface mounting (SMS) and PCB mounting (PMS). The SMS has large flat surfaces on the top side as well as on the other sides, which are also parallel to each other. This makes the SMS a perfect switch for automatic mounting. The SMS switch is suitable for the SMD soldering process

In SMD resistors, The shape and size of surface mount resistors are standardized with most manufacturers use the JEDEC standards. The size of SMD resistors is indicated by a numerical code, such as 0603. This code describes the length and width of the package. For size calculation, consult this link

Where will come from

I got most MATERIALS from this sources below; all electronics components and 3D Filaments were bought from these two sources but the MDF and acrylic used within the whole course are bought from a big local markets which unfortunately we can't link because they dont have a website most of them:

How much will they cost?

| No | Item | Quantity | U.price | Total | Comment | Link |

|---|---|---|---|---|---|---|

| 1 | li po battery | 3 | 30000frw | 30000frw | final project | Link |

| 2 | rotary encoder | 2 | 3500frw | 7000frw | final project | Link |

| 3 | PLA | 1 | 53000frw | 53000frw | final project & mold/casting | nyereka |

| 4 | plastic board | 1 | 30,000frw | 30000frw | molding and casting | Fred |

| 5 | XIAO ESP32C3 | 2 | 20000frw | 40000frw | final project | Link |

| 6 | copper pcb board | 5 | 4000frw | 20000frw | final project & the rest assignment | FRED |

| 7 | candle wax | 3KG | molding and casting | lambert |

Total: 175000frw

What parts and systems will be made?

Basically

- Design & Printing of the enclosure of the device that will house the pcb, the battery, the screen

- Design PCB & solder components

- PROGRAM a system for using this device using arduino IDE

What processes will be used

- I will use 3D printer to print the enclosure

- I will use kicad to design the pcb and arduino IDE to program

- I will use solidworks to design the enclosure

What questions need to be answered?

- How to measure longer distance?

- How to hold data of what measured

How will it be evaluated?

- This project will be evaluated based on its working principle, accuracy compared to usual measuring methods and the accuracy compared to whats already on the market of the same category