MECHANICAL & MACHINE DESIGN

Designing and building a CNC machine from scratch

CNC Machine Project

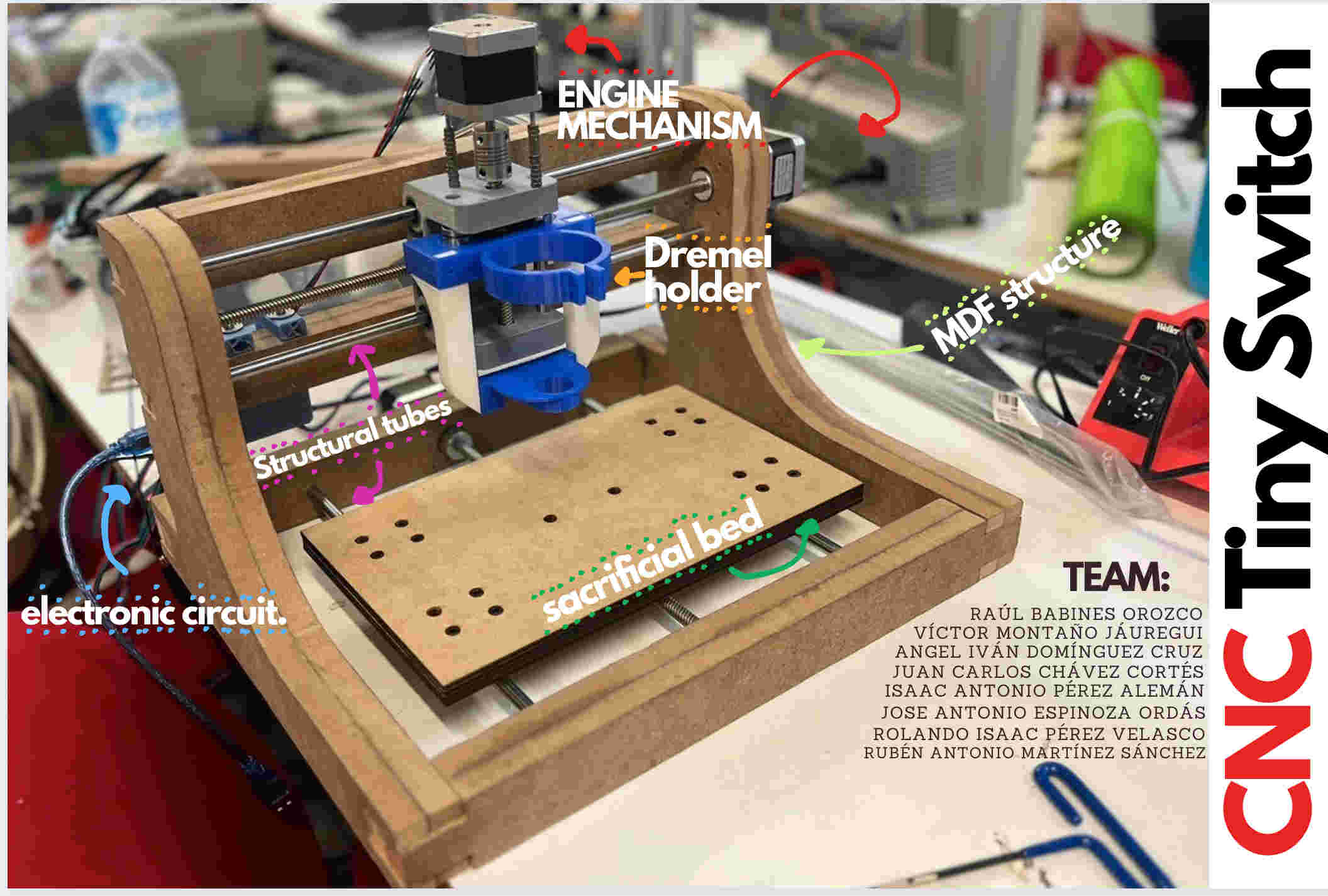

The primary goal was to design a CNC capable of accommodating a Dremel tool, with the understanding that if this tool works on the machine, practically any other tool could also be compatible. Our group task shows how we made this machine from scratch and the contributions each member made to the project.

Assignment Checklist

Mechanical Design

Machine Design

My Individual Contribution

CNC Cutting of MDF Parts

For this week's assignment, I was responsible for cutting the 15mm MDF parts using our lab's CNC router. These parts would form the structural framework of our CNC machine.

CNC Shop Pro 1325

The industrial CNC router used for cutting our machine parts, showing its large working area and precision cutting capabilities.

Cutting Process

The MDF material being precisely cut according to our design specifications, with proper dust extraction in place.

CNC Shop Pro 1325 Specifications

| Specification | Details |

|---|---|

| Working Area | 1220 x 2440 mm (or customizable area) |

| Z-Axis Working Area | 200 mm |

| Cutting Motor | Variable frequency spindle motor |

| Cutting Motor Power | 6 Hp (4.5 kW) - Max 24,000 rpm |

| Tool Change | Manual - ER25 Collet (5/8" max. shaft diameter) |

| Cooling | Water cooling, chiller included |

| Drive System | Rack and pinion (X/Y axes), ball screw (Z axis) with high-torque/precision servomotors |

| Real Positioning Accuracy | +/- 0.15 mm |

| Max Head Travel Speed | 35,000 mm/min |

| Material Clamping System | Clamps (included) / Optional Pressure Rollers and/or Vacuum Pump |

| Vacuum Pump | Optional (10 Hp turbine type) |

| Dust Collector | Included 2 Hp (dual bag) |

| Software | V-Carve Pro* original license for 2D + 3D design, compatible with DXF, DWG, EPS, AI, and other formats |

| Machine Weight | Approx. 800 kg |

| Electrical Requirements | 220V / 2 phases / 20 amps |

| Standard Warranty | 2 years / 1 year on accessories |

| Warranty Extension | Available (up to an additional 3 years) |

The CNC Shop Pro 1325 is a robust and powerful machine with industrial capacity. With a 6 Hp spindle motor capable of reaching up to 24,000 RPM, it offers a maximum cutting speed of 35,000 mm/min and an accuracy of +/- 0.15 mm, allowing detailed and vibration-free results.

Design Files

I worked with the G-code files provided by my colleague Rául to cut the structural components of our CNC machine.

Assembly Process

After cutting all the MDF parts, I assembled them using white glue for strong, stable joints. The precision of the cuts ensured a perfect fit.

Finishing Touches

I made adjustments to hide protruding screws, disassembling and rebuilding parts to achieve a clean, professional appearance.

Material Selection: MDF

| Material | Advantages | Recommended Adhesive |

|---|---|---|

| MDF (Medium Density Fiberboard) | Smooth surface, easy to work with, good adhesion, consistent density, cost-effective | PVA (white glue), Wood glue, Polyurethane glue |

MDF was chosen for its excellent machinability, stability, and affordability. The uniform density allows for precise cuts and smooth surfaces, while the material's stability reduces warping over time.

Bearing Benefits in CNC Design

Precision Movement

Bearings ensure smooth, accurate motion along all axes, critical for CNC precision.

-

Reduced Friction

Bearings minimize friction between moving parts, allowing smooth movement of the Dremel head. -

Precision Movement

Maintains stable trajectory of the cutting head, essential for quality results. -

Machine Durability

Reduces wear on components, extending the machine's operational life. -

Load Support

Supports the weight of the cutting head during movement and operation. -

Reduced Vibration

Absorbs vibrations during cutting, improving surface quality and accuracy.

Presentation Design in Canva

I created a professional presentation for our CNC machine using Canva, highlighting its features and capabilities.

Canva's intuitive interface and rich template library allowed me to create a visually appealing presentation quickly. The platform's real-time collaboration features were particularly useful for gathering input from team members.

Final Results

Our CNC Machine in Action

The completed CNC machine performing a test cut, demonstrating its precision and functionality.

Team Process & Problem Solving

Task Allocation

Our team divided responsibilities based on individual strengths:

- Mechanical Design: Raúl and I focused on the structural components

- Electronics: Juan handled the control system and wiring

- Software: Maria programmed the machine controls

- Documentation: We all contributed to documenting our process

Challenges & Solutions

- Material Warping: We solved this by using thicker MDF and proper sealing

- Alignment Issues: Implemented precision jigs during assembly

- Vibration: Added mass to the base and improved bearing alignment

- Tool Chatter: Optimized feed rates and spindle speeds

Possible Improvements

Enhanced Rigidity

Replace MDF with aluminum extrusions for critical structural elements to reduce flex.

Automatic Tool Changer

Implement a system to automatically switch between different tools during operation.

Improved Dust Collection

Design a more efficient dust extraction system to keep the work area clean.

Final Reflections

Key Learnings

- Understanding the interplay between mechanical design and machine performance

- Importance of precision in CNC machine construction

- Team collaboration in complex technical projects

- Material selection considerations for structural components

- Iterative design and problem-solving approaches

Personal Growth

This project significantly expanded my understanding of mechanical systems and machine design. Working with MDF on the industrial CNC router gave me valuable experience in material properties and machining techniques. The collaborative nature of the project improved my teamwork and communication skills, especially when coordinating with colleagues who were working on different aspects of the machine.

Seeing the machine come together from individual components to a fully functional system was incredibly rewarding. The challenges we faced and overcame have given me confidence in tackling complex fabrication projects in the future.