16. System Integration

The task for this week is to design and document the system integration for your final project, to achieve this I'm Taking into account the following points:

Building a dedicated structure

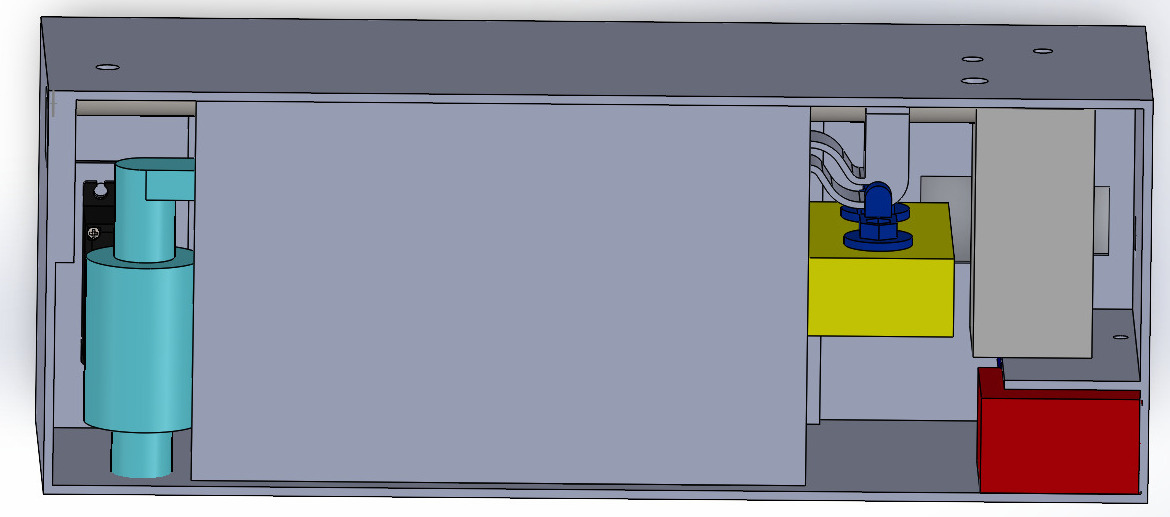

When building a prototype the first thing you have to achieve is the machine actually working, at first i thought of a aesthetic design, it's important but as a final touch, To ensure that the project works until the end of time we must give all the components their place, so within my 3D design software I will have to recreate or at least give place holders to everything.

Zip file with all the parts: Structure.zip

I left some space bellow the phone to help with the wire management later on, then with the help of a bernier i've measured all the sizes of the components and their respective holes, most of the place holder are boxes that cover the same area, that i'll change later on, i got the pieces try to arrange them to take meassure and crete them a little Assemble.

-

Type of fasteners:

For the project i'm using two type of fasteners, trying to translate them: bolts and screws, (in mexican tornillos y pijas), depending of the orientation: top and bottom use bolts with nuts while side use screws to save the space between the layers of the nuts.

-

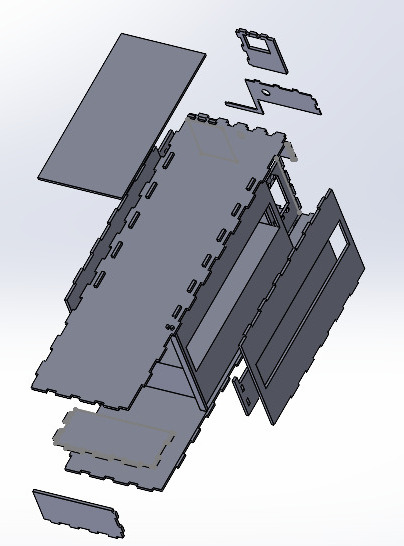

to create the .dxf to laser cut them what i learnt to do is to create a new sketch, copy all the lines and at the moment of extruding do it from a considerable offset.

This comes in handy if your material is wider than expected as you just use it as a reference and dont los the original sizes at the same time, As it usually happens in Home Depot, their MDF varies between 2.2 and 3.2 mm..

-

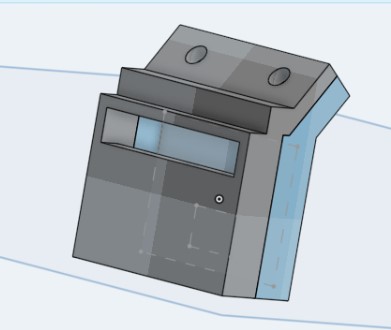

A rule that can look obvious is that any part related to a mechanical system can't be place with the help of glue or silicone as they will fall eventually, a example of this is the position of the distance sensor, it eventually gets touch by the sweep system and without a strong structure it's destiny will be in the bed where the phone should be.

This small part was made in Onshape while i was printing all the parts in the FAB: File

Wire Managment

Another super important part in system integration is to have a nice and simple arrange of the wires inside your project, meassuring the size needed and having caution using black tape or thermofit when needed.

This take much more time than what I anticipaded, but it was necessary, to control them i used a base for straps and straps obviously.

So what is System Integration?

At first I didn't understand what they meant by the term System Integration, but during Neil's presentations I think something became very clear to me: these are those steps or issues that if not handled carefully make your project disposable, which is why it is so important in the creation of projects, these are points like having the mechanical things perfectly assembled and adjusted by means of screws, nuts and washers, that everything has a designated space within the project, clean and understandable code, as well as good cable management and good soldering so that the project lasts as long as possible and is a reliable prototype.