Mechanical Design, Machine Design

On this weeks assignment we had to create a CNC machine. Creating a CNC machine from scratch is not something easy, that's why this task was made in teams. You can find how we did the CNC from scratch here.

The main idea was to create a CNC that could cut with a Dremel because, if a dremel works on this machine, almost every kind of tool could also work. I was assigned to do the Z and Dremel supports.

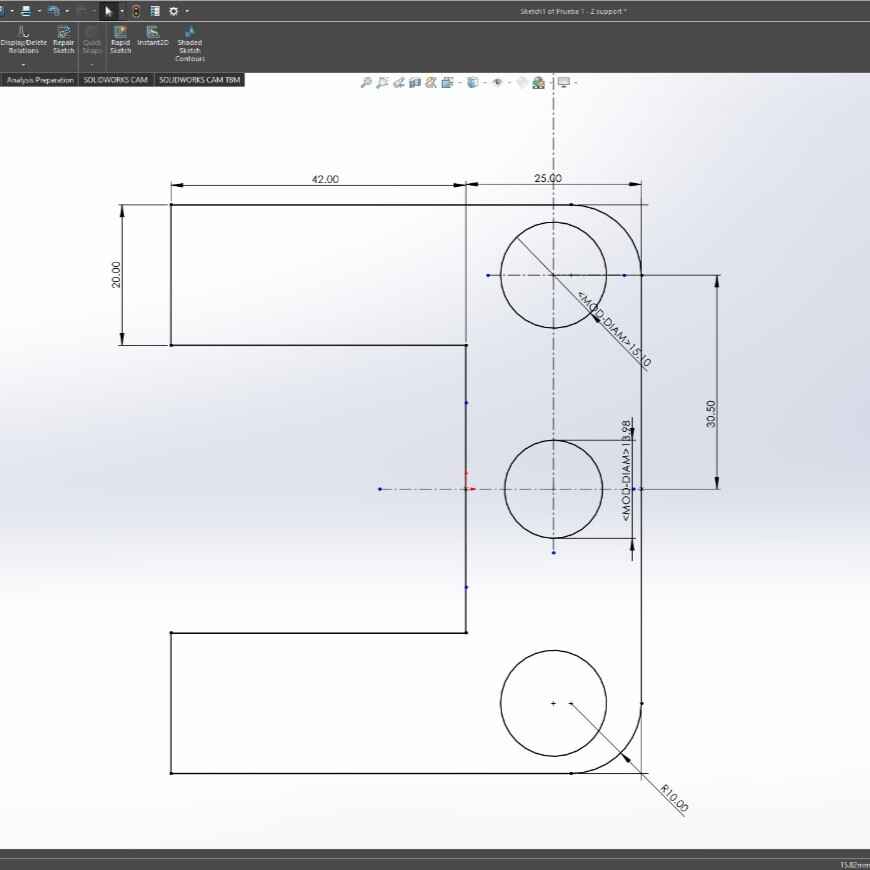

Z support

First attempt

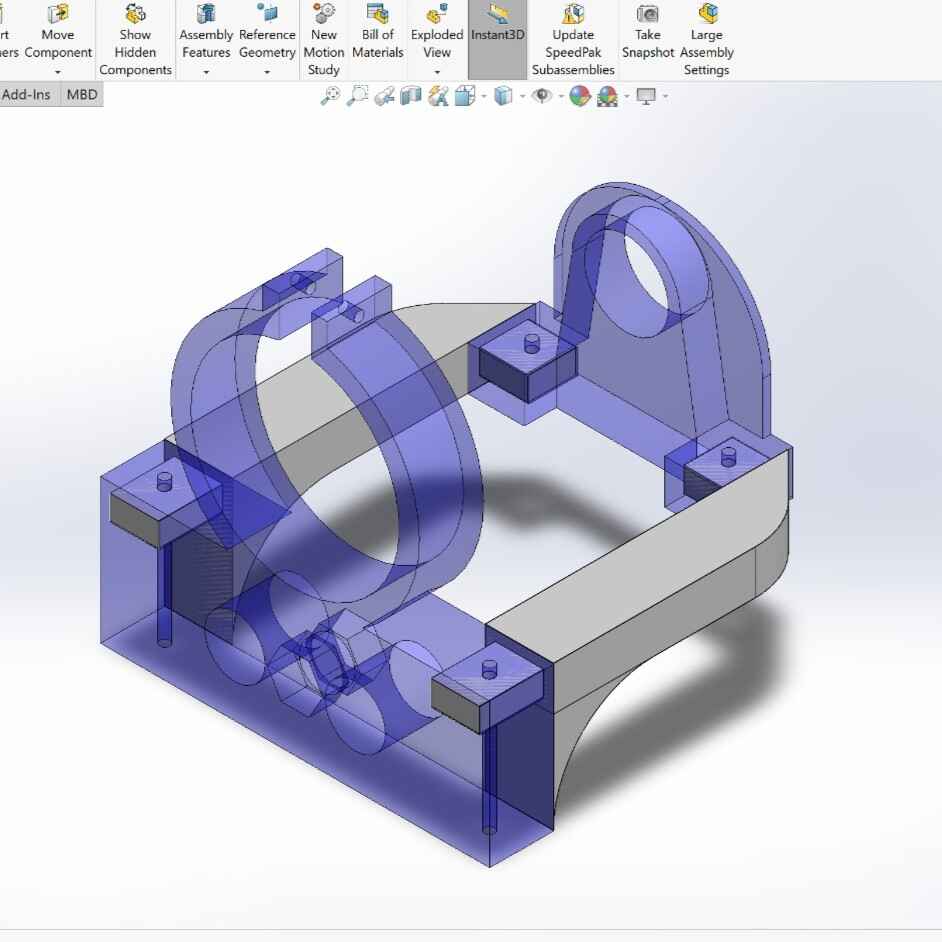

The design of the Z support was not that difficult, I got inspiration from a CNC machine that I did on my first semester of my career.

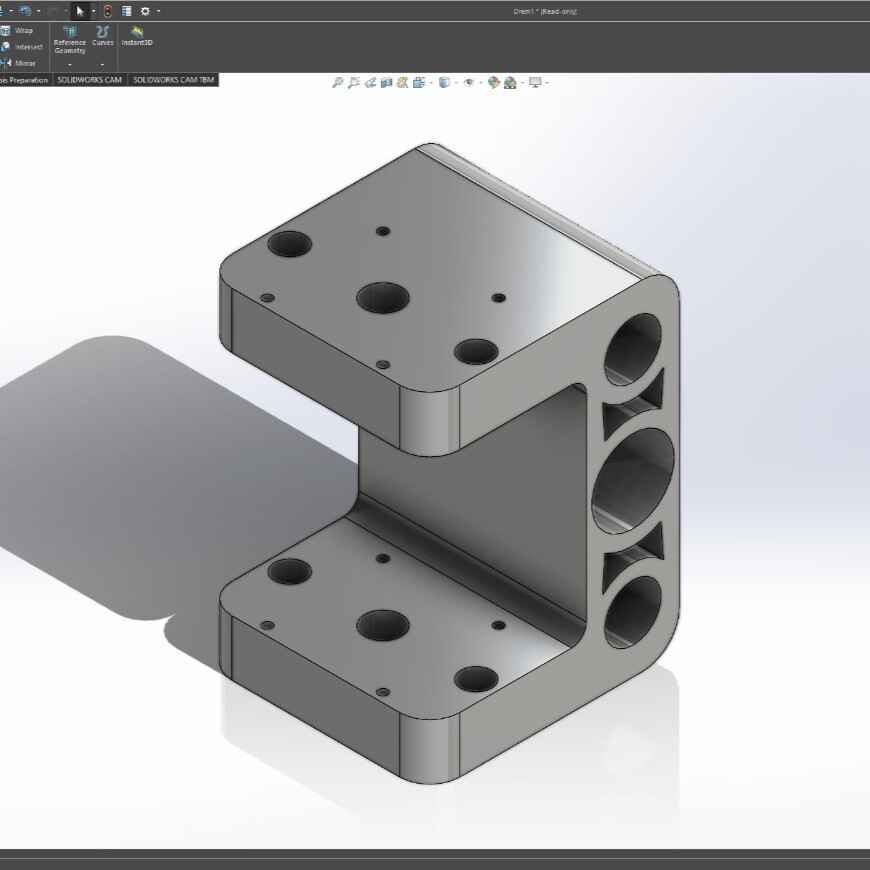

Thanks to the experience I have beem obtaining through my carrer I designed a more aesthetic and, at the same time, more resistant than the piece I design for my fisrt CNC.

Second attempt

The first problem that happened was that we had expected to use a normal hex nut but when we bought the screw spindle another type of nut came with it so, using the measures and a piece that one of my teammates, Angel, design I managed to modify the piece to adapt it to the new hux.

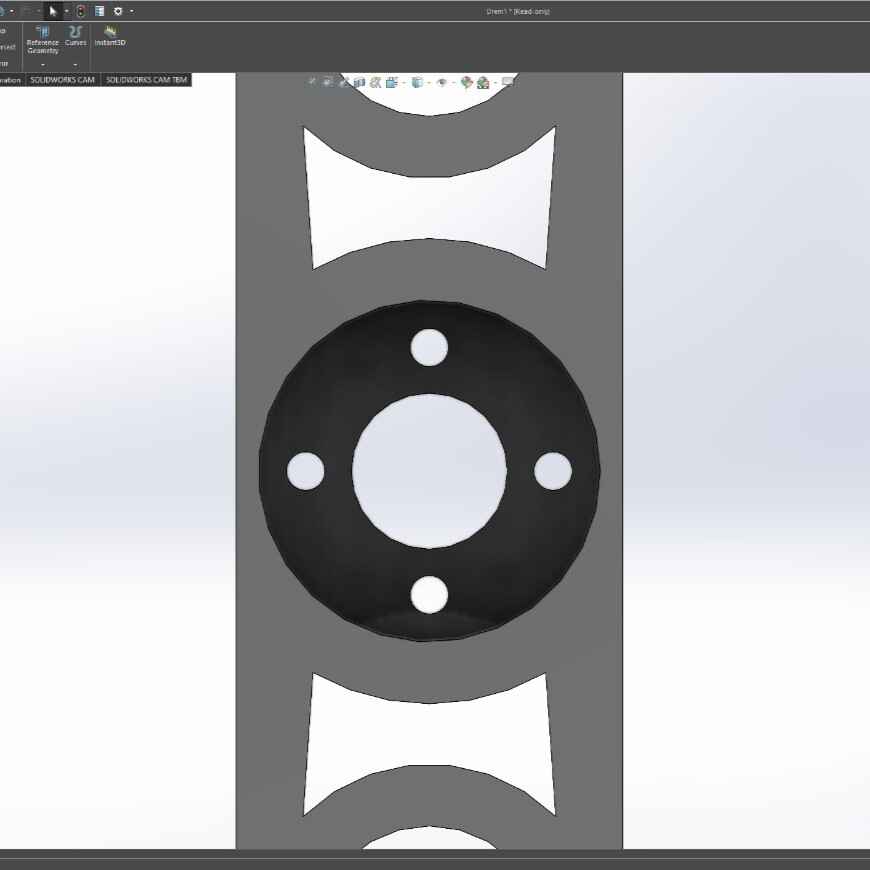

Dremel Support

For the dremel support I just had to join the two pieces that Angel sent me that holds the top and bottom of the dremel.

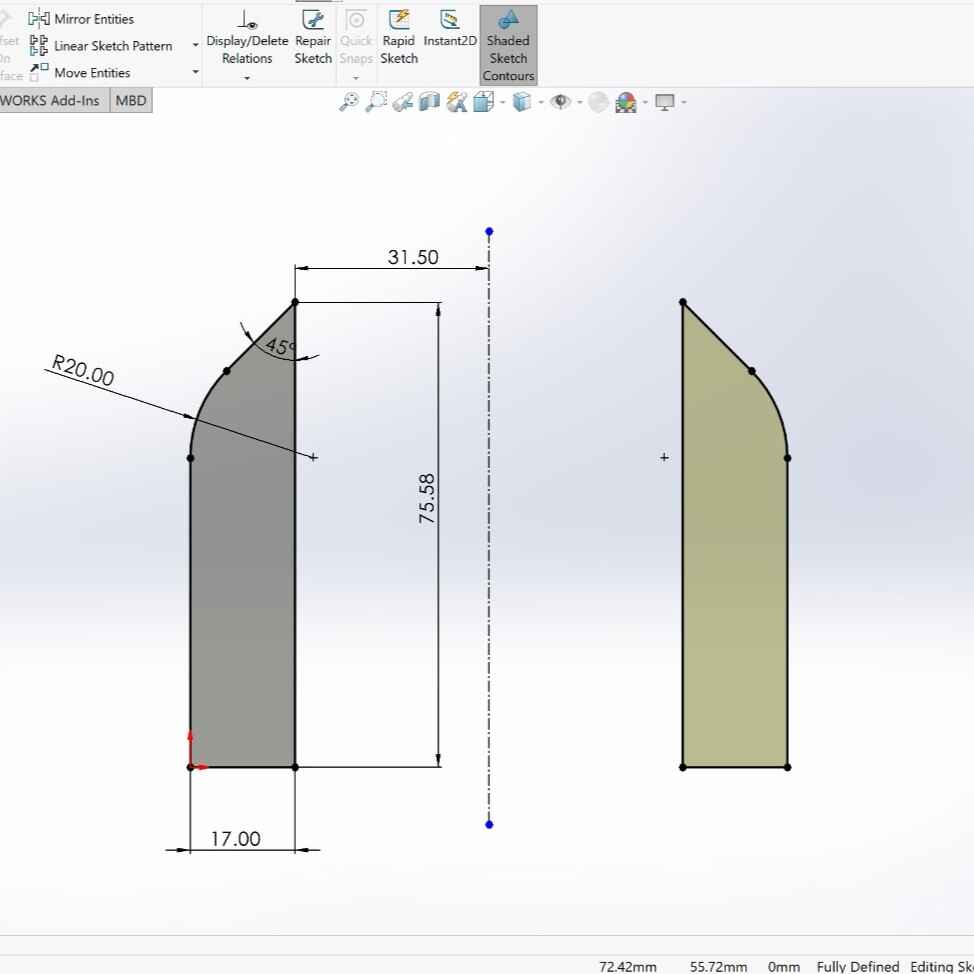

At first I designed the support in one piece, but we saw it that it was going to be pretty hard to print something that "big" and it will take a lot of time to print so I decided to divided it in different parts also, I helps in case one of the pieces went wrong we would only have to print that one again.

I also had to modify Angel´s pieces to make then fit into the connection I desgined.

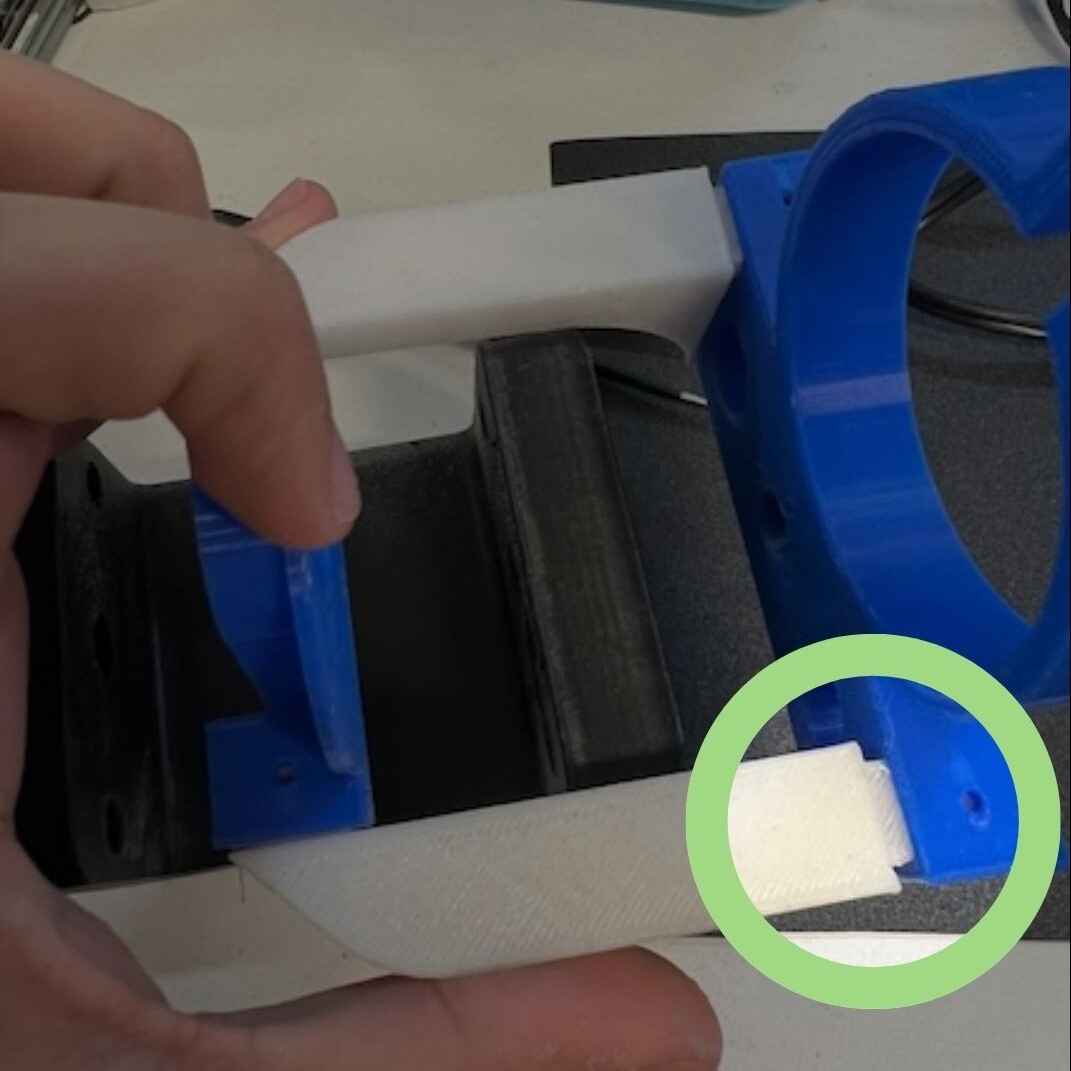

Assembly

The assemby of the Dremel support was simple but because of the tolerance of the pieces putting together the pieces was hard but I nailed it using a hammer.

Then, adding the bearings and the nut was not that hard but the bearings were longer than the thickness of the piece but it did not cause a problem.