9.Mechanical design & machine design

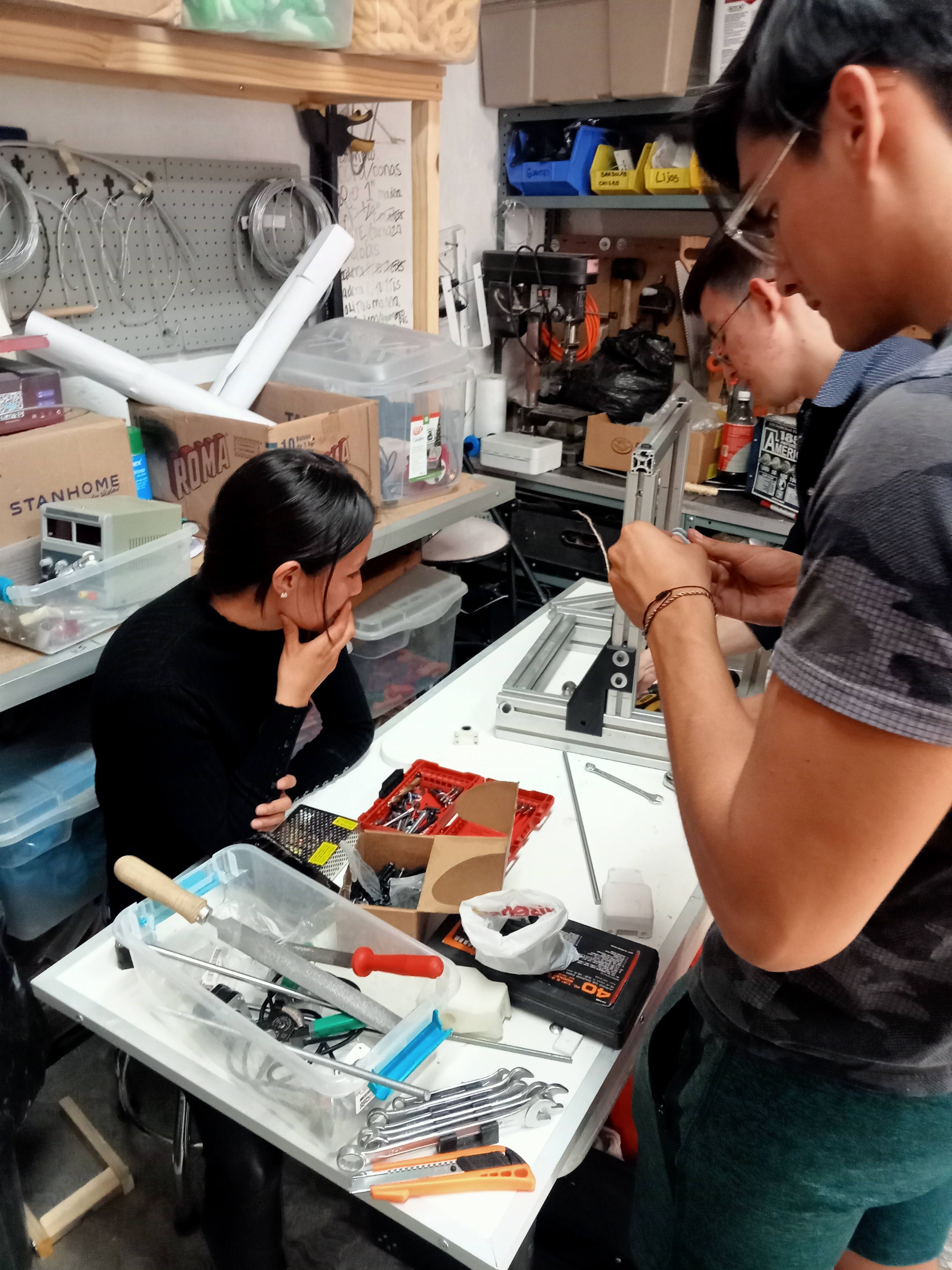

This week we were asked to design and build an automated machine as a team. Teamwork was complicated at the beginning, because knowing that everyone was good, none of them trusted to delegate responsibilities to the others, so the first days were a little tense and difficult to work because there was not much communication, but with time and the need to solve the work, we began to fit in and finally a positive and functional result was achieved. Teamwork can be seen.

Teamwork

Our teamwork was to design and create a ceramic printer, the task was not chosen, rather assigned. We worked for about a month and took several references of 3D printers. For those who do not know, this is an electromechanical equipment composed of 5 nema 17 motors and an incognito motor, a Rams1.4 driver and 3 A4980 pieces, among other elements. Technically, this printer will help us create pieces previously designed on the computer, reducing the need to get your hands dirty and creating more complex pieces.Individual work

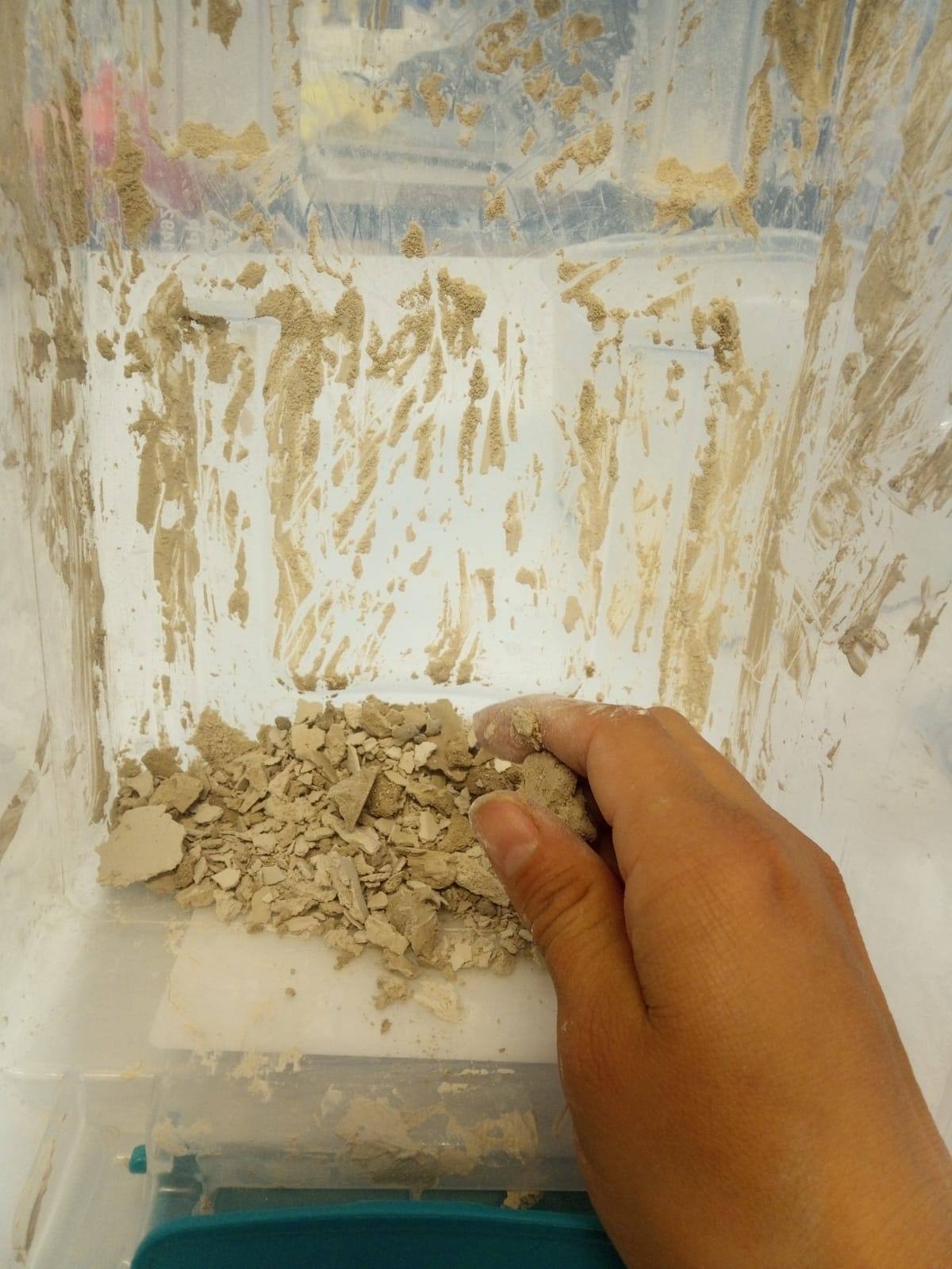

For my part, I helped in the elaboration of the correct consistency of the ceramic, many tests were carried out until we obtained a material that could pass through the extructor, then through the nozzle and finally that when it came to falling on the bed and piling one layer on top of another this material would not break, dry or drip. This leaves a clean and firm piece for future firing.

I also supported with the cleaning of the parts since when doing tests it was obvious that we would have to clean before trying again, this activity was very tedious since, lthough the material is noble and could be removed relatively easily we had to wait for the material to dry or leave it to soak and time was the least we had, Therefore, it was necessary to speed up the cleaning process without affecting the parts and recycle most of the material.

In the same way, I made the video of the final presentation, I wanted to make a very cool video with the techniques of “parallel actions” or “mach cut”, in short, I only managed to collect all the photos and the few short films that my partner Rosario managed to take. and I united them into something that could give a tour of everything that was worked on and show the participants in the activities carried out.

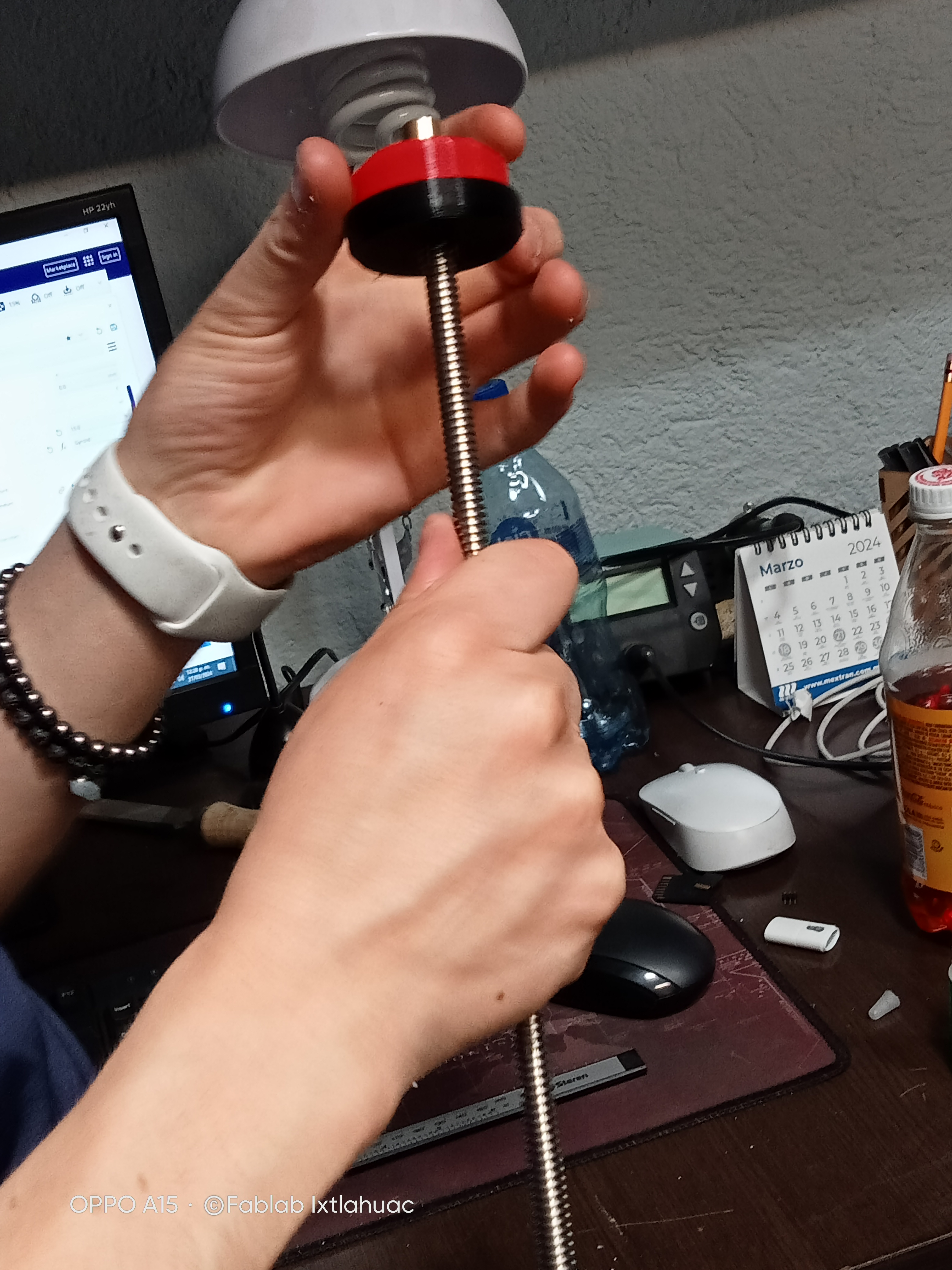

In the contribution there was also more help with ideas and observations to the tests, such as the use of the plunger and its modification and the storage size since it did not provide capacity for the route through the hoses and apart from the impression, in the same way I suggested the fact of contemplate that this tank was not fixed, but that it had parts that allowed it to be held and to be able to remove it to exchange for a spare part or, failing that, refill.

In general I liked learning and experimenting with my colleagues, the most difficult thing was not having been able to contribute with more work, but I trust that more opportunities will come to be able to do so.