3. Computer controlled cutting

This week I worked on my laser-cut parametric kit, and also a vinyl laser-cut design. This machines are

Group assignment

This week I worked on my laser-cut parametric kit, and also a vinyl laser-cut design. These machines are available to all the Ibero Puebla community. Link to Fab Lab Puebla web site: Fab Puebla

These machines work with a broad range of materials that provide the students and members of the university versatility with projects. The following list contains which materials can be cut and engraved with our lasers.

Table

Soft Materials

| Material | Cut | Engrave |

|---|---|---|

| Paper | X | X |

| Cardboard | X | X |

| Foaming | X | X |

| Felt | X | X |

| Cotton and mixed fiber fabrics | X | X |

| Natural leather | X | X |

| Rubber | X | X |

| Cork | X | X |

| 100.00 | ||

Hard Materials

| MDF | X | X |

| Wood | X | X |

| Plywood | X | X |

| Plastic | X | X |

| Acrylic | X | X |

| Glass and crystals | X | |

| Ceramic | X | |

| Metal | X | |

| 100.00 | ||

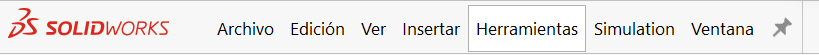

Kerf

One of the most important things to consider while laser-cutting is kerf. The laser beam has a thickness that ends up burning away a certain length of the part that wasn't contemplated in the design. The way we calculated the width of the part that was burnt out was to create a series of rectangles and cut them with the laser cutter, once the cut was done we could slide the pieces to the side, which leaves a gap. By dividing the length of the gap between the number of rectangles we calculated the width of the part that gets burnt up.

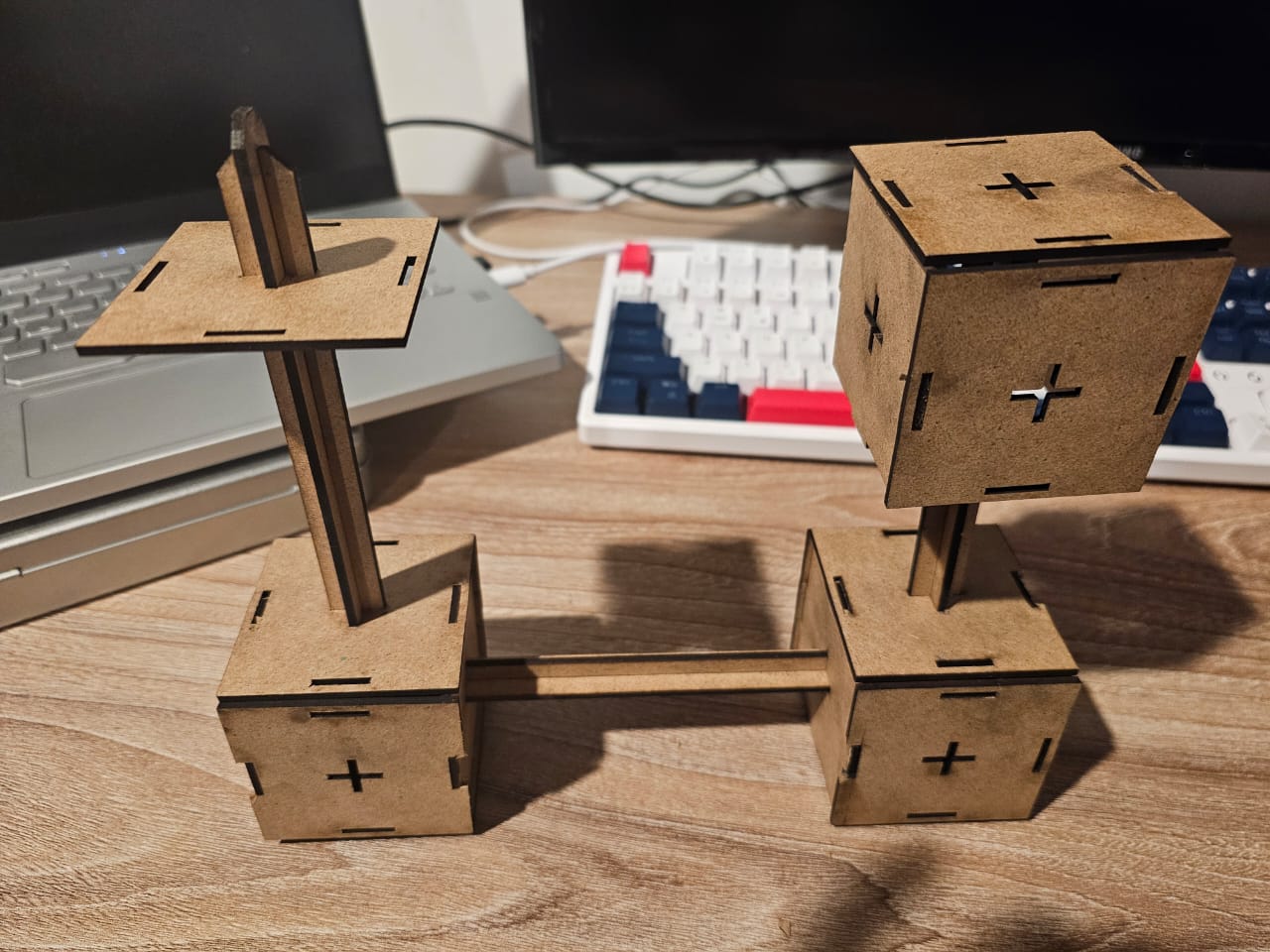

Parametric kit

A parametric design is a model created by establishing formulas that keep a part symmetrical if a certain length is changed. This allows the suer to adapt their design to a variety of projects.

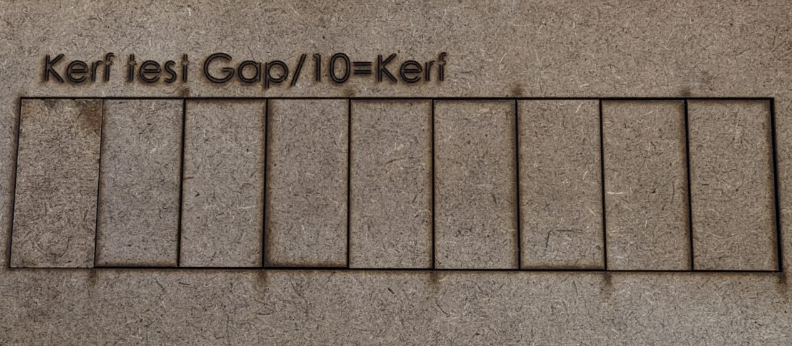

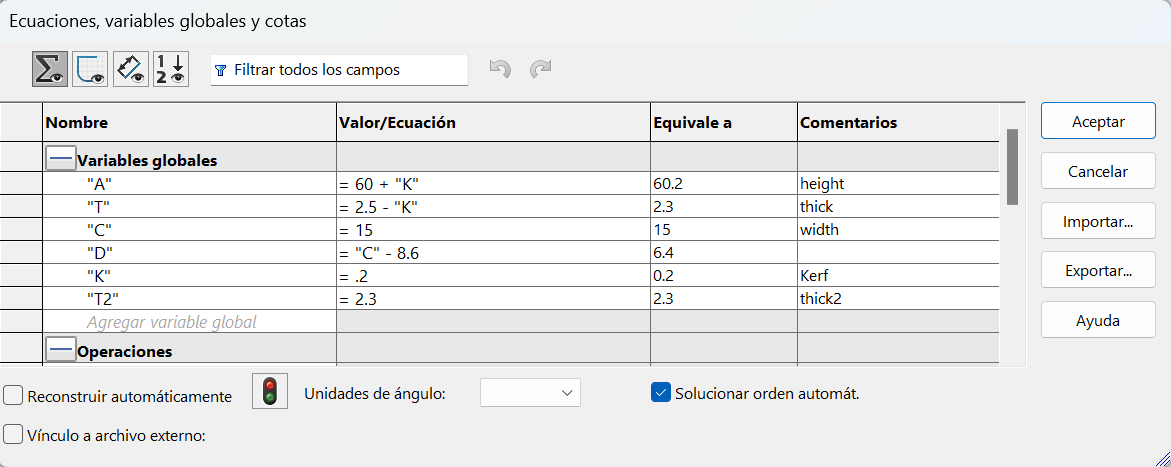

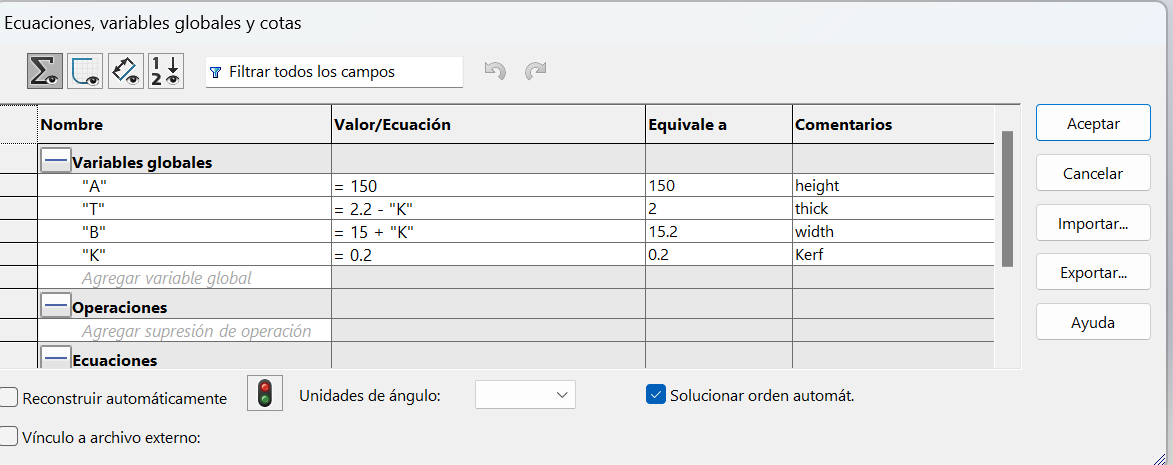

I did my parametric design in SolidWorks, which consists of three parts. Since our instructions were to create a parametric kit I needed software with an option for ecuations. Above the toolbar on SolidWorks ther's a menu, there an option called "tools" will pupo up, there I found the ecuation tool. This tool lets you creat certain valus thart then can be used on a design.

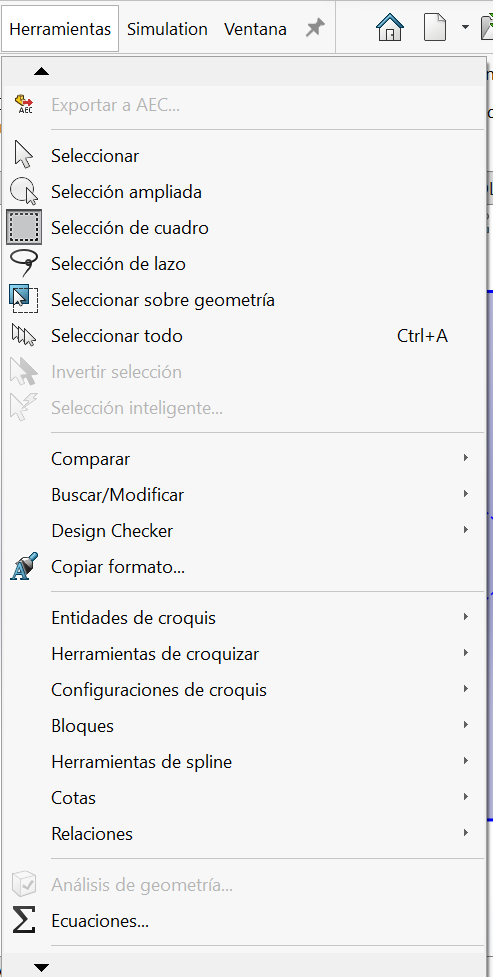

The ecuations menu looks like this:

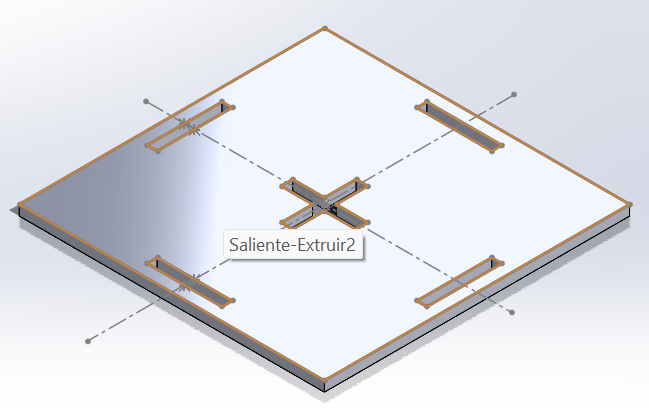

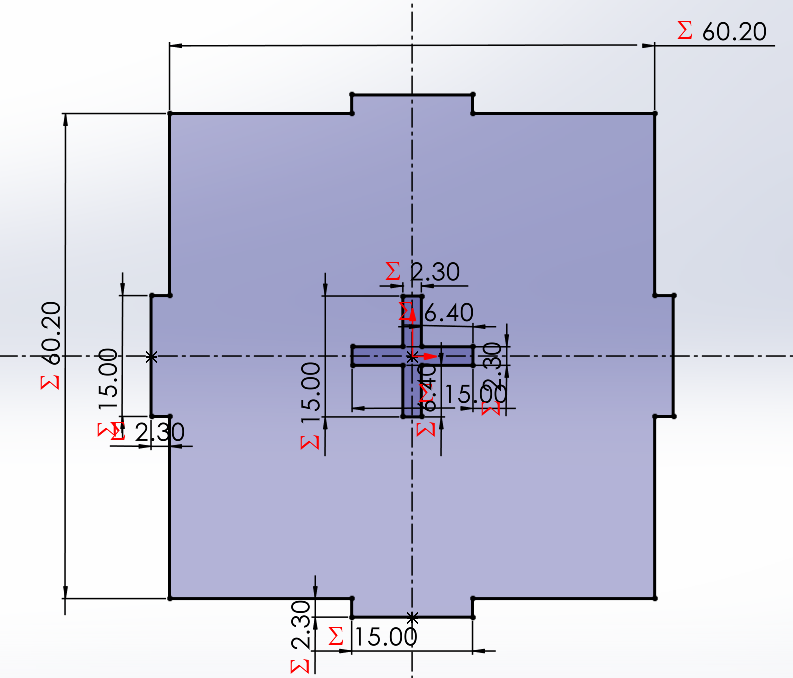

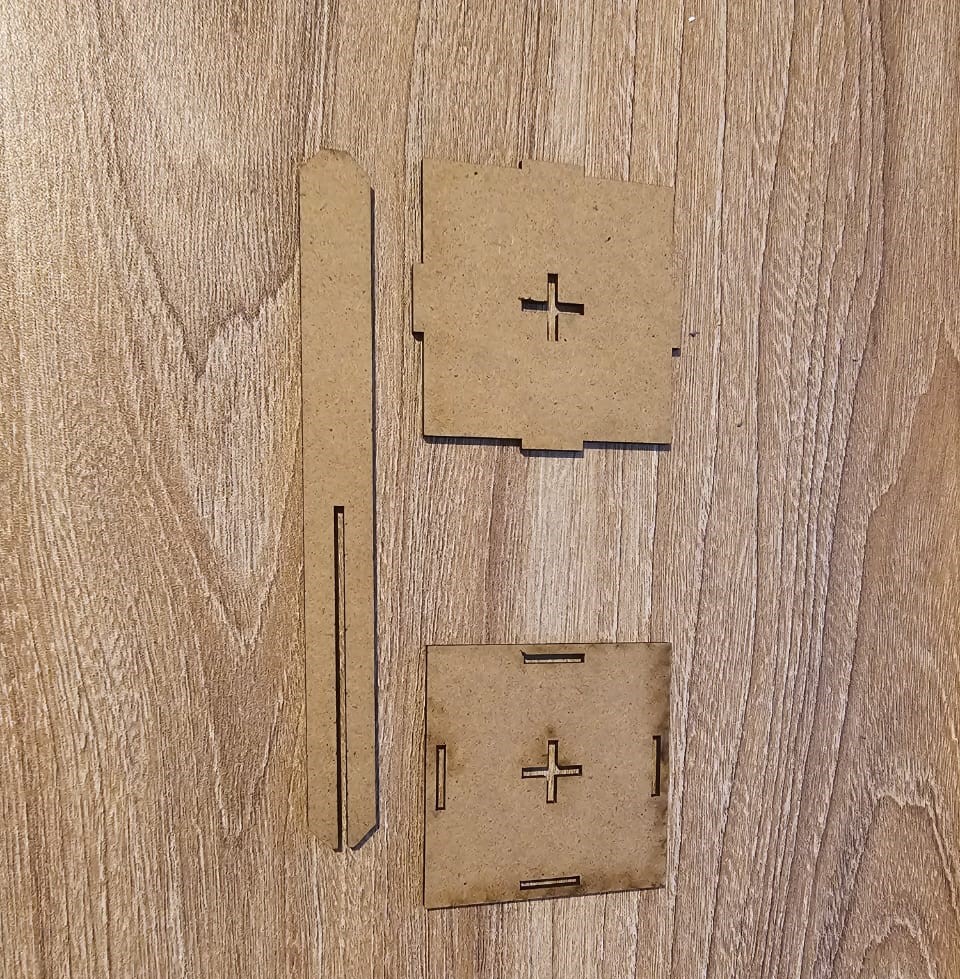

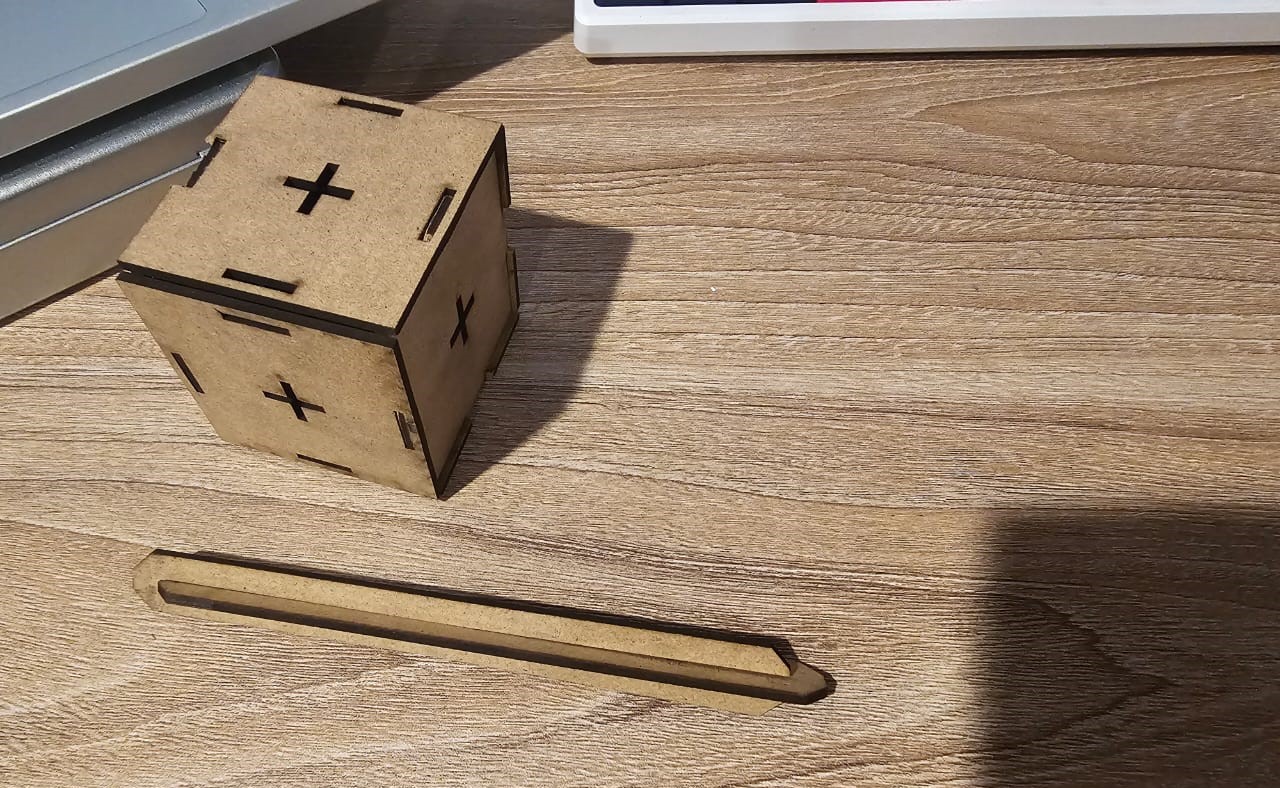

The first part of my kit is a square with four openings for joints and a cross in the middle for a union peace. I established certain parameters to make it a parametric design.

The second part of my part is another square but this one has joints that will fit into the openings of my first part to create a cube.

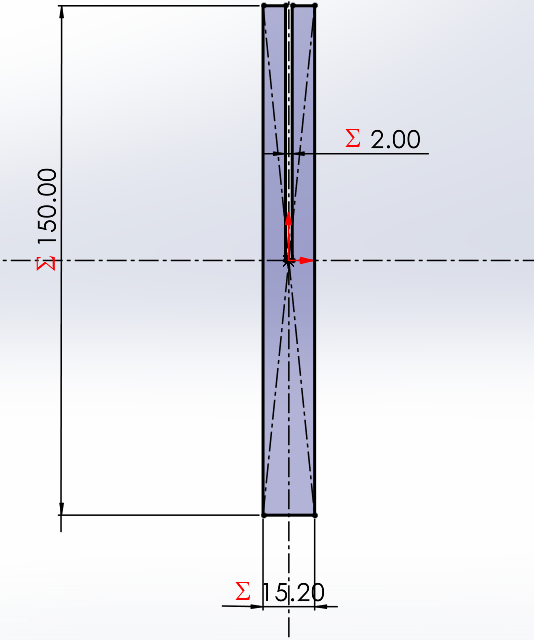

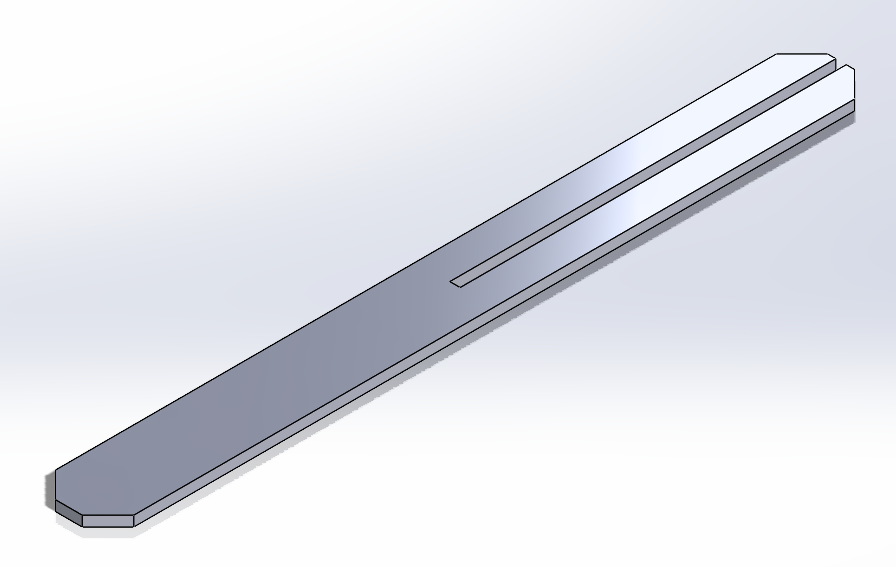

The third part of my kit is the union between the cubes, I imagine some kind of screw. This "screw' will be made by joining this part in a parallel axis.

laser-cutting

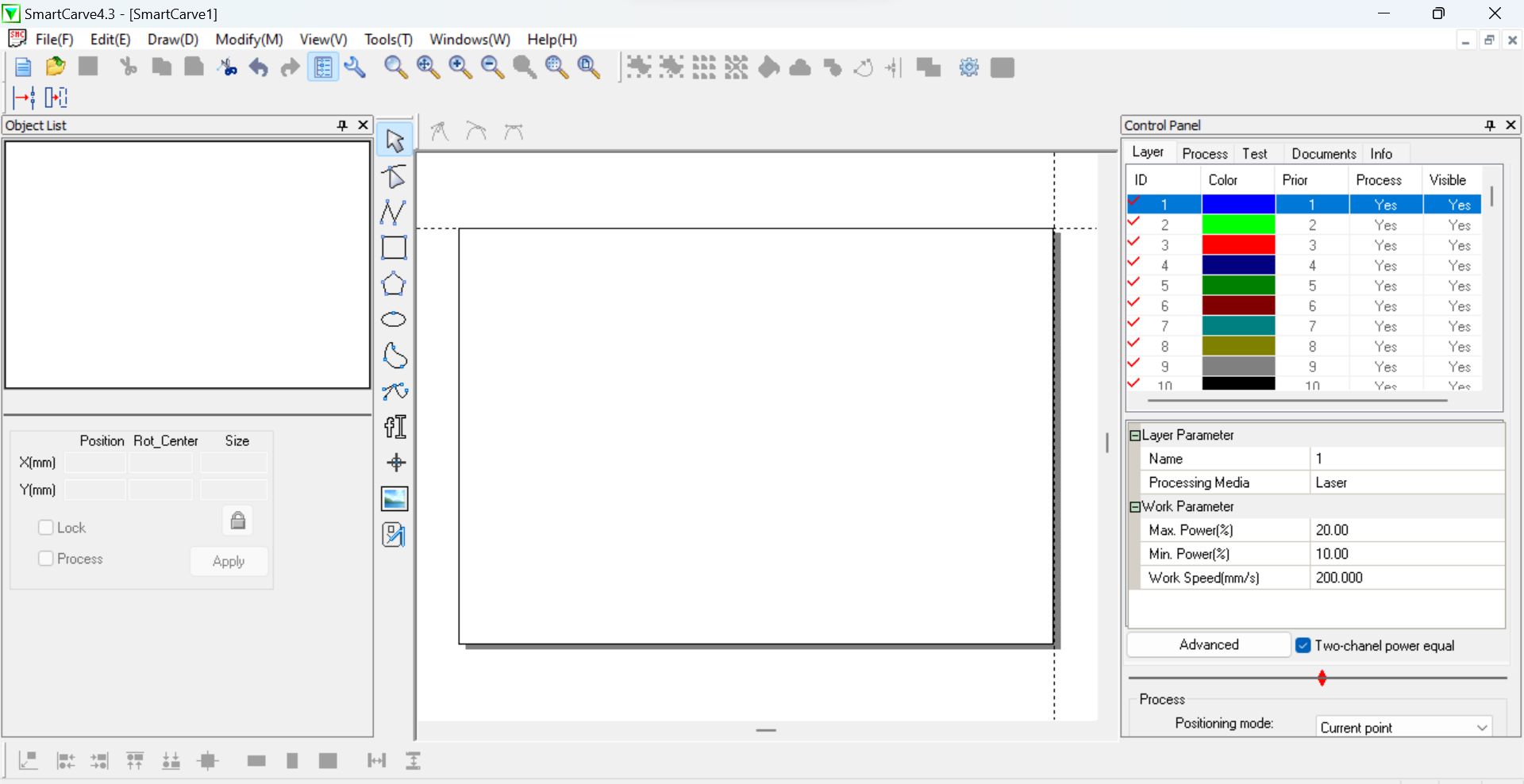

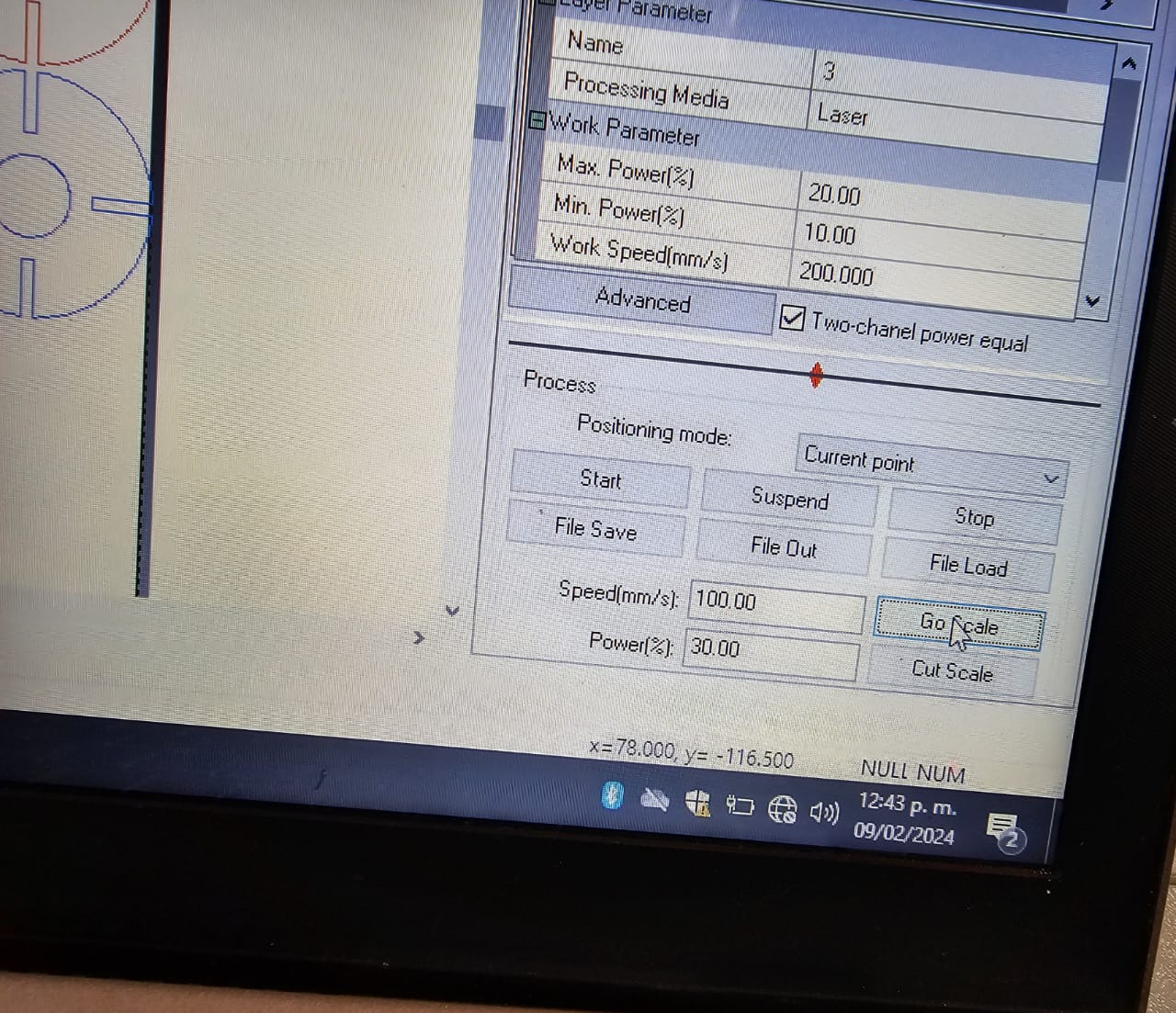

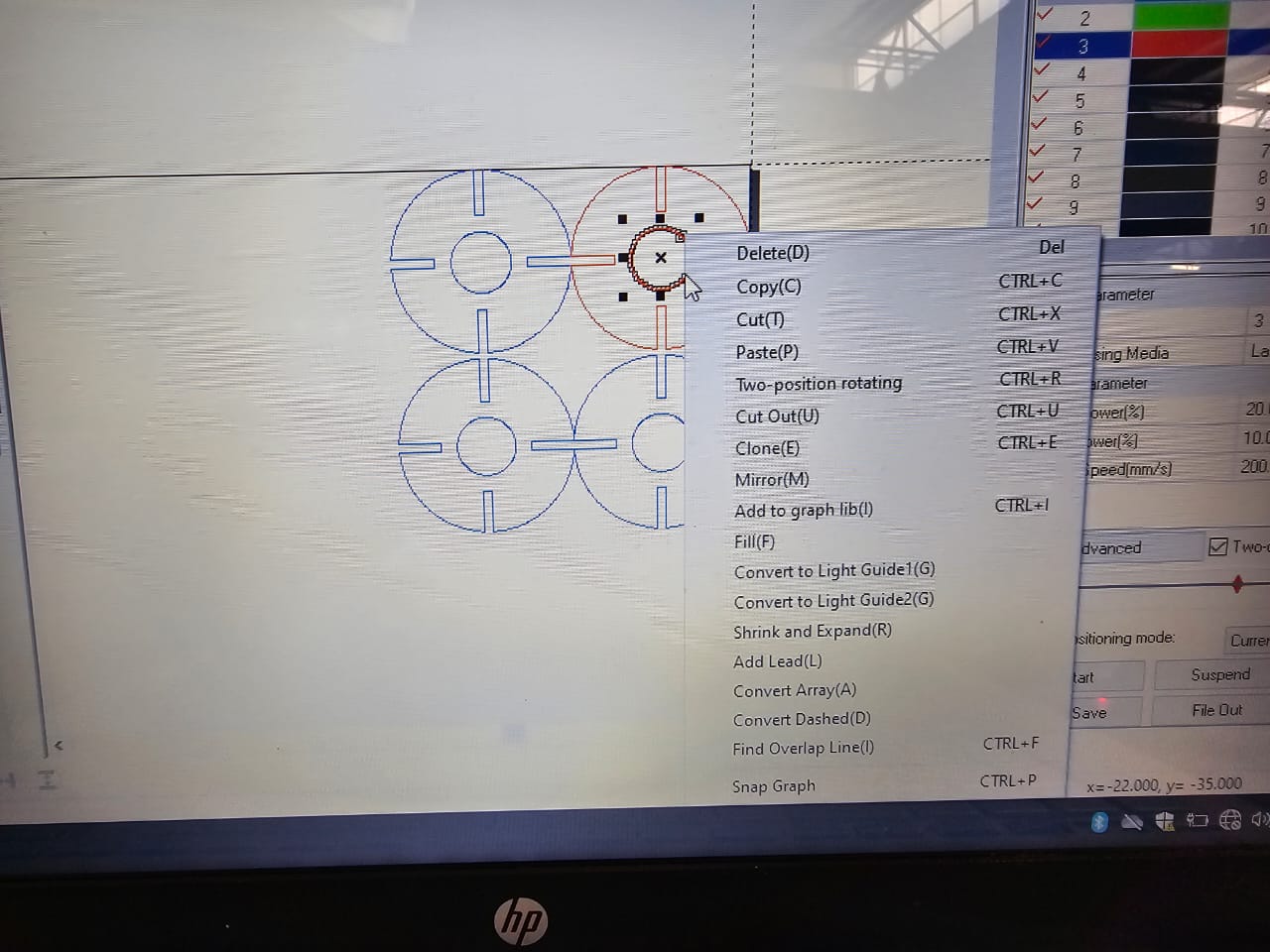

The laser cutters at Ibero Puebla work with a system called Smart Carved. To use it we need a Softdog that the University provide us.In order to upload a document, it has to be saved as Dxf. Once the user opens the design, it can be dragged to adjust its position. Using ctrl+c and ctrl +v you can copy and paste the design in order to make many parts of that same design.This program lets the user calibrate the percentege of power to the lasers as well as its speed. And also allows you to see the scale of your cut, this is useful to make sure that nothing interrupts it's path and the cut turns out smoothly.

After everything is setup it's time to finally cut!

Results

Vinyl Cut

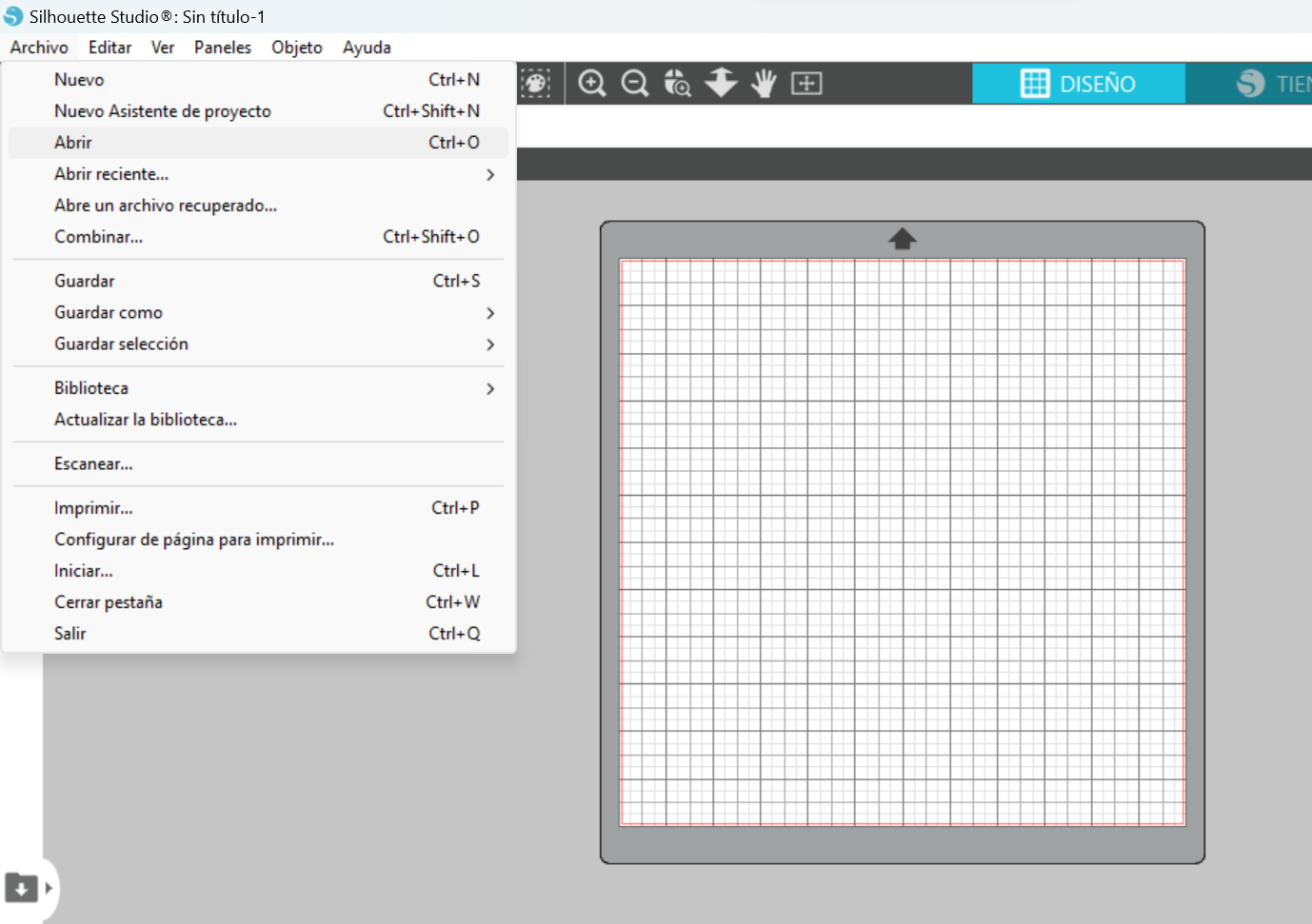

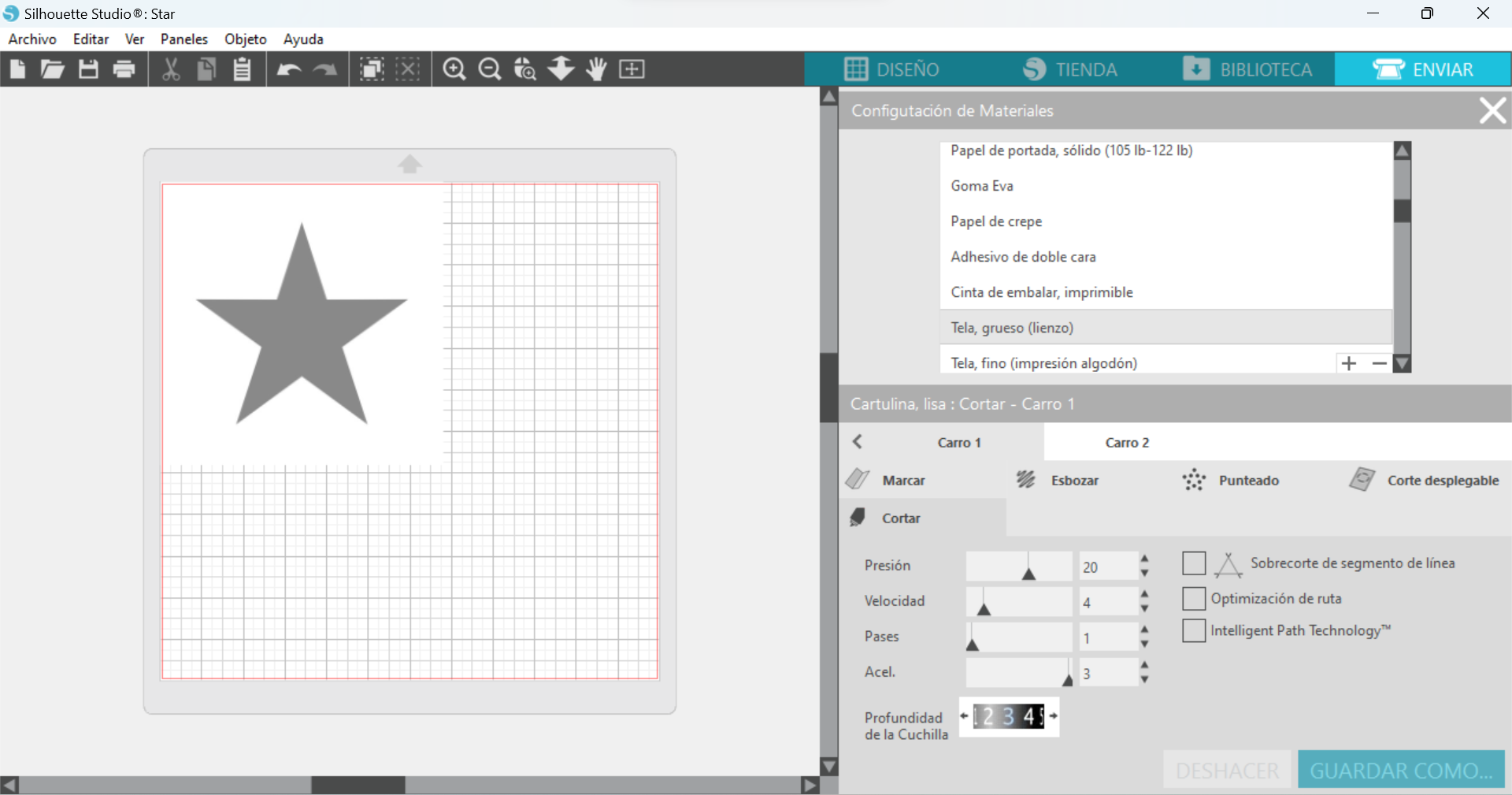

The software I used to make the vinyl cut is Silhouette Studio, I chose that software because is very user-friendly and I could send my design directly to the vinyl cutter from there. I downloaded an image from the internet and saved it on my computer, then I just opened it in the program. The image will be automatically vectorized for it to be sent to the cutter.

The last step is just to send it to cut using the "send" option in the menu.

Result