12. Molding and Casting

Individual assignment

1. Desing

I didn't know what to make a mold of or what material to use, but while washing my hands, it occurred to me to create a soap mold. So, I utilized the sample boat mold that came with my 3D printer to craft it.

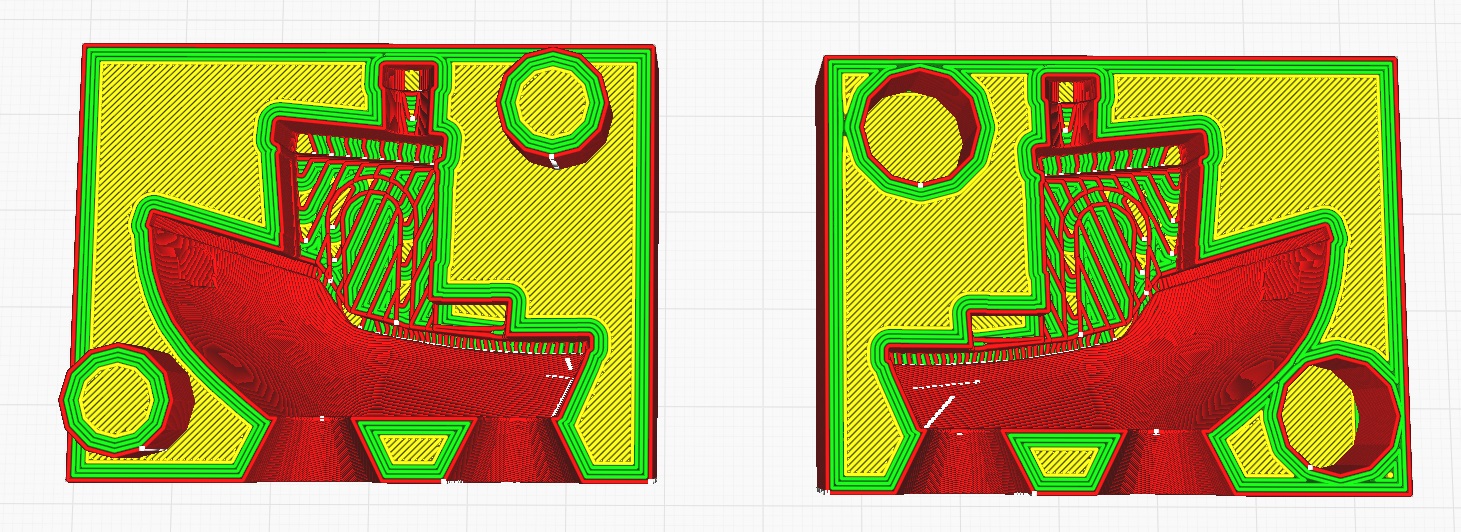

I proceeded to export the model to Ultimaker Cura, a slicing software for preparing the 3D print job. Within Ultimaker Cura, I configured the print settings for PEGT filament, a quality of .02mm, speed of 60mm/s, temperature of bed 75 degrees celsius, temperature of the nozzle 235 degrees celsius.

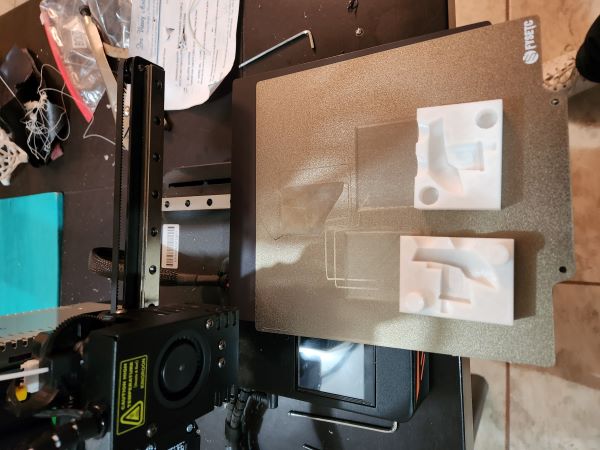

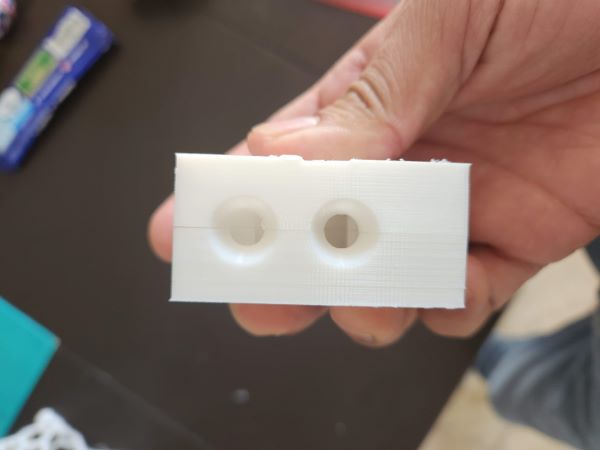

After the printing process was completed, I meticulously checked to ensure that the mold was functional and would fit seamlessly with the counterpart.

Then i cut little pieces of hand soap and put it on a cup with a little bit of water and then put it in the microwave for 1 min. Then stir it and put it in the microwave again, until it is liquid.

Afterward, I proceeded to pour soap into the mold, taking precautionary measures to seal the mold properly to prevent any leakage.

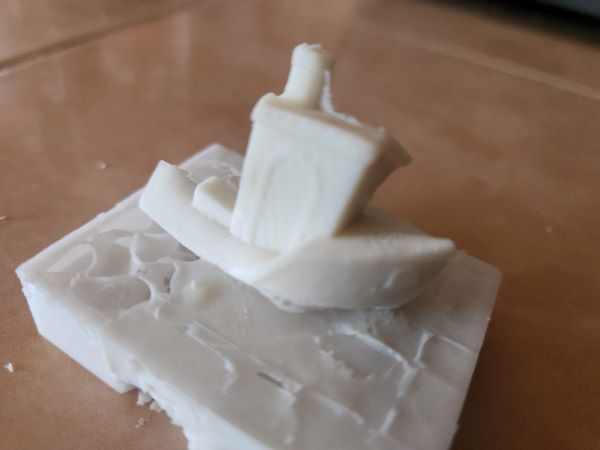

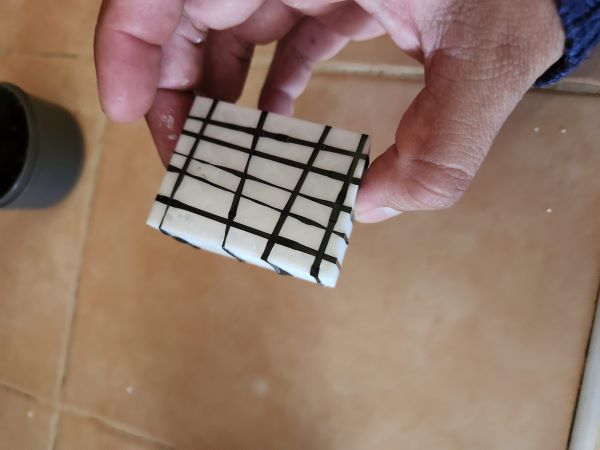

After let it sit for about and hour the soap had set and solidified, this is how it turned out. Overall i think it came pretty good.

I think i need to pour more soup in, because there was a little part that was not fill with soup.

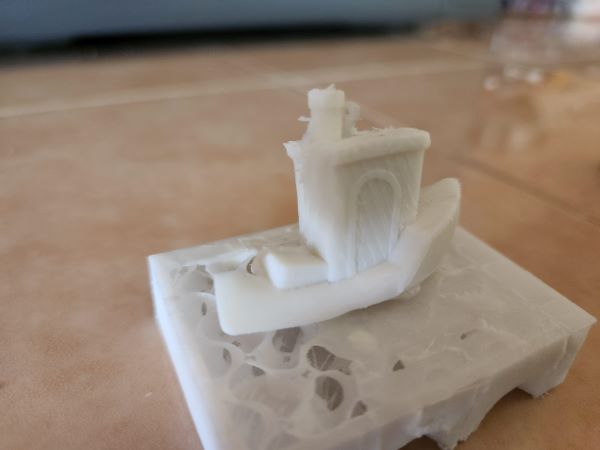

On the second attemp i had no problems with the quantity pour the mold. The result came pretty good.