17. Applications, Implications and project development

The task of the week is to propose a final project masterpiece that integrates the range of units covered, following the proposed questions.

-

What will it do?

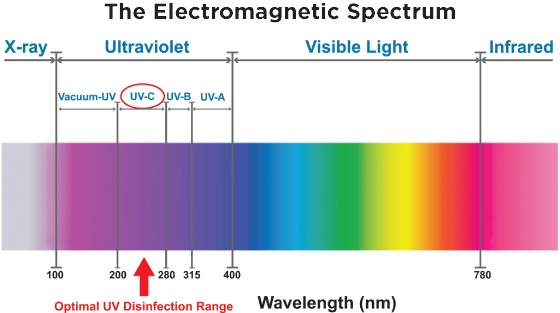

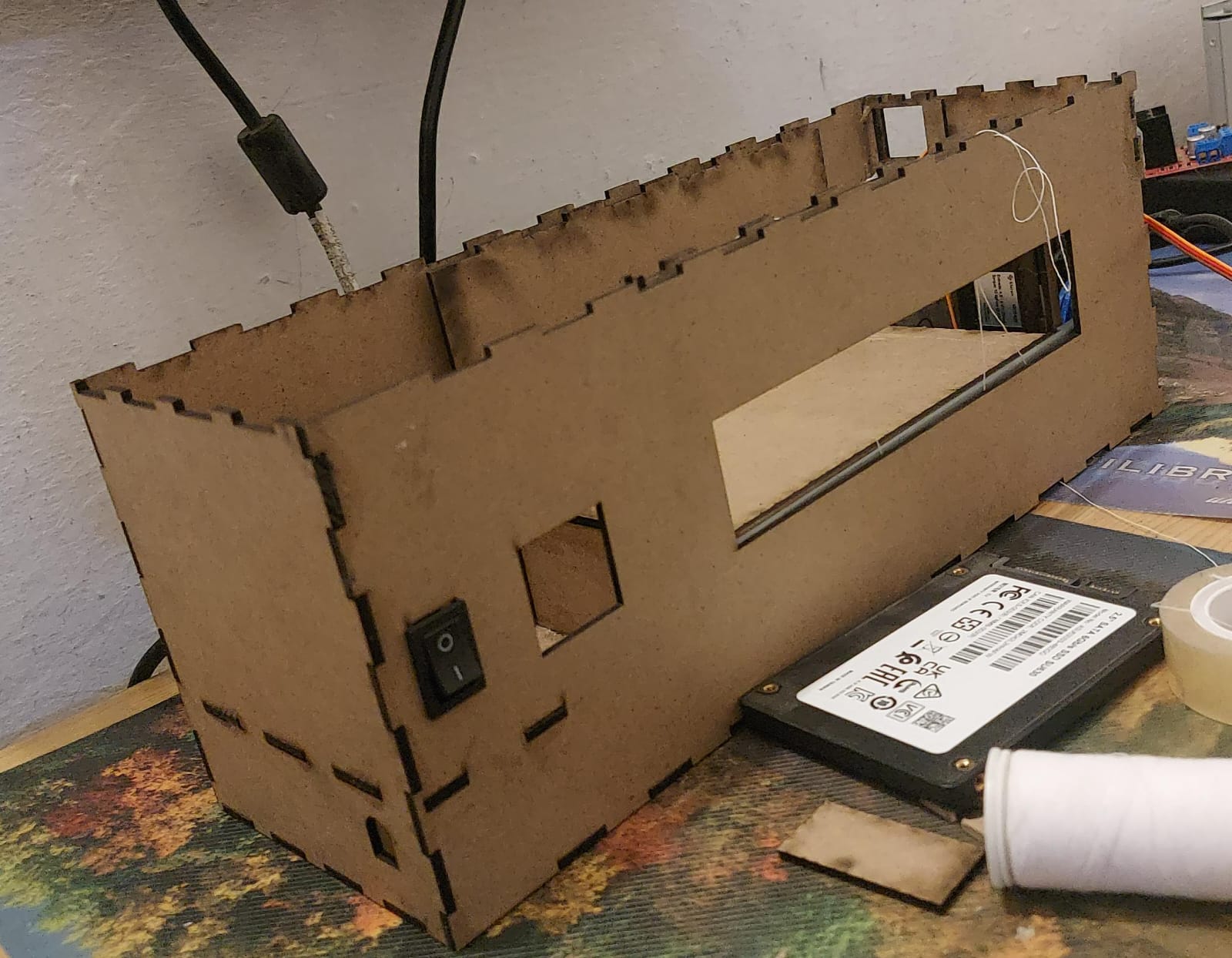

The idea of the project is to have a designated place in the common bathrooms for cleaning our mobile devices, this through a small container that can fit everywhere and perform a cleaning of the cell phone using a sweep system and UVC disinfection technology so it will have to be sealed to avoid unwanted radiation leaks.

-

Who's done what beforehand?

there are a lot of UV cleaning devices so cmo special towels to clean your cell phone, the question is that they are very little used, many times because the dirt in your cellphone is not so visible or for laziness, but it is always present, so I seek to create a comfort for you to go to the bathroom for common reasons and whithout your intervention in about 5 to 7 minutes have a clean cell phone.

-

What will you design?

There are many parts to be designed and others that i'll buy, here is the list.

- Two layers of protection, call them boxes, obviously designed by me.

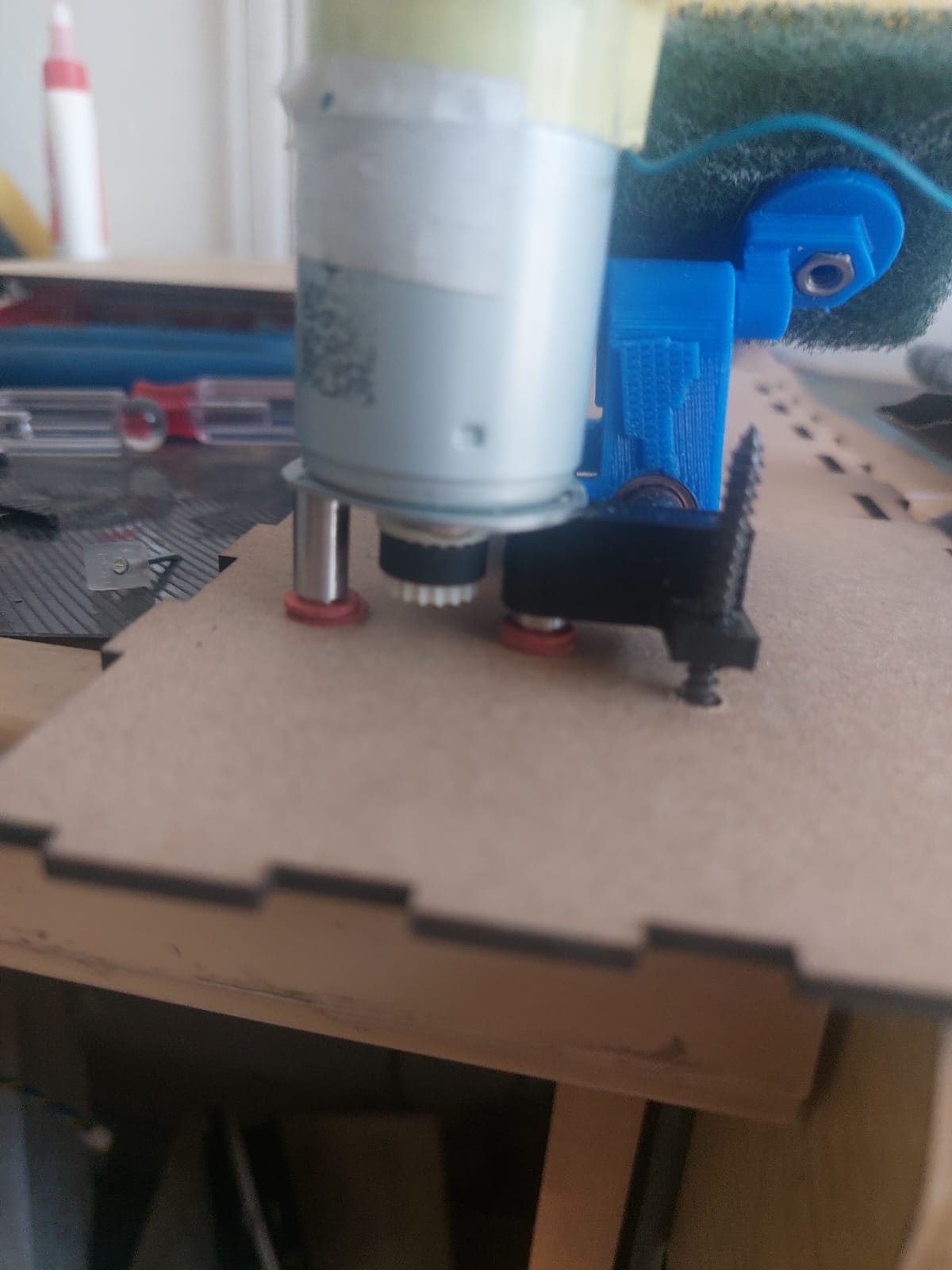

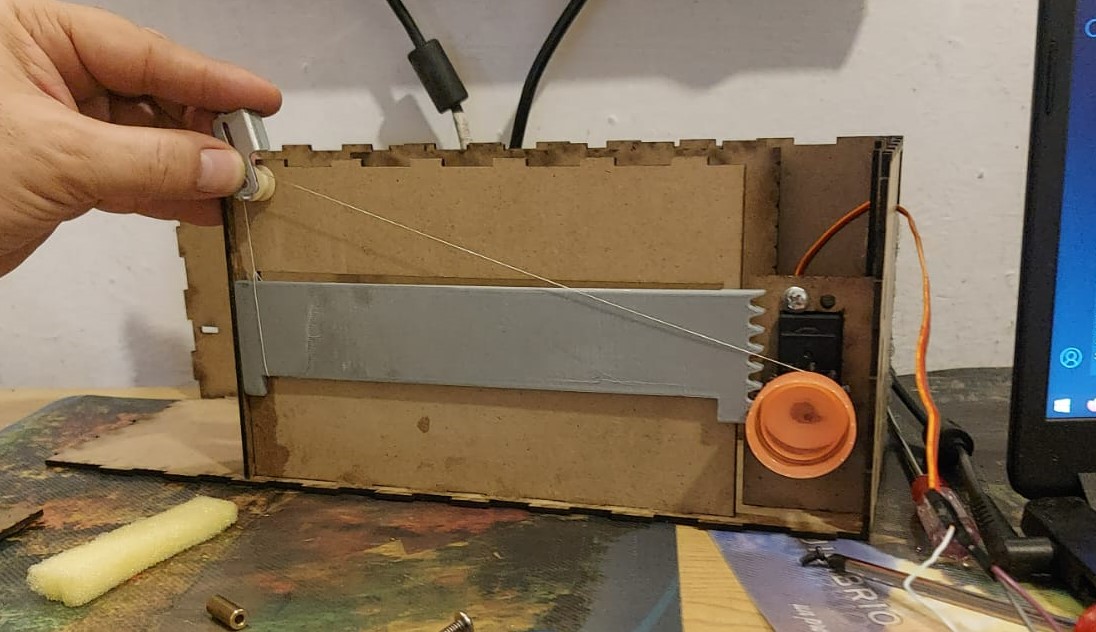

- Rack and pinion system design, with a black 11kg servo i've bought.

- UVC led matrix designed, leds bought since the beggining in china.

- Room for a spray mechanism.

- Design and solder the main PCB with all the inputs and outputs.

- The toothed band system to clean the touch surface.

- A box for the time of flight sensor.

- A bed and a eject system.

-

What materials and components will be used?

Bill of materials

Name Description Number Unit Price MXN Total MXN 2PCS 3535 UVC LED Lamp Beads for UV Disinfection Equipment 265-285nm SMD Chip LED Deep Violet Ultraviolet Lights Diode 1W 2W 5 $17,64/ lot $88,20 Capacitor for the start of the servos, 16V 470uF 2 $7 piece $14 female pins for the microcontroller 7 $2 piece $14 pins for the PCBs 30 $5 lot $5 Acrylic mirrored 40x60cm in 3mm width 1 $254 piece $254 Xiao esp32c3 Powerfull, small and economic microcontroller 1 $200 piece $200 female-female dupoint wire for connections between devices 16 $25 lot $25 Extra cord Less than a meter needed to extend and make exact lenght wire 1 $10 piece $10 black tape To protect wire joints, not much required 1 $80 piece $20 PLA filament For the 3d printed pieces 100g $500 piece $150 3mm mdf plate 61x122cm in 3mm width. 1 $44.5 plate $44.5 Oled screen Generic Oled screen for electronic projects 1 $95 piece $95 Miniature rocker switch, 1 pole, 1 throw, 2 positions Main power switch 1 $9.00 piece $9 L298N Driver that handles 4 outputs with 4 signals introduced 1 $55 piece $55 2.1 mm inverted jack for chassis To input the power supply 1 $5 piece $5 motor 12V dc 140RPM Main motor used in the sweep system 1 $180 piece $180 MG995 High Speed Digital Servo Motor With Torque at 6 V 12 kg 1 $111.33 piece $111.33 Micro Servo Motor SG90 Locked rotor torque: 1.2-1.4 kg/cm (4.8V) 2 $37 piece $74 Closed Band, 400mm GT2 Closed Timing Belt for 6mm and motor pulley Needs to match with the motor and the pulley 1 $130 piece $130 sponge to attatch to the sweep 1 $17 piece $17 Plastic pulley for 6mm with screw-on base Need to match with motor no more than 14mm outside 1 $40 piece $40 screw posts to match the height of the pulley and the motor pulley to attatch to the roof with secrews 2 $10 piece $20 304 Stainless Steel Solid Round Rod 6mm x 300mm 1 $68.4 piece $68.4 Self-lubricating composite bearing copper shaft bushing, small inner diameter, 6mm To attach the 3D printed piece to the rod 2 $15 piece $30 10cm x 15cm phenolic plate for the PCBs 1 $29 piece $29 Touch sensor TTP223B To detect the spray action 1 $20 piece $20 VL53L0X laser distance sensor Time-of-flight (ToF) sensor designed to measure close distances 1 $100 piece $100 30ml spray bottle for the liquid 1 $40 piece $40 12V Fan with screws for the cooling of the leds 1 $70 piece $70 Buck converter LM2596 Get a lower voltaje from the 12V Input to 5V 1 $26 piece $26 Power Supply 12V, 2A, 2.6mm jack 1 $120 piece $120 washers more small posible 2 $1 piece $2 nails and wire to set the sensor case and wire 3 $1 piece $3 nuts with bolts 14mm lenght, m3 10 $5 lot $5 screws 5mm lenght, m3 to fix the PCBs 4 $1 piece $4 straps and 3 x 3 cm self-adhesive bases for wire managment 2, 4 $10 lot $10 MXN to Dolar: 0.055 MXN$2000 US$110 Where will come from?

Any part can be bought online, however, the school will provide me the mdf, and the servo motors, while the other parts are remains of other projects in my inventory.

What parts and systems will be made?

From the upper list im designing the structure of mdf and acrylic; the rack and pinion(included in the door); assemble all and place the washers and join everything with the thread; the UVC leds and the main board; fasten the wire with straps managment, wire controll, assemble everything and print the 3D parts, cases and eject bed and system.

What processes will be used?

The heaviest process are laser cutting and engraving, 2D and 3D design, 3D print, milling and solder, embedded programming and interface and process design.

What questions need to be answered?

From the machine and mechanical week i understanded the sweep mechanism, i need to perfect the rack and pinion system and the eject system for last check for libraries compatibility.

How will it be evaluated?

To consider this first version of the project finished has to be the main routine finished, disaggregating: when turning on the Oled screen must show two steps the first with the distance sensor has to determine when a cell phone enters and then switch to the second instance where we wait for the liquid to be sprayed, once this is done the door is closed and the diodes are fastened the fan and starts the grinding while the OLED screen shows the progress, at the end the door opens, the cell phone is expelled and it is appreciated that the liquid has gone thanks to the sweep.

Project Plan

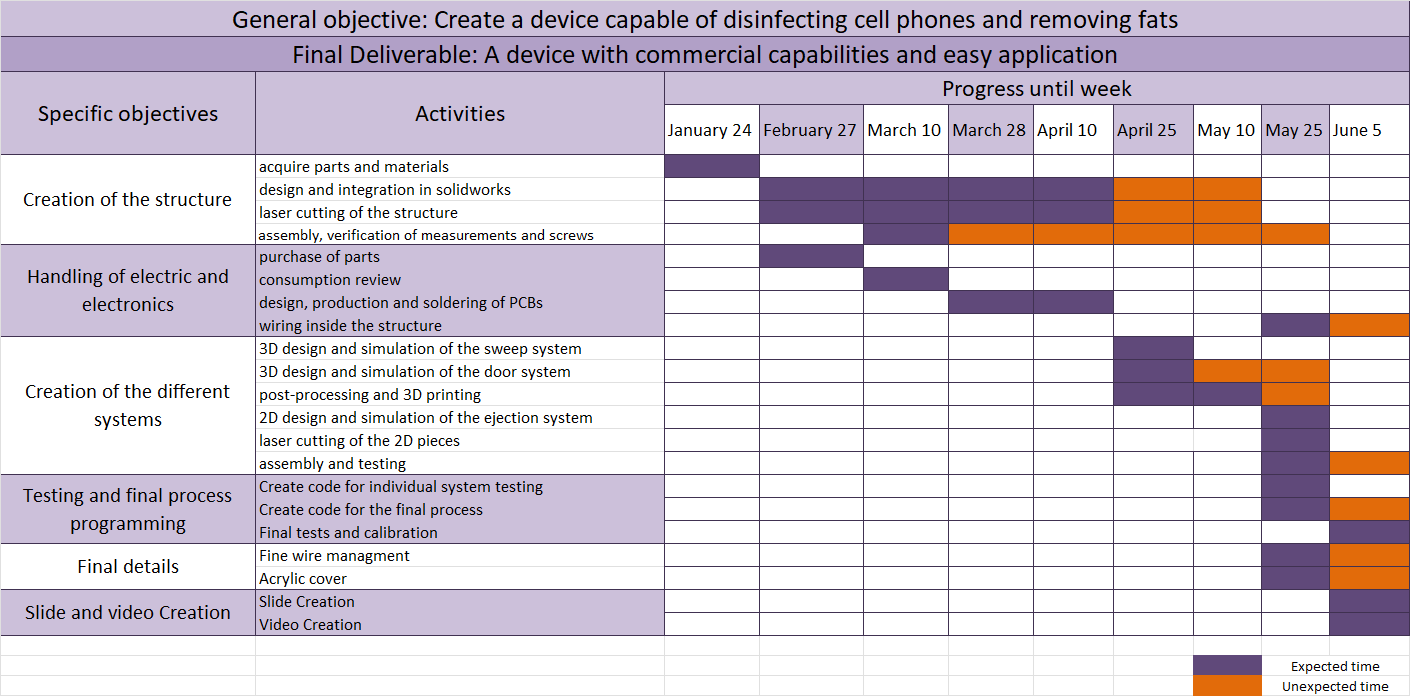

Gantt Table

Another little part of the week is to record progress of your project and determine if the way you've been working needs something to change in order to finish at the date of presentation, for me June 5, at the date of may 28 this is my progress:

what tasks have been completed, and what tasks remain?

Completed:

- All the mdf parts and structure designed and cutted

- Initial 3D parts designed and printed

- Get all the things that I decided to bought

- Started the assembly and electronis inside the project

- Tested all the mechanical, inputs and outputs systems

- Electronics design and production almost finished

Remain:

- Acrylic case and design

- Finish the assemblying

- Reprint the necessary objects

- Program the whole process

what's working? what's not?

-

The only thing that was failing for me was the door issue since I had not experimented enough with its final position, I observed that it did require taking the movement to the other extreme, so I needed to do some tests and I already solved it, it was enough to print the new 3D designs, in the other systems I already did the tests and everything works, it cost me a bit to level the sweep so that it had a fluid movement and an OLED broke down, I replaced it and end of problem.

what questions need to be resolved?

I'm having some trouble with the vl53l0x libraries while connecting them whit the whole process, besides form that the questions i got like the servo door and the calibration in the sweep system have been solved with their respective section of code to test and adjust.

what will happen when?

When the Acrylic arrive on Friday i need to have the design already done, to go inmediately to cut it, i need to print the necessary parts before the acrylic arrives and to fix the door, finish the assemblying on friday and program in the weekend, finish some details on monday and record the video and make the slide on tuesday.

what have you learned?

Just as mentioned in nueval "system integration & packaging: it takes more time than you think", all those little things that seem quick to make as wire management, They really are a pain and they don't get well the first time many 3D printing related things like the sizes the things need to be to fit and most important your project isn't static as everyone can allways give you feedback in order to improve it.