CNC Sewing Machine

This week's task involved collaborating with a team to build a CNC machine, with me serving as

the team leader. Inspired by a video showcasing a similar machine, we opted to create a CNC

sewing machine. This decision stemmed from the video's demonstration of the machine's capability

to automatically stitch designs onto t-shirts based on images uploaded to its software.

You can review our group assignment on our CNC sewing machine by

clicking here. It contains

comprehensive details explaining its functionality, construction process, encountered challenges,

and our future plans.

What did I do?

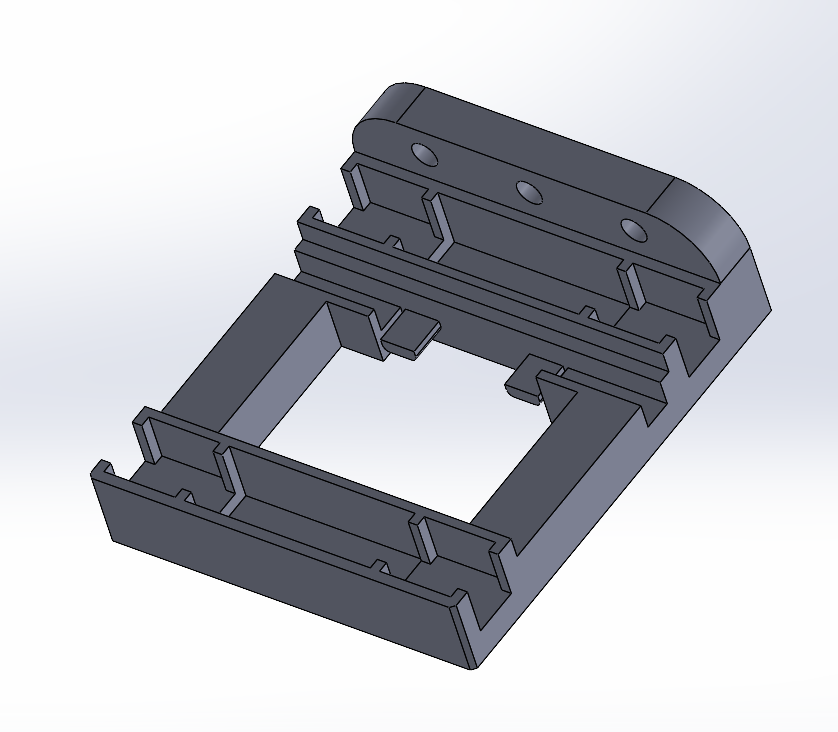

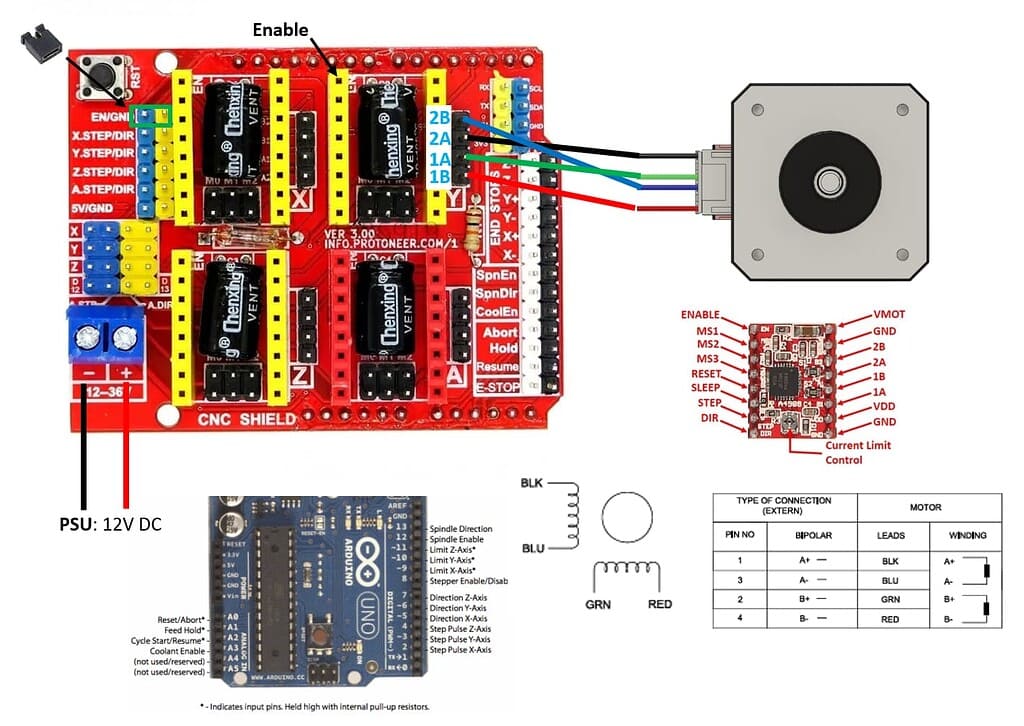

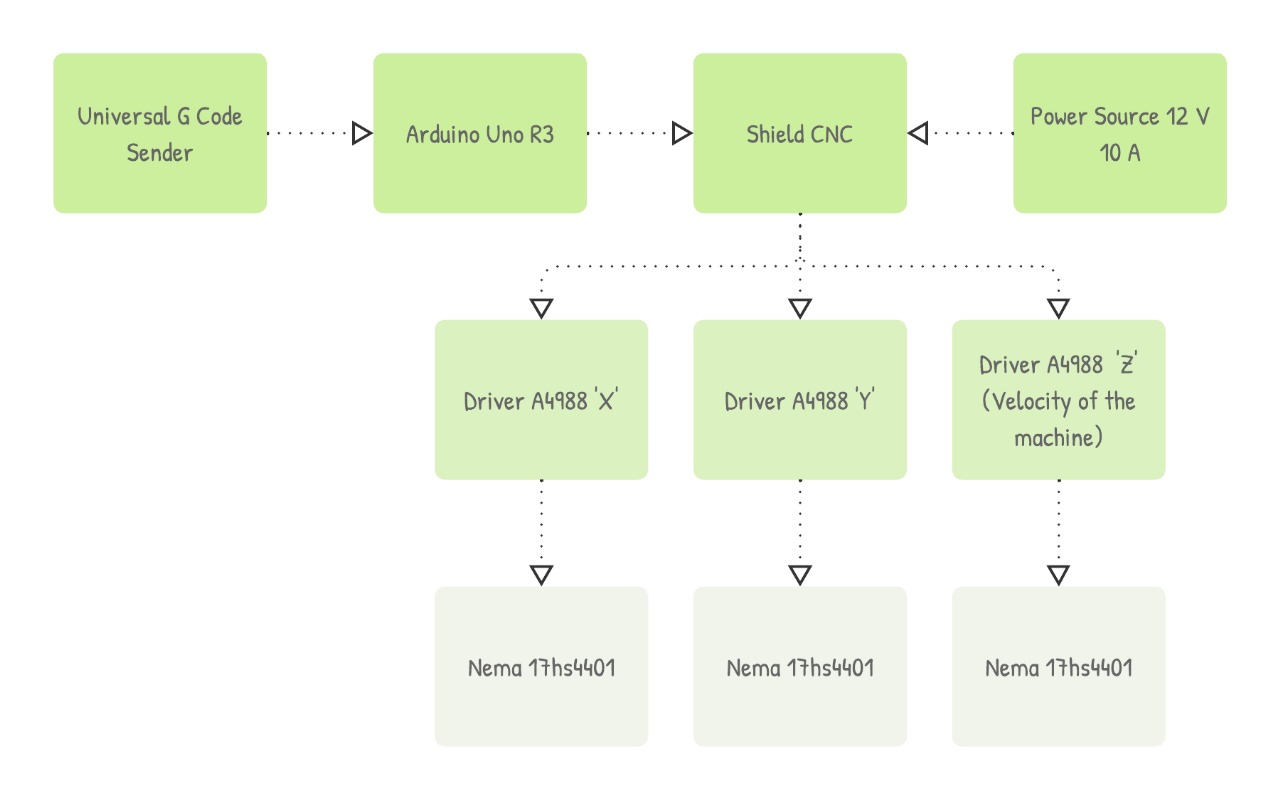

In our group project for the CNC sewing machine, each member played a crucial role in its development and assembly. My specific contributions included the fabrication of the white part responsible for movement along the X-axis, which serves to connect the CNC machine to the sewing machine. Additionally, I meticulously positioned the belts beneath the black components on the machine's sides. I supervised the design of the pedal piece, crucial for adjusting the needle's speed on the sewing machine, and calibrated its stepper motor accordingly. Moreover, I actively participated in the assembly process, ensuring seamless integration between the CNC and sewing machines. Furthermore, I handled the intricate electronic connections and conducted comprehensive testing to calibrate the machine and validate its functionality.