Mechanical Design

A CNC machine? By ourselves?

Finished Result

Here its the link of our finished CNC Machine!

Design and assembly

For the design we used a 15mm MDF board, so in order to achieve the 30mm we wanted, we are mirroring all the pieces in order to glue them together. We took measurements of the FabLab Milling machine for inspiration. Almost all the pieces have holes so they can be filled and be 30mm.

Once we had all the pieces cut, I then started to glue thbem together and assemble them! The process is really simple: I made cubes that would fit the holes we made in order for the pieces to snap to each other. Then I sand everything using a circular sander for a smother finish, I also cutted in a straight 90-degree angle some corners since the machine couldn't get in them due to the mill shape. I now just need to coat the side with glue, use the cutted squares and press.

.jpeg)

.jpeg)

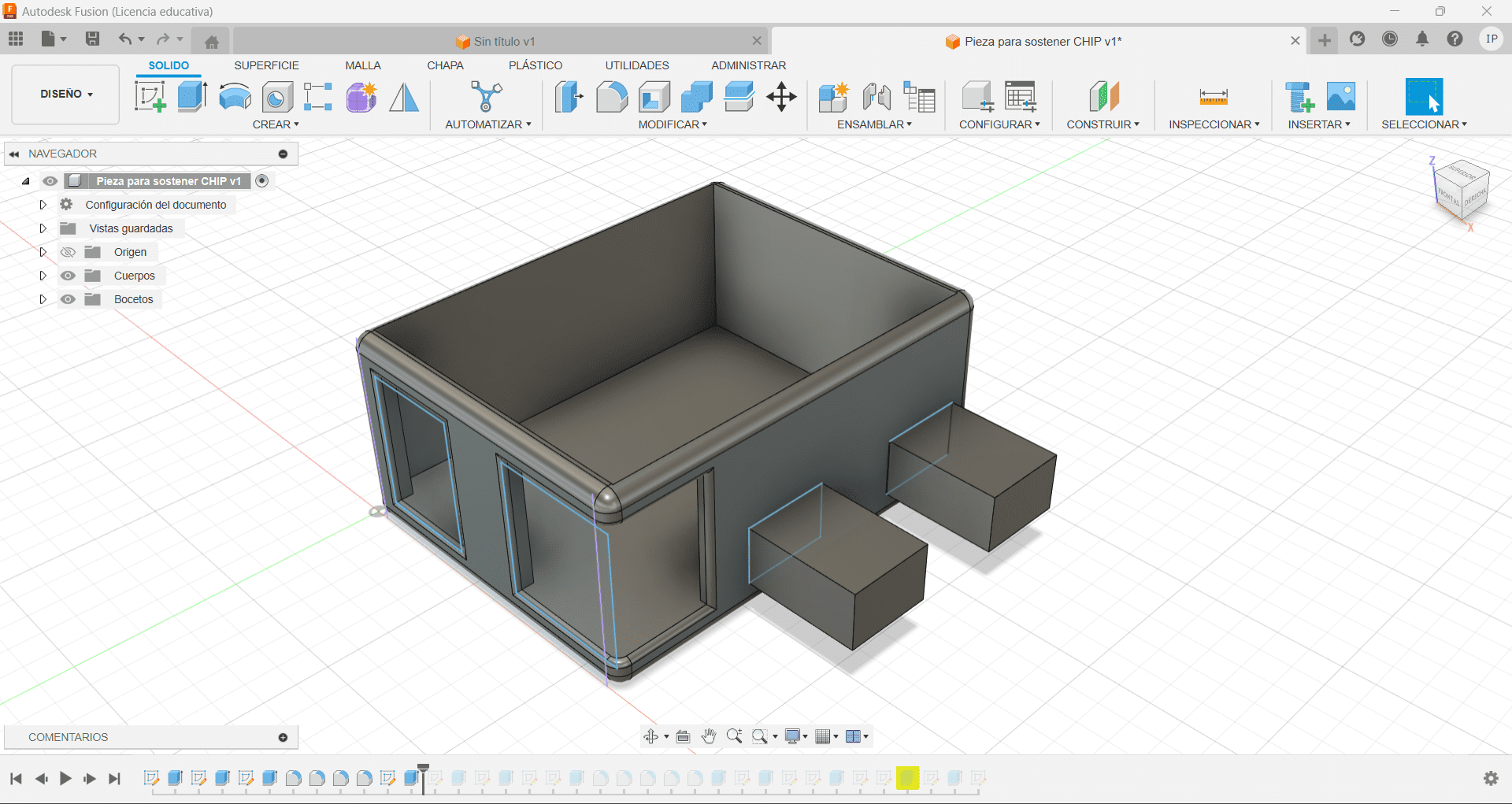

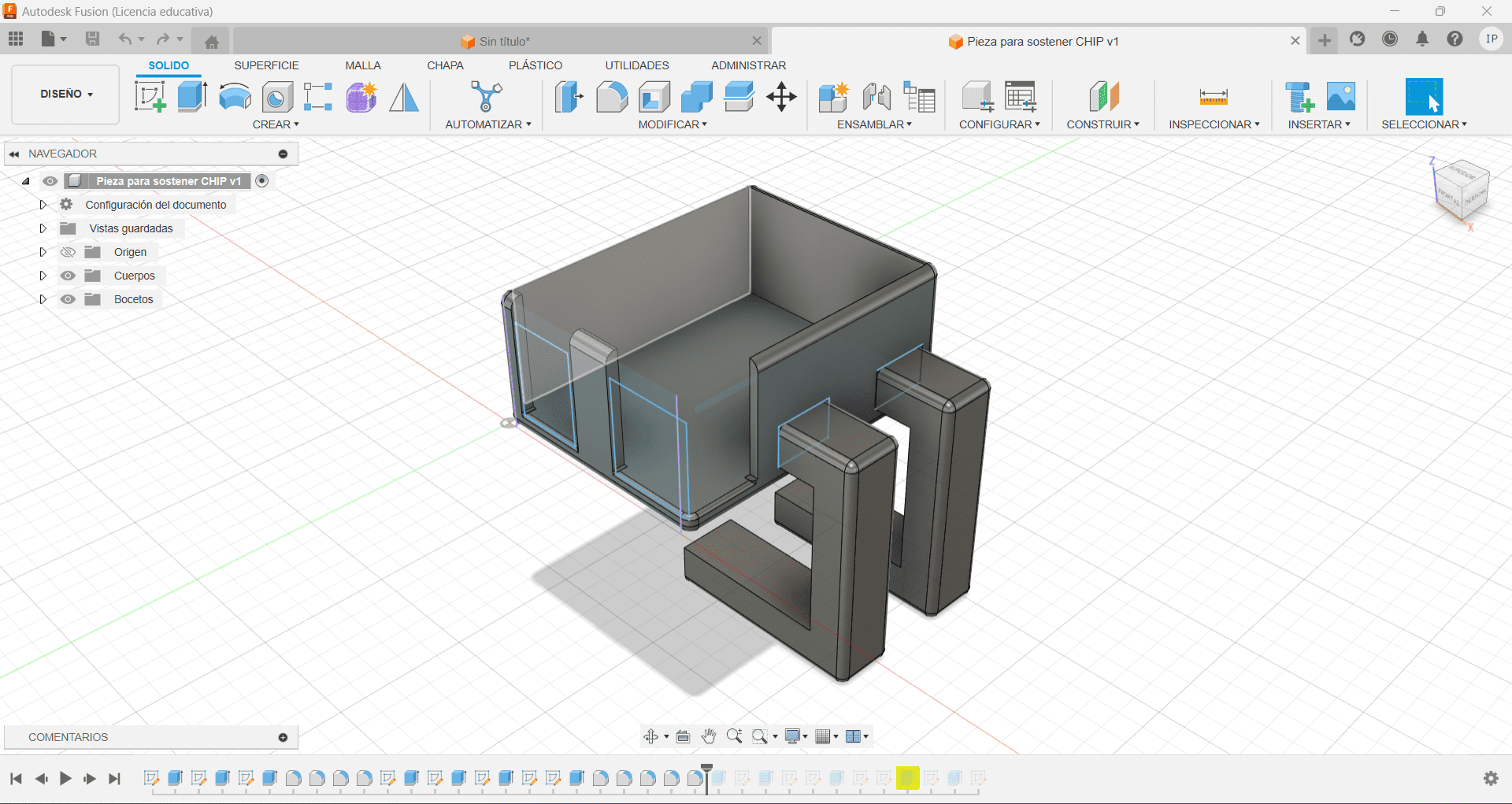

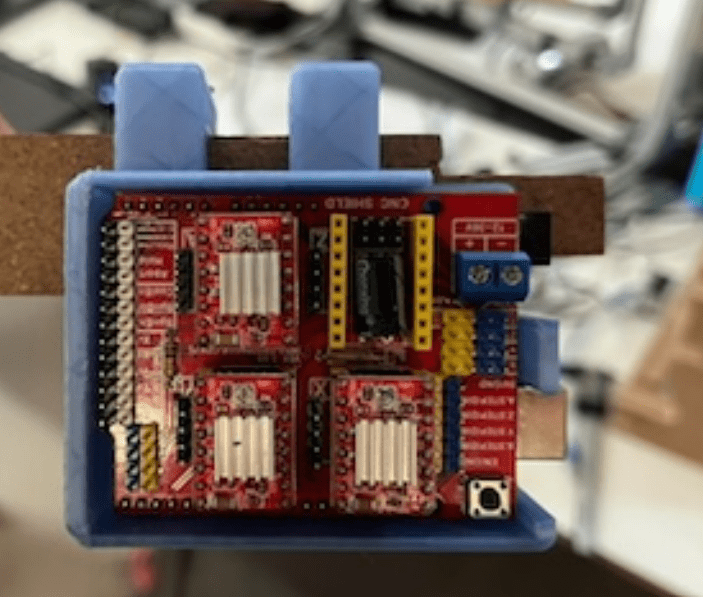

Arduino UNO and CNC shield cover

Now I needed to do a cover for the Arduino UNO and CNC shield, I first measured all the sizes and where the piece would go so it wouldn't obstruct the dremmel. In Fusion 360 I made the box with some open windows for the cables.